-

Posts

4,564 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Blue Ensign

-

Sorry Bob, I've mislead you, relying on memory. Mine is the one with the bench edge clamp, it has a slot to fit the clamp into. I've had it so long, and I've never used the clamp so I'd forgotten it was there. I dare say if I could remember where the box is I would find the clamp inside.🙄 It is the nicest and most useful small vice I have, I used it extensively building the Pinnace for my Pegasus build. The slot for the clamp can be seen here. B.E.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Bob, the vise doesn’t have a suction base but It is heavy and I haven’t found it necessary to clamp it down for the stuff I do. I particularly like the adjustable head angle, great for working on small parts. Cheers, B.E.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Sixty-six Looking at the Rudder. This is a nicely formed piece with pre-drilled holes for the straps. It is faced by patterns that display the sections that would normally make up a rudder. The blurb at section 251 mentions as an option slightly tapering the rudder before adding the facings. (see plan sheet 14) 2265 The rudder should be tapered toward the aft and down the vertical. The inner edges should also be chamfered to assist with movement of the rudder. I used the plan taper as a template to guide the sanding. Bearing in mind there are two extra mm added to the width of the rudder by the addition of the facing patterns, I think there is somewhat more tapering required than indicated. I also slightly tapered the inner sides of the facing patterns. The result should be that the rudder matches the taper of the stern post. 2277(2) With the rudder assembled I had a decision to make; either to go with the faux gudgeon/pintle set-up of the kit or use Chuck’s Syren gudgeon and pintle mini kits which allow the rudder to turn and is more authentic. 2271(2) The kit version using combined pintle/gudgeon etched profiles do provide a quick and simple answer to rudder fitting but lack authenticity. The Gudgeons are properly solid cast pieces with a hole drilled for the pintles. 5434 The Syren method reflects this using shaped Boxwood blanks. They are designed for 1:48 scale but can be reduced in size to suit. With the rudder temporarily taped in place the top line of the Gudgeons are marked on the Sternpost. 5436 They are glued to the sternpost and a length of brass tubing is fed thro’ all of the holes in the gudgeons to check that the set up is central to the sternpost. They are then carefully sanded and filed to shape and scale. 5430 Testing the fit of the rudder to the Gudgeons. The pintle straps need to sit at a level with the top of the Gudgeons. The Pintles are easier to represent by simply inserting a pin in the recess in the rudder. 2302(2) I say easier but it is quite tricky drilling holes in the upper faces of the pintle recesses keeping the pin sufficiently square to fit in the corresponding Gudgeon. 2297(2) I don’t fit the pins in sequence; I start with the lower one and check, then one of the higher ones, and check, and proceed from there fitting each pin and fettlin’ it to fit. 2309 They should slide into the gudgeons without much pressure, otherwise the gudgeons may become detached from the sternpost. There should be close fit between rudder and sternpost, as close as possible, whilst allowing movement. 2313 One advantage of this system is that that the rudder can be unshipped. 2319 2317(2) Hanging a rudder is one of the rites of passage in ship modelling and I would suggest that doing it in the traditional manner should be tried at least once. In Part Two I will complete the rudder. B.E. 19/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I consider myself lucky then Chris that I only have one shade to deal with, and on this model at least there is no weathering involved. Regards, B.E.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

As Grant says a blob of pva is a good option for the knob, I used that for the swivels on my Alert build. Also good for replicating bolt heads on rudder braces etc; B.E.

