-

Posts

519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Tadeusz43

-

Iron works and fittings. Iron works as anchors, chains, chain plates, plate knees, rings, bolts etc. for ships as also tools for shipbuilder was produced in forges powered with water wheels. The forge in Oliva ( part of Gdańsk), by virtue of its two large hammers called a “hammer forge”, is mentioned in written sources as early as in 1597. Two large hammers with weight 250 kg are powered by water wheel with diameter of 4 m with 44 blades and oak shaft with section of 0,7x0,7 m and length 8 m . Wheel and stove for iron heating are separated for each hammer. Separate wheel with diameter of 3,1m is powering eccentric cutters able to cut 40 cm of hot iron. Tadeusz Foto 1 Plate knees on HMS Victory Foto 2 Chain plates on HMS Victory Foto3 Cutters in old forgery in Oliva Foto 4,5 Forgery stowe with big bellows Foto 6-8 Big hammer Foto 9 Water wheel Foto 10 Anchors development

-

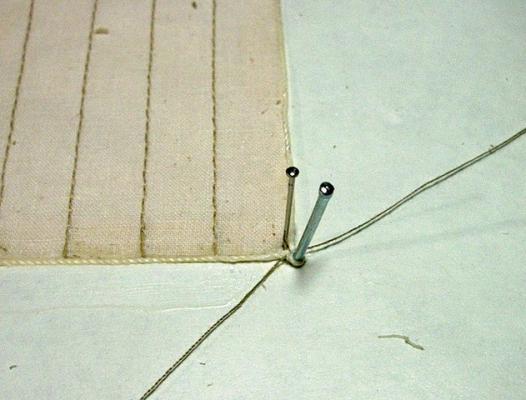

Hi, I use two types of support for planking. Foto 1 This is simplest way for support hull during planking Can be difficult to use with some kit buildings because they have integral deck as part of structure. Foto2 - 4 Revolving jig for hull planking For models scrap built is possible easily apply temporary brackets on bow and stern part of keel for attach to jig. Tadeusz ..

-

-

Hi, I think the dress sailors depend on the climate in which they sailed. Baltic is rather cold and the shoes were a necessity. When I sailed the Atlantic and Pacific Central not always wore shoes but sometimes it was necessary because the deck was too hot. Tadeusz

-

Hi, On the basis of shipwrecks found along the Polish coast of the Baltic Sea and found there remnants of personal items and clothing. The Maritime Museum in Gdansk recreates the look and dress of the seventeenth century sailors. This was possible because of Baltic sea water due to the low temperatures and low oxygen content well preserves the wood and other artifacts are also the lack of marine organisms destroying organic substances (leather, textiles). They had shoes. Was used methods applied in criminology and reconstructed on the basis of the appearance of the sailors found skulls. Tadeusz

