-

Posts

12,077 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Old Collingwood

-

Might be worth a look, or failing that I could resort to using the box the kit came in, turn it on its side and make a clear window for the front, I know that way it would be the exact size and cost nothing except something to cover the front with - clingfilm etc (isnt that stuff supposed to be able to go taught if heated with a hairdryer - or am I thinking of something else?) OC.

-

She is looking Superb mate - very fine work indeed. OC.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Its just a temporary cover I am after almost like a plastic cake cover, just a temp thing till xmas perhaps. OC.

-

Thanks for you imput lou - im trying to do it from anything I can find around the home. OC.

-

Hi all, just a quiry - does anyone have any ideas how I could cover my model to keep it dust free as I can not afford to buy a display case. OC.

-

Modern days I think they use amplifiers and it goes out all over the ship, when I lived near a naval base we could hear the commands from a few hundread yards away, mind you sound does carry over water. OC.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

I couldn't do it - not even close, I have poor enough eyesight as it is need glasses for almost everything and deffo stronger ones for bookwork.laptop building etc, then I have my magnifier under a powerful light just to do my build. OC.

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

There called Voice Pipes mate, very common in pre electronic versions. OC.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Same for me lou I view using win 7 and firefox, but sofar have not seen any of these pictures that Kp posts, I see them on the other forum he uses. OC.

-

Evening all, more work in the same area - I constructed the RDF office and brackets and glued it in place under the searchlight platform, then I was able to glue the platform to the main superstructure, then just a bit of touch up painting. So - the main superstructure is nealy there. OC.

-

Yap I will drill a few out not all of them just some random ones, I decided to paint first and drill after, saves having to re drill after painting. OC.

