-

Posts

214 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mfelinger

-

As always Nils, you doing admirable work. I like to monitor the progress of your log. cheers, Matija

-

Thank you Patrick, it's nice to hear praise from a man who is master of miniatures. Thank you Mike... always look easy if you work for pleasure (& when others are doing .) Pasara do that little "pause" of Pen Duick, it worked, now I can not wait to continue my work. Today, little progress but it has ... I would have more but I have go to work tonight .. Here are some photos: Regards, Matija.

-

Igor, excellent work, I like it. It's something different and interesting (for me). I follow with curiosity. Cheers, Matija.

-

Patrick, as always you are unmatched. I would like all the previous praise collect into one .... perfect! :) Matija

-

A big thank you Bob, Mike, Matand for nice words and all who visited my log and likes. Now I'm scared because I believe you have a high expectations of my work. I did not go according to plan ... but best to you see photos: 2k car Putty ... ribs do not currently exist and needs something to be harden Heating to warm the wax order to mold removed from the hull The interior looks really bad but it does not matter because it is filled with 2k putty Templates It is not an accident that I smoothed the outside of the hull. Pasara made a very clean and smooth with no visible cracks: Regards, Matija.

-

Great and wonderful job. I follow with pleasure. Matija

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

Here I tested the protection of the deck. I am satisfied, so I applied it to the deck. Regards Matija -

