-

Posts

1,877 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by catopower

-

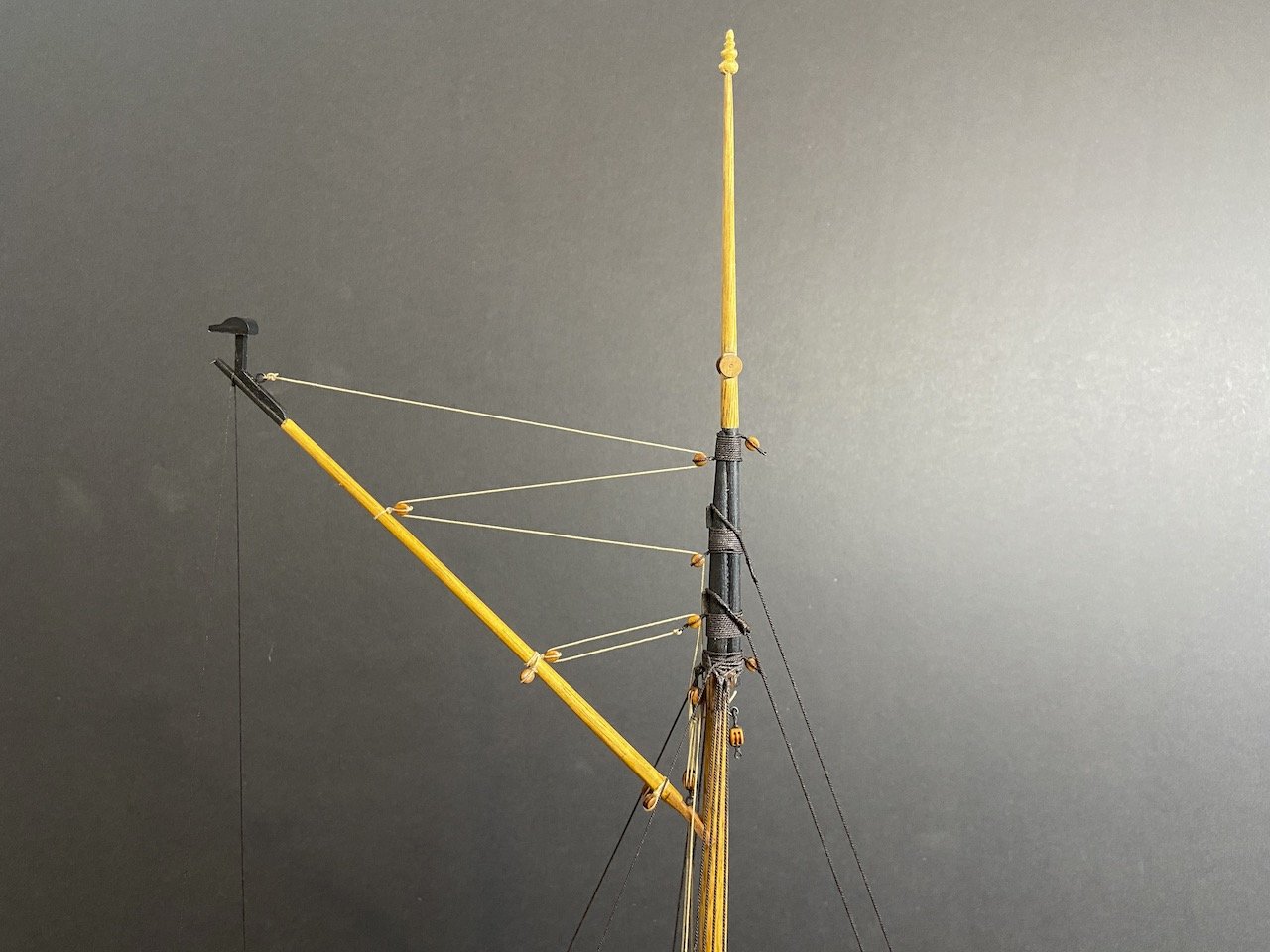

Also, I like the way this model looks so much that I'm afraid of ruining it when I get into the rigging. I quickly made a flagstaff and mounted the kit's flag. Also, started looking at building up the stern lantern. In the meantime, the Wolf makes a fine display... I've since given the flag a shot of matte clear lacquer to take some of the sheen off of it. If it bothers me enough, I'll just print my own flag, as that seemed to work pretty well on the yacht Mary model Note that I haven't placed the deck pumps. They're done and ready to be mounted, but to prevent damage to them, I chose to leave them off. I may just tack them into place like I did the officer figure, so they can be removed should I eventually decide to rig. Regarding rigging, though this is more lightly rigged than a three-masted square rigger, like a frigate, those larger ships have larger masts and yards, and I think they may actually be easier to rig, at least for fat fingers. Thoughts? I'm tempted to take one of my 1/72 scale Shipyard frigate hulls this far, and see about rigging that. And, even if it doesn't go beyond this stage, it makes a pretty nice display model. And, without the masts, yards, and all, it requires a MUCH smaller case and takes up that much less room in the house to display... 🤔

-

Well, my yacht Mary model is now done. I'm free to get back to HMS Wolf and other projects, but after the local IPMS show this weekend, I'm again rethinking the work on HMS Wolf. I took the Mary, my incompleted HMS Wolf model, and a couple small Japanese boat models to the IPMS show. I didn't expect to win anything, particularly the Japanese boats, which don't really fit any IPMS judging criteria. The yacht Mary was completed. I removed the masts from HMS Wolf and added a figure of a British naval officer onto the deck. Looking like an admiralty style model, it ended up winning in its category, as is. The yacht Mary got nothing. It's okay about the Mary, because even when I got it, it was kind of a roughly built model, though very pretty. But, the fact that the Wolf won kind of threw me a bit. I guess it has the painted hull and all that fits in better with the plastic models? Anyway, now, I'm kind of curious about how other paper models would do and also maybe a small one in a mini-diorama. So, I'm thinking of re-retiring the Wolf... again. It's back in it's acrylic case without masts, but now has the lower deadeyes. I'm going to put a flag on the stern, the stern lantern, and probably add the paper chainplates. The latter will act more like facades, as I already have wire chainplates on the model.

