-

Posts

1,505 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by archjofo

-

Hi Ed, your metalwork is very admirable, but not only this.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

SOLEIL ROYAL 1669 by michel saunier

archjofo replied to michel saunier's topic in - Build logs for subjects built 1501 - 1750

Hello Michel, I have been watching your building on the Internet for some time. I am glad that you are here now in MSW. Your model is fantastic. -

Hi Ed, I am impressed by your performance. This precision at this scale. This is model construction at the highest level.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Wonderful pictures of a fantastic model!

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

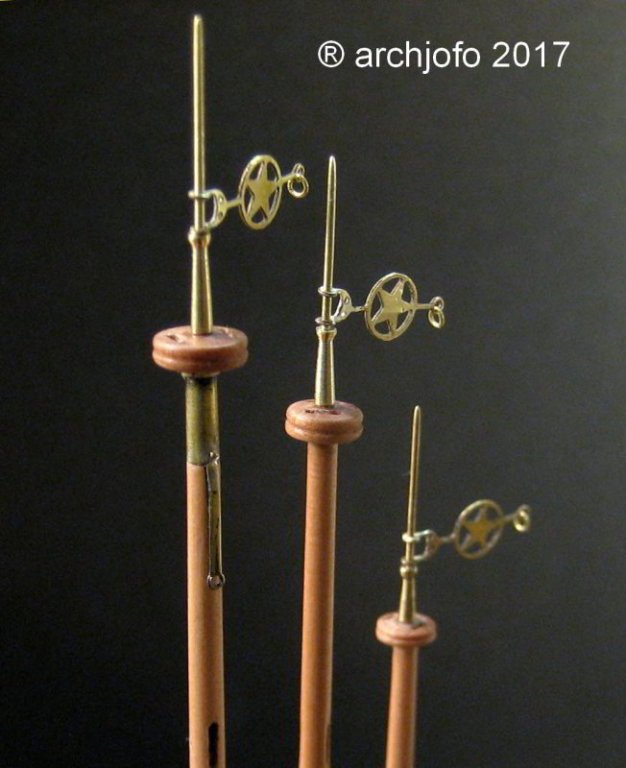

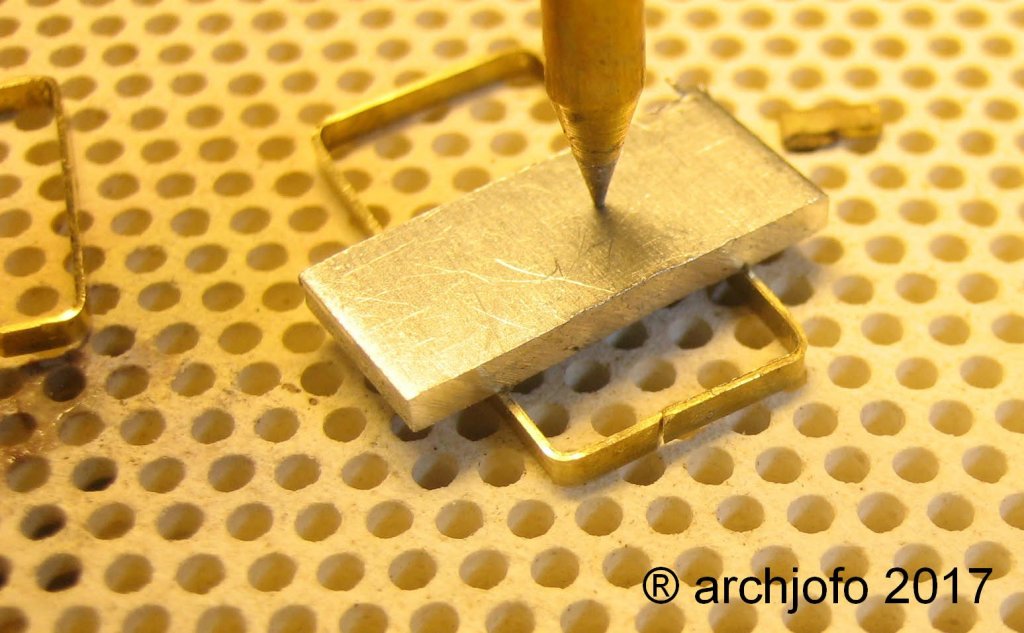

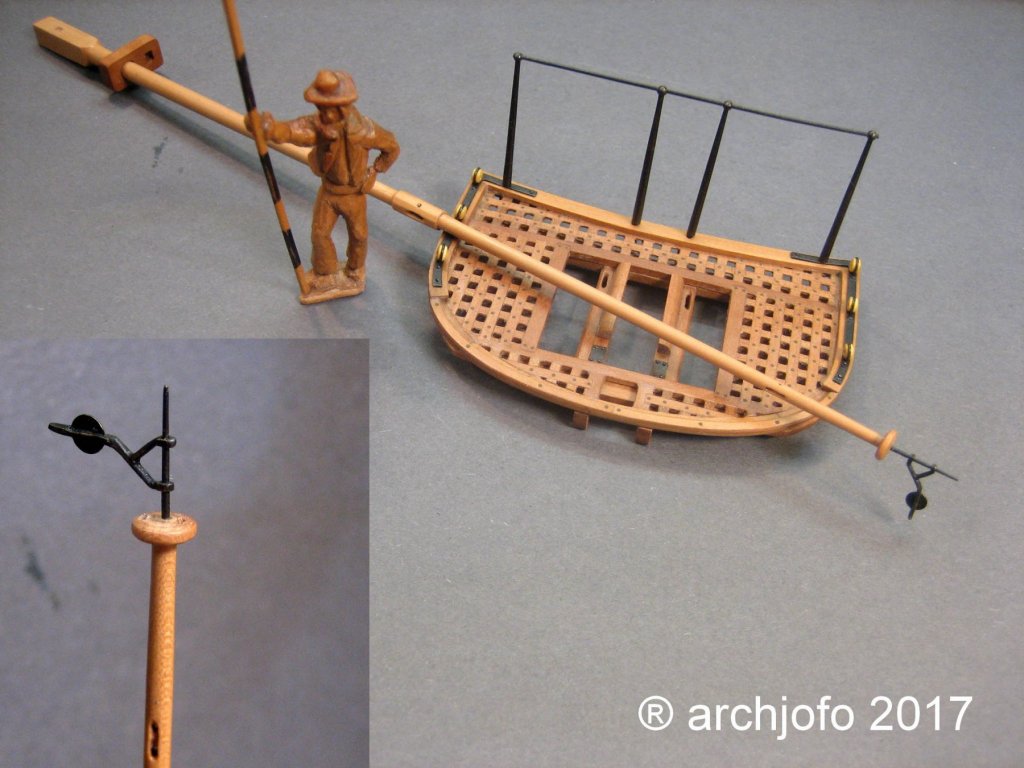

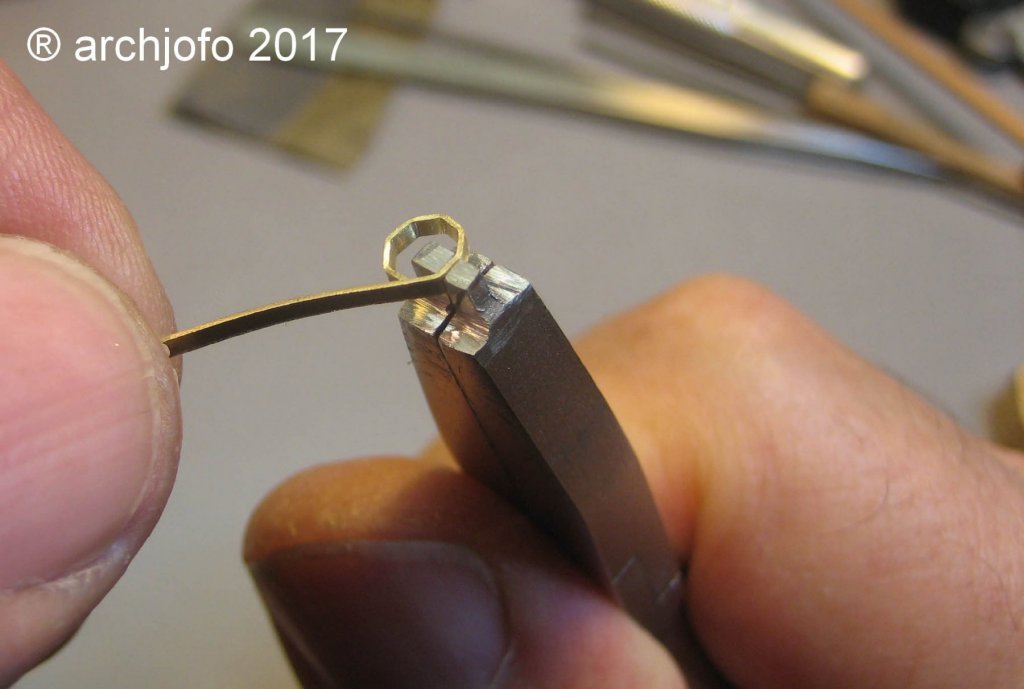

@dvm27 Hi, the La Creole carried max. 3 weather vanes. These etching parts are extremely filigree. The soldering of the mounting rings is very difficult, so some of them are damaged. So I had to produce more than I need. The etching board with the 18 weather vanes cost only 6 € including shipping in Germany.

