-

Posts

2,228 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by clearway

-

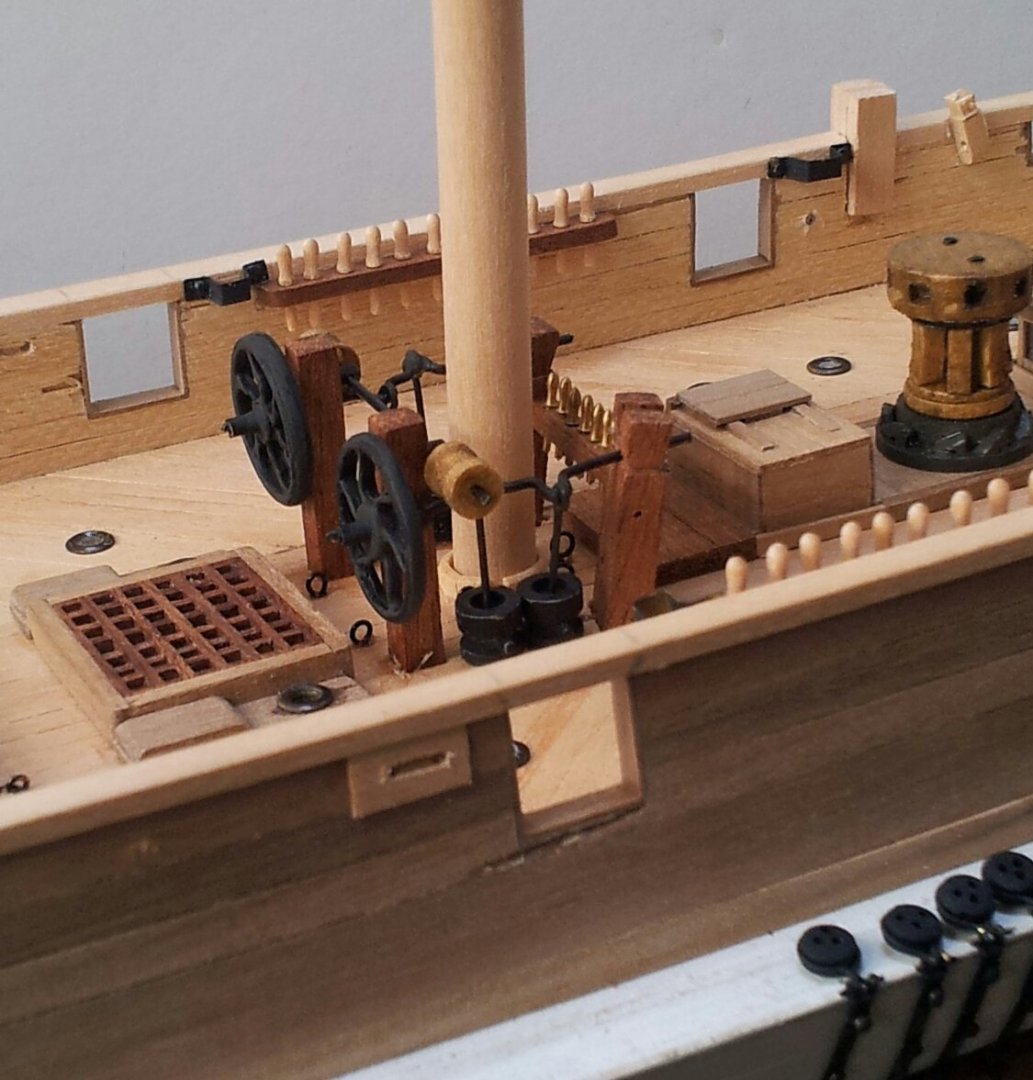

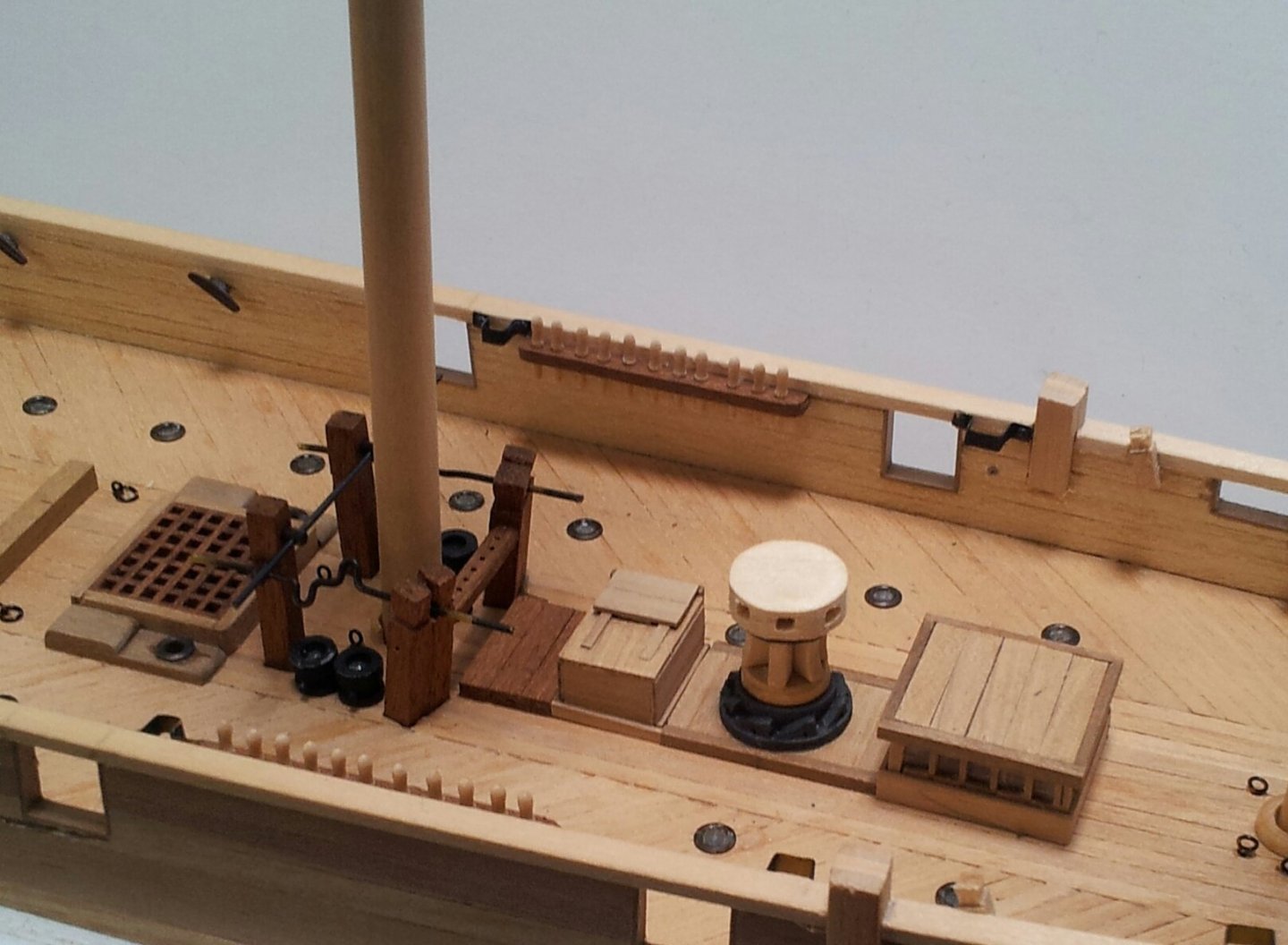

Thanks for looking in- safe to say we have definitely left the occre instructions far far behind! Have done more work on the Massey Pumps - will add handles later as opposed to bending them from the same piece of brass as the cam shaft (shows handles arranged like that on the admiralty plans), also using more thin black card and blackened brass eyes from the occre fittings to make the spider band on the mizzen mast, and added the warping drums to the fore and main jeer winches. take care all and thanks for the likes and comments- always appreciated Keith

-

i still think you are insane, but another outstanding build Greg- very very well done Keith

- 81 replies

-

- Micromaster

- Eduard

- (and 4 more)