-

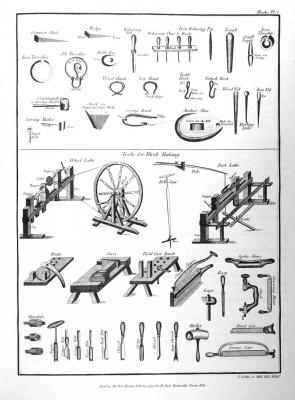

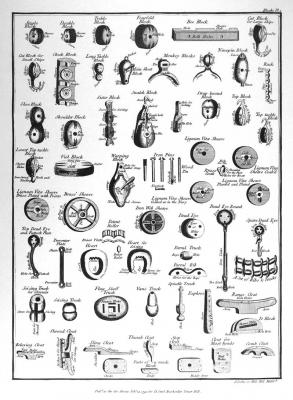

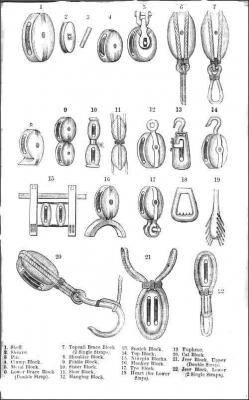

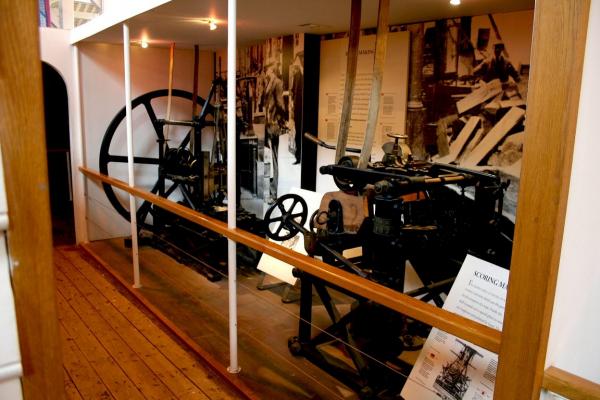

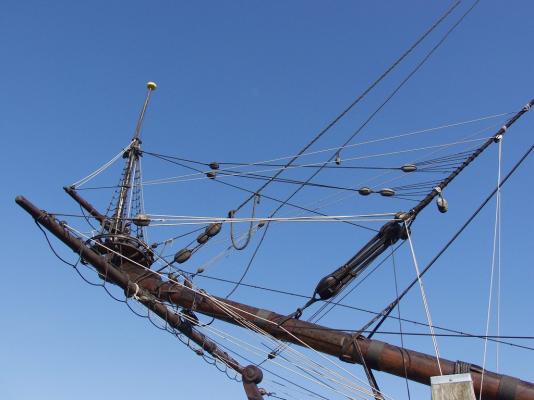

Hi, Rigging blocks. In ancient times and middle ages blocks were handmade by craftsmen using simple tools. The development of shipbuilding resulted in a significant increase in the number of blocks needed for rigging and their types variety. A typical ship of the line needed about 1000 blocks of different sizes. In 1802 Marc Isambard Brunel proposed to the Admiralty a system of making blocks using machinery he had patented and in August 1802 he was authorized by the Admiralty to proceed. There were 22 types of machines and their total number was 45. The machines were driven by two 22.4 kW (30 hp) steam engines. The machines included circular saws, pin turning machines and morticing machines. With these machines 10 men could produce as many blocks as 110 skilled craftsmen. Production finally stopping in the 1960s. Foto 1-3 Blocks from Ancients wrecks and block making craftsman. Maritime Museum in Gdańsk. Foto 4 Block making craftsman. Maritime Museum in Karlskrona. Foto 5 Blocks from Mary Rose . Historic Dockyards Portsmouth. Foto 6,7 Blocks on replicas of medieval ships. Drwg. 8-10 Period ship blocks and tools for block making. Foto 11 Block making . Maritime Museum in Karlskrona. Foto 12,13 Brunel's factory and machines. Historic Dockyards Portsmouth. Foto 14 - 20 Blocks on Batavia replica in Lelystadt . Tadeusz