-

Thanks GrandpaPhil! Following up, the original builder's widow has seen the photos posted here and is very happy and feels her late husband would be very happy with the final model. And, I think we're figured the final disposition for this model. I got this stuff through an estate sale that was facilitated by someone at Crystal Basin Cellars, a winery near Placerville, CA. They also have a stand and case that was originally purchased by the builder for this model. The plan is to put the model in that case and stand and display it at the winery. There, it will be taken care of and can be viewed and enjoyed by others. Gives me an excuse to go up there and visit the model, and maybe come home with a nice bottle of wine or two! Probably won't happen until after the Summer or possibly after a miniatures show in Santa Clara in October. So, for now, it's in a case to keep it clean and protected.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Druxey, thanks for the comments. I absolutely appreciate the info. I was wondering why the model carried the royal standard when so few paintings of royal yachts show it. Good to know the King is aboard, probably dining... 🙂 JacquesCousteau, Patrick, Chris, Gregory... thanks for the comments! I think I've learned quite a bit from working on this build. May not have incorporated all I've learned, and clearly the model is not perfect, but it's been a good experience!

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Okay, final pics. Managed to fabricate a decorative piece for the last of the flag staffs. Got the last flag added. This isn't a perfect model, but it was one I wanted to finish for the original builder, the late Richard Fletcher. Learned a few things, RE-LEARNED a few things, and had fun working on the model, and I'm satisfied with it. I still have another, original Mamoli Yacht Mary kit in my stash. I don't know that I need it anymore. There are a lot of ship modeling subjects I want to build. Perhaps I'll tackle it later. Don't know the final disposition of this model. I will take it to a couple ship model club meetings in July and August, and probably display it at a miniatures show in October. Then, we shall see. But, now, it's back to HMS Wolf and others!

