-

Posts

686 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveRow

-

Anchor Stock, It looked all too hard to do when I was planking the hull - what seems months ago now. I wasn't confident enough that I could do it justice back then. I wonder if I could now add the Anchor Stock pattern to my Endeavour wales ? Will have to think carefully how to etch the pattern to the planks, not stuffing them up. Hum ?? Dave R

-

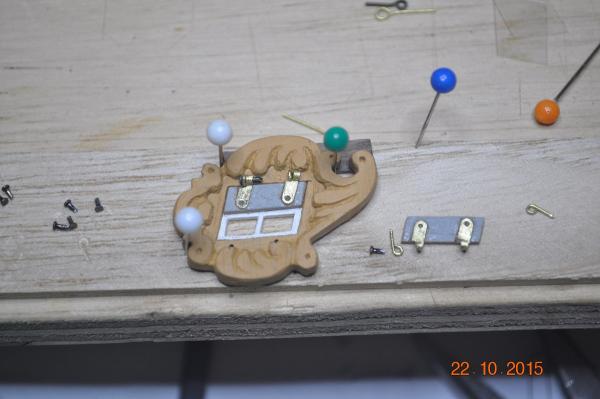

The Steering Wheel. The kit supplied a timber steering wheel(I used it), but with metal side frames and drum, no way. I did not wish to use the metal parts as they were out of scale and all wrong for me. The Capstan in the kit(which was too large for 1:60) I cut the middle out to use for the steering wheel drum. So: I made/shaped the timber side frames - red(similar ? from the replica) Drum from the kit capstan scale worked out well. Shaved the steering wheel so it is a bit thinner(recessed the drum on one side), although it is still thick, should of shaved more off. Used some brass washers for spacers(between the drum/wheel and side frames, but these pics you cannot see these) and end caps for the stainless shaft. The fore frame has a higher base than the rear, to counter the sloping deck. Total width came in at 13.5mm plus a bit more for the feet just fitted in the room between the companion and the mizzen base plate. I had to relocate the 2 eye bolts under, as they were not directly beneath the drum. Glad that little piece is done for now. Dave R

-

Hi Guys, Thanks all for looking in to the progress. I appreciate your kind comments. I must look like I have too much time on my hands ! I gather a lot of ideas and enthusiasm from looking through build logs and the AOTS. Having heaps of pictures of the replica also helps make decisions on how something may of looked. An item like the cable half cleat pairs, I copy from the AOTS. Dave R

-

HI Chris, I agree with Steve, plank from the main wale down. The first plank to the keel is the Garboard plank. Are you planning to have a rabbet on the stem ? where the planks run into ? I only did this on the 2nd planking layer. Let the planks lay(go) where they want to wrap on the hull, otherwise they will twist and (I) got into a bit of problem in this area until I got them back on track. Good that you want to practice the spiling and steelers ? On the second layer, it will look a treat. Dave R

-

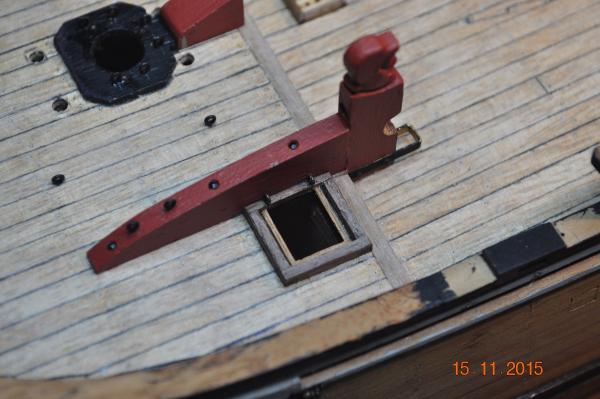

Fore Fall Hatch. Hatch came up ok, am happy with it. Underneath where it seals I have groove for the water to be drained away. Bit overboard I know, I tend to over think things. Dave R

-

Fixing things. I filled the pin holes in the 4 Jeers & 2 pin rails I had made, as I was not happy with the dia. of the holes(too big). The kit came with 10mm belaying pins(way to big, out of scale), I bought 6mm pins, but dia. still too big. So will be redrilling 0.8mm holes and shaving the 8mm pins down to fit. Will have to get my head in the right space to do that job. Dave R

-

Shipyard Update. A few days ago I drilled and installed 80 eyebolts around the decks. And still more to go; 12 more for the carriage guns in the rail stanchions. Probably more I haven't found yet. Best to get as many as possible done now before it gets busy(eh Greg!). Dave R

