-

Posts

1,311 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TBlack

-

Nice work and gives me an idea. but I thought they are turnbuckles on this side of the pond and bottle screws in the old country. Did I get that wrong? Tom

-

Bob, Wonderful set of photos, and you obviously know the Bar Harbor 31. But my hull doesn't really fit the Herreshoff design. I had originally thought the boat would make a nice example of a New York 40, and I could have made the deck and rigging to match, but then the heavy hull didn't fit the rest of it. With the full keel I'm thinking the hull fits a Grand Banks fishing schooner. Unfortunately, the owner wants a gaff rigged sloop. Tom

-

It depends on the wood used to fabricate the blocks. Basswood won't do. But any hardwood should be ok. Using a pin vise and a #78 drill should work all right. I'm guessing on the drill size, but #75-80 should do it for your needs at 1:64. Tom

-

Thanks, Keith A. I can't help myself. If I'm going to work on something it has to be as good as I can give. BTW, you have been my mentor in many ways over the years. If my efforts pass your inspection, I'm good to go! Tom PS. See this guy, my grandson, next to me? He just had his 11th birthday today 4/19. I need to change my photo.

-

Keith, No, just that he bought it in Kennebunkport years ago. And just to be clear, yes, I’m making this boat better than it deserves. In return I get to try out techniques without worrying that it will harm Uncle Jon’s enjoyment. For example, I’ve cut two gears, using my rotary table for the first time, and cut two bushings for the anchor winch moderately successfully. And, you haven’t seen it yet, there is a bracket to hold the boom to the mast which is in 7 parts all needing soldering. So, I’m gaining confidence that one day I will be at your level of accomplishment. Tom PS If you’d like to take over as prime contact for our uncle, I can give you his email.

-

Glue question

TBlack replied to Peanut6's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Kev, I, too, use the titebond, but the yellow stuff. It's more water resistant. I find that 20 minutes is a good wait time. And while you're waiting, can't you be preparing the second plank or work on some other part of the model? Tom -

Don, What's the diameter of the rod? And the scale? I'm assuming you have a lathe, and that you've incorporated the various rings, etc. in the profile? Tom

-

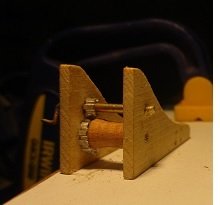

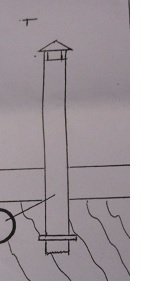

Next comes the building of the stovepipe. Supposed to look like this: First step: buy a brass screw: Second step, cut down the top: Third step, cut off the threads: Fourth step, drill out the center: F Fifth step, create vents: sixth step, make a pattern for the top seventh step, fold and solder: eighth step, attach to pipe: Finally, paint flat black, and install.

-

INVITATION TO A LIVE-STREAM EVENT

TBlack replied to kurtvd19's topic in NAUTICAL RESEARCH GUILD - News & Information

Sounds interesting. Thanks, Kurt, for getting us included. Tom -

Michael, Do you remember the model of the Vinal Haven that you helped me build? The hull plan came from the Mystic Museum and also had a “do not reproduce” stamp on it. I called the museum to ask for permission to copy for my own purposes, and it was readily given. Interestingly, the copy shop paid no attention to the stamp! Tom

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.