-

Posts

4,550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Blue Ensign

-

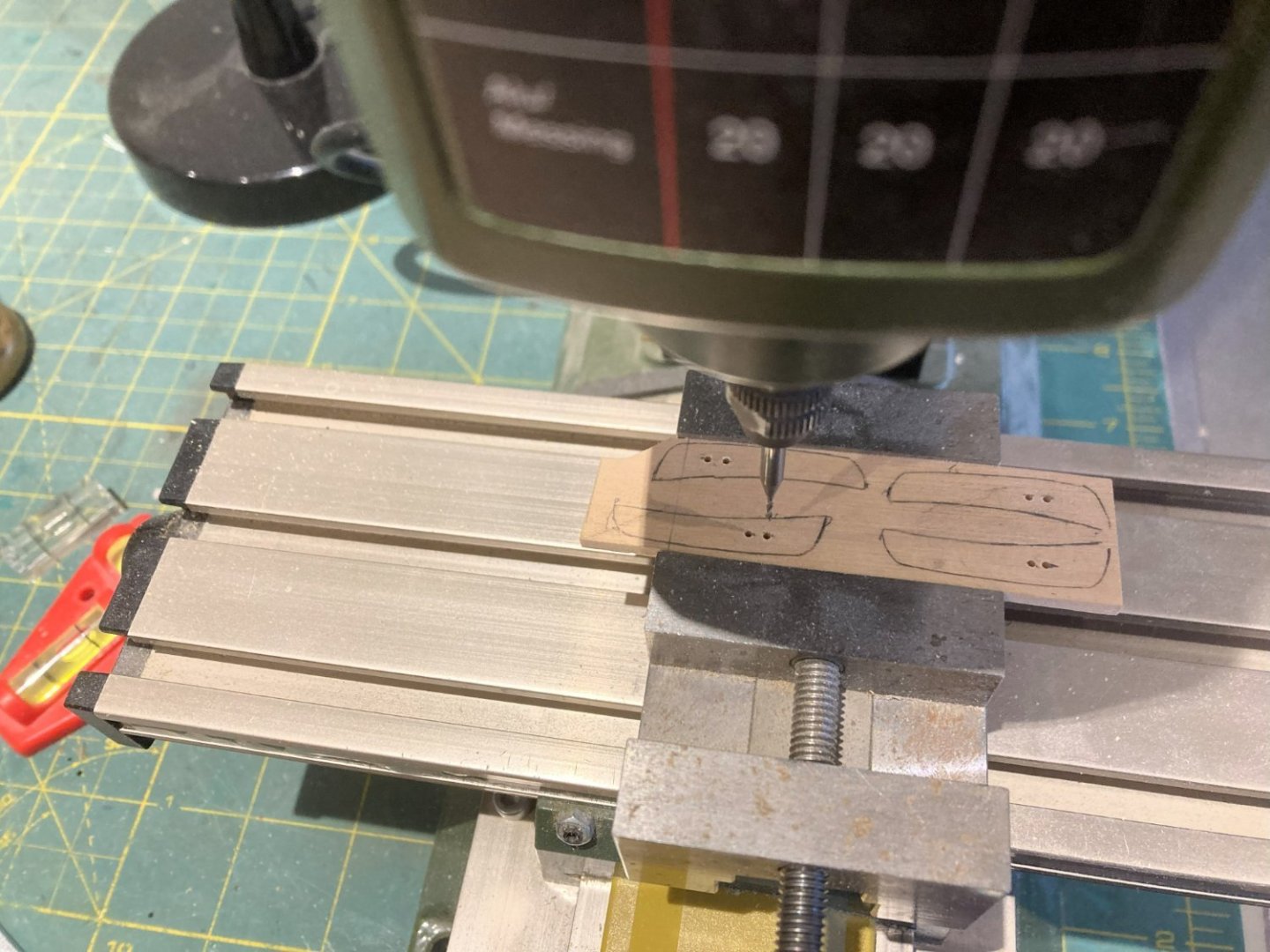

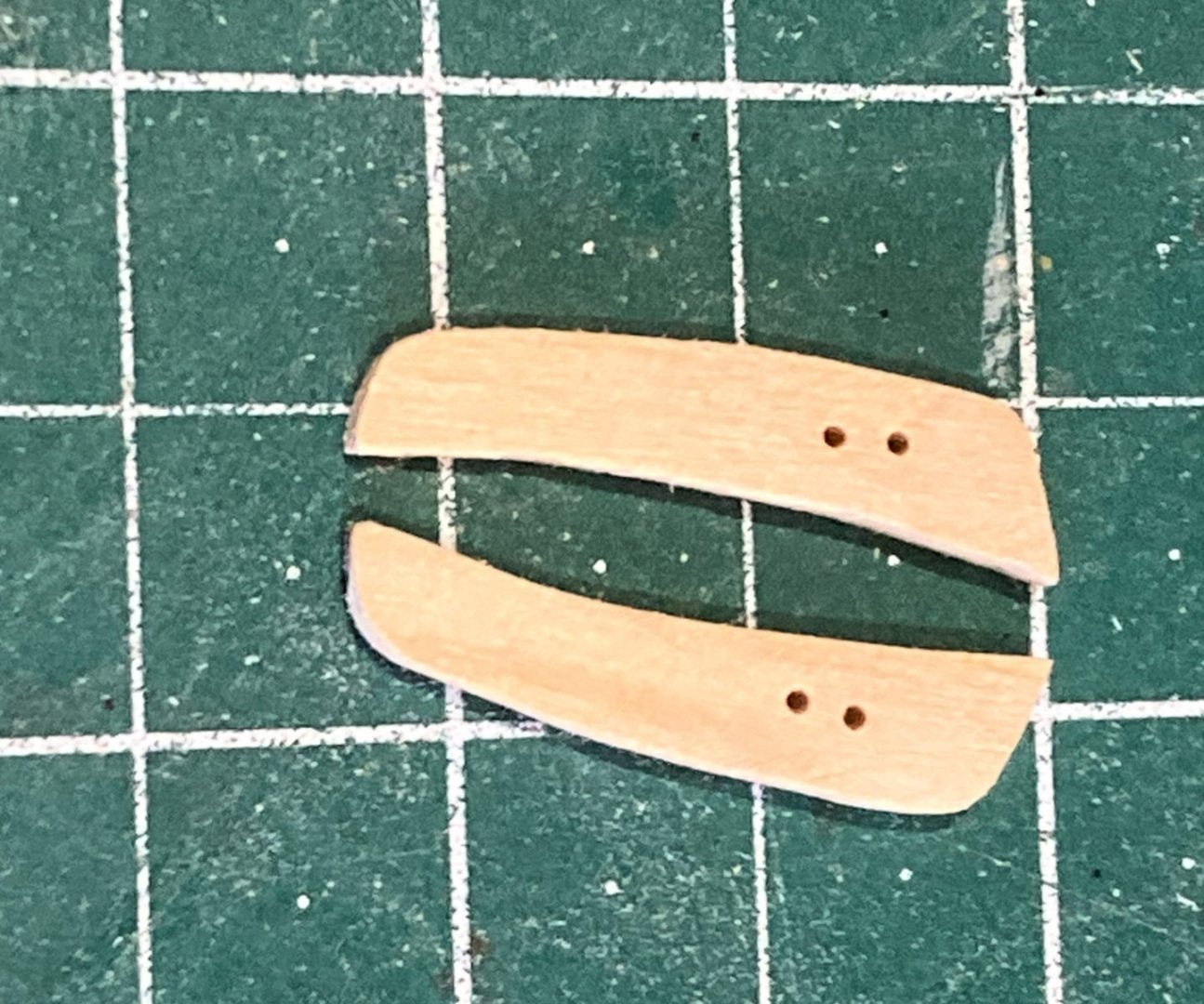

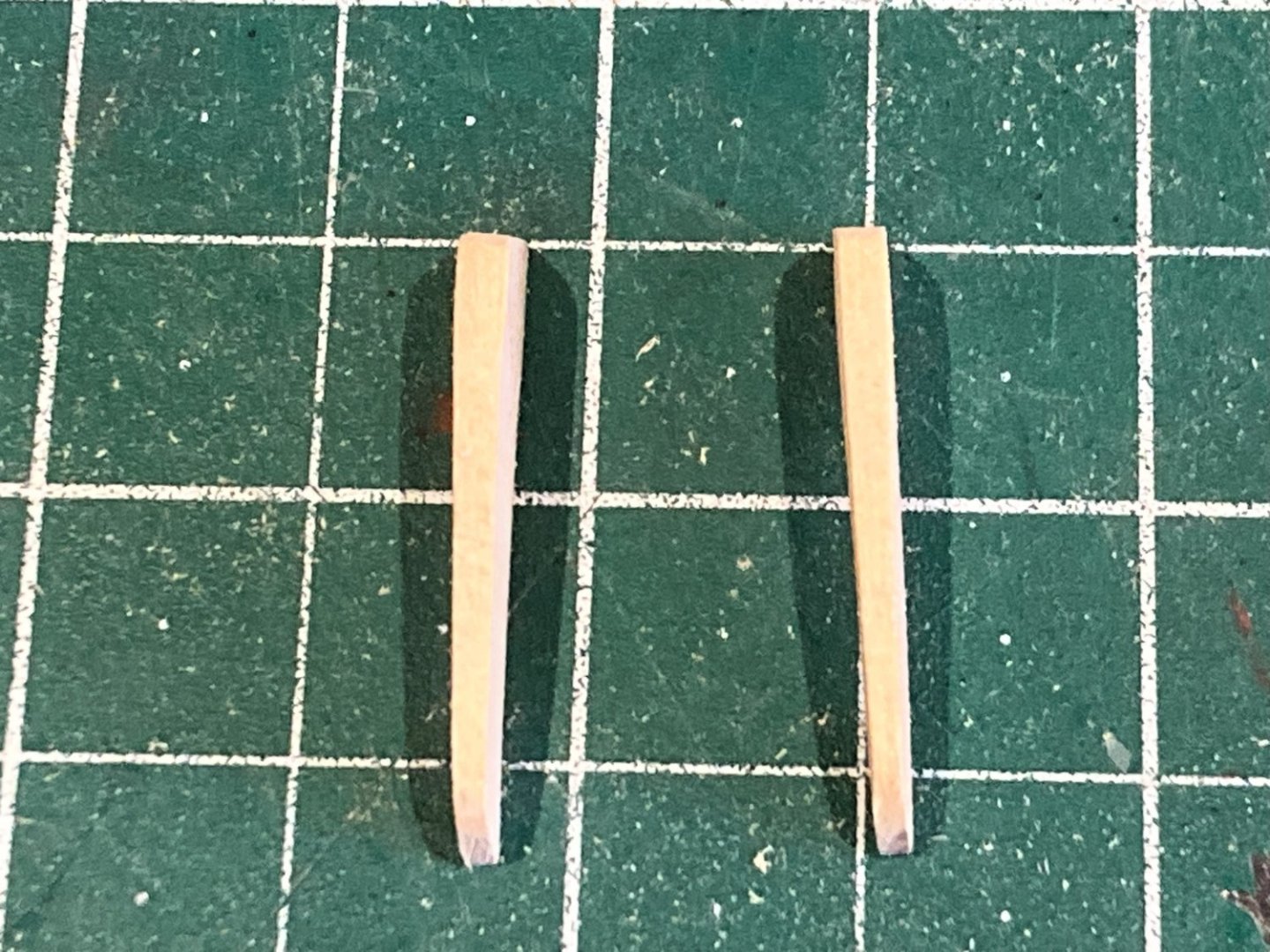

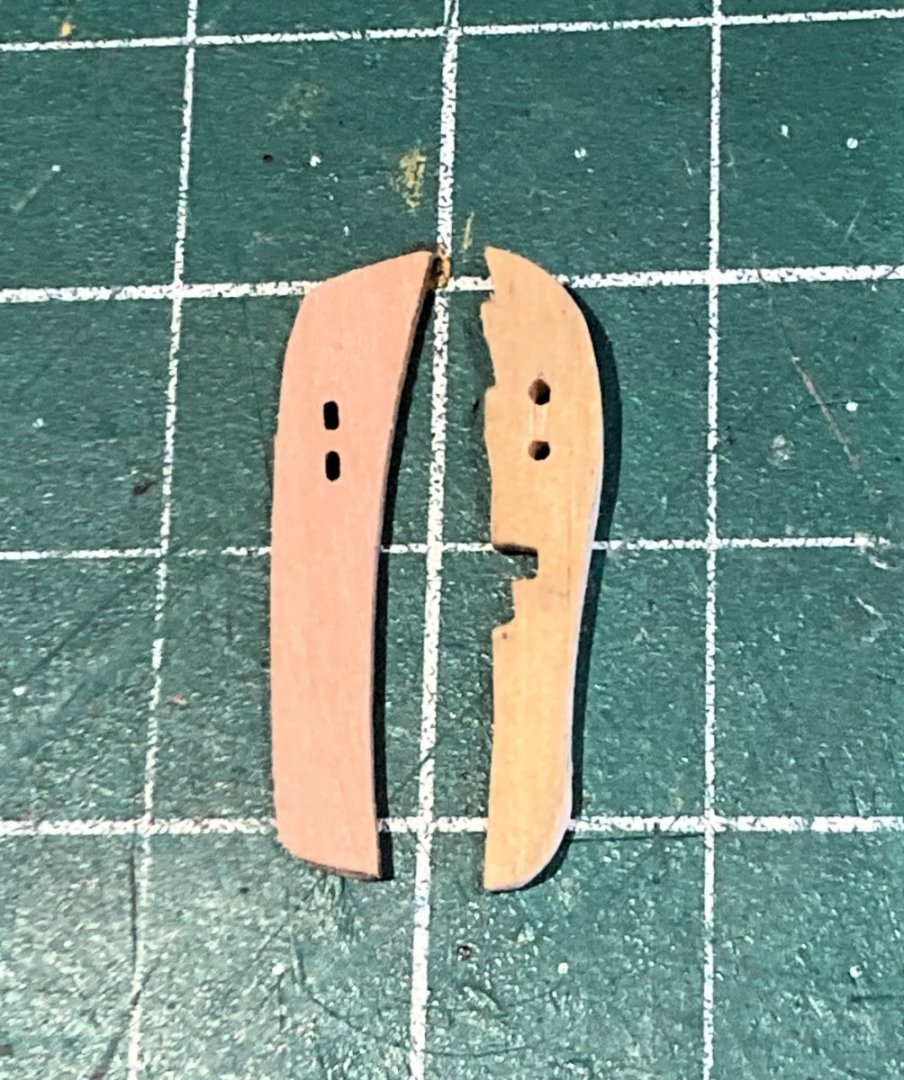

Post One Hundred and Twenty-five Looking at Chesstrees and Fenders. The kit provides a basic shape for the fenders and Chesstrees but they both stand a degree of enhancement to achieve a more authentic look. They are made of uniform 1.5mm laser cut pear which is about right for the bottom end at the wale but ideally should be slightly broader at the top, around 2.5mm. Using dimensions from the Adm. plan I cut replacements out of some Boxwood scrap. 