-

Posts

691 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveRow

-

Got to negotiate with the Admiral where to display the outcome. Another Wooden Boat is being considered. I have one in mind, which from what I have seen to date, has not been built much to detail. And that is probably because their is not much published detail about her. Matter of watch this space to keep the Intrigue.

-

Hey Rod, Masts and Blocks coming up nice I see. Making good progress. You'll catch up to me at this rate....

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

True young fella. I'm looking at the Leech, Buntlines, Sheets etc. to do next, deciding how far do I go on adding more and more rope/s work. Looking at James Lees and K.M. AoTS a few differences to decide on which way to go. Probably keep on truck'in along.

-

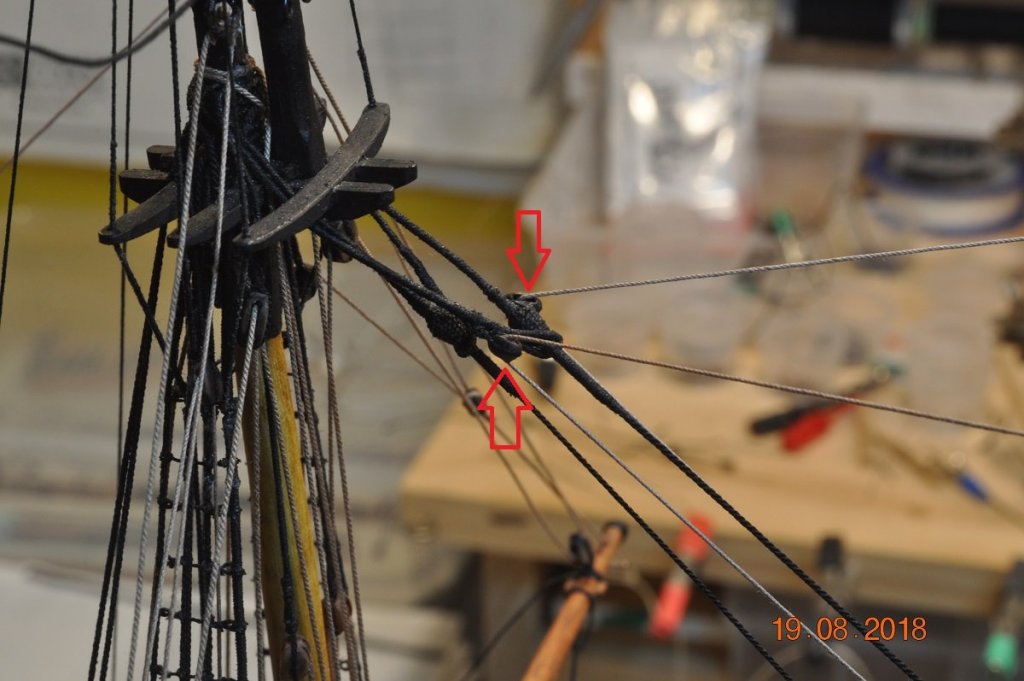