- 419 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

Great looking masts Ron, and excellent photographs. B.E.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Cheers Guys, @ Bug, - I tend to just use hand held on auto macro settings sometimes with flash or supplementary lighting. As long as they sufficiently impart what I’m trying to get over it’s good enough for me for general w-i-p photos. @ David, - thanks for looking in, and for the link, interesting stuff. In the case of the Sphinx build, painting of the topsides and other areas will take place over several weeks with additional touch -ins subsequently. For that reason, I have decanted the mix into a small paint pot. The transom decoration is pre-printed ‘borrowed’ from Chuck’s Winchelsea build. My artistic talents are unfortunately not up to recreating that level of decoration by hand. @ Ron, - unfortunately the cook has run and the Purser is thought to be ashore arguing with the Victualling Board rep. @ Glenn, - it was kind of Chuck to modify the Upper counter frieze with the Sphinx name, a much better representation than I achieved. Just held on with double sided tape at present but I will eventually use a smear of pva. It will eventually be fitted in conjunction with the top and bottom rails. I do have several sets printed off to allow for any cock-ups. For the colour I just played around with the basic formula for creating a Turquoise shade tending towards the blue spectrum rather than the green. Regards, B.E.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Sixty-five A question of colour. The time is approaching where I need to decide whether I am going to use the printed decoration on the Upper and lower counters, so kindly modified for me by Chuck. 2235(5) The patterns were scaled to size, printed on best setting, and sealed with Artists fixative. The ground to the printed pieces is a pastel shade of Turquoise with elements of Blue/green. I need to produce a paint mix that is a good match to the printed elements, and to this end I am using Vallejo acrylic paints. 2236 After a some time of trial and error I finally produced a mix that will I hope suffice. 2248(2) The mix contains 1:1 ratio of Prussian Blue and Tan Yellow with added drops of White and Pastel Blue. Sufficient has been produced to hopefully complete the model. 2253 The only point of contact between paper and paint will be the Quarter Gallery Berthing pieces, and these have been given a preliminary coat for test purposes. 2254 Always difficult trying to represent colours on photo’s, and my eye has to be the final arbiter on the actual model. I think I can work with this and tweak the shade as necessary. One other minor paint job completed, that of the ‘brick’ base on which the stove sits. 2261 This was painted with Vallejo Hull red ( which looks brown) over-washed with a red ochre, and finished with a dry brush using Vallejo Light slate grey weathering powder. I thought this would provide a nice contrast to the ‘iron’ stove. I think it is now time to attend to the rudder and progress the stern completion. B.E. 17/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I know your game Bug, just testing us to see if we’re paying attention.😉 B.E.

- 419 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

I think you have the Catheads the wrong way up Bug, the angled end should be deck down to provide the stive to the Cathead. B.E.

