-

Posts

2,234 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by clearway

-

Nice work so far, if you want to learn more about planking read Harold Underhill- plank on frame models volume1 from brown and furguson publishers. Keith

- 25 replies

-

- golden star

- mantua

-

(and 1 more)

Tagged with:

-

Coming along nicely there Keith, use india ink diluted 50/50 with water to colour the standing rigging- get mine from my local art shop. Keith

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

braces are the ropes used to "swing" the yards to the wind

- 237 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

excellent work there- i know the feeling from when i was at a similar stage with my billings cutty ark- the ends in sight! luckily i reserved a space in my workshop for mine though. Keith

- 237 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

excellent work. I have to agree about manufacturers and their instructions. aglad i didn't start billings victory without lots of prior experience! also they "cut corners" with certian features and dumb down others. Keith

- 234 replies

-

I recently remasted a very old mantua victory for the lad in the local modelshop and the copper plates were black in places! so deffo worth it. Keith p.s. sure your wife would be as eager as mine to clean the model !!!!!!!!

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

Nice work there.strongly recommend laquering the copper though- i did with my cutty sark and the copper still looks ok 18 years later. (see my pic on new to MSW post) Keith

- 104 replies

-

- victory

- billing boats

-

(and 1 more)

Tagged with:

-

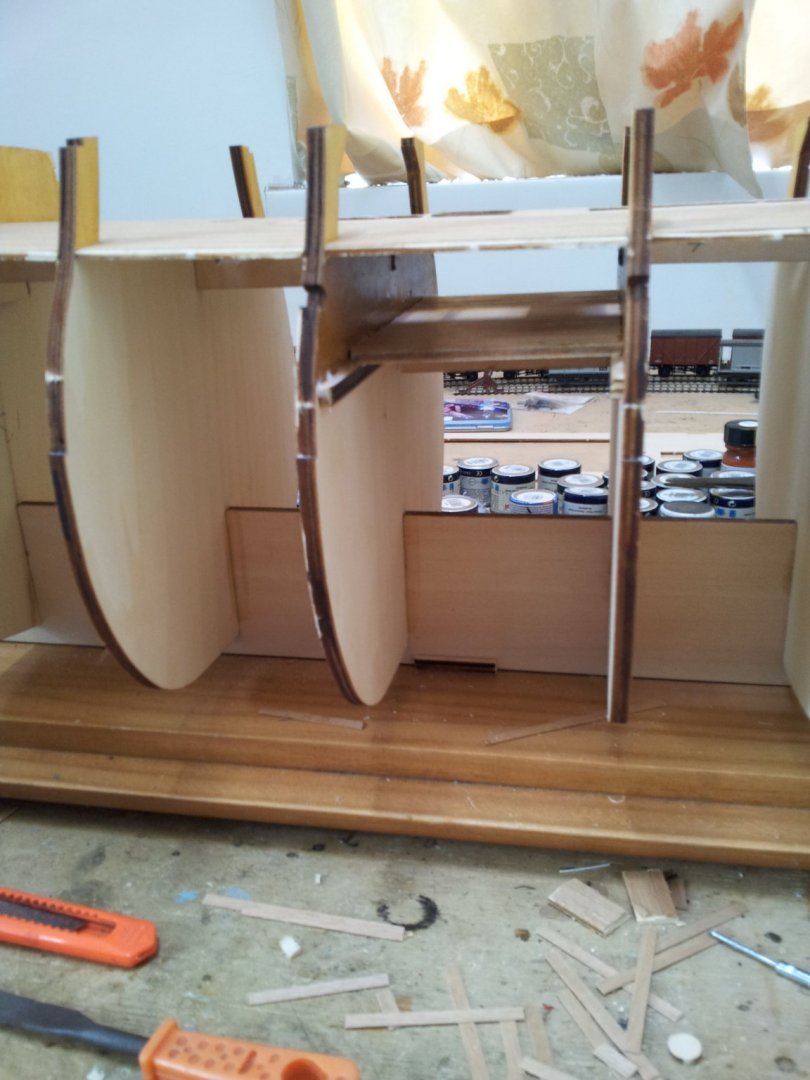

A few people have asked me to start a build log for my billings victory so here goes! Decided to add part of the middle gun deck for at least one of the sets of ladders from the main deck- will cover the other hatchway with a grating- didn't want to weaken the framework in this area to avoid "hogging". work so far- building up courage to start the planking next! Keith

-

Excellent work there and well done. I recently re-masted and rigged an old mantua 1/96th victory for the local model shop owner and fully understand the fun with the rigging! Keith

-

ty shihawk- i have always had a couple of projects on the go at once as well as building military vehicles and railway modelling- stops things getting stale! planking of hull in place- next the waterways then the bulwark planking- will need to make frames for the overhang on the stern as i am not using the "double skin" method. Keith

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.