Diver

Members-

Posts

402 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Diver

-

Welcome to MSW from a fellow Ontarion. (Kingston)

-

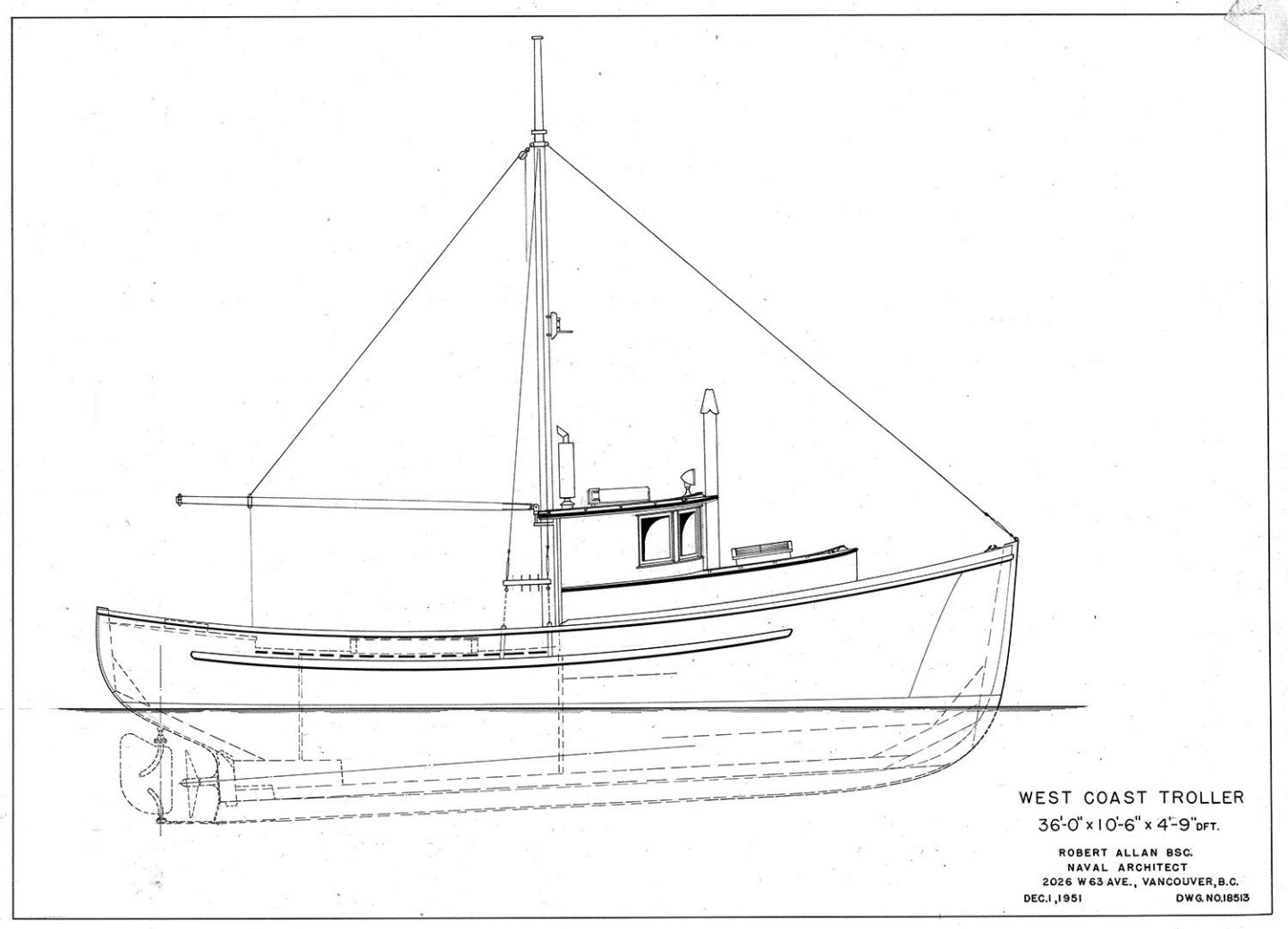

I to like these small working vessels. I hope some day to have the ability to scratch build a model of one of these West coast Trollers. They were the mainstay of the inshore salmon fishery. They fished with hook and line like a sports fisherman, except they had many lines

- 16 replies

-

- Sophia Rose

- Block Island cowhorn

-

(and 1 more)

Tagged with:

-

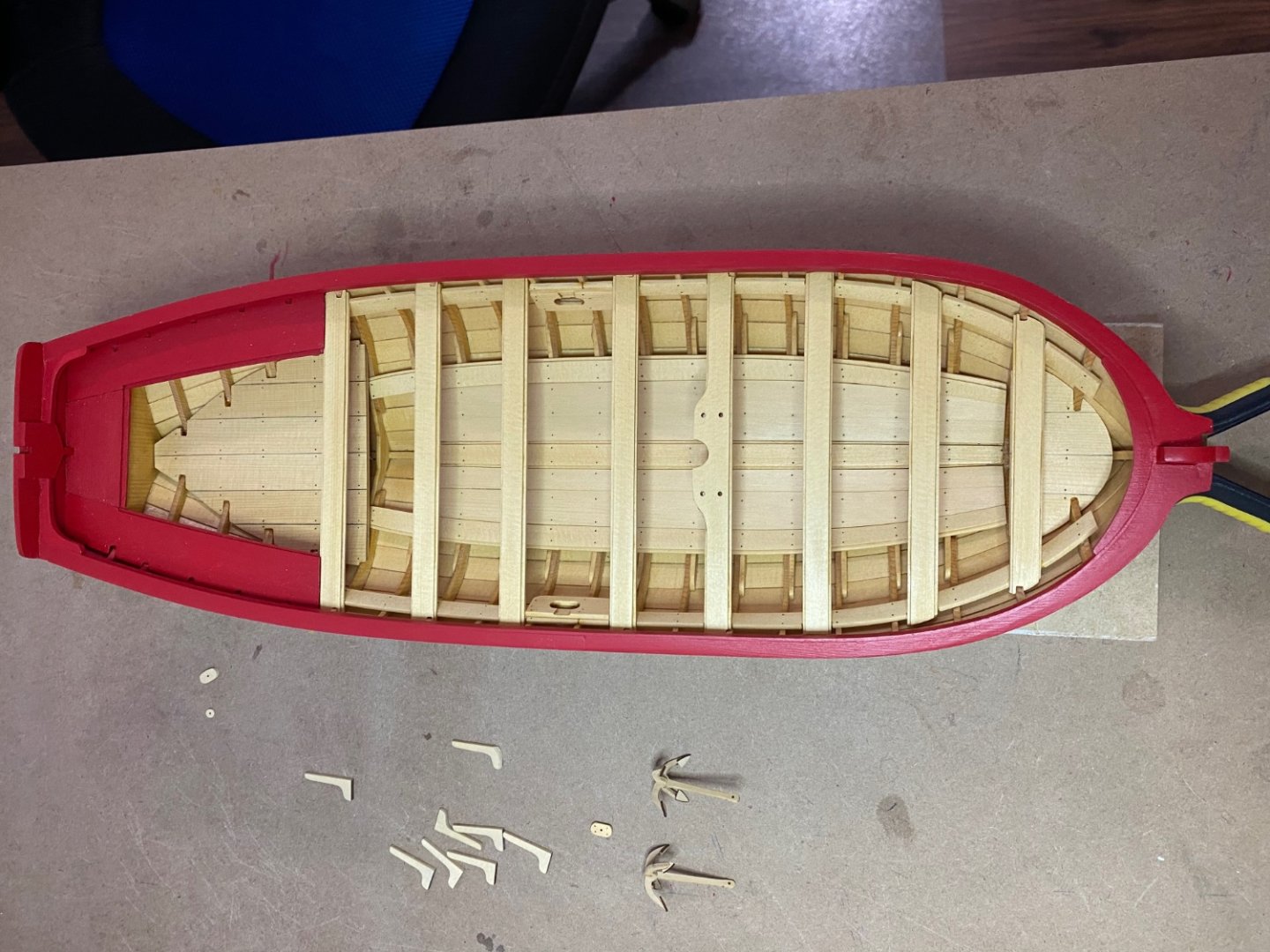

We have finished our move to what we hope is our final home. I have set up my work space in the spare bedroom an have got back into the build. The capstan and mast thwarts are not glued in yet. I am going to make the mast first, and can use the thwart as a reference for the diameter.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Good point

-

Thanks everyone for your input. I like Bob Cleeks idea of installing a disc on the Table saw and turning it into a disc sander,two tools in one.

-

Good evening folks. What would you find most beneficial in your workshop and why. A Byrens Disc Sander or Byrens Table saw. My limited budget will only allow one at this time. I do not think I will ever scratch build.

-

Welcome to the site Joe. I am a novice builder working on my fist ever build. The support and guidance I have received on this site excellent. I would have struggled without this site.

-

Welcome to the site from a fellow Canadian. Enjoy and use this site

-

Good evening James. What skill level will be given to this kit once it becomes available? When my Syren Medway long boat is finished in the near future I have decided I will do a Vanguard build next. I was leaning towards Lady Eleanor or Zulu, how will this kit compare in difficulty? Thanks. Bob

- 80 replies

-

- Grecian

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Now I am confused. In the header for the Medway group project it says 1/48.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Sorry Chuck. Just proves again I can not read. LOL

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

the scale of my Medway is 1/48. The kit was purchased from Syren Ship models, designed and manufactured by Chuck Pessaro. A challenging but rewarding plank on frame build.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Welcome to MSW from the north, (Oh Canada). Enjoy the site, there is nothing but help and support here.

-

Welcome aboard Stephan. Nice to see some fellow Ontarians here.

-

Just started to follow your build. My Medway is nearing completion and I want to do a Vanguard build next, probably the Lady Eleanor. If that works out, HMS Alert will be next in line. Just contemplating purchasing the Serving machine so that I can start the rigging of the Medway. Have a good day. Bob

-

Thanks Chuck. I am really enjoying this build and learning a lot. It has been a challenge, but a rewarding one.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The rear cockpit is complete and glued in place. The thwarts are all glued in except the one fore the mast. The grapples and sheave for the stem are complete. I started on the knees and realized the front thwart was not installed correctly. It was removed and reinstalled. I am apprehensive on starting the capstain, do not want to mess it up. I ordered some v blocks to hold it when I start to shape it.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I am following your build with great interest. I am building the Medway longboat by Syren, my first ever build. When complete I would like to attempt one of Chris Wattons kits, Lady Eleanor and after that the Fife. I just love the looks of this vessel. Like you, if I build the Fife I would like it to look like a well worked boat.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.