-

Chris(cabbie), Plenty of ways to build things. One just has to get there head around how they want the end result to look, and work at how the get there. For instance: the main and for jeer bits, the AOTS shows sheaves in the posts. I used 2 different thickness timber strips(laminated) around the 2.5mm sheave/s. By the time they are painted, you would not know this. And the paint will hide the sins/errors. Happy construction. Dave R

-

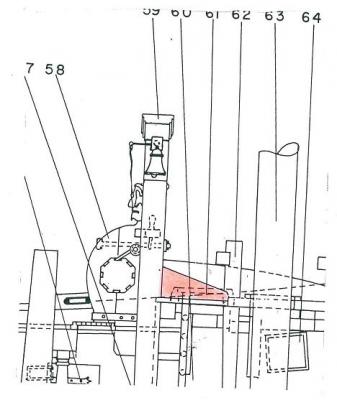

Hi Greg, The brace you mentioned. Only item I could see that may be the brace you mentioned is the highlighted frame in the enclosed. ? Yes ? Easily missed. 2 of them running to the fore jeer bit/foremast partner. I'll be adding cleats as well. Another item to make now. Thanks heaps Dave R

-

Thanks to all that have been looking in on the build. I was on the replica on the 6th Oct, took plenty of pictures to assist in details. Windlass Update, I have spent hours on this baby so far. The side Standards & Bit Pins are glued in place now. This allowed me to fit the pin rails to the Pawl Bits(the bell tower !) The barrel is 95% complete, fitted and turns in place between the Bits(pin & cheek) complete with brass bolt and nut to lock in place - for final lockup. Neat eh! Made up some pawls - bit rough but at this scale lucky to get them. Need to trim them back a bit. Still more to go - the belfry cap to finish off. Then onto more bibs and bobs. Dave R

-

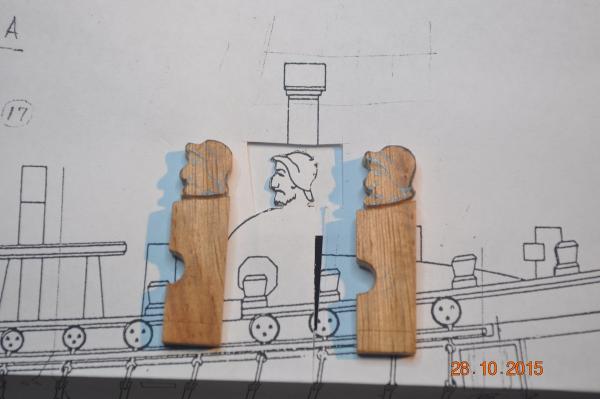

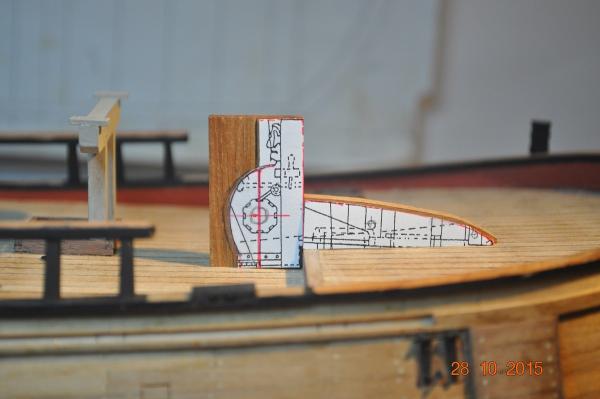

Some progress on the Windlass. I turned up the barrel on my home made lathe. The Bit pins & cheeks(ends) come apart to house the barrel, the cheek bottom held in with a brass bracket, the top with a brass bolt. Took a while to finely tuned the fitting to get the barrel to turn. I was surprised the figure heads came up fairly well I reckon. Only 2 days work. ! Next to add the pin rail, whelps, brackets etc. make the bell tower thingy. Mine will be something based on the replica, 2 posts. PS. I have yet to trim the ends of the barrel off, left them on for now. Dave R

-

Michael, As the "Earl of Pembroke": 81' 3/8" was the length of the keel for tonnage. This is recorded in Ray Parkin's book "H.M. Bark Endeavour" Also noted: Length of the lower deck from the after side of the rabbit of the stem to the foreside of the rabbit of the post: 97' 7" Hope that helps. Dave R