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

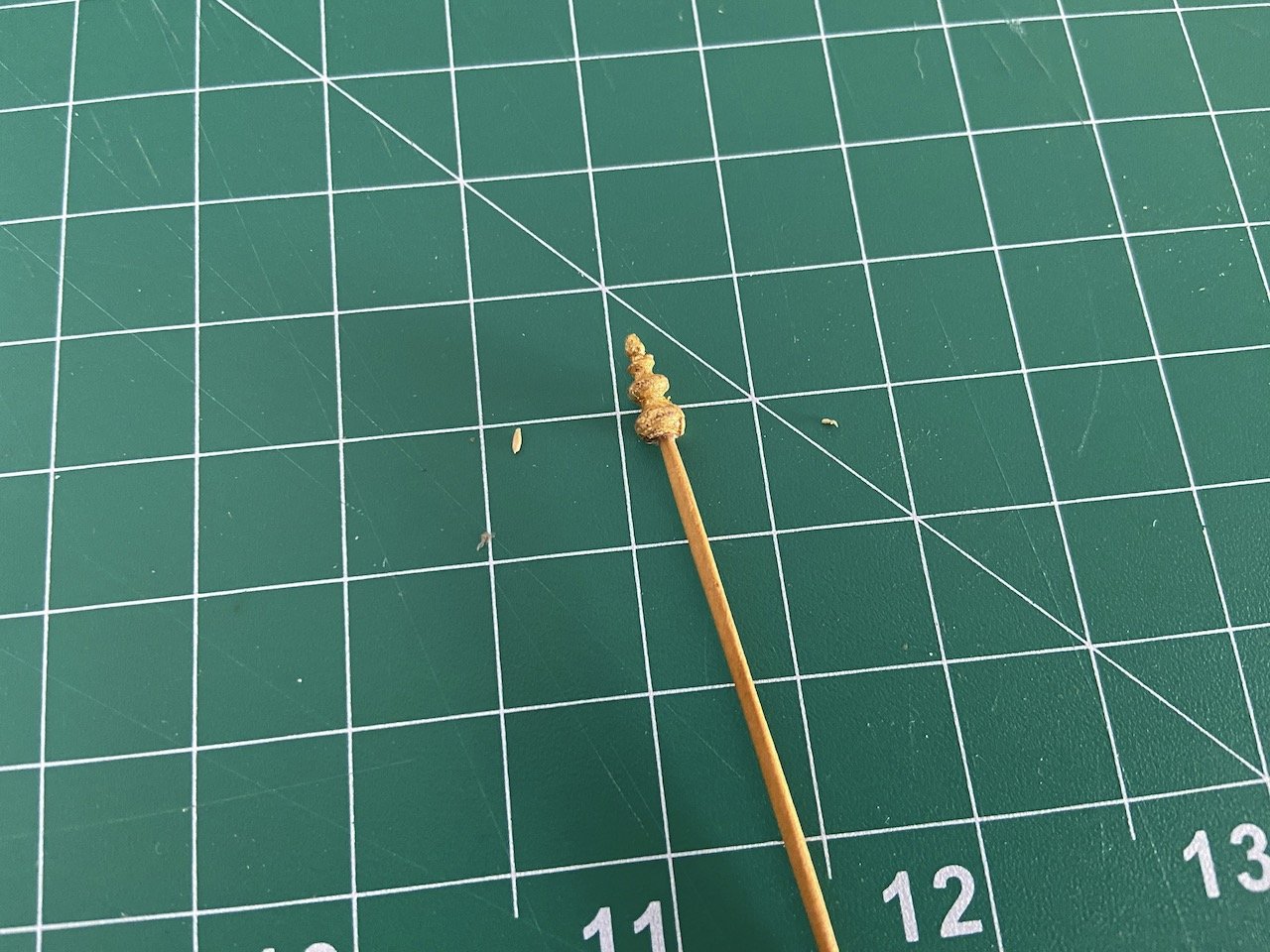

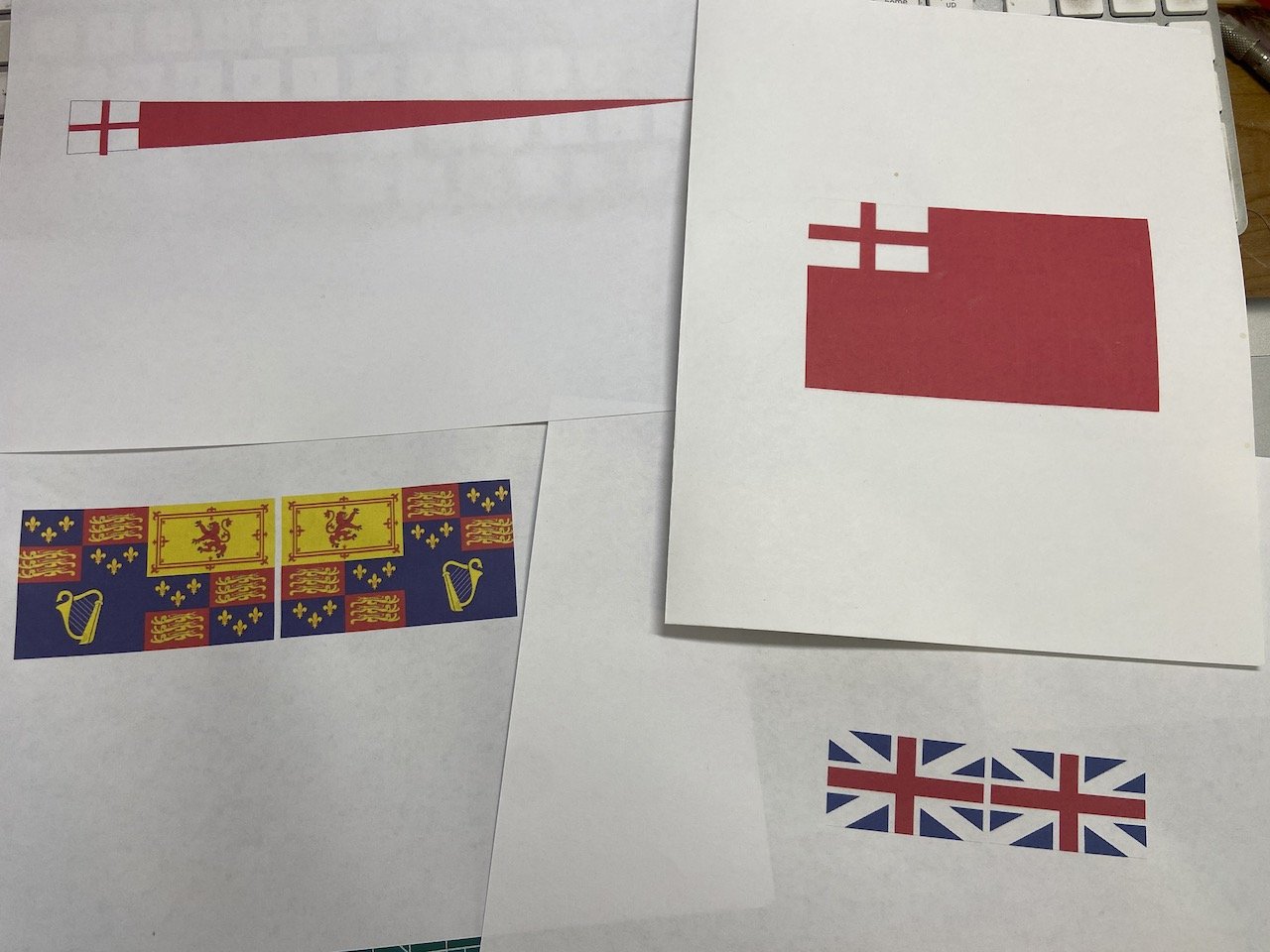

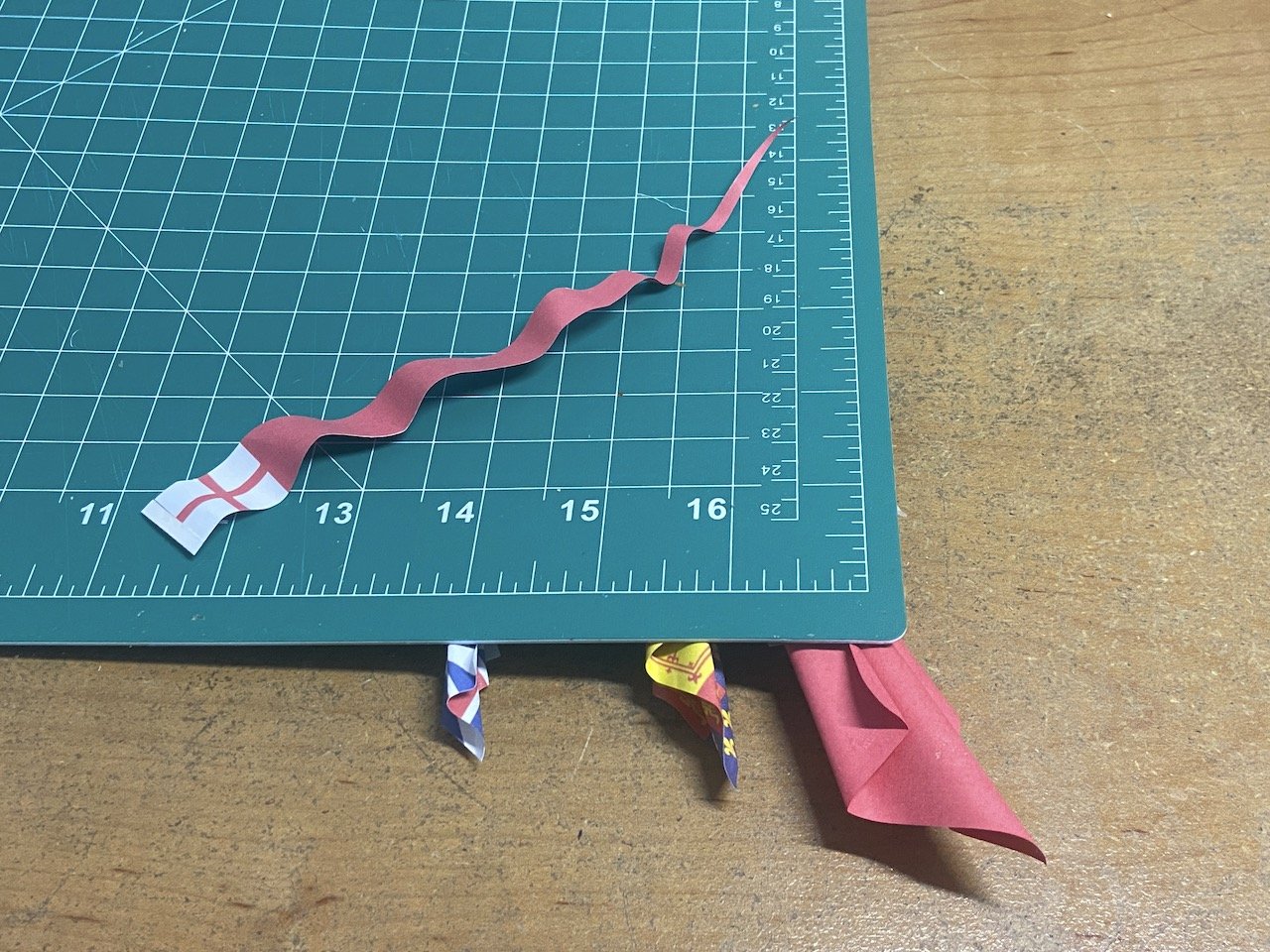

Adding flagstaffs now, and discovered that one of the decorative fixtures for the flagstaff tops is missing. 🤨 So, now, I need to either replicate one, or make something simpler... It's a bit hard for e to get this exact shape, and I want them all to look the same. I'll see what I can do to replicate this one, but since I want to take this to the IPMS show in Fremont tomorrow, I may end up clipping them down to the ball at the base. That's easy to reproduce. Anybody know how accurate these are for the Mary? In the meantime, I've been adding flags. Something interesting that I've noticed about this Dusek produced Mamoli kit. The flags are just a tad different than the original Mamoli kit. The original kit had a pennant flying from the end of the bowsprit, but with a red pennant with a Union Jack at the base, whereas the Dusek kit has a red pennant with St. George's Cross at the base. I know nothing about what's correct, or where each of the flags should fly, except for what the instructions call for. I'll be following the instructions on this. Below, I've already cut out the flags I printed, and am giving them some shape. I shaped them with various round instruments – a pen, a dowel, a paint brush handle, etc. Then to help them hold their shape, I applied a bit of pressure to the folds by slipping them underneath my cutting mat. The weight of the mat was just enough to hold them in place until the paper "relaxed". The folds turned out surprisingly well and I'm very happy with the results. Two more to mount. But first, I need to figure out if I can replicate that decoration.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Hello Ab, Thank you for the advice. I will consider changing the topsail later. I may save these suggestion for a future model of the Mary, as I have my own un-started kit in storage. If I build another, I will remember to alter the mast so that the sheave for the topsail halliard is higher, and modify the topsail itself so that foot arcs up higher to clear the jib. Also, might lower place the tackle for the jib halliard a tad lower on the mast.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Thank you for the comments Ab. The mast was already constructed by the original builder, and I chose to keep as much of his work as possible. But, even so, I'm afraid I don't have much general knowledge of Dutch shipbuilding, and the it plans, as you may already guess, are somewhat lacking in the accuracy of these details. I did make some modifications to the rigging, which was based, in part, on your models. If I build another similar model of the Mary or similar, I will remember your comments about the location of sheave of the topsail halliard. I didn't know about the iron brace. After this weekend, perhaps I'll go back and see if I can add it to the model "after the fact". Another issue I noticed when I started adding the topsail is that the spreader yard seems a bit too long and heavy. If I were to do this model again, I would consider correcting that as well.