-

Posts

538 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SGraham

-

Thanks, J. The line is from Chuck. When I finish this build I think I'm going to check into learning how to make my own. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

J, keep us posted on the case, if you don't mind. I'm curious to see what you come up with. Steve -

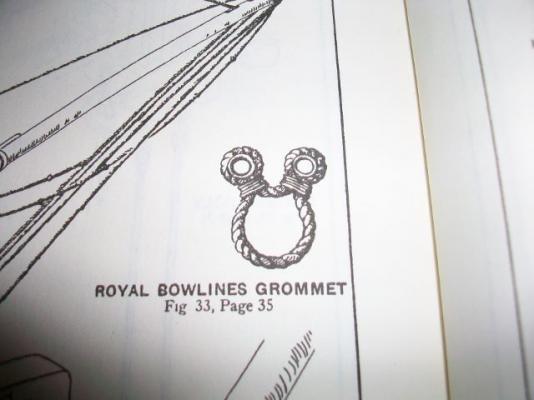

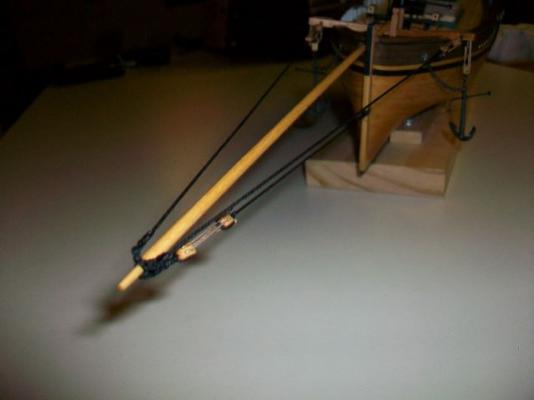

Good to hear from you, Scott. I'll enjoy checking out your building logs. I started rigging the bowsprit. I was looking in Murphy and Jeffers Spars and Rigging, from Nautical Routine, 1849 and found a plate of a royal bowlines grommet. It's the first photo--the one that looks like a pleasantly surprised frog. I don't have the foggiest notion of what a royal bowlines Grommet is, other than a guess that it lives with a royal bowlines Wallace. Anyways, I thought it might work on the end of a bowsprit, and it looked fun to try. Ha! This rigging stuff is way harder than the building. I came up with something that sort of resembles said grommet, and it provides 3 nice purchase points for the standing rigging of the sprit. It's a little bulky, but oh well... The lanyards that attach to the catheads are seriously lopsided too. One side is half again as long as the other. Still, it goes right along with the lopsided scuppers. Thanks for reading! Good night. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

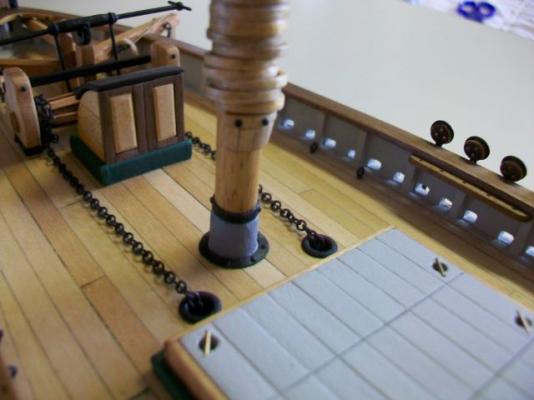

Thanks J. The ring around the base of the mast is card stock. The ports where the chains enter are the brass ones that came with the kit. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Got a little more done today. I added one more cross piece to the cross trees. I also made a support for the boom. Then I attempted a mast boot. I learned that at least some were made of canvas with metal bands above and below to fasten them to the mast and deck. For the canvas I used a piece of paper towel covered in shellac. The metal bands were made of card stock and pinned to the mast and deck with blackened steel pins. The paint on the boot is pretty garish looking, especially in the flash of the camera. I may change the color. Thanks for reading! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I think a sewing machine pedal would work fine on a variable speed rotary tool. The foredom's pedal looks suspiciously singer-esque. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Wow, Jesse, those sails look amazing on the spars. Thanks for sharing the tip about how to get nice clean holes in sailcloth. Steve

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks J. I'll be getting to ratlines soon. Be still my heart! A while ago I picked up a used foredom tool with a bunch of used burrs from a retired jeweler. I used a tiny cylindrical burr on the ends of the spreaders. It's quick and accurate. With the dremel tool I had been using, with its on/off only capabilities, tool points were scooting all over the place. The foredom with its rheostat pedal makes it a lot easier to keep the tool point where I want it. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Here's a tiny bit more progress. I made and attached the spreaders for the backstays. I think they are yellow boxwood. The yellow doesn't look so garish in real life. The ebony is going to be left unfinished. The boxwood has a little tung oil rubbed into it. It's funny that such a seemingly simple part could take so long to make and attach. Like the crosstrees, these are notched on the ends to take the stays. Thanks for reading! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks Jesse, Sam, Nils, and J. I appreciate the kind words. I'm finding the mast to be more challenging to build than the hull. I'm glad this little ship only has one mast. Welcome aboard, Scott. Thanks for the nice comments. This is my first build log, and I've found folks to be very encouraging and helpful. What are you building right now? Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I think you call these the cross trees. They are about halfway done. I used some ebony scrap from a piece of leftover guitar binding to make them. The ends of the spreaders are grooved to take the deadeyes and futtocks for the topmast. This was the fiddliest work yet for my stubby fingers. Thanks for reading. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

The ratlines look perfect. I really like the detail you put into those yards. That's very impressive. And the sail looks very realistic on the yard. Excellent work! Steve

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks for the replies, Jesse, David, and Steve. I've heard others, like David, report great success with Brass Black. I'm still having a hard time getting it to work well. It takes a lot of prep and then needs a couple of treatments. And then the coating is very fragile. For simulating round-headed bolts, it's really fast to use a steel pin, turn it against a file and hit it with gun blueing. Like Steve, I find the metal turns immediately dark black with a durable finish. I don't even degrease the pins first. I guess I need to practice more with the Brass Black. But when I need round-headed bolts now, the steel is an easy solution. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks J and Jesse. What does gun blueing do to brass?