-

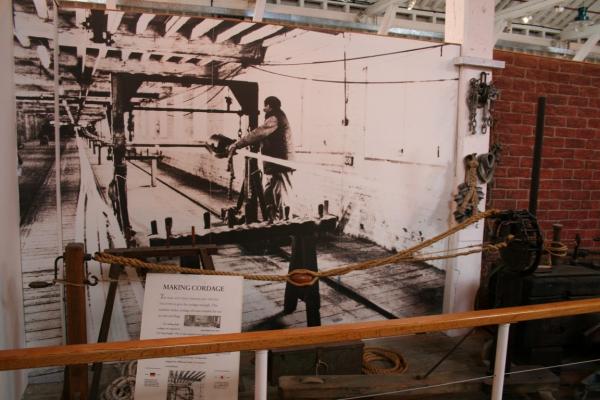

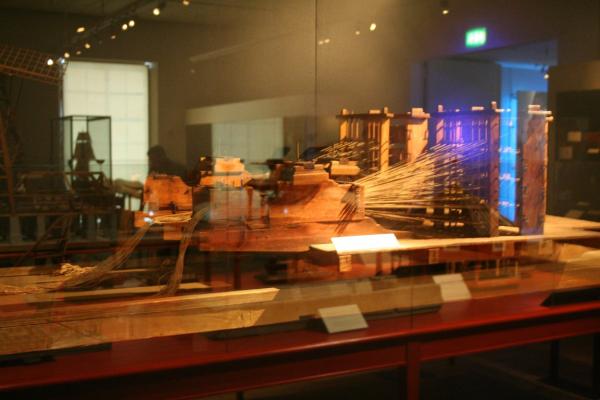

Hi, A very important piece of equipment of ships were ropes. A large sailing ship rigging require approx. 16 km ropes of different diameters. Ropes produced mainly from hemp fibers using ropewalk. Foto 1,2 Ropes in HMS Victory hold Foto 3,4 The Ropewalk in Karlskrona dating from 1692, the rope factory terminated production in 1960. With a length of some 300 metres (980 ft), the Ropewalk is Sweden's longest wooden building. Foto 5-7 Rigging worshop in Maritime Museum in Karlskrona Foto 8 Rope making tools in Maritime Museum in Gdańsk Foto 9 Rope making tools in Historic Dockyards in Portsmouth (UK) Foto 10 Big ropewalk model in Maritime Museum in Karlskrona Foto 11-15 Rope making tools in Maritime Museum in Gdańsk. Hemp fiber was cleaned by combing with iron hedgehog. Then it were twisted in to the cords using reels. Finaly on ropewalk cords was twisted in to the ropes. Foto 16 Rigging worshop in Batavia Shipyard in Leystadt Tadeusz

-

Hi, When began to build more and larger ships to set masts cranes were needed, that were also helpful in loading heavy items of equipment such as guns or ship cargo. Some of them have survived to our times. Foto 1-6 Old Crane in Gdańsk was built between 1442-1444. Served mainly as a device port for loading goods and ballast on ships, and to put up their masts. The device was able to lift the weight of four tons, for the height of eleven meters. The mechanism of two drums having a diameter of about six meters. Used as a driving force of people with their feet on the inside of the drum. Foto 7 Masting Crane in Copenhagen was built in 1748–51 as part of Royal Naval Shipyard at Holmen. Foto 8-9 Old crane in Karlskrona ( Sweden) was built in 1803 in brick with a roof covered with sheet copper roof, the building consists of six floors and is 42 meters high. At the heaviest lift is required 96 man to drive once at the capstans.. The machines are still fully intact. Foto 10 Old crane in Stockholm . Styckekranen crane is a unique construction works in wood, from the mid-1700s . A lifting and swiveling crane, used by, among others loading and unloading of pieces ie guns to the Navy. The drive mechanism consists of two paddle wheels (treadmill) where boatmen or punished walked in the wheels during shifts. A third wheel is available in the crane upper part which forms the swivel mechanism in order to get over the cargo to and from vessels. It required frequent high accuracy at work to fit into the cannon into place in the vessel with respect to the vessel also were often in motion during the task. In each paddle wheel could be up to ten hike, a total of twenty men. Foto 11 model of early floating crane i Maritime Museum in Karlskrona. Foto 12 mast lifting in Gdańsk. Tadeusz

-

Tapering masts, spars and yards

Tadeusz43 replied to bryanc's topic in Modeling tools and Workshop Equipment

-

Your best sail cloth and technique

Tadeusz43 replied to steven sturgis's topic in Masting, rigging and sails

Hi, The adhesive is not diluted, unwanted stains of adhesive on sails can be easily removed by scraping. Tadeusz -