-

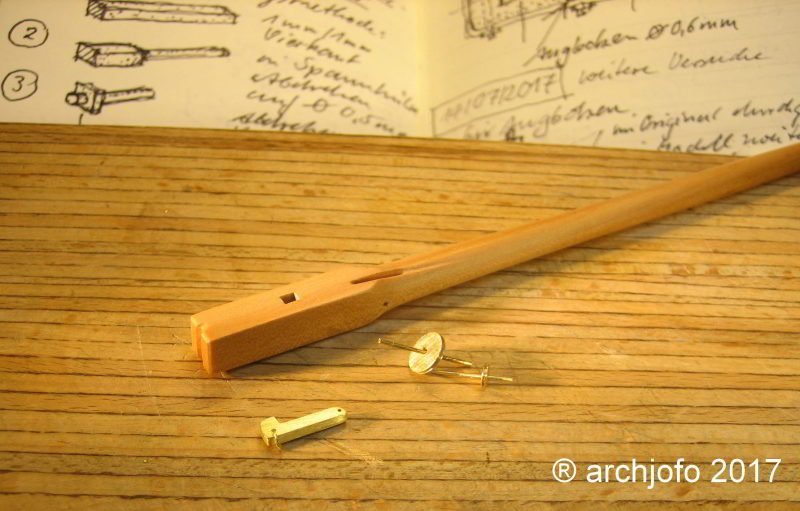

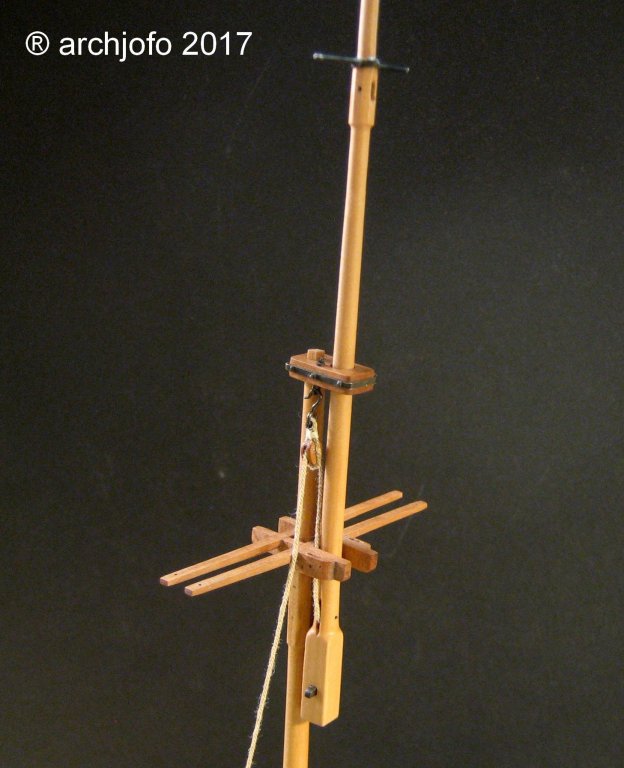

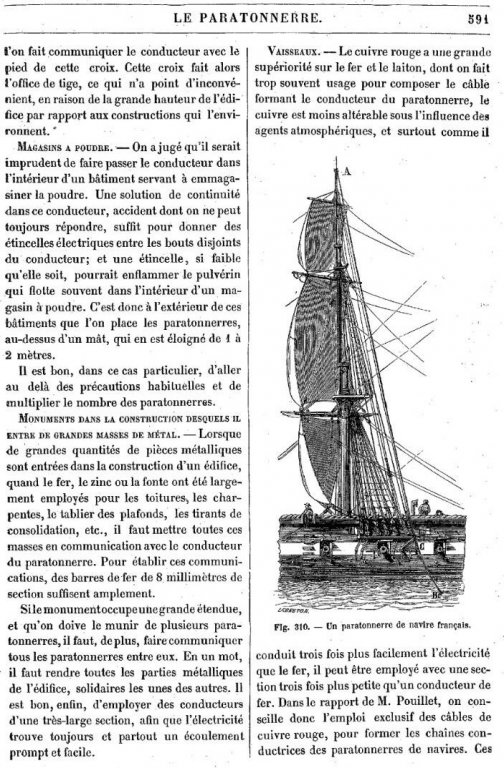

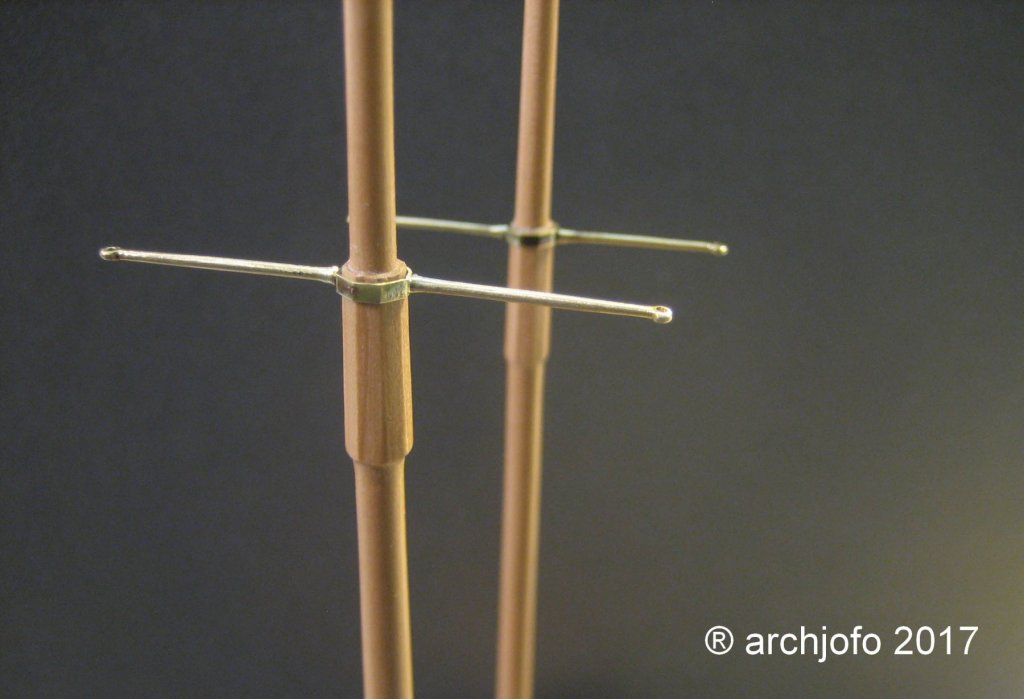

First of all, I would like to thank you for your supportive comments and for the LIKES. Let us remember LINK Meanwhile, I got the etched parts for the weather vanes delivered. I immediately went to work, and built the weather vane with lightning conductor for the mainmast top of the La Creole. In this context, I would like to mention this report on the lightning control of sailing ships. There are many parallels to the lightning conduction of the La Creole. I have also worked on the topgallant masts. Here are the results.

-

Hello, thanks for the nice comments and the LIKES. My previous interpretation of the weather flags and the lightning conduction for the La Creole is completely wrong. Our forum colleague Dirk @ Dubz showed me a picture from the book "Modeles Historiques" by J. Boudriot from the top of the main mast of the Paris model of La Creole. I also want to make this beautiful detail for my model. For this I use the etching technique. I have already drawn the necessary template.