-

If using chain drive on a steam anchor windlass you have two pistons either side of the chain gypsies with a large geared wheel as part of the manual back up - substitute the geared wheel with a drive sprocket and ignore the chain gypsy and warping drums et voila Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Looking good so far- i have this one in my ever growing stash and will be doing a kitbash on it like my Pccre Terror, Erebus and Endurance. I agree about the occre 2nd planking material and i use 3-4mm x 1mm walnut strip. One thing though - i am not sold on the carronade mounted in the bows and might leave it off? and will extend the deck right up to the bows under the anchor deck. Keith

-

oh the mental anguish we do like to create for ourselves😉- i would go for a chain drive system as some industrial steam locomotives used them and it can take a bit more abuse and is more adjustable than machined gears. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

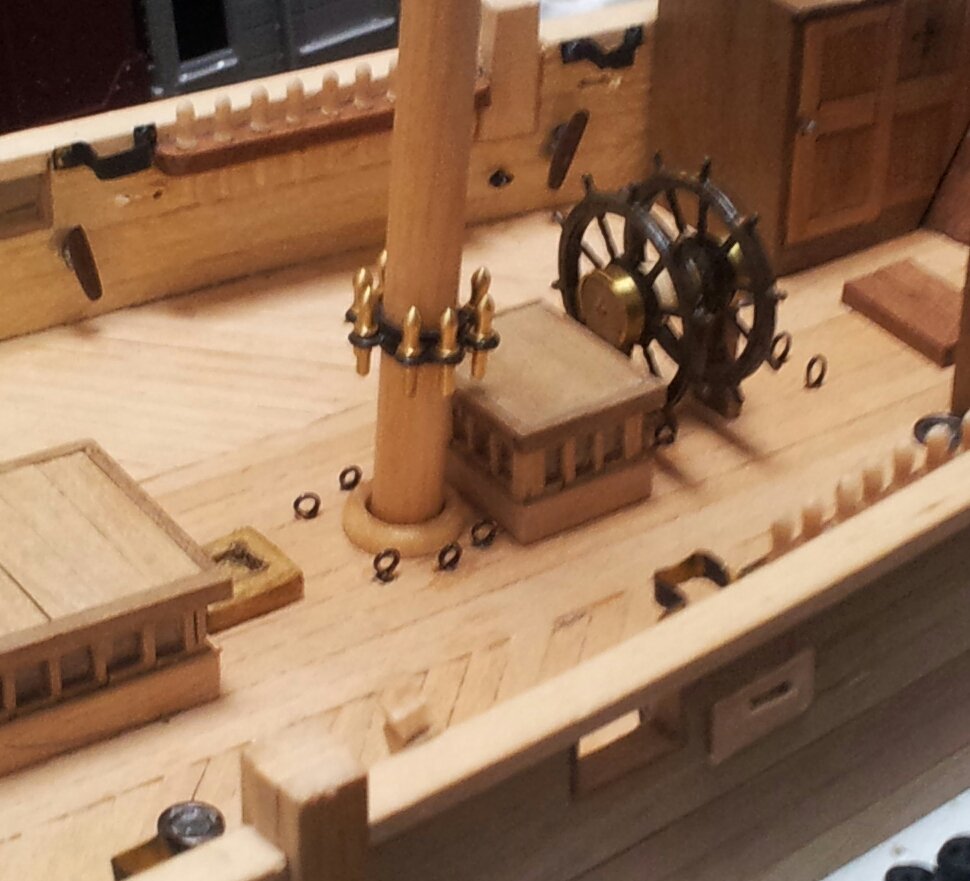

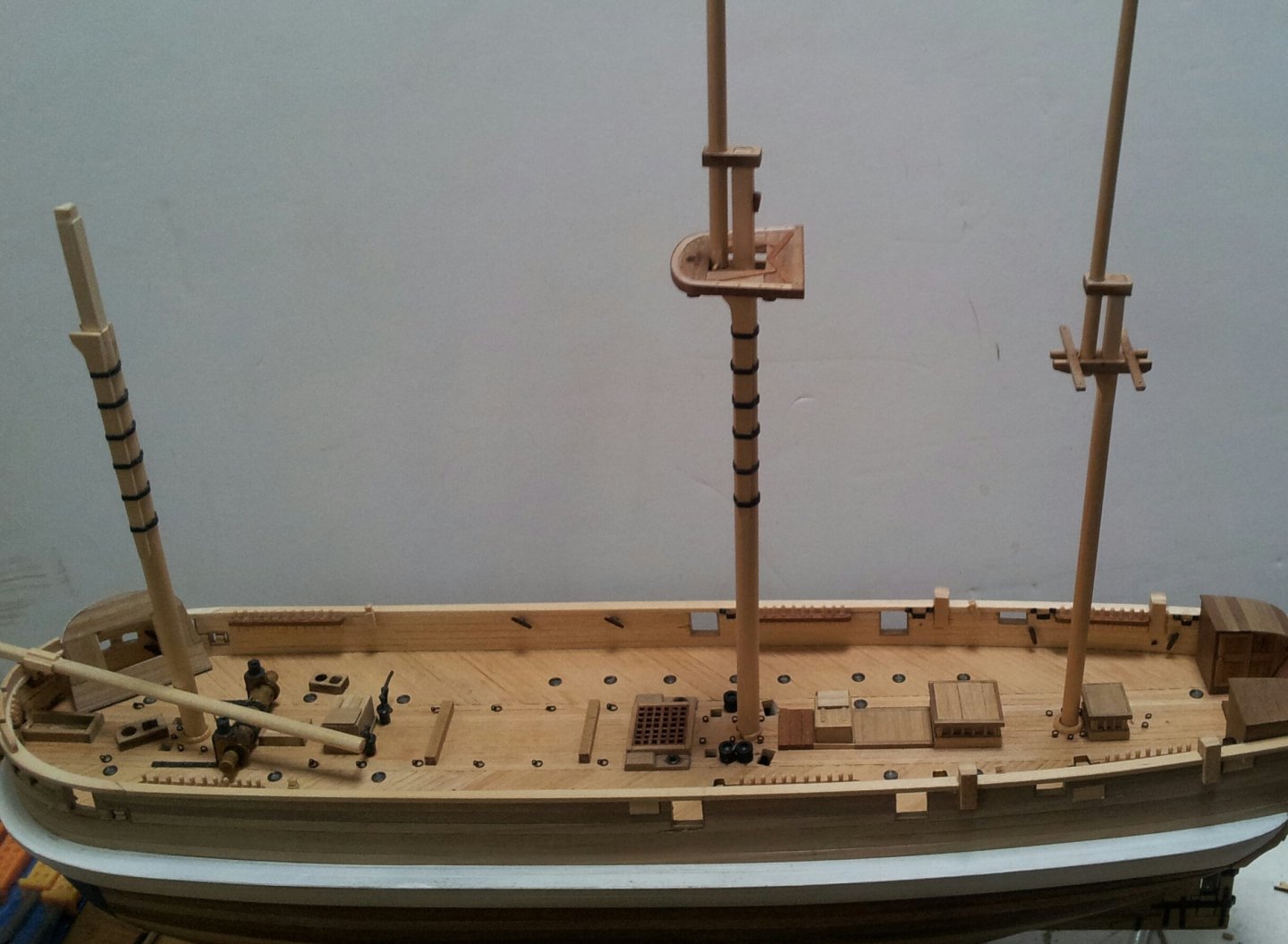

Thanks for looking in and the likes - finished the Philips capstan and added the fife rails around the foremast and added the ships bell and pawls to the windlass - the bell is not the kit supplied one but was ordered from Cornwall Model Boats along with chainplates- on my Terror i scratchbuilt the strops around the dead eyes but chickened out this time and used Amati turnbuckle chainplates along with some 0.5mm diameter soft brass wire omega loops made using a pair of round nosed pliers. The chainplates are shown pinned to some card awaiting spray painting black. also the kit supplied 5mm deadeyes were replaced with more accurate to scale 4mm ones- not much different but makes a world of difference to the spacing along the hull. Take care all Keith