-

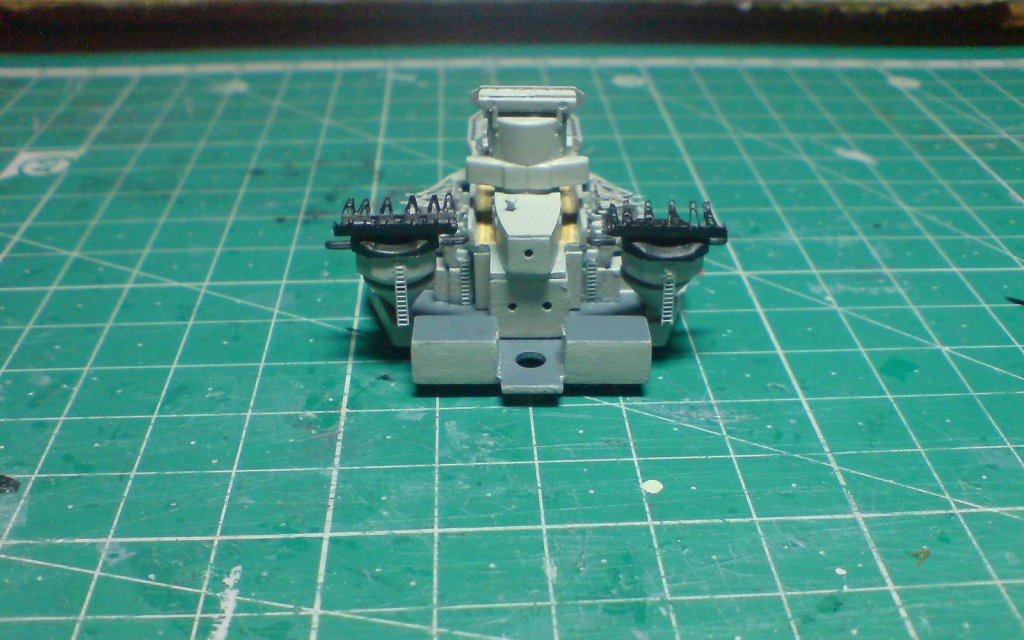

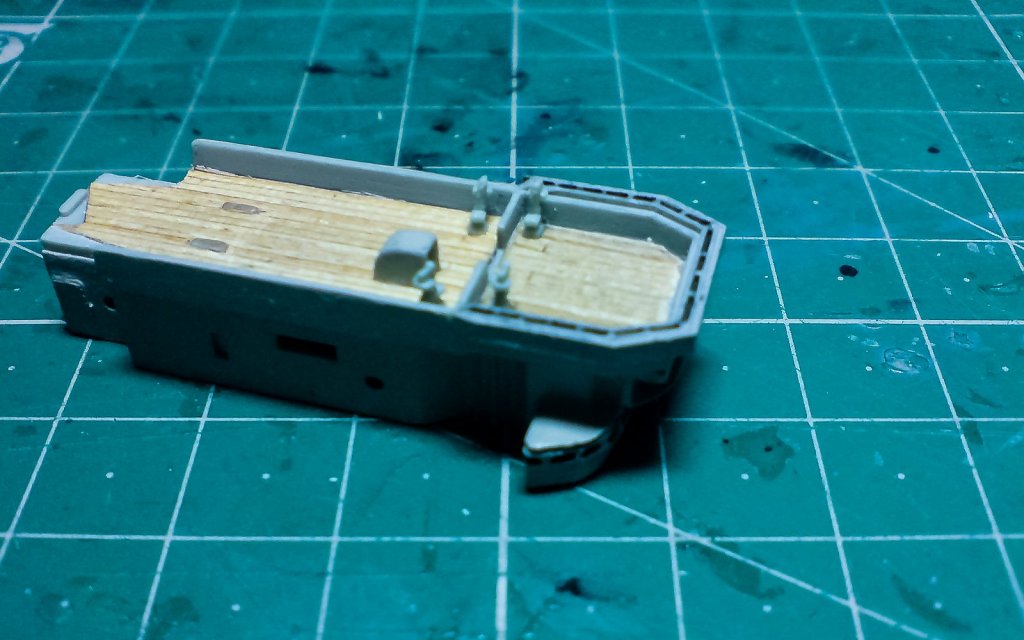

Evening all, Firstly a huge thank you to all the interest and follows. A good day today working on the main superstructure, this was assembled using five sections - once it was jigged together and set, I set about painting the two camo colors AP507B/C, I did my normal brush painting routine of doing the first normal thickness then I added several more thinned down coats at roughly 50/50 consistancy. Here are a few pics firstly showing the dry fit of the parts and the un painted superstructure, and a pic of it painted. OC.

-

I do wonder that with rigging at 1/350 wonder if we could get away without it? OC.

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

I find when working with pe or rigging its one of those - hold my breath times, and if it goes to plan its a just luck, I could do identicle parts requiring pe straight after each other - one could turn out ok and the second one could be wrong or not as good as the first, to me its the stressful part of the build (sometimes). OC.

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

Scarily good work greg - its amazing the level of skill you have is amazing - I dont think its even practice to get to this stage, its just pure skill. OC.

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

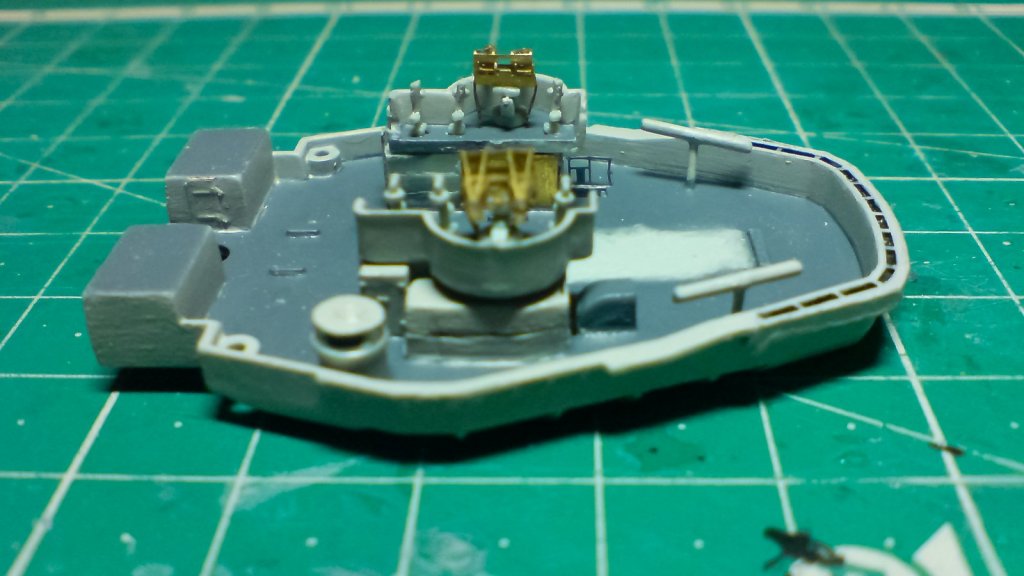

Evening all, I finished the the bridge decks today including building and attaching the two 285 radar devices including some pe pieces, next will be the main superstructure walls. OC.

-

Very tasty looking guns - she is coming on really well mate. OC.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Evening all, more work today on the bridge areas - first I constructed the main gunnery control system, I firstly fitted the two kit radar sections - then I fiited some pe in the shape of a couple of doors, ladders and two pe radar fronts I then glued it down onto the control section, next I started constucting the two PPD radar devices, these consist of the kit base part with three very delicate pe parts for the top. Then I decided to populate the bridge and ppd decks with a few binocular devices. Note to self - "need to do a bit of a tidy up to the paintwork re -dust" Just a few pics. OC.

-

Surgeon steady hands, lots of working space, good magnifiers and good tweezers or similar long nose devices. OC.

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

-

Yep saw both - was watching from the bench when greg performed his surgery with pin point accuracy, my mouth is still on the floor, when I try it - "well we all know about that". OC.

- 405 replies

-

- tamiya

- king george v

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.