-

Posts

1,299 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bedford

-

Good on you! A proud moment for any model maker to receive that recognition

- 170 replies

-

- ogallala

- praire schooner

-

(and 2 more)

Tagged with:

-

Guys I met John on Wednesday after endeavour returned to the maritime museum and had a good look at this beautiful little boat and pics don't do it justice. It was good to meet you John and to see the pritt

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Hi John. She certainly looks beautiful, even more so in the flesh. It seems I missed you by a day! Had an interesting chat with Col though and he told me about the big joint project you are all working on. She'll be a beauty too

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

As the others have said, glad you are ok and getting on and remember this is a hobby, you don't owe it or us anything, just do your thing in your time. Doing the kitchen...........brings back memories of a supposedly very fast drying floor sealant that took a week before we could walk on it!! That mucked our plans up and gave the fast food sales figures a boost!

-

Thanks so much Michael. I know 3 jaw chucks are rubbish for re-centering so I always work out how to do the turning in one go. I do have a 4 jaw independent chuck as well but have only used it once or twice as I have not had any job that was that involved I needed to mount and re-mount. The tip about 3 diameters is gold and probably explains the problem. I see much more live end use in my future. Next I guess I need to buy a ground bar, is that an item designed for this purpose? I have been thinking about collets for a while, I know they are much better and watching what you are doing with them really confirms that. I won't be doing anything about it for a while though, I head for Sydney on Tuesday morning in readiness to sail out for Hobart on the Endeavour on Wednesday. Really looking forward to that! Steve

-

Michael, it's a cheap Chinese job, Sieg C6 with the mill attachment. It will be good enough for most of what I do but I think I need to learn a lot about it, like I have a feeling the head isn't exactly square to the bed as I always seem to end up with a slight taper on longitudinal cuts, maybe I am just thinking the stock material is more rigid than it really is though.

-

Michael, I have a thread cutting lathe with a whole bunch of gears that can be swapped around to set the pitch, the thought of it is a bit overwhelming at present and the fact that the instructions aren't great doesn't help. It doesn't change the fact that I never would have thought of making a tap though, another lesson filed away. I would have thought the die would be the easy part, drill, tap, drill three adjacent holes for the swarf and then harden. But then I have absolutely no experience.

-

I am learning from using the lathe and as such decided to make something else for the ship, a tool. I used to just have this as a piece of 2.4mm brass wire about 200mm long but thought I would make a better version for the sake of the exercise. The tool is for tying off the running rigging to belaying pins. I catch the line in the groove at the end of the tool and while keeping tension further down on the cord I can easily place it around the pin, top and bottom. I am learning, the ferrule on the handle end is straight of the lathe and is a much better finish than the tool end which has been buffed with the dremel after soldering the tip in.

-

I've milled the rings and soldered the bars on, next step will be to fit it to the ship and work out the geometry of the pulls. Before mounting I must remember to turn up the pin that will mount to the servo horn and engage the bars. Once it is mounted and I have worked out the geometry I will solder on the rings to tie off the lines to.

-

I am making the mechanism to handle tacking of the stays'ls, I developed something earlier but it worked on differential motion where it let heaps of line out as it took a little in but I have realised that I need the windward line to go completely slack before the lee line takes up so I have adapted something Jerry posted somewhere like page 13 and am making a mechanism that will do just that (he said hopefully), only testing the completed mechanism will tell and I figured it is easier to make it properly than try and jury rig something. The idea is two long arms pivoting on the servo shaft and pushed by the servo arm, one at a time. They will both lie parallel at rest with a pin rising from the servo horn between them to push one or the other. So I turned up a pivot that will fit into the top of the servo horn and be held down by the servo horn screw. There are two 4mm thick rings that will have 4mm square brass tube of approx 115mm in length soldered to them but first I have to mill some flats onto the rings to locate the tubes but I have done enough machining for today. And because I am learning from Michaels Skipjack build I have turned up a plug to go inside the two rings and hold them in perfect alignment when I put them into the mahine vice to mill the flats for the square tubes.

-

You're a brave man to rely only on paint to keep water out of the glue, in my schooner build I painted the whole thing inside and out with thinned epoxy resin to guarantee protection for the timber and glue. The other side of doing this is that it increases the strength of the timber and the joints by bonding the whole thing into one.

-

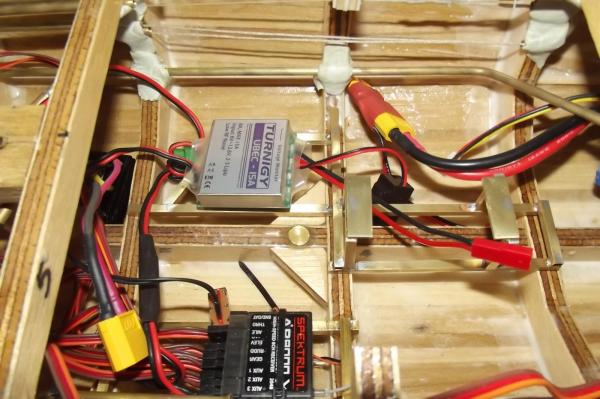

I have made the cradle to carry the UBEC (power supply) and the stays'l tacking servo. I was going to use timber for the servo but relised I needed to keep the UBEC up out of any water that may get in and doing all that with timber was going to be bulky and heavy so 35 grams of brass and solder later.............. The servo sits accordingly, I still have to drill and tap the mounting holes but that won't take long. In place with the UBEC where it will be secured with cable ties, when the servo is fitted there will be plenty of room around it. Now I know the solder work is a tad ugly in spots but it is below deck.......................

-

Absolutely beautiful design and workmanship there Michael. It all makes perfect sense and is such a simple elegant concept typical of the age. On a side note, just looking at that heavy flywheel supported by quite a thin crankshaft, are you concerned about the weight of the flywheel forcing the crank out of true over extended periods of non use? I have no experience with such small machines so I realise it may never be an issue but I know the diesel engines my brother works on must be kept rotating by way of an electric motor even when not in use otherwise the cranks will sag and they then have to run them with the motor for a week or so to get the crank true again before they can start it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.