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I started work on the spars today. It's raining (hooray) and working in the boatyard while listening to the rain come down is a very pleasant way to spend an afternoon. Here is the top of the lower mast. I made the ring below the mast cheeks with card stock. I love paper! It's great for folks who don't know how to solder yet. The cheeks and little cleats are walnut. I had to inlet the cleats into the mast because they were having a hard time staying attached. Inletted and pinned, they seem to be staying put. We'll see when I add more rigging. The block is from Chuck's store, Syren. He sells some really nice fittings. The round-headed pins are steel pins that I turned in my dremel tool while holding them against a file. I chose to use steel pins instead of brass because you can blacken them with gun blueing. It goes right on without fastidious degreasing and it stays on real well. Thanks for reading! And check out J's Half Moon. He's all done! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

That's a breathtaking little ship! Congratulations, J! It's been fun watching her come together. Are you going to add the Moon to the gallery? Steve -

Shenandoah by Leo-zd - 1:200

SGraham replied to Leo-zd's topic in - Build logs for subjects built 1851 - 1900

My potatoes keep getting in the way too! And I'm working at 1:75 scale. Ha! Steve -

Shenandoah by Leo-zd - 1:200

SGraham replied to Leo-zd's topic in - Build logs for subjects built 1851 - 1900

Thanks for posting, Leo! Very impressive. I don't know how you can control the details at such a small scale. I looked at your photos in the gallery. I'm really glad you are also posting a build log for the cutter. Steve -

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

J, the gauge for the ratlines is a great idea. That's going into my need-to-know file. The ratlines and rigging are really making the Moon come alive. I'm looking forward to seeing the flags hoisted. Steve -

Wow, Jesse, beautiful sails. What an accomplishment! Steve

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

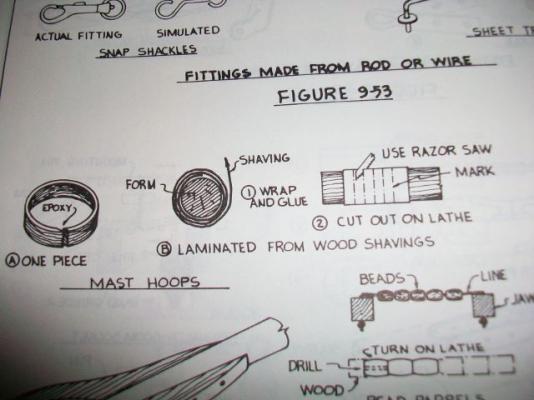

Thanks Sam, Jesse and Larry. I got the idea from "Watercraft Modeler's Handbook" by Benjamin Lankford, Jr. (Nautical Research Guild, Inc., 1988). He has a lot of helpful tips that are diagramed clearly enough for folks like me to follow. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

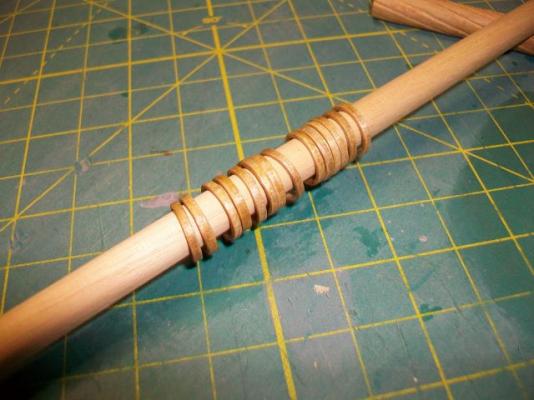

Before starting the mast, I decided to try my hand at making some mast hoops out of wood shavings. I hope I'm not stating the obvious, but here is the process I followed in case any other newbies like me care to give it a try. 1) I cut the shavings with a plane. 2) The wood I started with was some generic "white wood" they sell at the big box stores. It had weak spots in the grain streaks that tore open as soon as they were touched. 3) I switched to a piece of clear maple and got much better results. The piece I used was about 8" long and 3/4" wide. 4) I used short wooden dowels as plugs and covered them with cellophane. 5) I rolled the shavings out and sprayed one side with contact adhesive. Next, I rolled them tightly onto the plugs. The roll with the blue tape was glued with wood glue. I got the same results with the wood glue as the spray adhesive but had to wait longer for it to dry. The spray adhesive was easier and faster to use. 6) After a few minutes of drying time, I sanded flat the ends of the rough rolls. 7) I cut the hoops with an X-acto knife. By the way, sanding and cutting was done with the hoops back on the dowels. 8) I finished the hoops with amber shellac and buffed them out with #0000 steel wool. 9) I made way too many rolls of shavings. The Shenandoah calls for 14 mast hoops. It only took one and a half shavings to get that many. So, I have enough glued up rolls for all the models on my shelf. One last thing: I had to flow a little thin super glue onto the cut edges of the hoops to stiffen them up before sanding them. Thanks for reading! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks so much, Sam and Bob. I'm going to try to start on the mast today.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.