1687a The sheaves were marked and drilled out on the little miller, and the shape cut out on the scroll saw. 1688a 1689a At this stage the same pattern as the kit items but with a taper applied. 1699a Together with a taper, a more elegant serpentine shape is better representative of how these things should look. 1694a 1695a Testing for fit. Altho’ I have used Boxwood to match my hull timbers, the kit parts could be laminated to allow for a taper, and a little more shaping to be applied. The same approach was taken with the fenders. Even on completion I thought that the depth of the fenders looked too much, almost out of scale for the hull. I looked at many photos of fenders and chesstrees on models contemporary, and modern, and they all seemed finer than the kit offering. 1707a I didn’t have any exact dimensions to work from but I fined down the pieces until they satisfied my eye. 1704a 1705a This is the result. Getting there but I still think I can go a tad further. The convex shape of the fenders initially looks odd given that on purpose built single deckers they are more concave in shape with a slight serpentine effect, due to the tumblehome. On ‘Indy’ the tumblehome element of the waist has been cut away leaving just the lower hull round for the fenders to follow. Before completing the fenders I will make the side-steps. B.E. 02/01/2024

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That's the trouble with canine assistants, my spaniel considers anything that hits the floor is his. I have to take great care, particularly with stuff that may harm him. I was once missing a needle; that cost me £200 for x-rays, and I then found the needle on the kitchen floor, well away from my workshop. I'm sure you will get around this Chris, an interesting build you have chosen, and I look forward to seeing progress. B.E.

