-

Posts

693 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by RichardG

-

-

The Byrnes thickness sander is next on my list of "expensive" tools. However, that will also mean improving my dust collection system. Fein vacuum cleaners are supposed to be amongst the quietist, so that's on my list too. But there's also the space issue. One option I have considered is some good pre-planning and just using the sander outdoors as weather and season permits.

This is not a simple hobby 🤔

-

-

-

-

-

-

My wife is teacher who is currently doing remote learning because of the pandemic. She's been finding all the sitting makes her very stiff, so we purchased a nice adjustable desk with a 42"x24" top. I've just realized this would make a really nice bench when she retires in 3 years or Covid ends (whichever is sooner). I won't mention it to her yet though.

We ordered it from Amazon https://www.amazon.com/gp/product/B08L5JZ6J5. It was not cheap ($300) but it is very sturdy.

- Canute, Ryland Craze, bruce d and 1 other

-

4

4

-

Bill, my like of your post was that you're persevering with the build, not that I'm happy with the problems with the kit.

-

35 minutes ago, CharlieZardoz said:

Hi everyone just an update, here it is a 1 mm strip! This one was made of basswood but if I was able to do basswood this precise, harder woods should be even easier. I followed the advice of 3/8" by 1mm and then cut the strip. I wouldn't say I'm great at it yet but I have the means now to keep at it and practice. Thank you all for assistance in helping me understand to usage of the machine. What a smooth cut! 😊

I'm curious, what size blade did you use?

- mtaylor, Canute and CharlieZardoz

-

3

3

-

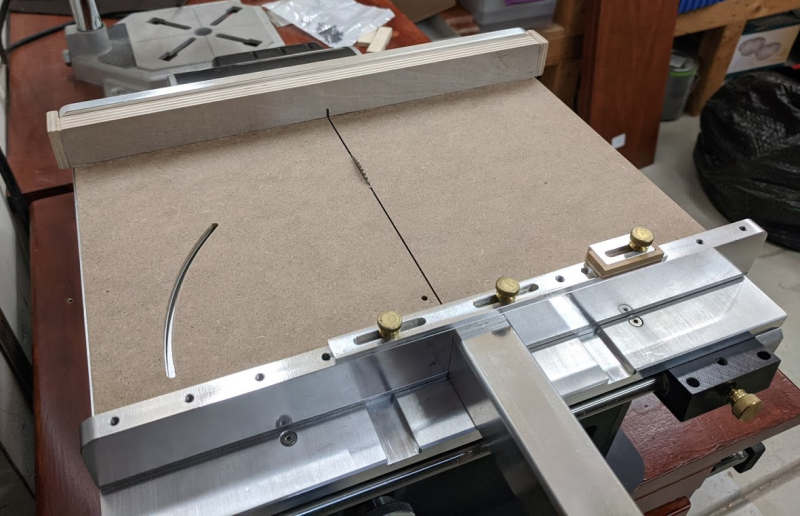

As I was beginning to use my new saw, I was getting some tear-out when using the cross-cut sled with a 3" 70T blade. So I decided to make a zero clearance insert.

Using some 1/8" hardboard and plywood, I came up with this:

I made a quick jig for my scroll saw to allow me to cut the slot for the angle fence. The fixture just lifts in and out, the base is a snug fit front to back and the plywood at the rear stops any sideways movement.

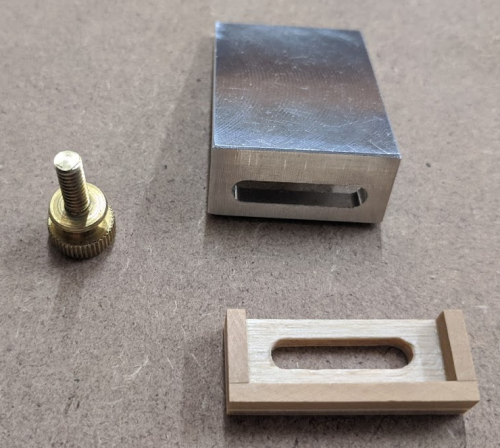

The stop was then 1/8" too a tall so I made a small fitting from 1/16" plywood and boxwood to raise it up.

The original thumbscrew was too short so I replaced it with a new brass one. Although I didn't need to, I replaced the others to match.

I also needed a longer pivot screw for the angle fence but the main adjusting screw was fine.

This of course means I've lost 1/8" from the maximum thickness of cut. Most of the time this will not be an issue but I have additional 4" blade if I need it.

- Canute, gjdale, Ryland Craze and 1 other

-

4

4

-

51 minutes ago, Chuck Seiler said:

SYREN Ship Model Company. Right down the street from you. Sponsor here, Great quality. Strongly recommended.

Absolutely agree but not for planking strips 😉.