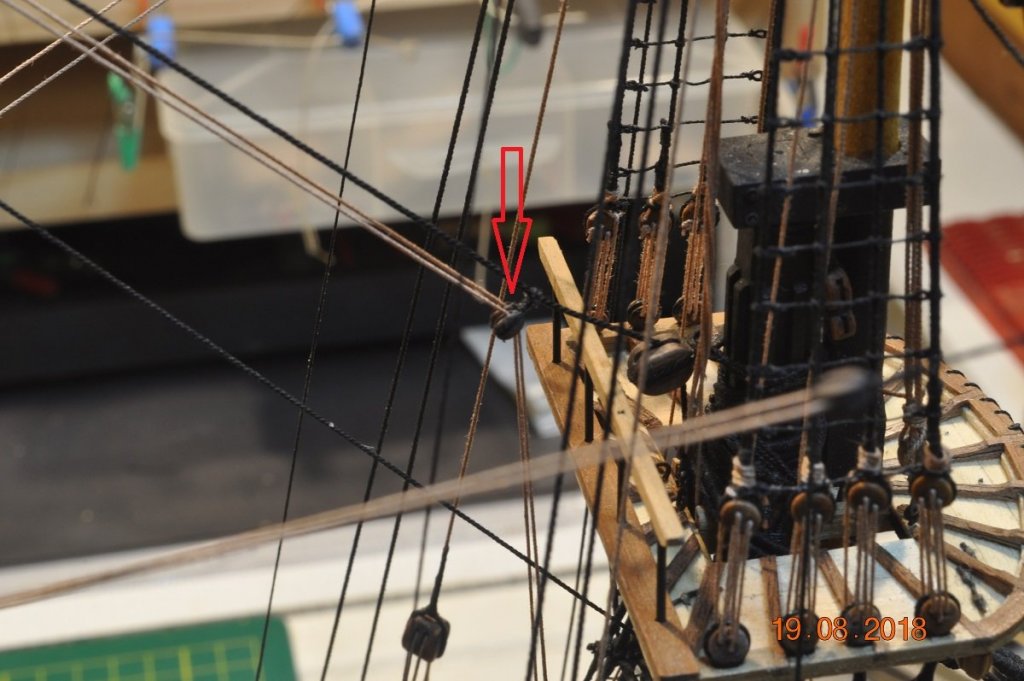

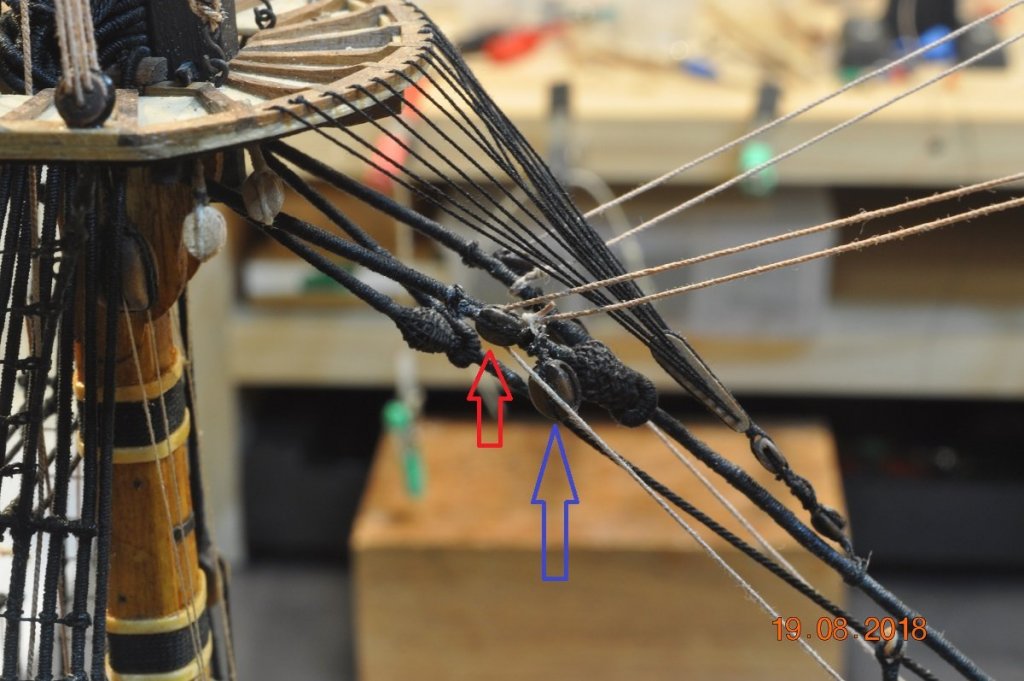

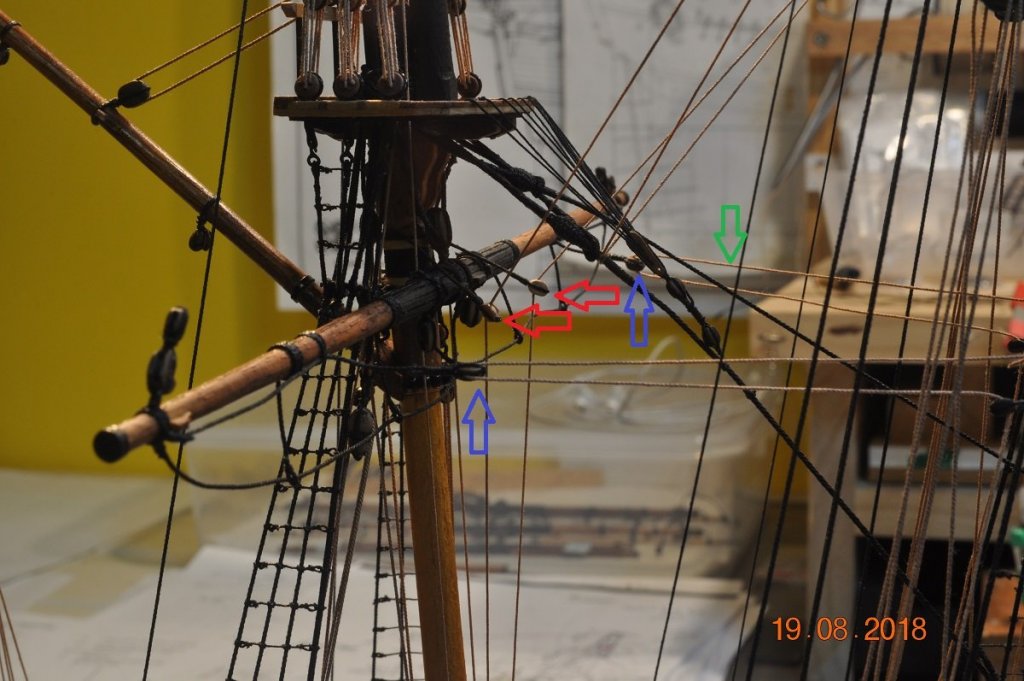

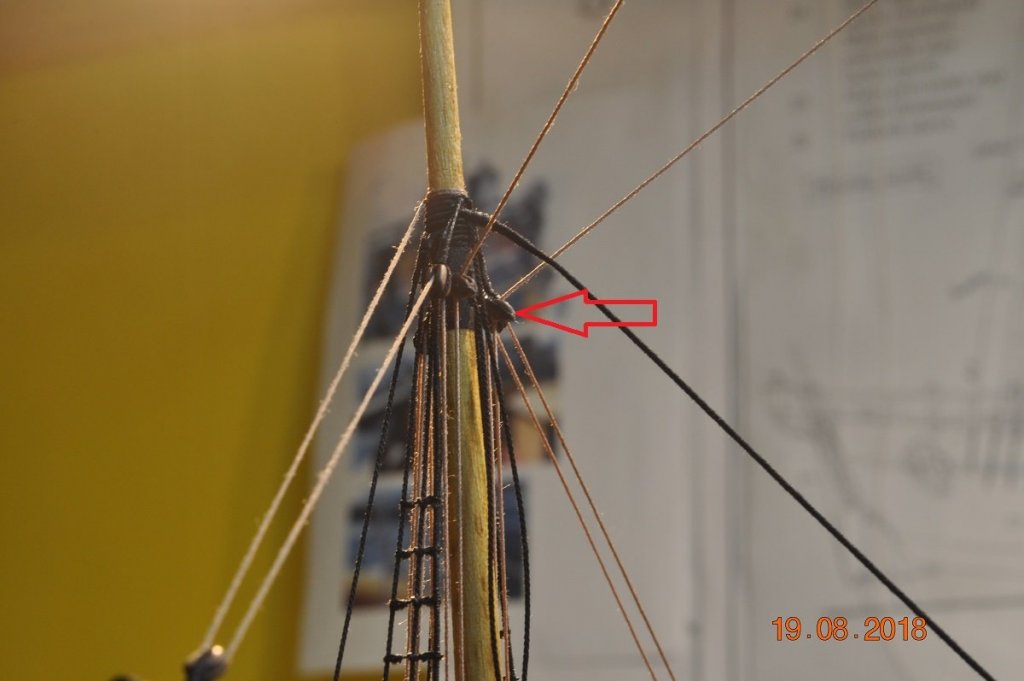

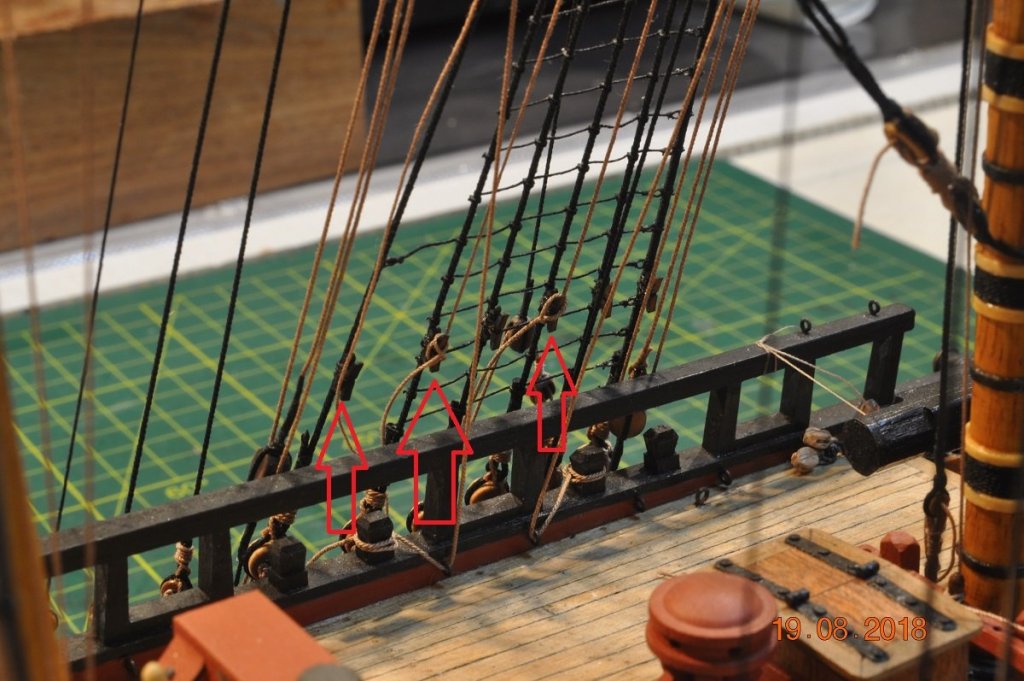

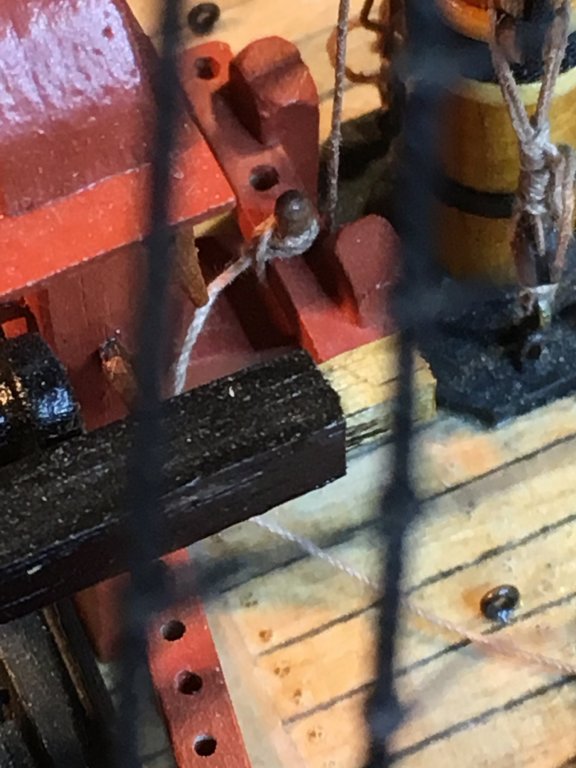

Shipyard Update: Yard Tackle & Yard Tackle Falls The Main and Fore Mast Yards have a Tackle at the end of each. K.M's. AoTS has indicated a thimble at the end of the Pendant(# 11 below), which I had prepared many months ago. I attached a Double block to the thimble, however... James Lees The Masting & Rigging........ , page 71 states "The Yard Tackle was introduced about 1685 and comprised a pendant spliced to each arm with a long-tackle block spliced into the end. Up to 1706 the pendant was one third the length of the yard length: after 1706 it was one quarter the yard's length. ... The long-tackle block was