Your best sail cloth and technique

Tadeusz43 replied to steven sturgis's topic in Masting, rigging and sails

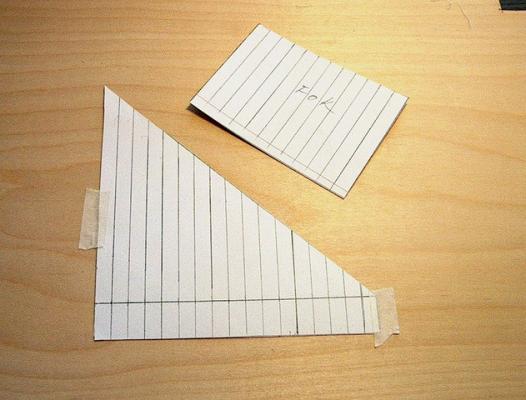

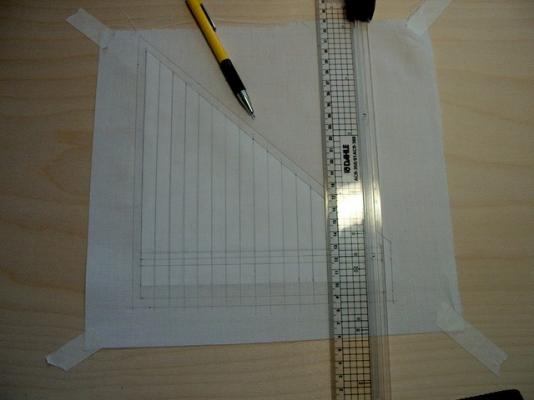

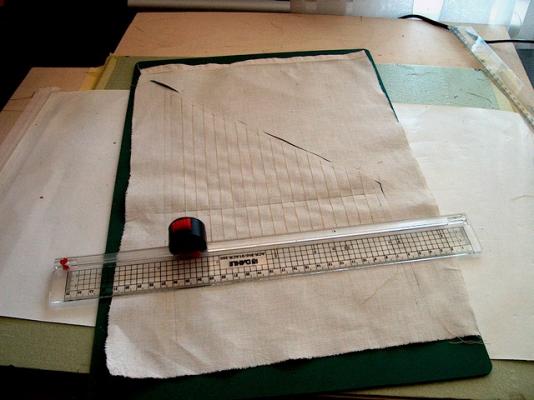

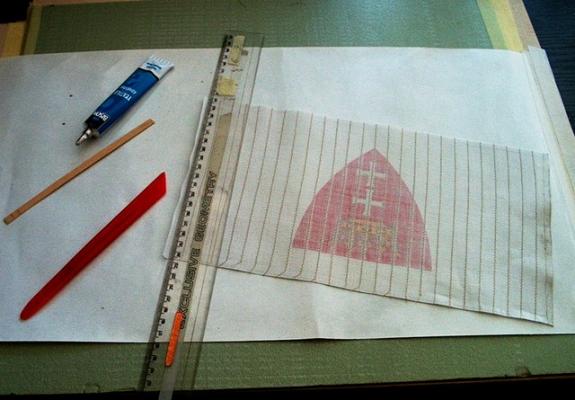

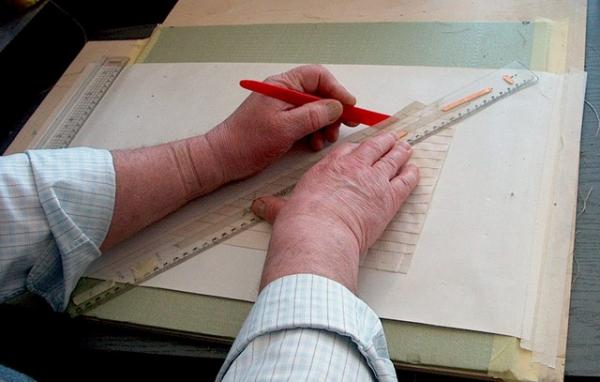

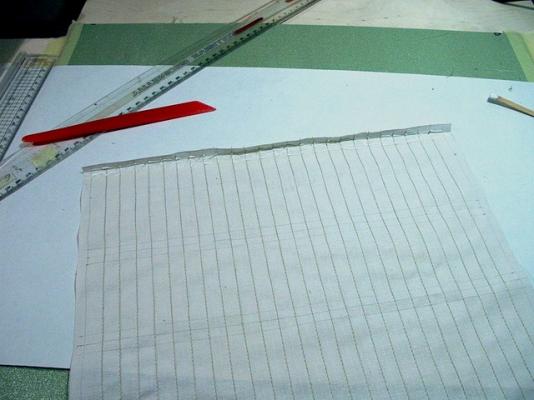

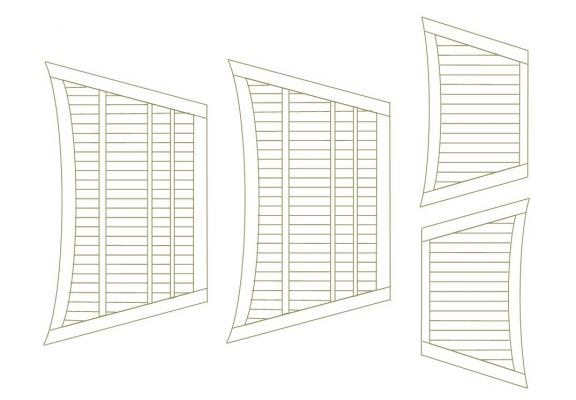

Hi, I make sails for models in scale 1:75 with seams of the cloths sewing marked with single thread ( courtesy of Admiral ). For models in scale 1:100 I use computer printing of cloths lines and reef bands on thermal transferring paper for ironing on to sails fabric . Sails leech, head and foot ropes are fixed in its place with use of textile adhesive . Material for sails I prefer is old bed linen many, many times washed. Work step by step 1.Make paper stencil for each sail and check it’s dimensions on your model. 2.With soft pencil transfer all lines in to fabric – add stripe 5-7 mm around sail edges. 3.Make all necessary lines on fabric using sewing machine and thin thread with light brown or beige color. For sails with thermal transferring of line any sewing is not necessary. Cut of sail shape. 4. Fold the edges stripe to reverse side of sail and apply textile adhesive 5. Put sail on flat surface protected against glue adhesion ( wax paper ) and fix it with pins and nails for forming clews. Using textile adhesive attach thread around sail and form clews and cringles as necessary. After adhesive excess removal from sail surface and final ironing your sail is ready. Foto 1-10 Sail making Step by Step Foto 11 HMS Speedy - printed sails Foto 12 HMS Warrior - printed sails Foto 13 Patern for printing sails for S/S Savannah Tadeusz -