-

Post One Hundred and Twenty-four Back to the Bow … and several things to attend to. Areas of paintwork that I needed to tidy up particularly around the mouldings. This is a tiresome task with touch-ins on touch ins, ad nauseum. 1684a The Decoration is added to the Trail boards Fit of the Figure/ Bowsprit. Left naturally the stive of the Bowsprit was insufficient to clear the top of the figure. Whether this is specific to my build due to moving the Bowsprit stop aft to its proper position between the foc’sle bitts, I don’t know, but we are where we are. 1667a 1673b I didn’t wish to change the figure so a little inventive jiggery pokery was required on the Bowsprit. 1654a The heel of the Bowsprit is visible below the Foc’sle deck, and the aim is to fool the eye of the observer. 1673a I intend to fit stump masts; for these I use Ramin my favourite dowel type. Light in colour, it provides an excellent match to Boxwood and other light wood types. 1685a My only use for Walnut is for yards where the colouring is black. I’ve probably got several lifetimes worth of walnut dowel in my wood stock. 8778 Not that I have an interest in yards on this build, but the stump masts will be kitted out with those fittings applicable, as shown here on my Sphinx build. B.E. 30/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well done Peter, a beautiful looking model. 👍 B.E.

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

Post One hundred and Twenty-three Naming the ship. The kit provides a water-slide decal for the name with a spare just in case you mess it up. 001 An issue for me is that the lettering colour, fine for the kit indicated scheme, is a little bright for my scheme. I decided to create my own version on word incorporating a curve to match the counter. I chose Baskerville old face at 36pts which equates with the kit provided version. 3155a 3155b I created two types as above. 3153 The solid background version was tested for fit on the model. The background match to the stern paint looks pretty good to my eye. Previously I have used Letraset dry rub transfers, a method I like, but I can’t seem to find the correct size or font in this medium. Maybe just as well, with a name of thirteen letters, accurate positioning could prove a trial. I have decided to go old school and use the printed version applied over the counter. I did this for Sphinx, after Chuck’s ‘Winnie’ build, and that turned out well. 3160 The print was sprayed with fixative before cutting out using a template from the plan. 3170 I used spray mount applied to the back of the cut-out to fix into place. 3163 I think I could have imparted slightly more curve to the first and last two letters but overall, I like the look. 3168 The important thing is that I have proven the system to myself, and I can re-visit at any time. B.E. 28/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One hundred and Twenty-two Re-visiting the Poop The position of the skylight is still something of a puzzlement for me. 3141 The original position as indicated on the Adm plans is over the Coach, the standard position for skylights. 3143 With the shortened Poop deck Chris has re-positioned it over the Great cabin, on the basis that this would be a practical move. 3144 Aesthetically, with the reduced Poop, it looks much better than the usual position over the coach. The Skylight has been raised by 2mm to compensate for the absence of planking. 3145 The new position does beg the question whether a skylight over the Great Cabin, with its access to extensive light thro’ the stern, is really necessary. We do know that Pellew didn’t want the round house at all, but the reduced length was as far as the Navy Board would concede. Pure speculation, but it seems to me that Pellew might well have dispensed with a Skylight altogether, on the basis that it wasn’t necessary and presented an additional weakness to the structure. 3146 3150 Even so, it is a nice little feature that adds interest to the Poop deck, along with the Mizen Bitts which still seem to be oddly positioned to my eye. Still ‘Indy’ is a knocked about Sixty-four, so who knows.🤔 B.E. 26/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One hundred and Twenty-one Completing the stern decoration This comprises Acanthus leaf designs and a plaque with the Royal cipher. 3109 Before I fitted the pilasters between the lights, I added the decoration for the cove. I found it best to do this before fitting the pilasters. 3108 The Pilasters did need a light sanding across the tops to fit the available space. 3111 I decided to add a capping rail to the transom to hide the laminations of the stern. On 'Indy' I used Boxwood, but thin styrene strips are also suitable. Roof shingles Chris has provided pre-cut card versions that do very nicely. 3113 The lower two strakes were fitted as strips, the upper one individual tiles trimmed to suit. The remaining stern decoration followed. 3135 1634A 3133 1639A 3121 3116 This Polybak decoration works very well, but great care must be taken particularly with the long delicate string attached to the cipher. Break this and there may be difficulties in matching the smooth flow of the design. My last post before Christmas, so seasons’ greetings to all my fellow builders, and many thanks for those who have liked and shown interest in my builds over the year. B.E. 23/12/2023.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Beautiful detailing Nils, always a pleasure to see your work. 👍 B.E.