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Yesterday, I had the day off, so I took the opportunity to add the topsail and finish tying off all the running rigging. I ended up having to belay a lot of the lines incorrectly, but you can't tell in most cases. In other cases, I figure that I'll be adding rope coils at a later date to hide some of those details. Flags are yet to go on, but I'm no longer feeling pressed for time to get the model done for the IPMS show this weekend. And, in any case, I should have time to get the flags done by tomorrow. Would like to have braced the topsail around more, but the spreader yard was starting to hit the port shrouds and I din't want to deform them. Also, not sure what others do about this, but that spreader yard has no lines that pull down on it. On most ships, you at least have the sheet lines, which can be rigged to apply some downward pressure. As a result, the spreader yard halliard was too slack. So, I cheated, and if you look really closely, there's a thin black thread pulling the yard down, tied off to the staysail sheet horse. It's hardly noticeable, and it works! Anyway, flags are next...

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Thanks Julian, I appreciate your comments. I have to admit that as much trouble as I've had in the past with uneven bulkheads and such, the Mamoli kits can look really nice when completed. It always surprises me when I see a completed Mamoli kit. A friend of mine just built Mamoli's HMS Victory and now working on Mamoli's Royal Louis, looks really nice, and makes me want to build one. I actually have a partially built Victory that someone was giving away as he was leaving the hobby. Nobody else wanted his stuff, so I took all of his stuff to store. I managed to find homes for all of his stuff except this HMS Victory model. I'm thinking maybe I'll try to pick up where he left off. That seems to be a thing with me these days!

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

I kind of wondered the same thing. Amati even has a large range of America's Cup yachts, and 3 kits of the Endeavour in two different scales and construction styles. But, all the bigger manufacturers tend to make their own versions of what they think is a popular subject.

-

Thank you Druxey, Baker. I made some adjustments and I'm MUCH happier with the mainsail. Also, I realized that the lighting in the last photo is what main the staysail halliard look too big. Here's an updated photo. Still have to secure the lines. Then I can add the square topsail and finish up the flags.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Thank you Druxey and Baker for the sentiments on Ken. I've been recently realizing that his loss may also have a profound impact on the activity of the South Bay Model Shipwrights club, of which Ken was Vice President for as long as I can remember. He also wrote up the club newsletter, The Foghorn, and now I find I have nobody in the club that I can really discuss ship model industry news, and historical aspects of ship modeling with. Anyway, thanks too to you both and Gregory for your comments on this model. Sails are going on now. I've pulled the gaff off the model to add the mainsail. It's back on now, and I'm adjusting and belaying lines. Not LOVING the sails, but they're okay. Looking at this pic, I think the jib halliard is too thick. Not sure why. It's not difficult to replace that line. Don't know that I like the set of the mainsail either, but there are a lot of lines affecting the angle of the gaff. I want a slightly steeper angle on the gaff and haven't quite figured out what lines are keeping me from getting it. Might be the throat halliard... Anyway, it'll probably all be fine by the time I'm done. Should be another week. I did a lot of work on it yesterday. Taking the day off from it today and will try to make a big push on Monday.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