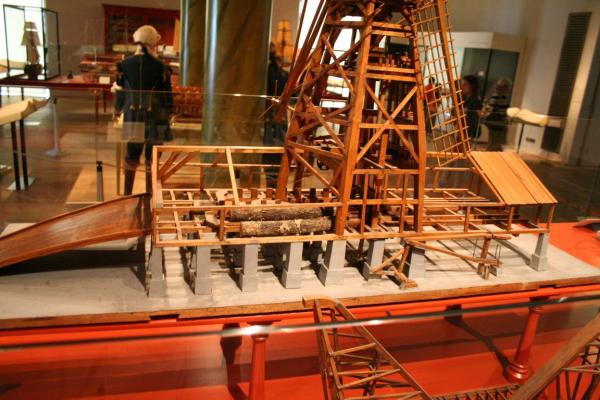

Hi, The wood used in the construction of ships in Europe, it was mainly oak. For the construction of HMS Victory used more than 6000 trees. In ancient times, the tree trunks were cleaved to the corresponding planks then began to use handsaws a technological breakthrough was the use of sawmill powered by a water wheel or windmills. Naturally curved tree trunks was used for ship construction elements. Sometimes, even the deformed growing tree to obtain in the future desired shape (something like bonsai) Strips on the hull were bent over the open fire. Foto 1-4 Vasa shipyard (Vasa Museum in Stockholm) Foto 5 Sawmill with wind power (Maritime museum in Karlskrona , Sweden) Foto 6-10 Viking boats shipyard ( Roskilde, Denmark) Foto 11 Batavia - sample of knee shaped bu nature Foto 12-14 Nature shaped elements of shps (Maritime Museum in Gdańsk) Foto 15-16 Shipbuilding forest on Baltic coast in Poland Foto 17-18 Shipwright's tools Tadeusz

-

Hi, Some of these shipyards have survived and are still working. Foto 1,2 Arsenale in Venice Italy - still on duty Foto 3-5 Darsenas i Barcelone - now Martime Museum Foto 6-7 Karlskrona Sweden Foto 8-9 Historic Dockyards in Portsmouth UK

-

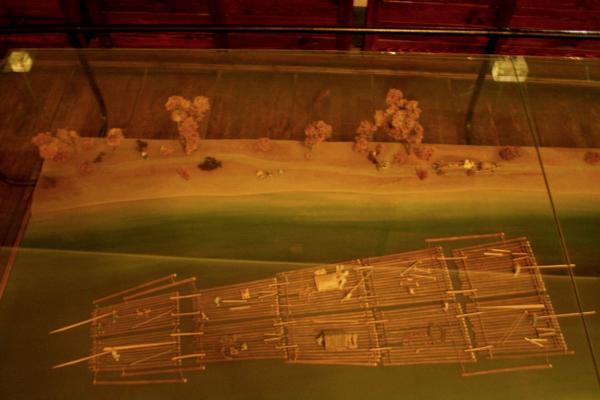

Hi, When a project of new ship has been approved by Admiralty and King could be start the construction. If it was not shipyard just meadow on the banks of the river was suitable for collect logs of wood and start building the ship. Logs were often supplied by water in the form of rafts. Over time, next to the construction site grew the colony of workers and eventually arose real shipyard, which could build larger and more technologically advanced ships. Foto 1-9 Martime Museum in Gdańsk Foto 10 Historic Dockyards in Portsmouth UK Foto 11-14 Batavia Shipyard in Leystadt, Netherlands ( construction of De Zeven Provinzen replica) Tadeusz