- 330 replies

-

Post One Hundred and Twenty Lights and Frames I always view this job with a degree of trepidation. I started by using ‘Future’ (now Klear) Applied with a brush to the glazing surface the frame was placed on top and allowed to set. Once dry a bead of Future was painted around the reverse edge. I had mixed success with this. The Qtr gallery lights were more stubborn and I resorted to applying tiny spots of odourless ca to the back of the frame, and carefully placing the glazing. 3095 I removed the protective covering from the front side, and partly peeled the aft side which I used to hold the glazing for positioning. This ideally needs to be done as a one-shot effort, to reduce the risk of ca spread. I did have to replace the glazing on several lights due to marring, cut from the glazing fret. Fitting the frame/glaze combo by comparison is easy, the merest pass along the edges with a file, and they do indeed ‘pop into place.’ I started with the Qtr lights, and once they’re fitted it makes a significant difference to the look. This is Chris’s best Qtr Gallery innovation to date, the seat of ease is clearly visible and with the Gallery door left open the light flows thro’ enhancing the realism. 3103 3105 Addition of the fluted pillars completes the effect. For the stern I opted to have only two of the sashes open as per Jim’s prototype build, I thought this gave the most balanced and aesthetically pleasing effect. 3101 All the stern light glazing pieces were attached to the frames using ‘Future’ prior to fitting. The Upper sash frames were attached to the frames using odourless ca. 1620a Onto the decoration. B.E. 22/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Nice work on the rattlin' down Glenn, no hint of shroud distortion. 👍 Personally I'm not keen on inking the ratlines post fitting for fear of ink spray on the decks. If I'm going to blacken the ratlines I dye the line first, but on my version I'm spared that task. The decks look nice and shipshape. B.E.

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

HMS Indefatigable - 1:64 scale – The Art of Age of Sail I just randomly came across this, another 1:64 scale kit out of MarisStella To early to say how it will compare with Vanguard's kit, but there are some photos on the link above. B.E.

-

Thank you, James, I’m aware of ‘Klear’, or ‘Future’ as it was called last time I used it, beloved of model aircraft builders for canopy fixing and finishing. I’ll certainly give it a go with odourless ca as a back-up. Regards, B.E.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you Nils.👍 Post One Hundred and Nineteen. Back to the blunt end Time to attend to the unfinished stern. I had figured out on the bow area how to finish the Pearwood mouldings and pilasters to be used on the stern. 3088 Vallejo Ochre Brown over the Pear followed by a coating of the water-based wood stain I used on the Boxwood hull timbers. This gives a fair match to the varnish hull finish. 3086 The stern is otherwise painted in Vallejo Black/grey. 3085 3084 3091 3093 3094 When it comes to the frames for the lights I have seen examples of white frames which look quite attractive. However, they would be the only white elements on the model so I am sticking with Ochre Brown. 3080 The frames are prepared on the fret, priming with Metal prep 4K, followed by two coats of Ochre brown. The trickiest part of this exercise will be fitting the frames without marring the ‘glass’ with glue smears. Tomorrow’s interesting little exercise. 🫤 B.E. 18/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That looks an excellent build of these tricky little boat hulls. 👍 B.E.