- 419 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

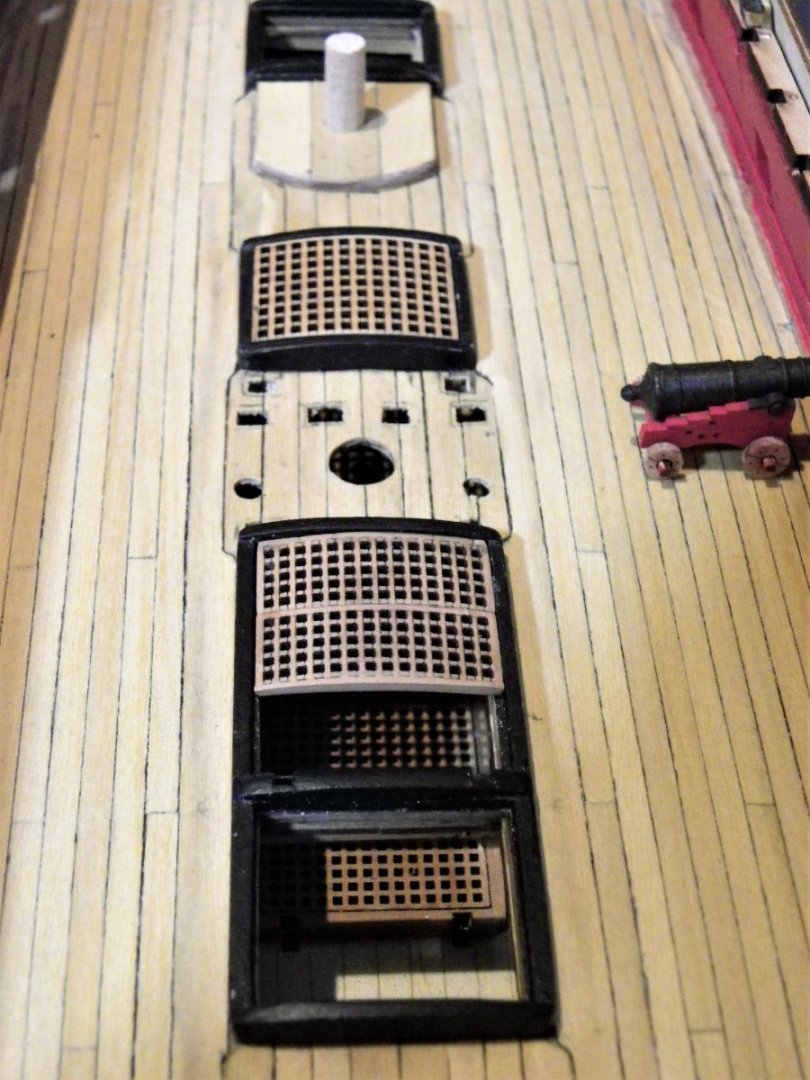

Post Sixty-four Bits and pieces. Time to make up the ladders leading down from the Upper deck. There are two laser cut sets in Pearwood, nicely formed with added decoration down the stiles and shaped treads, a cut above the standard fayre in many kits. 2195 The only point that struck me was that the Main ladderway midships is quite wide and I wondered if a central stile was appropriate to support the treads. 2178 Still need a little cleaning up at this point, and a finish with w-o-p. 2209 Ladders are tricky little beggars to fit, and I always attach a length of cotton to the top tread so it may be recovered if it slips onto the lower deck, or even deeper into the hull. I wasn’t happy with the Aft hatch grating and Chris was kind enough to sell me replacement bespoke gratings both for the Upper deck and the Quarter deck, which I thought also may present me with similar issues later on. 2176 The gratings are cut, soaked and bent around a large circumference tube to impart the necessary curve. 2188 It took two of the basic aft hatch gratings to make one split version, which is more historically accurate, and satisfies the detail devil that lives within me. 2190 Now satisfied, I can move on. The kit contains simple Mast rings to glue on the deck over the mast holes. With open beams I thought a minor enhancement to better represent the mast partners was in order. 2217 Not entirely authentic but sufficient for the purpose.. I believe the rings are supposed to be a representation of the wedges used to secure the mast against the partners. 2222 Fore mast partners. When doing this sort of modification it is worth checking how it will affect the surrounding fittings. 2226 The Fore riding Bitts and supports needed the mortices tweaking a little to fit, but with the surrounding fixtures very little will be seen of the partners. 2231 Looks like a major char removal exercise is looming. B.E. 15/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well done Glenn that looks a fair base to apply the seconds layer. 👍 If you feel better about it, you will progress better with it. If you need to take a step backwards, take it. B.E.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

I much appreciate your comments guys, and those who look in and 'like' Post Sixty-three Sorting out the deck fittings A couple of hours work to clean up the fittings holes on the Upper deck and trial fit the pieces. 2159 Surprising how long it took to identify all the relevant parts, and group together in their respective sets. All were labelled and secured in six separate plastic bags. I don’t want any falling within the sphere of my yard assistant, whose first rule of operation is:- ‘if it’s on the floor it’s mine’ There’s a lot of char to clean up but that can wait for the present, a job for a day when watching paint dry isn’t an option. 2163 The deck is taped and the coaming/hatchways are repainted using Vallejo matt black. 2171 I decided to represent treenail covers using 0.35mm drill holes filled with tinted filler. They are barely visible, as should be, and are only applied to the butt joints. A final scraping, followed by a sealing coat of Vallejo matt varnish. 2170(2) 2164 I think I will make up the ladder sets next and fit those whilst the decks are clear. B.E. 13/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Nice job on the wheel Bug, one of those is currently winging its way across the pond for use on my Sphinx. I hope I make as nice a job of it as you have. Great progress on Pegasus. B.E.

- 419 replies

-

- Victory Models

- Pegasus

-

(and 2 more)

Tagged with:

-

I found this of help when I was working on the headworks of Pegasus, It has been many years since I tackled one of these and the thought of it gives me the yips. I recall getting that smooth transition between the Upper cheek and hair bracket, and the Eking Rail and the Lower rail a very testy exercise. Wishing you a trouble free passage in completion of one of the most critical areas of a build. 🤞 Regards, B.E.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Post Sixty- two . A five month photo review. With the planking completed I was keen to see how the hatches and gratings looked. 2148(2) 2140(2) 2137(2) 2136(2) With the decking in place it all looks so much better and things are proceeding to plan. 2152 2146 My eye keeps catching the slight difference between the Aft hatch grating and the others. I am otherwise happy with the modified coamings and curved gratings. 2141 2144(2) I will now spend some time ensuring that all the deck fittings slot into their allotted holes before moving on. B.E. 11/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Sixty-one ... and more deck planking. The second bite at the planking cherry went better with fairly rapid planking along the deck using 3.4mm strips. At the bow end I merely butted the planks against the margin, back to the Bridle port, but this part of the construction will be obscured. When it’s straightforward I find deck planking quite relaxing, as with most things it’s the fiddly bits that take the time, and tend to frustrate. As the planking line approaches the Margins, Hooded planks become a requirement. I am not using joggling into the margins on this build. Wider planks as necessary are needed to make hooded planks; it’s not that difficult, the tricky part is getting the tail to match the standard 3.4mm wide planks that extend from the hooded strakes. At this point I also considered using Top and Butt planking for the outboard four strakes as indicated in the Tffm Swan books. On contemporary models of the period there is not any evidence that I can see to support a general use of this planking form. This is what Peter Goodwin has to say on the subject. (The construction and fitting of the English Man of War 1650-1850) In most vessels all the planking was of parallel strakes, with the butts square. Some builders fitted two strakes of either top and butt or anchor stock 4 ft from each side of the ship. This practice was probably adopted towards the end of the eighteenth century. Much as I find Top and Butt visually appealing, I have decided to forgo the pleasure; I did trial a mock-up but the t&b planks would extend some 26mm from the margin with a high point of 5.5mm. They covered over half of the broadest deck width, and seemed to my eye to overwhelm the overall look. Well that’s my excuse. A further three days work and the planking is complete. 2107 The process of deck scraping begins. 2116 2114(2) Once I’m satisfied with the scraping I will apply a coat of flat matt varnish to help protect the surface. I will then need to re-vist the finish on the coamings which has suffered somewhat during the planking. B.E. 10/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Allan, The kit supplied Pearwood gratings are very nice; the ledges are 1mm and the battens 0.70mm. The after market equivalent from Vanguard are still good but slightly less fine than the kit specific ones. I had originally intended using Syren curved Boxwood grating kits but having made up a sample, on this particular model I thought the Pearwood looked better. The kit coamings etc were designed to sit atop the supplied etched decks, so I added the thickness of the deck to the bottom to represent the depth down to the beams (represented by the false deck) The Boxwood planking is now at the same level as would have been using the kit set -up. The Head ledges were added as a 'round-up' wasn't represented on the kit set-up, and it's something I like to see. Thank you for looking in. B.E.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post Sixty Planking continues. The tricky business of laying down the binding strakes is next. These incorporate the tabs that fit around the coamings and are cut from wider 6mm strip. 2086 I had a few goes at getting the cutting right particularly along the section that encompassed the Main and aft hatchways, but got there at the end of a long day. The next tedious stage was re-cutting all the holes for the deck fittings and masts. Drilling, cutting with a scalpel blade, and finishing with files. 2079 The deck will look much better once it has been cleaned up. This will involve scraping using an old small plane blade, I never sand decks. The cut-out holes for the fittings will be fully cleaned up once the decking is complete. This work needs to be done with soft hands using needle files, as the merest hint of harsh filing has a tendency to rip the thin Boxwood planking. As he who needs no introduction would say: You are not carving a bear with a chain saw here folks. I love that saying which has stuck in my mind from my Royal Barge build instructions. 2088(2) From this point I moved to using the 3.4mm planks and I start to apply tapering towards the bow and stern having marked the decreasing widths on the false deck. After a days work I decided it wasn’t good enough, and I didn’t like the look, so at close of play most of the planking beyond the binding strakes was ripped up. 2094ps Fortunately, the planks came away mostly intact simply by slipping a thin blade beneath one end and sliding it along. Frustrating, but it had to be done, and it’s back into the fray today. B.E. 08/01/22

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks for looking in Tom, and for your kind appreciation. These two kits do make attractive little models. B.E.

- 91 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Sorry to confuse, The cut of the recess of the crutches should be angled slightly inboard so that the boom rests in them when moved across from the central line of the mast. B.E

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Great start to the deck planking. 👍 I can't quite tell from the photos did you check the angles for the boom crutches atop the counter timbers? B.E

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

PS.thumb.jpg.b3c8fc66afc8bd8778cc6a7f87de43bf.jpg)

PS.thumb.jpg.a031d989c75b1e5067eedd51418aea06.jpg)