-

-

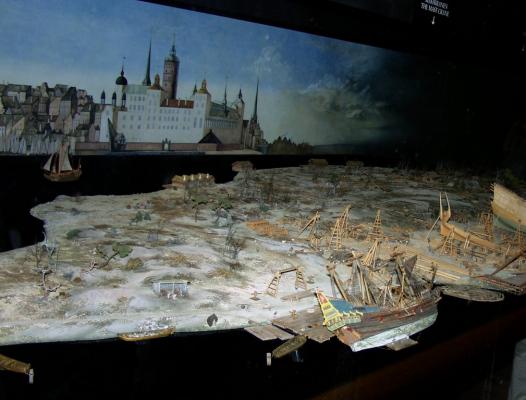

Hi, This time, something has gone wrong Often accident occurred when the experience failed as it was in the case of the sinking of the warship Vasa and the Mary Rose and Kronan. http://faculty.up.edu/lulay/failure/vasacasestudy.pdf http://self.gutenberg.org/article/WHEBN0002187141/Kronan%20%28ship%29 http://www.maryrose.org/discover-our-collection/story-of-the-ship/why-did-the-mary-rose-sink/ Kronan sinking Vasa sinking Mary Rose sinking Tadeusz

-

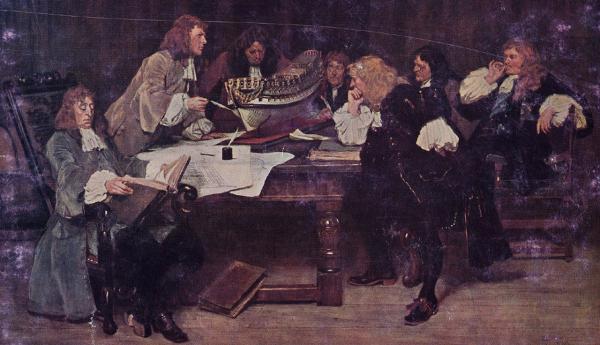

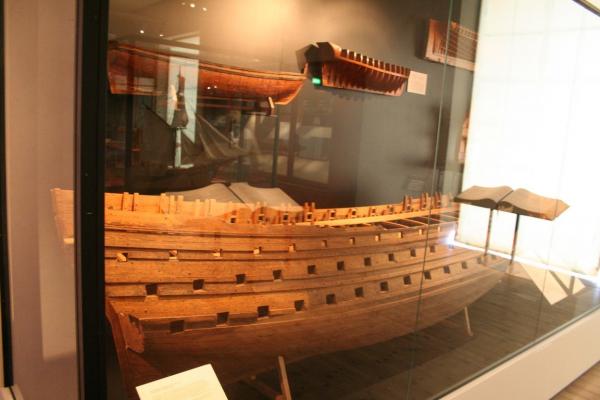

Hi, Art of shipbuilding. Due to the lack of scientific methods of calculation and design of ships ship building in the old days was a kind of art and everything depended on the experience of employee master of shipbuilding. Gathered here from my archive of photos from various museums showing how ships were built centuries ago. A few photos from the net is because old shipyards are still in the Navy possession or a ban on photographing in some museums. Project. Construction of a new ship ordered by the King was preceded by a performance of the model to the Admiralty can assess whether the project meets its requirements. Many of such models have survived to our time, they show the details of construction of the hull, we call it The Admiralty Models. Because in those days there were no scientific method stability calculations all based on the experience of masters of shipbuilding. Admiralty models Assembly of Admiralty Tadeusz

-

Hi, On period ships howse holes were round as the anchor cable was pulled to the lower deck through a hole in the hull. On contemporary ships anchor cable is pulled to the upper deck through howse pipe and howse shape depends on the angle of penetration round howse pipe through the shell plating. Hawse holes on : Jylland Danish frigate Sthandard HMS Victory HMS Warrior Tadeusz

-

Question on how to curve metal figures?

Tadeusz43 replied to tbrix's topic in Metal Work, Soldering and Metal Fittings

Hi, This is a delicate matter the material is probably zinc alloy which can be brittle. I advise you to perform silicone mold of figures before bending. If bending fails, you can make a new resin cast as substitute.. Tadeusz -

Hi, Being impressed by the scope of the study and craftsmanship ffotek include a few of my archive. Lisa von Lubeck in Gdańsk. Tadeusz

-

Hi, A few photos from my archive concerning anchors, catheads and davits . I think that they are self explanatory. Foto 1,2 Jylland Danish frigate Foto 3-7 HMS Victory Foto 8 HMS Warrior Tadeusz

-

Blackening brass problem

Tadeusz43 replied to Maury S's topic in Metal Work, Soldering and Metal Fittings

Hi, Try again with new Blacken-It . This you have lost of power. Most of the chemicals is limited shelf life. Tadeusz

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.