- 22 replies

-

- 24 ft Launch

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Cheers Guys, and thanks for the support with the 'likes'. The figure is now back in the box for safety. B.E.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One hundred and eighteen Thoughts about the Figure This seems a good time to check out the Figure. The resin warrior version provided by Chris is a mini work of art, beautifully detailed and styled. 2998 We don’t know what Figure ‘Indy’ actually had, but the choice of a Bronze age Greek Warrior fits perfectly. During the late 18thc it was practice to paint Figures in natural colours, rather garish looking in some cases. I have been pondering how to finish the figure, and I’ve concerns that too bright a finish may clash with the more muted tones of my build. I have several books on the subject, but contemporary ship models of this period with ‘painted’ figures are hard to find. A lot of Navy board models are without figures, and for those that have them they are usually either gilded or varnished. For ‘Indy’ I want to use more muted tones with reduced contrast between the shades. How that will turn out I’ve no idea at this point, but I first need to wash and prime the figure. 3002 3006 I use Vallejo Surface primer which shows up the detail beautifully. Before I start painting, I create a colour chart of the likely shades I will use. 3032 These are painted over the primer coat so I can determine the coverage required. 3038 Incidentally, these little lidded 3.5ml pots obtained from Amazon are ideal for paint mixing small quantities and keep it fresh for a long time. I painted the model in life colours but aimed for a soft tone. Vallejo paints were used throughout. This is the result. 3068 3071 3073 3074 3078 I think the colours tone in very well, and the figure sets off the model beautifully. I am particularly pleased with the Bronze used on the metal work, and the Red for the cloak which has a dark wine colour. The reinforced linen of the Pteruges (skirt) were painted with Dark sand, and the tassels in Ivory. For skin tones I opted for Ochre brown with a spot of Burnt Umber added. The shield is Hull Red with the embossed hub and rim in Bronze. I had intended to apply washes and varnishes, but I’m now thinking I should quit while I’m ahead. It is after all a figurehead on a ship not a real-life depiction as may be created for a specific model figure. A pleasant diversion from recent activity, but back to the build now. B.E. 15/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One hundred and seventeen Timberheads Not much to say about these, a little chamfering around the tops and ensuring that those flanking the gunports are vertical, and the others line-up. 3008 The much larger tops of the two knightheads or Bollards either side of the Bowsprit opening are the tricky ones. 3011 These need to be positioned accurately and appear vertical from all angles. 3009 The final addition are the snatch blocks for the Cat tackle. I added a sheave for these, cut from a slice of 3mm ø dowel. 3018 3027 3028 A little light sanding, a re-coat and they should be good to go. B.E. 13/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One Hundred and Sixteen Completing the Headworks Gluing the Main rails in place is always a critical business. 2971 I fitted the Starboard side first which went on without issue, the pieces held using pva and sectioning clips. 2980 I took the precaution of marking the level above the capping rail on the Port side rail to assist fitting. 2978 2975 Always a relief once this part is completed. 2992 I am pleased to see that the level looks good athwartships. Not part of the kit is the Saddle. 2996 This is a section of timber triangular in shape, that spans the Main rails where they converge at the back of the head and effectively ties them together. 2982 For the convenience of the crew I have added two additional seats of ease positioned at the aft end of the gratings adjacent to the False Rail. In the Indy kit the False rail is an integral part of the Main Rail, and contains the Capsquare for the Boomkin. The Headwork construction battle is now over, but I still need to do some tidying up and redo’s on the paintwork, but that I can do at my leisure. B.E. 11/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Sometimes it is useful to dry test well in advance of actual fitting to avoid any issues that may arise later on. On my build I can see that the angle of the Capsquare will need to be adjusted, and possibly the seats of ease profile modified. B.E.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you Glenn, have you tried the fit of of your Boomkins yet? B.E.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post One Hundred and Fifteen Main Rails These are the most prominent rail of the Headworks and require careful positioning. The laser cut parts are very nicely done and contain extra length. Accurate trimming is required for a good fit, I removed 11mm from the fore end. 2957 The Main rail should look elegant and I fined down the forward end where it meets the Hair bracket. I also tapered it on the inside as it runs towards the bow. A gentle heat bend was applied to the forward end, forward of the Capsquare, to provide a less stressed fit to the hair Bracket. 2959 A slightly risky business but the bend is very shallow, not much is required. To finish these Pearwood parts, Vallejo Ochre Brown is used for the first coats, followed by my wood dye mix which produces a close match to the Boxwood varnish finish. 2965 The panel detail is black ink. 2966 2968 Dry fitting the rails. As I played around with these rails I noticed that the Capsquare for the boomkins looked close by the seats of ease. This may cause issues with the Boomkin fitting. 2969 Plan sheet 9 shows the Capsquares sitting aft of the seats of ease which would allow a clear line of fitting. All the build photos I’ve seen seem to show the position adjacent to the seats of ease, but no one has reached the stage of fitting Boomkins yet. It will be interesting to see how the other members of the ‘Class of ’23 get on with this fitting. I hope to get the rails fixed in position today but I suspect it may take a while. B.E. 10/12/2023

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

It doesn’t feel much like fun for me at present but we go thro’ the full gambit of emotions with model building. The excitement of a new project, the boredom of doing repetitive routine elements, the frustration when things go wrong, the elation when things go right, the relief when a tricky element is successfully completed, and the pleasure of a project completed to satisfaction. For me model building is a deeply absorbing activity, the research, the interaction with fellow builders on MSW, the striving for improvement, I couldn’t be without it in my life. ☺️ @ Darius – Thank you, - at present I don’t think I’m doing her justice! but that will pass.🤞 Regards, B.E.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.