Cold_Fire

-

Posts

31 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Cold_Fire

-

-

On 11/6/2023 at 4:36 PM, modeller_masa said:

I don't understand how a 1400+ euros retail price doesn't include budget for lasercut beams and structure. They just forgot about decks curved shapes, placed many oak strips inside a very nice box, and they think this justifies the price.

- modeller_masa, Canute and mtaylor

-

3

3

-

Disarmodel is or almost bankrupt, I know a supplier of theirs who has several unpaid invoices at the moment. I suppose this is interesting for anyone considering buying a kit from this brand. I doubt that the after-sales service works, and it's a miracle a disarmodel kit is complete and correct...

- mtaylor, thibaultron and Canute

-

3

3

-

5 minutes ago, Morgan said:

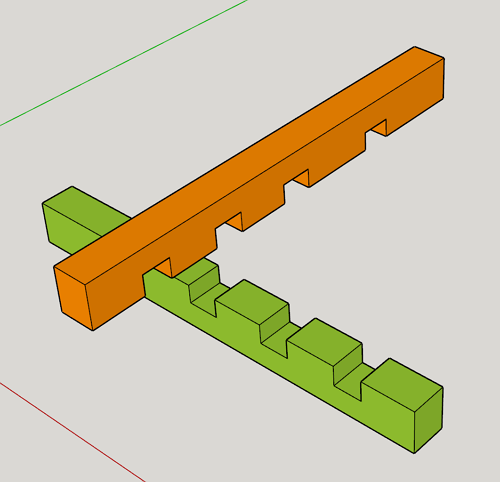

Interesting, no camber anywhere. The release video shows the parts are laser cut, so why not put that extra detail in?

All for a regular price of USD $1,700 / €1,400. The price and detail run contrary to where the leading manufacturers are.

It seems a matter of style over substance. Maybe we are missing the point and the target market isn’t the discerning modeller.

Gary

I'm watching this and my comments come from a modeler perspective.

If you think it as a product, I don't doubt it will probably have success.

- Canute, Keith Black, Morgan and 2 others

-

5

5

-

4 minutes ago, Morgan said:

It is a mish-mash of styles for sure, and clunky! Certainly not sure about Oak as the ribs and frame, not easy to work or detail at that size so won’t lend itself to modification. Also, that lattice frame approach to all the decks could easily have been substituted for a proper set of deck frames as they are all laser cut. A lot of authenticity lost for more than over simplifying the design.

Also at 1:87 that is a really odd scale, OcCre don’t seem to have settled on a uniform scale.

Gary

Check this video:

https://cdn.shopify.com/videos/c/o/v/13c5bd39e4ec40d69cc81e76b89887f1.mp4

I don't know if beams are just strips or lasercut, but I see flat decks. The model just doesn't make any sense.

- Keith Black, Canute and Morgan

-

3

3

-

-

Thank you for the read, friends.

- thibaultron, mtaylor and Canute

-

3

3

-

-

Following this build - love your work and the read.

- mtaylor and Blue Ensign

-

2

2

-

That looks like a good place to hide in!

- Charter33, thibaultron, mtaylor and 2 others

-

5

5

-

Love these classic cars - even more when finished as superb as this one!

-

On 3/29/2021 at 7:13 PM, archnav said:

Hi Allan,

sorry that my answer above was so detailed, but I thought it would be interesting to you.

It`s sad to here that Chuck is no longer producing model rope, it was quite looking good.

If you and others are interested:

In the meantime I have built the fifth model-ropery and developed a professional machine that can twist at 4500 rpm. I have spent many years developing a professional machine, also the production of optimal cordage has cost me many thousands of attempts.

Today, however, I am able to produce model ropes between 0.1 mm and 8 mm in diameter. Two-stranded, three-stranded, four-stranded with core, hawser layed or cable layed. I have experimented for a long time to be able to produce the perfect model rope and have orientated myself on the production techniques of the 17th and 18th centuries.

I have studied all the books and documents from this period in detail and will also write a book about it one day........if I live that long.I have already thought about whether I should post a detailed report on the production of a professional model ropery, because that is a lot of work and at the moment, as you have noticed, I am still busy researching the ENDEAVOUR.

I would also show the making of model rope step by step. Most model ropes are far too soft and loosely twisted and can be pulled apart like chewing gum with the slightest strain. This is a common problem with those who try. But that's only because they don't yet know exactly how to do it, that's all. The machine and the knowledge are elementary prerequisites for success.So if there is interest, I will make an effort to make an appropriate post. A longer introduction to the basics of rope making and a bit of historical knowledge, would then be the first areas.

So if that is really wanted, then I will try to do my best.Hi! Did you finally share this? Any link to another thread? Thank you so much!

-

On 1/2/2021 at 7:41 PM, Johnnyoldboy said:

Lady Nelson is my first build. Have been struggling with first planking. I bought bender but tough to control. What I found was the best technique was to wet the plank for 1 minute and then bend over a soldering iron. You are able to bend and put a twist on the plank pretty easily

Try any steam source. I usually use a facial steamer my wife discarded years ago, some seconds into steam convert the usual measurements of strips in something really easy to be bent.

-

-

-

-

-

The best source for different types and sizes of masking tape is your nearest automotive paints and refinish store.

- thibaultron, allanyed, mtaylor and 1 other

-

4

4

-

-

Hi to all!

If you want a slightly bigger sander that works like charm for models you can make it using Philips sneaker cleaner or an old Philips shoe polisher. These items can be very easily converted to a custom sander. I have one made with the shoe polisher, I made a custom part and a mold, then I made copies of the part with resin. In this way you can have many replaceable heads with different sandpaper grits.

- grsjax, mtaylor and Jolley Roger

-

3

3

-

It looks like Artesania Latina is back, the website is online again. The data in the website shows another company took care of the brand, I think.

- mtaylor, WalrusGuy, Ryland Craze and 1 other

-

4

4

New Occre Release 2-18-2024

in Wood ship model kits

Posted

It's a model that has at least 15 years. They have put inside a box a partworks collection they made for Altaya / Planeta (DeAgostini group) many years ago.