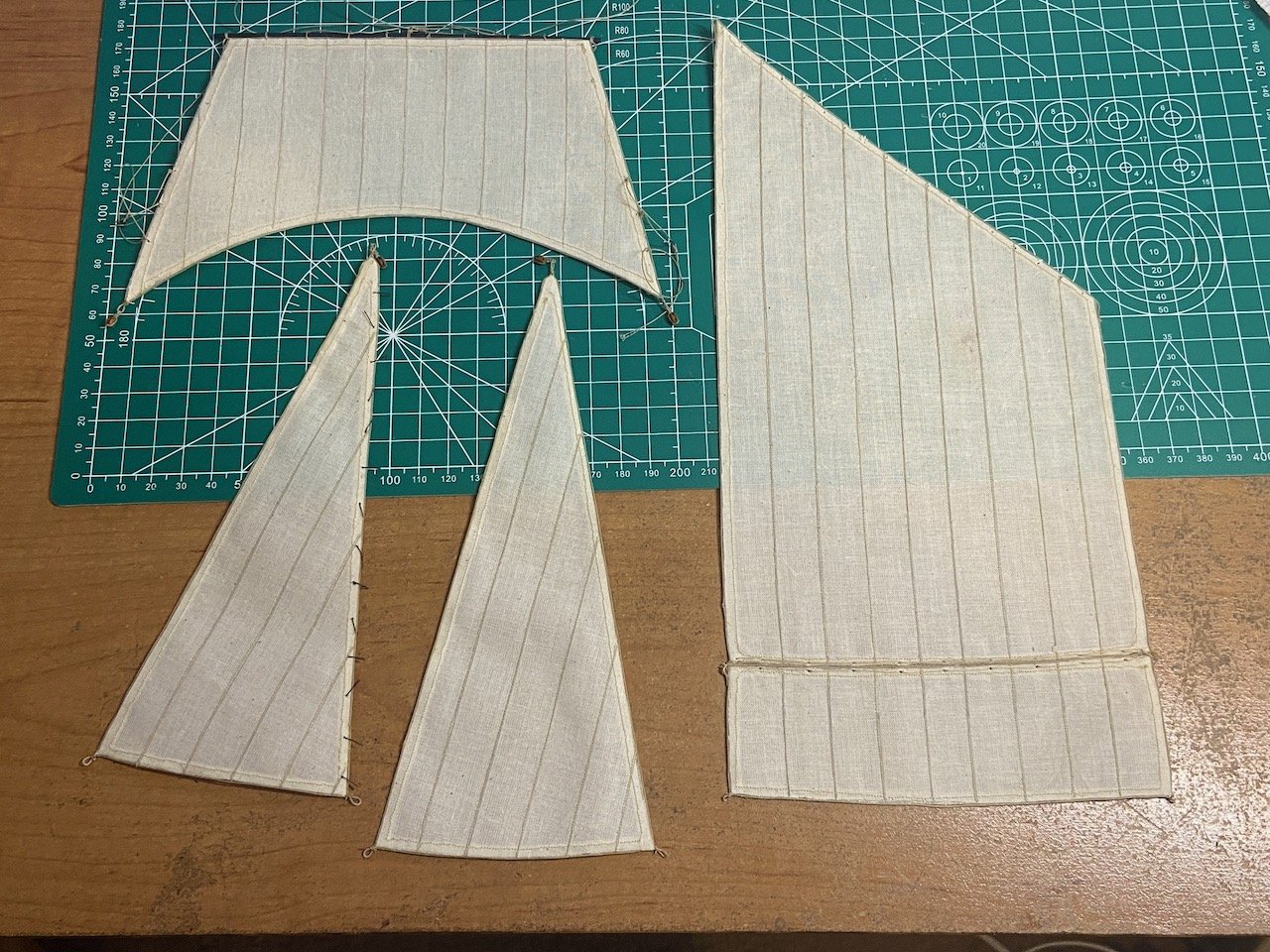

Slow going, but still progressing. I had to deal with jury duty this week, plus trying to deal with some work related bureaucratic junk. But, the worst thing was losing another ship modeling friend, just about three weeks ago. Just saw the guys two days before he died at a local ship model meeting. His name was Ken Lum, an NRG member. He was a great guy at the meetings. Hadn't built a ship model in, I don't know, 20 years or more. But, he was always very up to date on the ship modeling hobby news, and knew something about EVERYTHING, so he was always a big part of any historical or ship model discussion. I'll miss him very much for quite some time I think. As for the yacht Mary, work continues. I finally finished making the sails, including the bonnet on the mainsail. Some blocks have been added, bowlines, etc. Sewing machine is now put away, and I'm ready to rig. I've got some sheet blocks to add to the staysail and the mainsail, then I'll bend the mainsail. In the meantime, one thing confuses me a bit. I know the Mamoli/Dusek plans call for parrals to be added to the main gaff jaws, but I don't see any on the photos of the Utrecht replica that Baker posted (post #17), nor do I see any on Ab Hoving's English royal yacht model. Is this something the Dutch didn't bother with on such a small vessel? Like omitting ratlines as they were unnecessary? And, before I add the sails, I'm now thinking again about reef points. The Utrecht replica has them on the mainsail. But, as Druxey pointed out, they don't seem to appear in paintings of the period. I'll give it some more thought, but still leaning towards leaving them off.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Hi Druxey, I'm actually figuring on trying that on my HMS Wolf build, which I want to get back to soon. I want to try some furled sails and figure it will also be easier to do with silkspan. Also, the smaller scale of that model really calls for it (1/72). For the Mary, in part, I wanted to build it the way I think the original builder would have done, though I have no actual evidence that he would have even added sails or what type. It's just more of a judgement from the "feel" of his building style. Even the way I'm making the sails now doesn't seem quite right for his model. But, I needed to satisfy myself too. These cloth sails are somewhere in between.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Thank you for the comments, Ab! While the Mary was Dutch built, I assume it ended up operated by English sailors, with an English captain. So, I wonder if some changes were made to her at some point to accommodate English practices. I have considered both rig possibilities, but I'm too chicken to declare the rig to be one way or the other, so my model will end up somewhere in between. Probably, this will cause it to have a rig that was never correct. But, at least I'm learning (I think).