-

Hi Michael, The filler blocks. front or back run them all the way to the keel, so it is tight and square to start from. Too late now. I am leaving my keel 4mm thick, paint it brown probably, then it is same thickness as the rudder. The rudder, I tapered it slightly to the rear. Pics in my log if you want to see. June this year. I cut all the light ports out after the second plank layer. The thought being the planks lay truer when drying, cut out later. The Corel plans are full of mistakes. I completely remade the stern, threw the metal window thing and their design to the wind. Have you got yourself Karl Marquardt's "Anatomy of the Ship", a lot of the guys building the Endeavour use this as a definitive source of what the ship was most likely like. Up to you though. Dave R

-

Hi Greg, Will concentrate on the deck items from now. All makes sense. I did push on over the weekend to get the Quarter Badge Deadlights made and fixed in place on the hull. I started the badges in April this year. I love making very small hinges , did I say that ? I am over them. I rebated the hinges on the deadlight so they did not stand out so much. At such a small scale, I found it difficult to make them smaller. At least the deadlights open, when all the glue is fully dry will snap a pic, post, then close them for the remainder of the build. The deck awaits the shipyard. Dave R

-

Hi Pat/Greg others, I agree, will have to leave the items that are loose/swing off to the end. Anchors, Boats, Cannons(maybe fit them up and glue in place ?) I should start to move onto the deck items next/soon. Get these tucked away in place then back to the outside/mast bottoms. Dave R

-

Hi Ron, Going well I see. Oh man, the rigging is going to be a tough one to tackle for me. Seeing what you and the others are doing, going to be a challenge. I have spent some time already looking into the rigging. Was definitely going to go black on the standing rig. Tan on the running. Dave R

-

Greg, Had thought to leave them off, however got to go on sometime. They are glued on with 2 Pac epoxy, like the rest of the whole ship. Very solid joints. Time will tell how they stand up. Phil, The CA glue(I used PVA, is that the same ?) was BANYAN(Pat) advice, and for now just left the card unpainted. It is a slightly different shade than the painted post. I follow a lot of the guys build logs to get ideas how things are done and see if can come up with other ways to construct parts. Good fun and rewarding. Dave R

-

Swivel Gun Stocks. Well the shipyard pushed ahead and has completed the Port & Starboard Swivel Gun Stocks. Although in the haste, forgot to drill the holes in the top to mount the little cannon. Bad boy ! I'm happy they have come up ok. Pat. thanks for that PVA glue tip. I used a 50/50(PVA/water) mix that disappeared quickly(absorbed), and dry quickly. I have not painted the cardboard. Onto making the hinge sets for the aft cabin side shutters. Then will glue the decal on. Slow and steady... Dave R

-

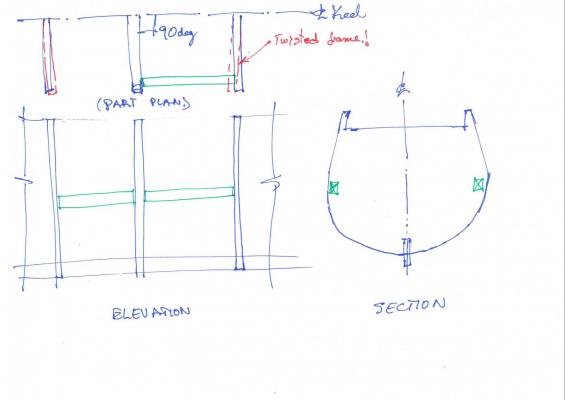

Hi Michael, Great progress, going well. One thing that I really regret in the early stages was NOT paying attention to the exact alignment of the frames, to make sure each was 90 deg to the keel, not twisted. e.g. some of mine were just a wee bit out(twisted) makes a difference to the hull shape, and later I noticed this when taking dimensions of them. If I were doing another hull, at the stage you are at, I'd place "blocks" between each frame equal to the distance at the keel. I did a quick sketch to show this. Picture better than words sometimes. They would also stiffen up the hull. The transom on my Corel Endeavour was out 1mm out as well. I didn't notice it till well into the planking. Not very noticeable, but peeved I did not pick it up earlier. Hope the planking goes well. Dave R

-

Had the shipyard working on the Swivel Gun Stocks. The Starboard ones made and fitted. I used black card(idea from another post) to simulate the metal straps. Each was Super glued to the stock, as each wrapped around. I will follow on after the black painting by impregnating the card with the Super Glue to harden it up(hopefully from deteriating). Well I hope that will work. Dave R

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.