-

Posts

1,315 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TBlack

-

Help with depicting extra line on bitts

TBlack replied to usedtosail's topic in Masting, rigging and sails

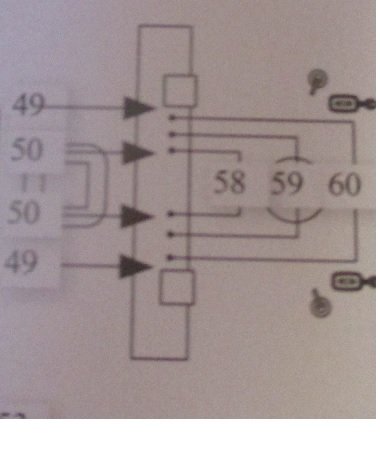

Gregory, They are bowlines, sheets and clews. Here is the plan view: Given this information, maybe Lester's solution is the best one -

Help with depicting extra line on bitts

TBlack replied to usedtosail's topic in Masting, rigging and sails

Tom, So far there doesn’t seem to be an answer to the issue. I’m facing the same problem with my Sophie build which is an alteration of Speedy. Hope someone comes up with an answer. Tom -

Now I've served and rigged the lower main shrouds which will be all the progress for a while, as we are away for a week:

- 347 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Isn’t it water soluble? At the very least you should be able to sand it off.

- 496 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

I've tried, desperately, to include pictures of my progress. Not going to happen! Nevertheless, you'll have to take my word for it that I've installed the Jeer block/tye assembly, the truss pendants, futtock staves, catharpins, and finally the fore stays.. I've got a picture or two; they're just not very good, for what it's worth, here they are. Anyway, I'm on to installing the shrouds for the main mast.

- 347 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Greetings from a clueless Patrick O'Brian fan

TBlack replied to Galkar's topic in New member Introductions

Galkar, Your interest in the HM Sophie hits a soft spot for me. I, too, am a fan of the O'Brian books, and, as it turns out, my youngest daughter is Sophie. So there was nothing for it but to build a model of the HM Sophie. As you have discerned, a good starting point is with the Speedy from Chris Watton (I have a very early version; you should benefit from the up-dates). Check out my log (HMS Sophie). The interesting part is the back end that has to be bulked up to accommodate a quarter deck and captains cabin. Otherwise, the build is pretty straightforward according to the kit instructions. Tom -

Something to do with where the boiler has to be?

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

,I should have mentioned that, too. Good eye/hand coordination!

- 496 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Good idea on the sub decking. Your idea of heating the glue is new to me. Good luck. Tom

- 496 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Gary, I’m late to the party, and I’m reading that you are dealing with stiffness in the shrouds. Some folks put a little water on them to make them more pliable. Tom

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

I've done the lower fore shrouds. I thought serving them was going to be a challenge inasmuch as the serving thread was so small. But, no, with Chuck's little machine it turns out to be quite simple. That part was easy. Everything else, as always, I seem to have to do 2-3 times to get it right. In setting the upper deadeyes, I used the usual spacer. And that works OK, but Druxey has a different approach that he outlines in his TFFM vol. 4 and his Speedwell book vol. 2 that I think I'll try for the main shrouds. The benefit I'm looking for is a neater appearance of the seizing around the shroud above the deadeyes which can be done off the model. I think before I do that I'll rig the truss pendant on the fore yard, using Toni Levine's excellent tutorial.

- 347 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.