- Chuck Seiler, Canute and mtaylor

-

3

3

-

-

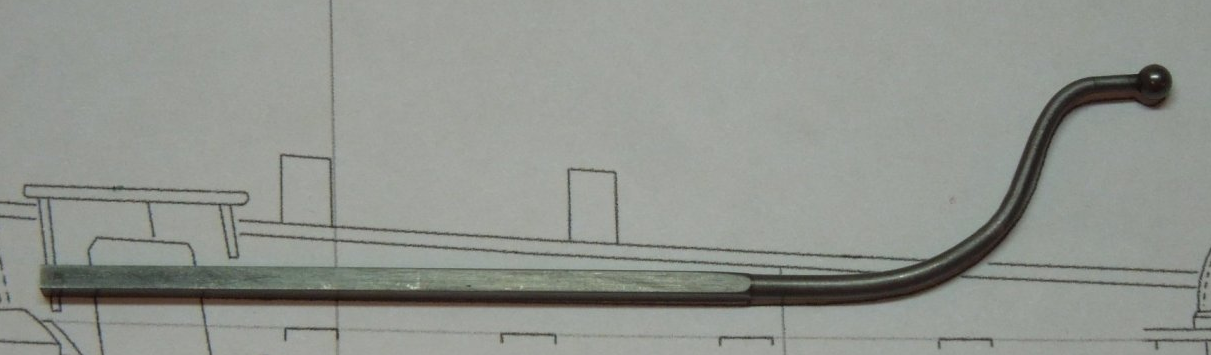

Apparently the saw will cut "larger" stock as well. Greg Herbert used the saw to help make this tiller.

-

-

I've used paint stirring sticks. The one gallon size is about right. HomeDepot sell them for about a dollar for 10.

- Canute, Ryland Craze and mtaylor

-

3

3

-

As a newbie to the Byrnes saw (although I've used a larger saw quite a lot), I don't think you need a push stick that small. You would be cutting 1mm strips from a wider strip that is 1mm thick. You keep cutting strips off until the remainder is too narrow to work with. The remaining strip will be wider than 1mm. How narrow a strip would be left will come with practice but I'm assuming several mm.

- Ryland Craze, CharlieZardoz, Canute and 2 others

-

4

4

-

1

1

-

3 hours ago, dvm27 said:

Actually I use holly with the Fiebings leather dye. Holly bends much easier (especially useful in the wales). But be sure to stain the wood off the model. You can carefully touch it up after installed.

This stuff is great. Make sure you use the alcohol based one, the low-VOC version is not as good.

- mtaylor, Canute and Chuck Seiler

-

3

3

-

22 hours ago, WalrusGuy said:

K so I don't think its easy to explain with words and pics without overcomplicating the process, so I took a video instead 😄

(Let me know if you are unable to see it from that link and I'll try uploading it differently)

Also wear gloves when doing it, I was just lazy to grab gloves for the example video, but if you touch it without gloves, fingerprints will come up.

Hope this is sufficient

I did roughly the same, starting it with a knife and making sure I curved the paper back not the foil. Holding with the knife while peeling is a good idea - that I didn't think of.

As to gloves, I didn't use those. I find with working at a small scales, my coordination is difficult enough even without gloves. I did not have any issues with fingerprints. I think this varies from person to person. You might want to try first.

- Overworked724 and WalrusGuy

-

1

1

-

1

1

-

Patrick, I forgot to mention that the hull already had a coat of poly applied many years previously. You might want to using sanding sealer prior to the acrylic. Just sanding sealer would work but I found the color evenness of the primer helpful in keeping the copper lined up.

-

Just a bottle of acrylic from Hobby Lobby I think. Thinned slightly and a couple of coats. Since I was covering it up anyway, it didn't have to be perfect (which is good given my below average painting skills).

-

I think sealing the wood is a good idea. I used a gray primer on my hull before coppering. This provided a smooth base, enabled me to use a sharpie to mark the waterline, and was a good contrast with the copper color.

100% agree on the basswood.

-

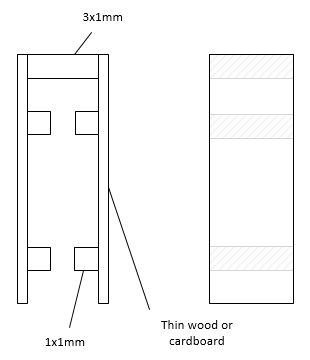

Maybe a small jig made from scrap wood or card. By using a little bit of the 3x1mm and 1x1mm you can get the spacing correct. I'm thinking of something like this

This would be flexible enough to use with fingers to hold the spindle in place while gluing. If the top and bottom rails are already in place then just have the 2 pieces without the top strip. If you make the width of the jig the right size, it might also help with spacing.

-

1 hour ago, Bob Cleek said:

I'd be curious to see the bad reviews on Amazon. I've been using squares for sixty years or so now and in all that time I've never seen or heard of anyone complaining about a commercially made square of any material being out of square or otherwise "inaccurate." (The rivets in a machinist's square can sometimes be loosened and the blade be out of true if the square has been dropped, but that's another matter entirely.)

I returned a steel center finder from Amazon recently. It was definitely off. The item was cheap and I wasn't too surprised. The Amazon reviews were mostly good with a few "1's". Lot's of people saying the bad reviews were because they didn't know how to use it. I suspect it was bad quality control.

-

Seawatch Books

in Book, Monograph and Magazine reviews and Downloads. Questions and Discussions for Books and Pubs

Posted

My most recent order was placed on Oct 13th and arrived yesterday. Unfortunately we've all been spoiled by Amazon and their billions of dollars investment.

I can see the mail arrive from my "working from home office". Yesterday I could see him put the mail in the box but noticed he had a flat cardboard package as well. He drives a couple of feet to the end of our driveway. I then manage to get downstairs and beat him to our front door. This is what passes for excitement in these times.