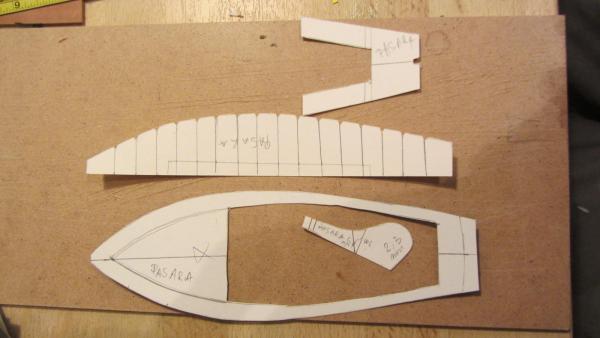

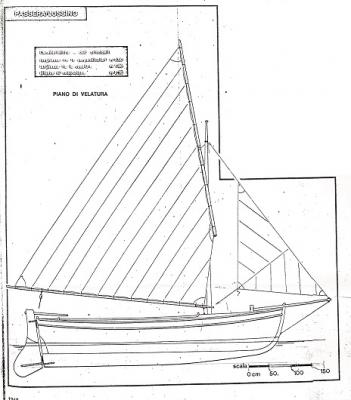

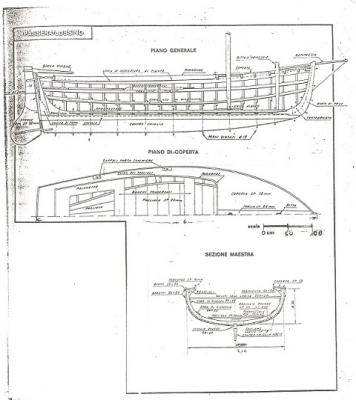

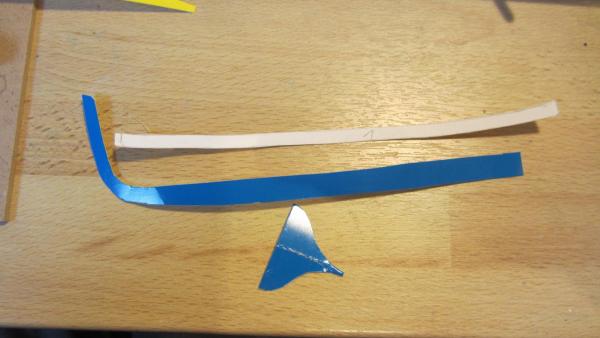

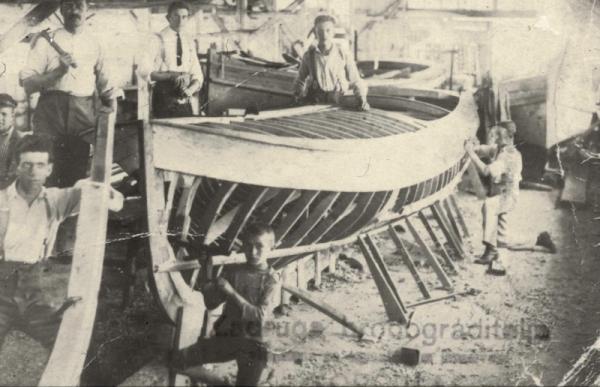

For a longer time l was looking miniature masters at work ... so I decided to try something similar. I'll make something simple to start. Pasara - Croatian traditional boat. My building is not traditional, but you will see ... Pasara is a middle-sized boat, similar to other traditional boats by her design and by purpose. The pasara´s characteristic feature is the transom stern. The flat broad surface of the transom allowed easy fitting of the outboards motors, making the pasara very popular among the recent boatmen "barkarijoli" who used to rent their boats and offer their navigational services to turists for short trips. The smallest pasara used to have no deck, The middle sized and the larger ones of 5 to 6 meters of length were usually partly decked up to about a third of the boatˇs length from the bow. In recent times special wooden covers, similar to hatch covers on larger boats, were used to cover the entire pasara to protect the inside of the boat from rain or sea. A small pasara was used for fishing as well as for transport, but was frequently also used as a by-boat, named "kajic" for larger sailing boats. When not in function of connecting the large boatwith the coast or towing her in the calm, "kajic" was usually the lugsail and the jib. Various local shipwrights tended to develop thier own practicular design features. It was easy to discern those caracteristic local features among pasaras along the coast. Thus, the pasara hull design which was subject to local preferences too. The pasara could be seen carrying the lug, but also the lateen , or even the gaff sail. Traditional boats of the Croatian Adriatic several old photos of pasara: M 1:30 Length: 16.5 cm Width 5 cm I made a wooden mold for the hull: Mold I smeared with wax: greetings Matija

-

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

Hi Mike ..perhaps it is better epoxy & rowing placed on the outside of the hull. So I protect Pen Duick with epoxy, sprayed the 2k car putty (??) and painted also paint for cars It is described at the beginning of this log The paper should not be a problem, the problem is wood (planks) if twisted due to moisture, it happened to me on one project. Regards, Matija. -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

Thanks Mike, I would false deck before glued planks protected with epoxy resin. I think it is excellent glue that you intend to use (tidebond III) You can also protect the epoxy finishing layer deck but will look glossy This is the best protection, but I think that the protection of matte varnish or oil also helped. Here is an example of what it looks like epoxy to plank. See the detail where the epoxy resin was used, see the difference in color. Here is the entire ship impregnated with epoxy resin Regards, Matija. -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

Do not worry Lawrence, we are all occupied with its own problems and work, that's life. I am glad that you like my work, even more will be glad if you find interest that will help you in building your beautiful models. I enjoy watching it how she grows Just be persistent. Jan, Such comments are pushing me away, to be persistent, thank you to these comments Cheers, Matija -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

Thank you Patrick, Elia, Bob ... and all the faithful visitors of my log. Elia, this is a beautiful ship, I am impatiently waiting for several years to begin work. It is a great pleasure to work. ... I hope I will not regret it Cheers, Matija. -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

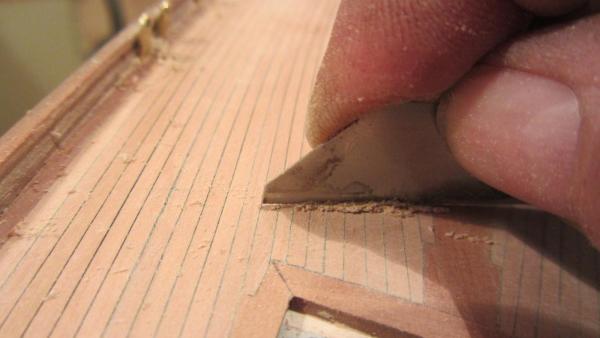

Thanks to everyone that follow my log, which give likes, support and nice words. Row, it's all luck, as all fingers is complete, so far I have only good sanded nails .. Thanks Mike, I'm also a joy to see your log and the progress of construction. Today I finished my deck. Now give him a lot of attention, sanding and coating ... Here are a few photos, I hope you will like: Regards, Matija. -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