-

Thanks for the likes and comments- always appreciated, have now moved on to the philip's capstan - used the original base of the occre capstan but cut the head off and added one made from scratch, also added 6 instead of 8 timbers around the barrell as suggested by occre (still more work to do). Work also on the main mast bitts and fife rail - the fife rail looks like it should be made of wrought iron on the 1836 admiralty plan but stuck with timber. The mizzen topmast is also progressing with the hounds and 'pole' carved and filed to shape at the masthead. Take care everyone. Keith

-

Turn your back for a second and away he goes again- going to have to rename you" the stern wheeler kid " Keith😁. Here is a pic of the coal fired dredger Clearway which worked Whitehaven harbour from 1928 till 1991 - the original steam crane was replaced with a diesel one in the late 60s and the pic shows the inflatable life boat which replaced the original wooden ones in the early 80s and yes she kept her coal fired steam plant right til the end which when she was scrapped was converted to oil firing and ended up in a scandinavian steamer that was being restored. keep up the good work Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

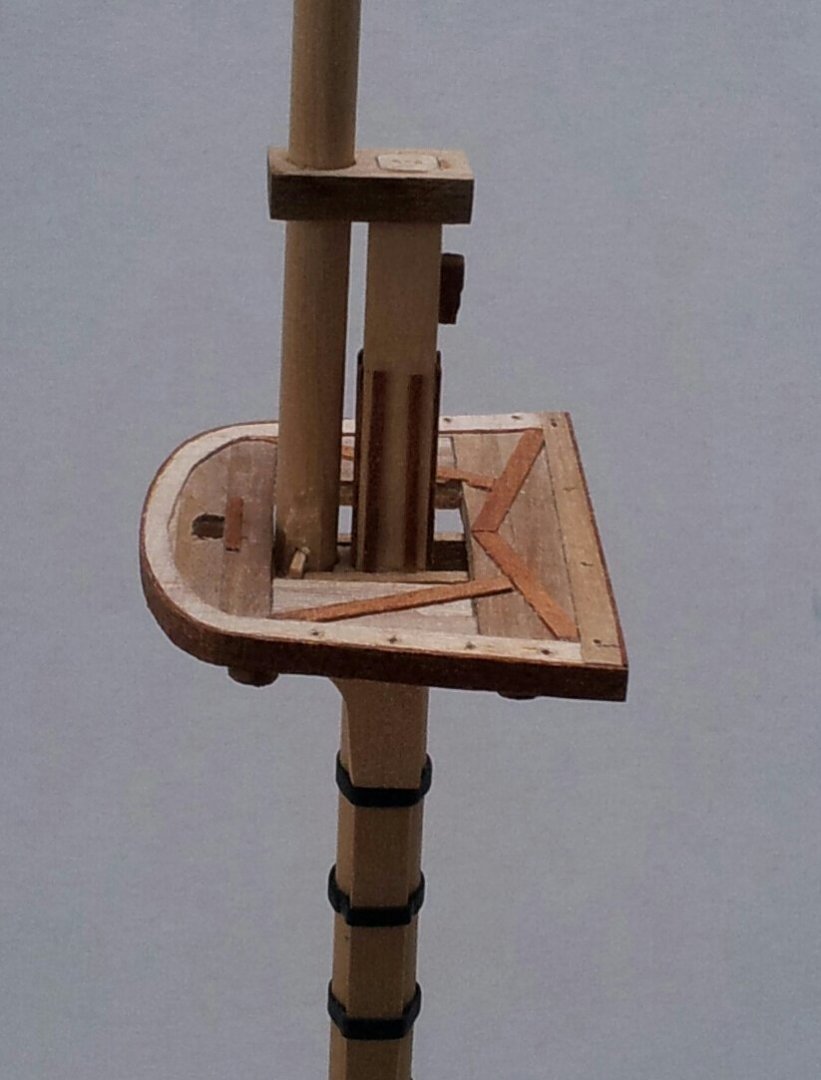

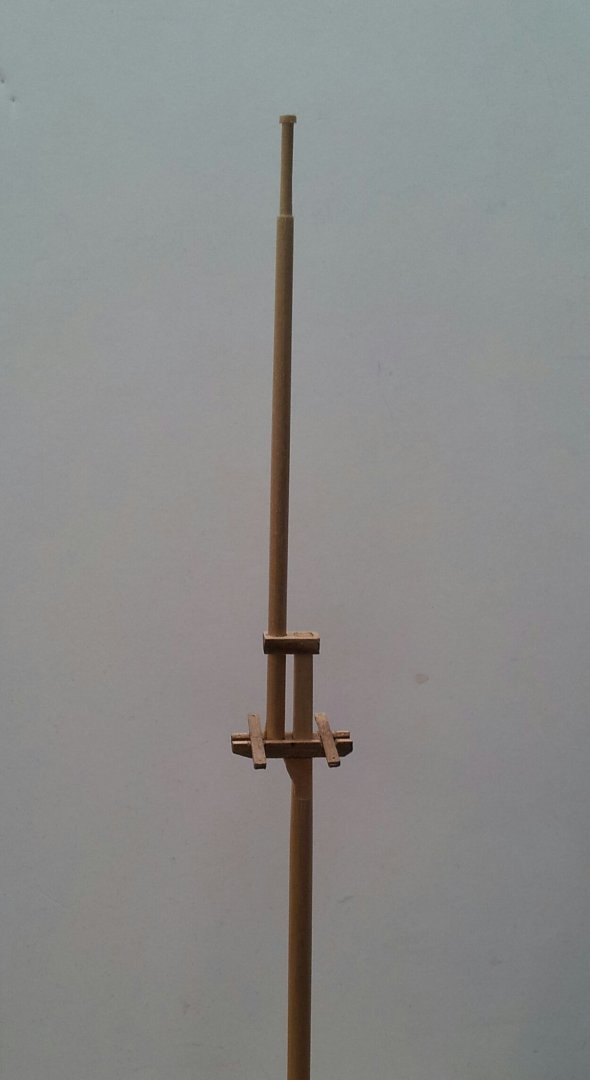

Thanks for the likes and comments everyone- Have added the iron hoops holding the cheeks in place - on My Terror i added mastbands as well but have since thought would they have used a "made" mast of them diameters and i don't think so so haven't added them- also no indication of them on the plans from the Admiralty. Also added more details to the top. Lees masting and rigging states that smaller vessels would have had 5 to 6 hoops for the cheeks which Occre got right but the diagrams in Lees shows them evenly spaced not in groups of two like occre have them. Take care all Keith

