-

Posts

1,790 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ulises Victoria

-

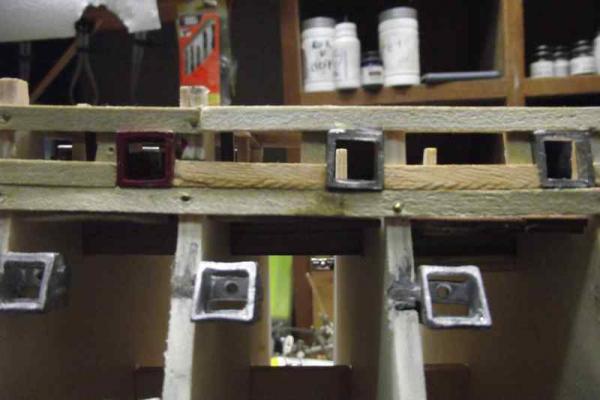

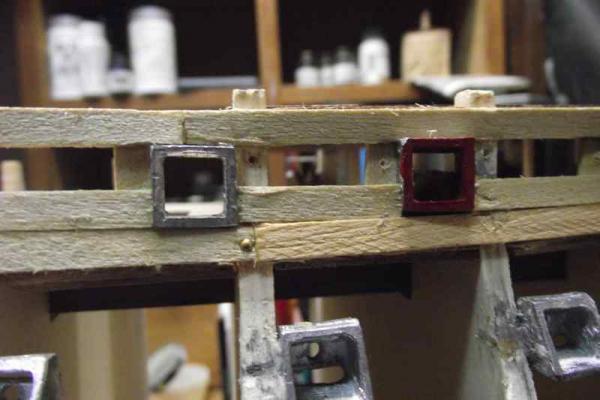

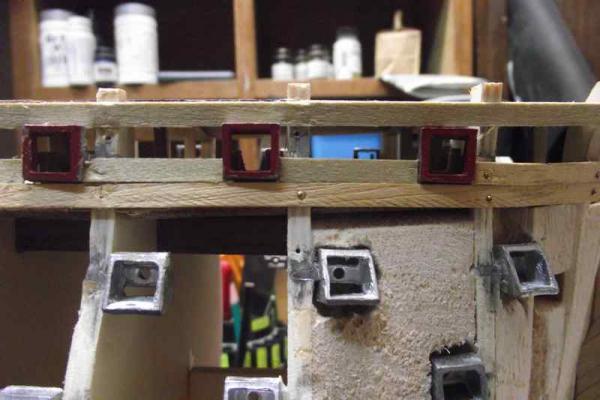

OK Some photos of the fix suggested by Sjors and Nigel above. Thank you guys!!! You can see some of the small vertical planks I added as suggested. (This wood splinters so bad.) Also, here is a photo of a plank I just place momentarily there for the purpose of showing the other problem I mentioned before: the gap that is going to be between the top and the next plank. I'm thinking to fill with with planks put sideways.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

I definitely see this one as my next project. Good thing is, I already have it, and I got it really cheap.

- 71 replies

-

- panart

- san felipe

-

(and 1 more)

Tagged with:

-

Thanks Sjors. I just placed the vertical supports behind the planks I already have. Photos to follow pro'lly tomorrow. Thanks David. My problem will be to fill the gap that certainly will be between the top and next plank. I'll post some photos later. Thank you Mark. I think I will have more trouble with your approach. It may be more work, but I think that filing the metal frames after the first planking is laid, will allow me for a smoother finish. I sincerely thank all and every response. Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Nigel. Indeed. What you say about the vertical planks is something mentioned in the instructions. I did not do it because I felt the frames were epoxied and very firmly placed that I though there was no need to reinforce them, BUT... you are quite right regarding the support for the in-between planks. I may not be too late to start doing that. Thanks for your comment.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Sjors: I just don't understand the instructions, so I'm working just following my gut. I had to tear apart a few planks of my first attempt. In my second try, I placed the plank that goes over the frames (painted red), then the one that goes under, and then 6 frames that go in-between those, which you can see in the second photo and are unpainted. Then I started cutting pieces of wood to the precise length to fit between frames. A snug fit to make the frames more stable, and glued side to side of the bottom plank . The metal frames will have to be sanded/filed down later to make them flush with the first planking. The problem I am seeing now is that the vertical distance between the top and bottom planks is not exactly the width of 2 of the planks, so a gap is going to happen between the upper plank and the next. I foresee a lot of wood filler to be used here. (sigh) I hope this makes sense!!! Thanks for your comment.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Update Sept 12 2014 On Tuesday 9th started with the first planking. You will see not much progress in 4 days, but this has been a real challenge for me. I definitely don't like this system of the metallic gun port frames. It makes things harder instead of easier, *in my opinion*. You are forced to plank the hull in segments between frames, and it's harder to do an even planking job. I prefer the method of "cut your own". Anyway, I thought before starting that this was going to be a nice challenge, and I wasn't wrong. However, if I manage to do it right, the sense of accomplishment will be equally big. I keep telling myself that first planking is some sort of "training field", so things are easily patched and fixed. Thanks for visiting.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

latino nail nailer

Ulises Victoria replied to djs's topic in Building, Framing, Planking and plating a ships hull and deck

Hello. If it's like the one I'm using, it accepts a wide variety of nails. The inner rod, the part that pushes the nail is magnetic, so that you can insert a nail and drive it vertically without it falling out of the tool. Obviously, nails made of non ferrous materials will not be attracted to the magnet. Hope this helps -

What??? I cleaned it before taking the photos!!!!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Update Sept. 7. Finished planking the keel of my Royal Louis. I will start first hull planking next.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Mark. Here are some closer photos. Also, comparing the piece of wood with the sheet of paper included in the kit with different colors, the wood looks close to what they call "Beach wood" which I think they mean beech wood. Unfortunately my photographic skills are not top notch and the color in the photos may not be very accurate. I'm still confused. Thanks all for your input.

-

Why are ships of the same size and configuration rigged different? If two ships have 3 masts with 3 yards on each, why they are rigged different? Let's say I want to use Victory rigging plans to rig my Royal Louis, just because I like Vic's rigging better: Is it possible? What problems could I encounter? How many people could tell? Would that be a Capital Sin? Is this a dumb question?

-

Hello Testazyk. I will be following this build really close. I have this kit in my stash and will most likely be my next project, as I love this ship. Still a long way to go, though, as I am in the beginning stages of the Mamoli Royal Louis. Please keep adding photos and advice to your log. Best of lucks. Ulises

- 71 replies

-

- panart

- san felipe

-

(and 1 more)

Tagged with:

-

I will really appreciate someone tell me what wood this is. It is used in my Mamoli Royal Louis to second plank the hull in the area below the main whales. Previous builders of this kit may have a clue??? Information in the kit is very confusing. In some places it says it is walnut and another some strange names. I'm sure walnut it is not! If not certain, at least tell me please a close match. I am a bit worried that the material included in my kit will not be enough to finish the intended plank job, as some other people has said already. So I want to buy if not exactly, at least a batch of a close match. I'm sure a few planks scattered in a different shade will not look bad. It may be the opposite. Thanks in advance for any input . Ulises

-

The "balls" usually have a hole on them, so you have to file the upper part of the mast to a diameter such that it would insert into the ball hole. A drop of glue is all that's needed, and there is only one "ball" per mast at the very top. Not sure if the parts in the last photo are the 116 parts in your diagram, but in my opinion, not likely. 116 parts are more like... well... balls. Hope this helps

-

The "balls" usually have a hole on them, so you have to file the upper part of the mast to a diameter such that it would insert into the ball hole. A drop of glue is all that's needed, and there is only one "ball" per mast at the very top. Not sure if the parts in the last photo are the 116 parts in your diagram, but in my opinion, not likely. 116 parts are more like... well... balls. Hope this helps

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.