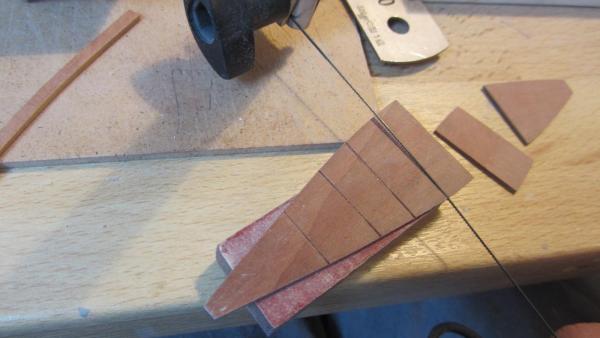

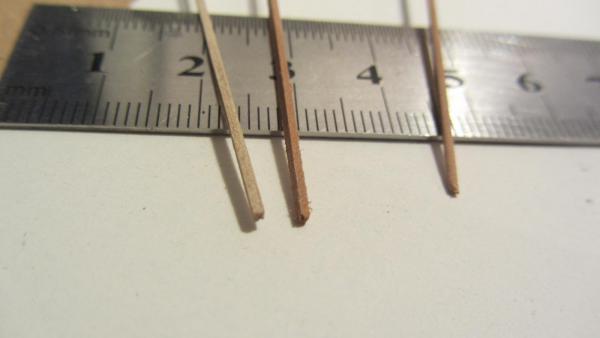

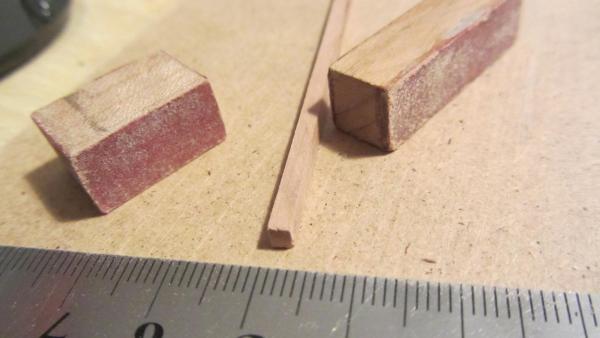

Thank you all for your interest and good words. Michael, I hope that the deck will remains the same after the coating protection. Corners I got after several attempts. I first tried to laminate. The thickness of the finished slats is 1.25 mm. When bent in several layers, very thin wood, it is badly looked or cracked. I cut it out from pieces of wood and manually processed. No dark art only work and repetition The pictures show cutting only for example, now I cutting the bad tree Finishing with power tools and hand Matija -

Mike As I said before, a serious approach and work,- the result is fantastic. Impatiently Awaiting a continuation Matija

-

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

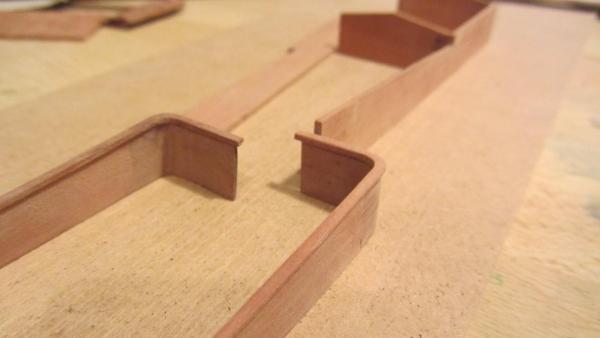

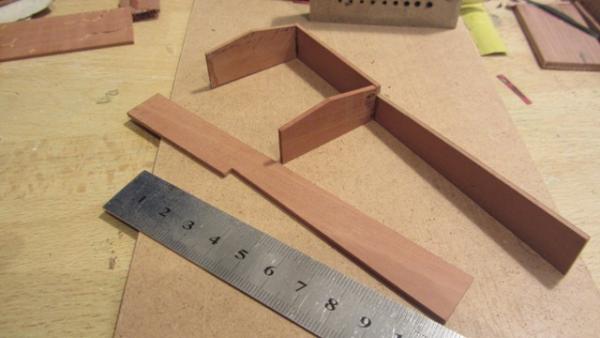

Thanks Mike, I'm glad if I could help a little.. I hope that I will in the future be of help. Thanks Michael, I have seen your masterpiece Maria ... You are unsurpassed, congratulations. Thanks to everyone else for the kind comments and likes - Mark, Druxey, Patrick, Leo,... Work on the deck is nearing its completion but still slow going. While the adhesive dries I started working on the deck furniture Matija -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

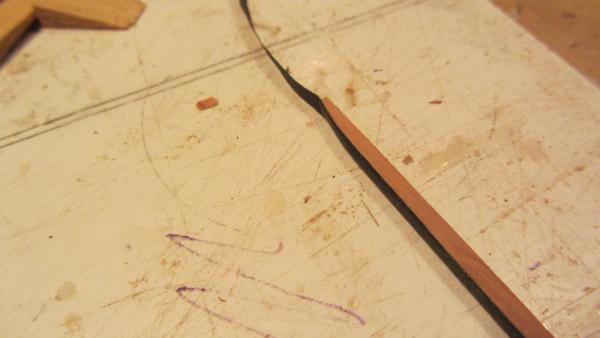

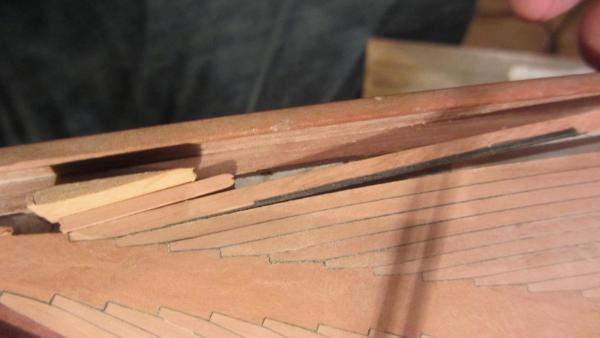

Patrick, thanks for the compliments. Nice to hear from a true master How do I have a problem with bad English I made a few pictures to explain how I do it. I do not think I'm doing something special that others do not work. maybe is the secret to great pressure on the planks glued part. each plank especially sanding and checking measures It begins like this the coarse sanding but must be at right angles checking adjustment Here it is evident that the pressure on the plank gets result follows gluing black paper placed plank is for example, not glued Patrick, I think I could answer on your question, and I hope it is understandable. I hope that I helped to someone Regards, Matija. -

Pen Duick 1898 by Mfelinger - 1:20

Mfelinger replied to Mfelinger's topic in - Build logs for subjects built 1851 - 1900

-

Hi Denis Meticulous work, it looks very nice, congratulations. Matija

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

Mike, Very nice work, this is serious shipyard. Also I look forward to the continuation Regards, Matija.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.