-

Pleasant, compact and interesting Keith- well done😁 Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Thanks for looking in - more progress with the mizzen mast - the trestle trees have been added (scratch built with walnut from my spares pile) and the cross trees sized from offcuts from the laser cut walnut for the mast caps etc. The mizzen topmast has been cut to length and tapered- still need the fid hole and the cap/ hounds carved/ sanded at the mast head. The mainmast has had the masthead squared off, cheeks and bibs added. The mainmast trestle trees and cross trees have been scratched and aren't actually glued yet (just the half lap joints holding them together I was in two minds as to the style of the tops i was going to use- on my Terror i went with the style from around 1810, but decided i will opt for the version from the1830s (still in progress build wise) using Lees masting and rigging to get the measurement ratios (Occre's tops are actually about the right size but add a thin strip above the top not the timber added to the edge they specify in the kit) first pic shows the trestle and cross trees on mizzen and main- the mizzen does not have a top as shown in kit instructions. 2nd pic shows replacement main top and 3rd shows the kit supplied top For the main and foremast will use black card for the mastbands again as on my Terror. Take care all Keith

-

oh yes- there is a pic of him pinching my shipyard chair on my pourquois pas build log. Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

i hear ya Keith- to think the Egyptians worshipped them as gods! Lula getting more and more character as she evolves. Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

we do like to "entertain" ourselves Keith- it's a kind of sado-masochism 😁- crew look great and i like the story being told. Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