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

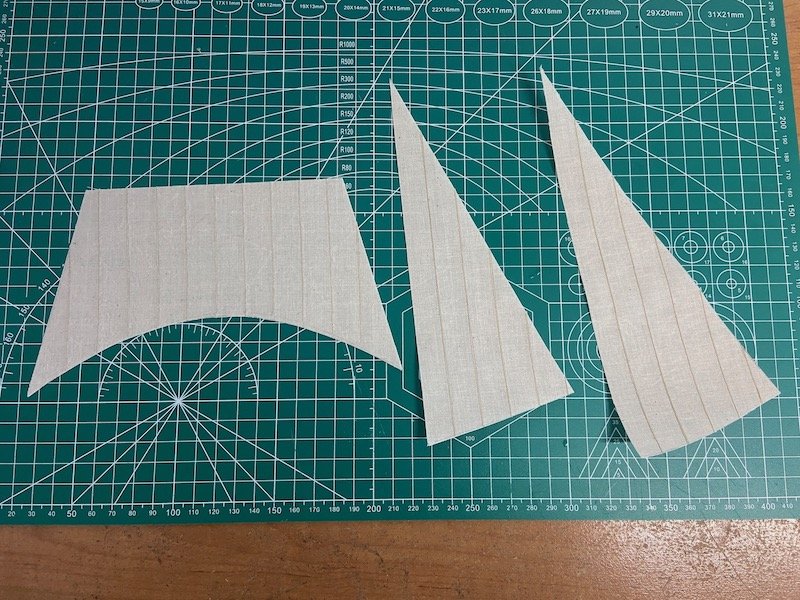

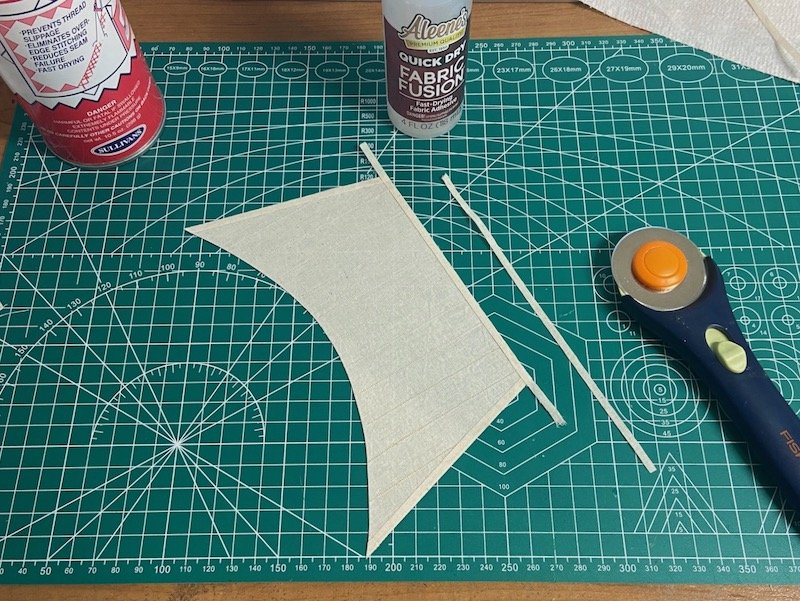

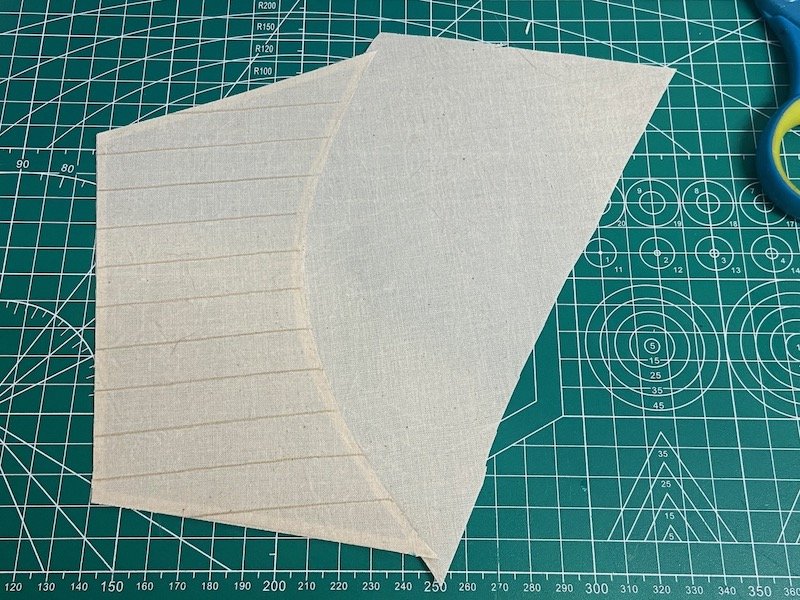

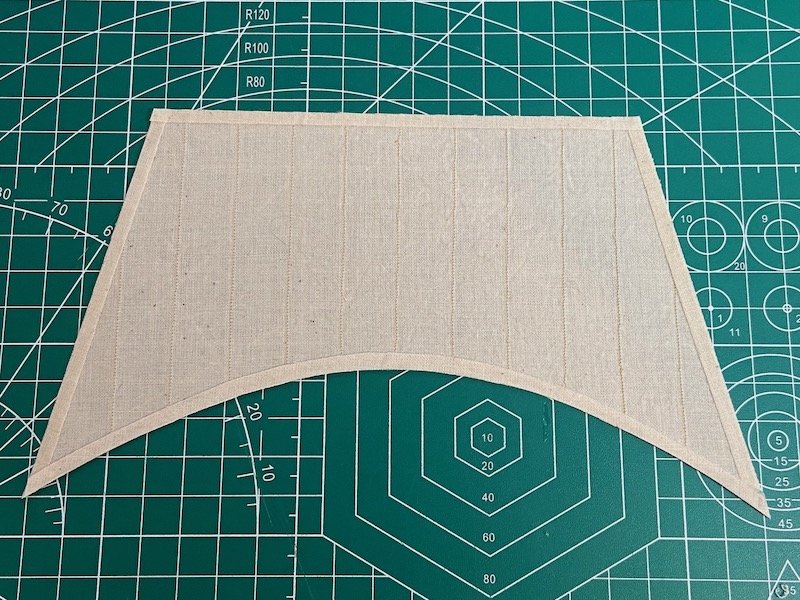

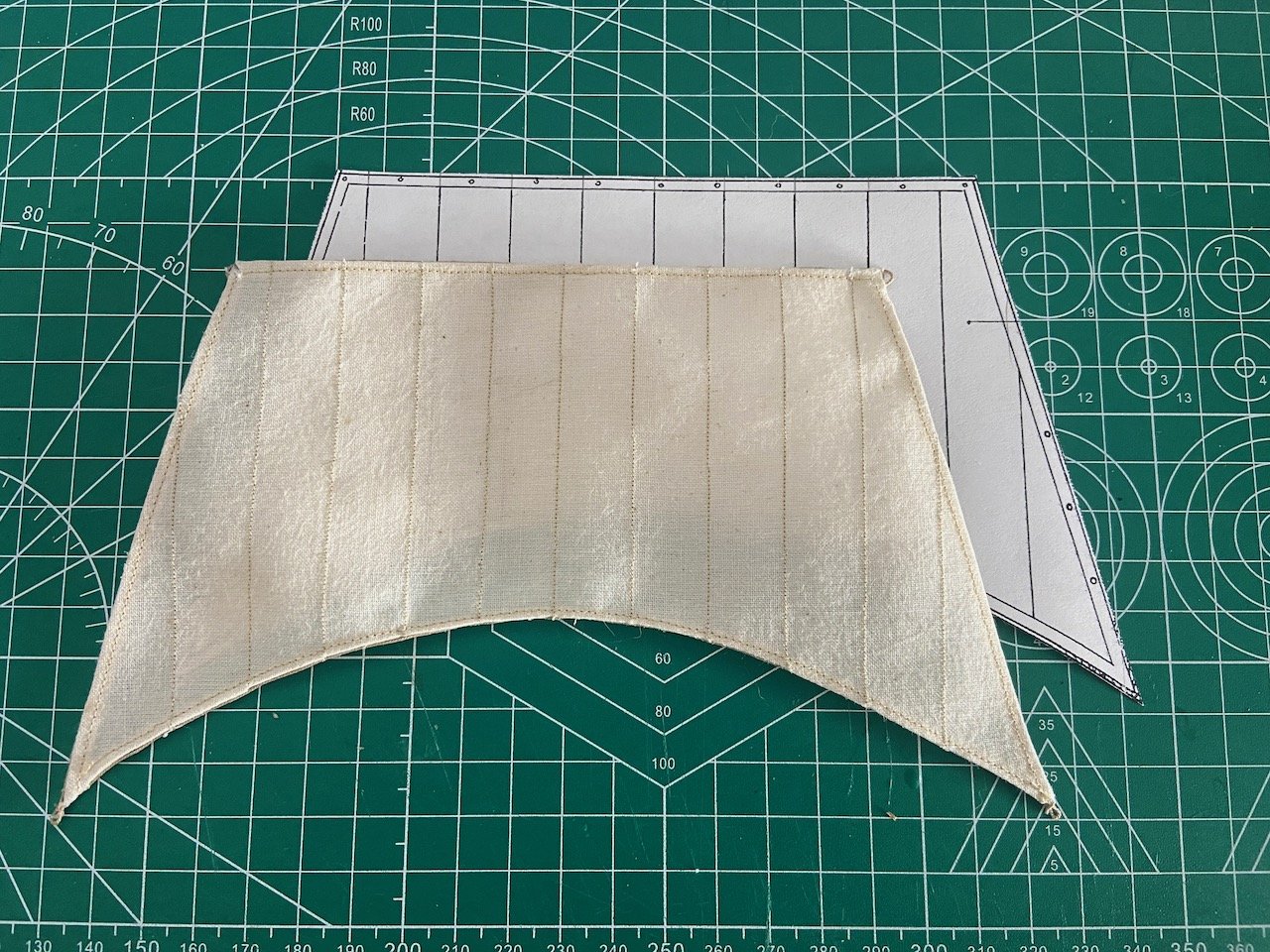

Not much to actually report, except that I've been trying to get these sails done for a couple weeks, and since I switched my sail making technique, I managed to make good progress over two days. I probably mentioned this before, but I'm using unbleached cotton muslin. This was hand washed and then treated with a fabric stabilizer called Terial Magic. This has to soak in for 15 minutes, wrung out, then the material is ironed. The resultant material acts like paper. The stabilizer can be left in or washed out later. Topsail and head sails were initially sewn and cut to shape. I cut some strips of fabric and sprayed them with Fray Stop, which is like the fabric stabilizer, but it doesn't wash out. It smells a lot like lacquer(!). I'm doing this, because I think I'm going to wash the Terial Magic out of the sails later (maybe), and I'm a little concerned that later the edges of these strips might start to fray. I'm gluing the strips using Aleene's Fabric Fusion, which is a clear, permanent fabric glue. I've never used it before. It's possible that my using the Fray Stop may keep the fabric glue from sticking as well. Not really sure about that. I didn't really consider that when I cut and sprayed those strips. We'll just have to see how it goes. I glued the strips into place using Aleene's Fabric Fusion. I'm showing a rotary cutter in the photo below, but I actually ended up using a scalpel with a fresh blade for more of the cutting. The rotary cutter might have worked better if the blade was newer. It was fine really, but the fresh scalpel blade was better. That curved edge of the topsail was the biggest challenge. I matched the cure as best I