-

Hi Ed, this is a beautiful sight. In addition, your report is for me a textbook for modeling, where I always find great suggestions.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

ancre Chebece 1750 by Jeronimo - FINISHED

archjofo replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Hi Karl, Beautiful progress! It is a fine precise work. -

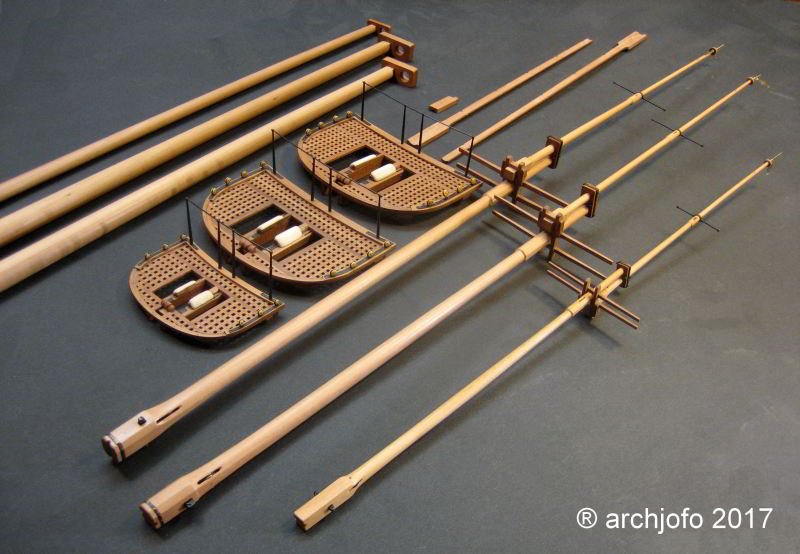

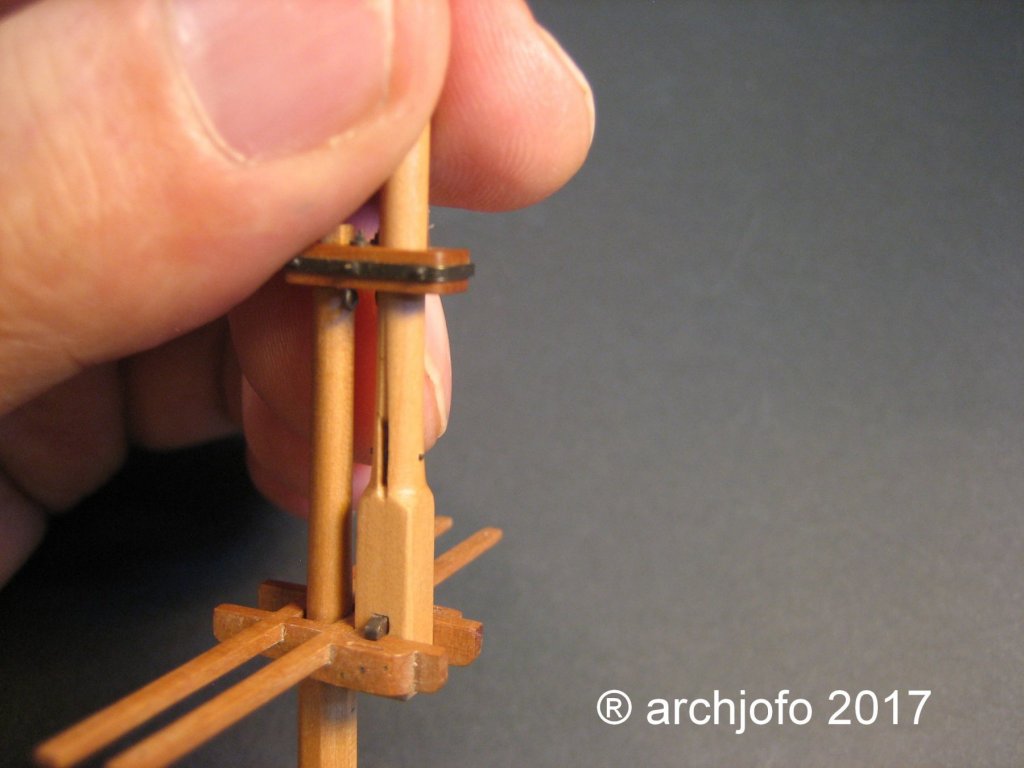

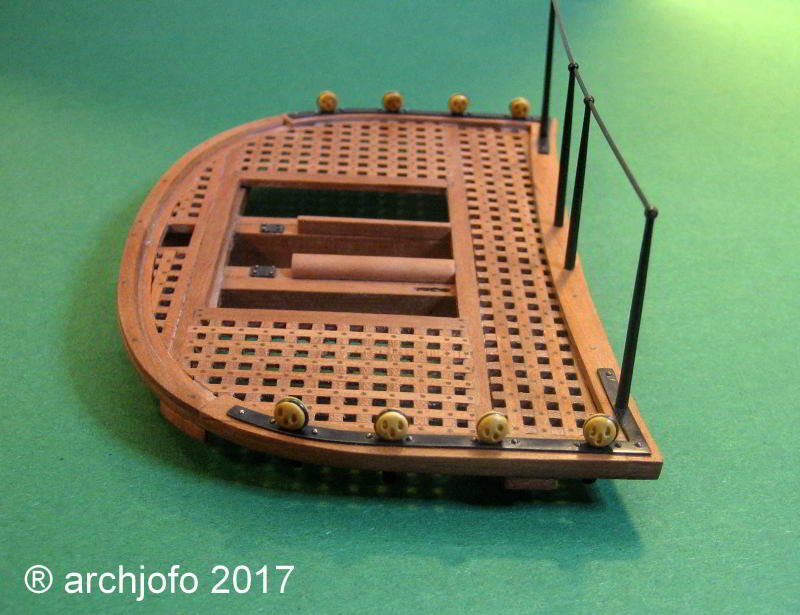

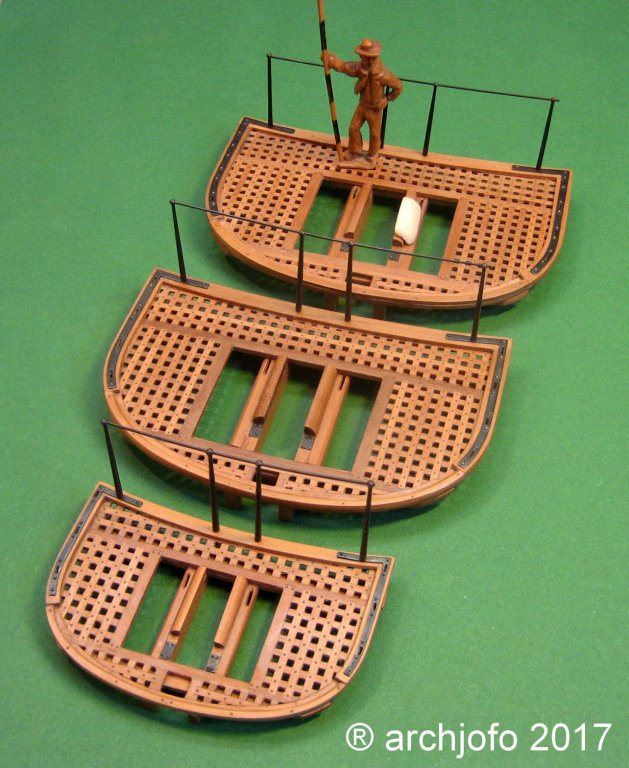

Hello Albert, Thanks, and everyone else for the LIKES. Meanwhile, I made the futtock shroud plates for the tops of the foremast and the mizzen mast. The difference between the deadeyes of the top of the foremast and that of the mainmast is barely recognizable (0.2 mm), yet it is important to me. The difference between the deadeyes of the top of the foremast and that of the mainmast is barely recognizable (0.2 mm), yet it is important to me. Furthermore, I produced the royal cross trees for the formast and the mainmast. I hope the pictures explain everything so far.

-

Hello Doris, it is amazing how exactly you work. You have developed your technique to the highest level. It is unique, I know nothing comparable. Please do not let us wait too long until the report continues.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Nils, as always an eyecatcher. Wonderful model building.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.