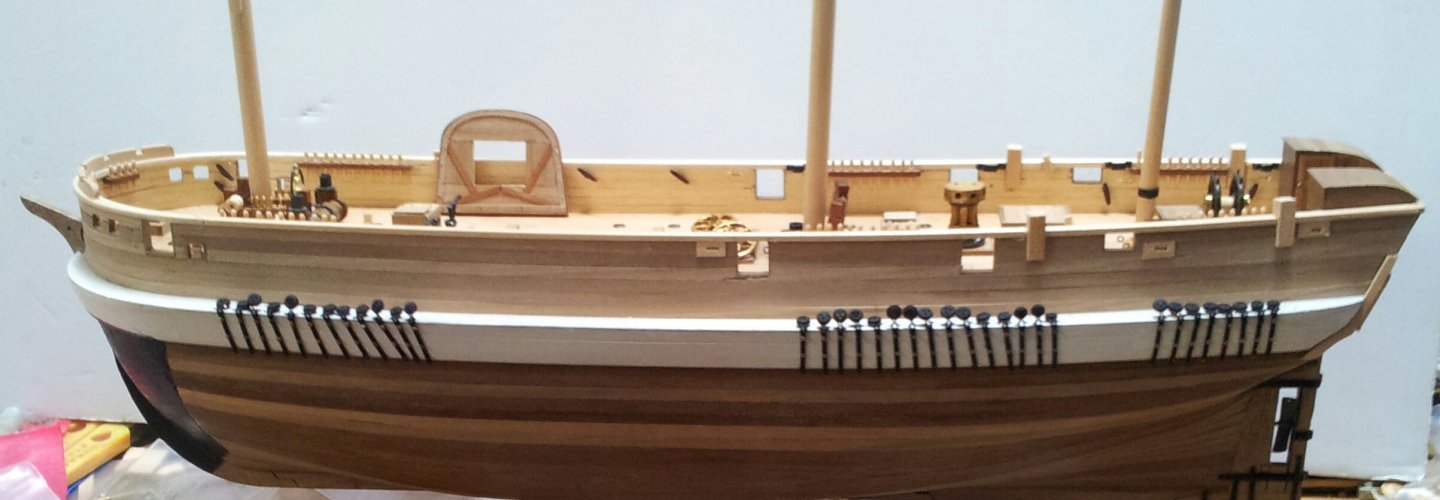

After making some headway on my Pourquois Pas build, put Erebus back on the bench and fitted the eyebolts and rings on the deck and made a start on the mizzen mast along with adding the hatch behind the mainmast fiferail for storing the rudder- one improvement on their Terror kit is the use of laser cut walnut instead of ply for mast caps, keel timbers etc (hoping if i get far enough with the masts it will inspire me to make a start on the chainplates! Take care all and thanks for looking in. Keith

-

looking good and yes chainplates bring pain (check my Terror log regards my self inflicted pain🤪)- one of the main reasons my build has faltered! Regards the caldercraft ships wheels i used humbrol acrylic primer but then used enamel paint and washes along with a coat of varnish to protect the paint and make it look more "woody" Keith

- 72 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

-

Thanks for looking in- after putting it off for ages i tackled the deadeyes- used thin tinned copper wire wrapped and twisted then trimmed off and gel c/a glue was used to glue them into the holes for the plastic kit supplied deadeye assemblies. The 3mm ones were o.k. but oh boy them 2mm deadeyes are soooo small! i will add the chainplates once the angle of the shrouds / backstays has been worked out. Keith

- 22 replies

-

- Pourquois Pas

- Heller

-

(and 1 more)

Tagged with:

-

I hear you Keith- i used to roll my own cigarettes and it was the whole ritual before lighting up and the smell of my old zippo petrol lighter! Back on topic and lula is looking great and the little details are bringing her to life. Keith

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Thanks for looking in- a little more progress with the painting and deck fittings along with the decorative board behind the bridge deckhouse. Also the decks have had an extra couple of washes using humbrol matt 26 khaki. soon will have to start thinking about deadeyes and chainplates. Take care all Keith

- 22 replies

-

- Pourquois Pas

- Heller

-

(and 1 more)

Tagged with:

-

8mm would be ideal- the brass billings pins on my Terror are 11mm but don't look too overscale as the heads are a smaller profile than the Occre belaying pins- the Terror and Erebus kits are roughly 4mm to the foot. Keith

- 72 replies

-

- Arctic Exploration

- Erebus

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.