could in a larger piece of cloth, then glued the whole cloth to the sail. I then just cut the excess away. All tablings glued into place. I considered just leaving the sails in this state, but I wanted to show stitching of the tablings. I also thought that the tablings might hold up better if I end up washing them after I sew them. Finally, here are the first three sails. Just the mainsail to go. The tablings are all secured with one line of machine stitching. That part turned out okay, certainly a lot better than my earlier attempt. I still need to add the bolt ropes. I'm not too worried about that part. I'm just gluing them into place. But, I'll probably add the bolt ropes to these three sails before I make the last sail.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

After making the head sails and the topsail, I can honestly say that I hate how these are turning out. I can sew just fine, but the tablings are too bulky, and they're ruining the appearance of the whole thing. It's hard to get the corners done nicely, and all. I think I'm going back to making the sails in the way that I can do best, which is making them almost the same way others make paper sails. I think the process will also go much faster, which is a good thing, because I'm getting tired of remaking sails. The topsail isn't great, but it's actually okay. Still, if I'm going to change the way I make one sail, I have to change them all. I'd just love to be able to move on. Unfortunately, I probably won't have time to do much until closer to the weekend. But, on the positive side, there are only four sails to make, so we'll see.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Baker, sorry I didn't reply to your flag printing suggestion before. I think I'm happy enough with the double-sided, plain paper flags, but I may give your idea a try, just to see how it works out. And maybe it will be useful in a future build. Thanks!

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

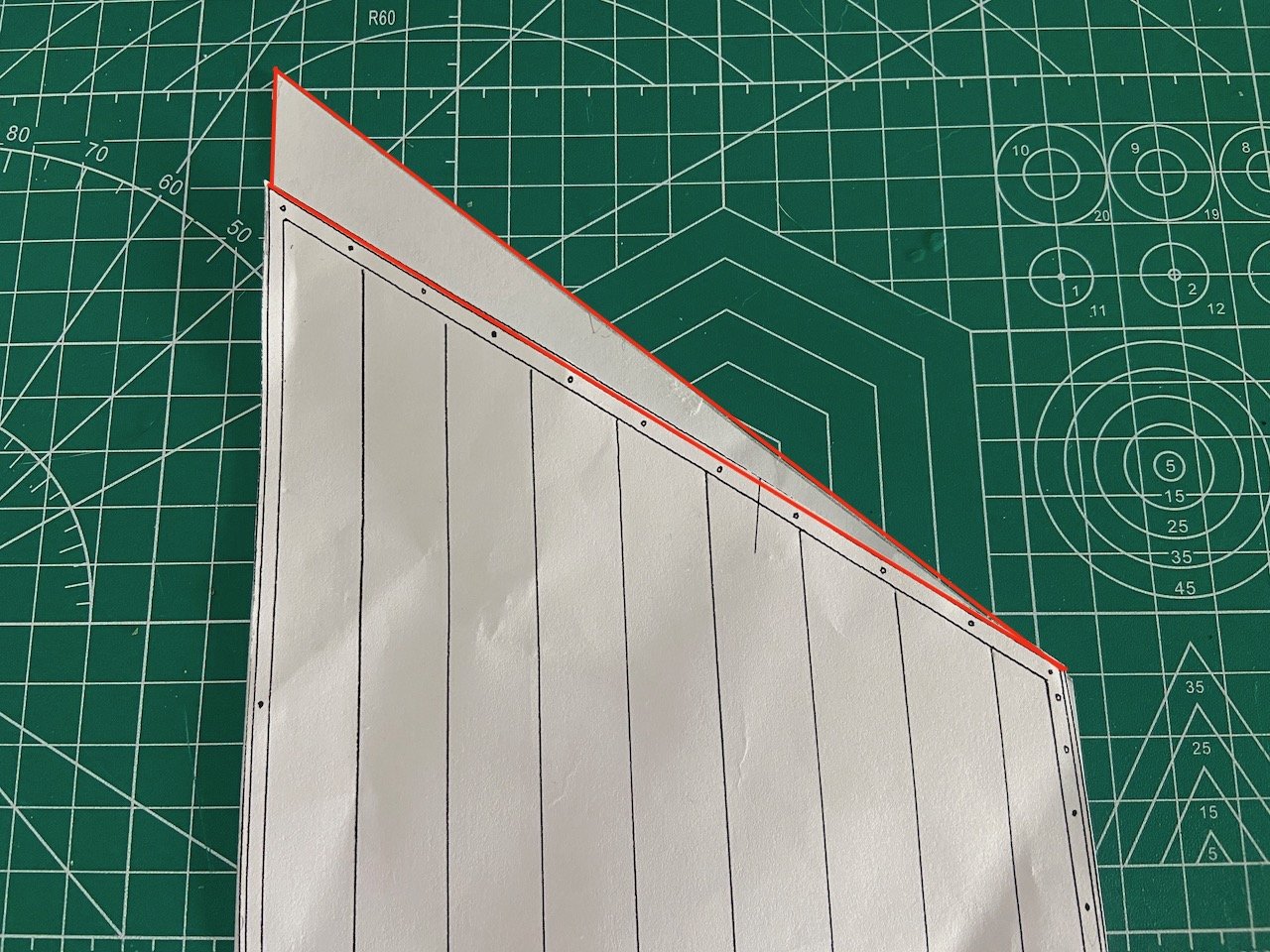

The shrouds are now "rattled down". I didn't get too fancy and just did my usual clove hitches all the way across. It's the way I've always rigged the shrouds, but in the future, I think I will try using cow hitches at the ends as someone suggested. I can see where this could actually make the ratlines easier to do, as well as make them more secure. It's not easy to trim those end knots and for them to stay secure. So, I gave them a strong dose of PVA to hold them. Not perfect, but it's done! I redid a few of the ratlines where I needed to do some adjustments and had a few knot failures. But, it's all secure now. Also, the photo is before I added one more ratline at the bottom end. By the way, for the fun of it, I decided to record myself tying ratlines, and I posted the video on Facebook and Youtube. Nothing fancy, just video... But now, I'm dealing with the sails. My sails usually turn out fine, but I'm never happy with the process. I've done other sails on other models and used fabric stiffners and glued all the tablings and reinforcements, and I'm very happy with how those turned out. In the future, I'll be trying out making silkspan sails. But for this model at this scale, I wanted to follow a more "traditional" process, where I sew all the tablings, and that's slowed me down a lot, mostly because I'm thinking about things too much. The first sail completed with a glued-on boltrope is the topsail. Folding over the fabric at the foot was sure a pain. I wasn't able to do a double fold, so it's not as sharp on the back side as I'd like. And, oops, somehow I managed not to take a photo of that side... 😬 The main issue I have is, of course, the mainsail. I'm not done with it yet, and thinking maybe I'll just get the jib and staysail done first, since they're pretty straight forward. But, here's the first issue with the mainsail... I've constructed my model with higher peak, so I can't use the kit pattern as is. I cut a new pattern with the added area highlighted in red, above. Now, I guess I'd better be off to start working on these remaining sails. Still not sure about the bonnet and reef points, so maybe I will just start with those head sails...

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

Forward, Back, Cha Cha Cha... That's the kind of dance it's been the past couple days on this project. I made the standing portion of the vangs. Are these pendants? Anyway, made all four of them with 8mm fiddle blocks stropped in their ends. Then, I realized that I didn't rig them with beckets. Had to redo all four... 😖 Today, I fixed the issue, cut away the temporary line I had in place of the vangs, and rigged the vangs. All looks good. They're not permanently in place, since I may have to remove the gaff when I rig the sails. During this last step, the stropping of one of the double blocks (the very last one I was working with, of course) gave way, so I had to remove the eyebolt for that block. It didn't want to come out, but finally did. I destroyed the eyebolt in the process, so had to replace it and re-strop the block to it before finishing up... three-four... cha cha cha... Now, I'm all set to get to work on the sails. They're basically cut and ready to finish up. More on that next time.

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

- 82 replies

-

- Yacht Mary

- Mamoli

-

(and 1 more)

Tagged with:

-

In my own experience, contact cement has worked fine for attaching wood veneer planking, and I think it will continue to do so. If working with thicker planking, I would use PVA and a little CA glue. But, there is very little hold necessary for veneer planking. It's not like a countertop or shoe that has to stand up to decades of abuse. Never seen contact cement bond fail. But, that's just me.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.