retained until well into the 19th century and it was 1840 before an ordinary double block was used instead." Well the shipyard has made a bit of a bungle here and used a double block. The Tackle Falls as noted in Lees "... comprised the pendant block a single hooked block. It was quiet long........ to lower boats etc. to the water. When not in use the tackle was hooked to the Futtock shrouds and made up along the yards. The Yard Tackle Tricing Lines(outer and inner) were used to pull the pendant and fall up to the yard. etc... Fore Mast, Port-side Yard Tackle falls made up along the yard, hooked to the Futtock Shroud(below) I authorized the yard( ! ) to attach a block to the Futtock to hoist the single hooked block up to the Futtock. This brings it up closer to the Futtock than a Inner Tricing block on the yard - IMHO. The hooked block can be raised/lowered from the deck along with the outer Tricing line. The Fore Starboard Yard Tackle hanging before the Inner Tricing Line attached. Outer Tricing attached. All up not exactly as it probably should be, but works for me and demonstrates the methodology. REVISION Update to above Yard Arm Tricing Line Blocks I've added another Tricing block(red arrow'd below) to the stays - all 4 locations I had run the Outer Tricing line back through the Clew/Garnet Block(wrong) - Blue arrow'd block below. The Outer and Inner Tricing lines are belayed to cleats on the first and second shrouds of the Main and For masts. So now have 2 blocks on the stays to hove the Tackle up through blocks on the shrouds, on same shrouds as the cleats below. The ol' saying "Happy Jan" Above: Outer Tricing Line "in Red". I dropped in down below the other inner block to clear the hook block as it comes up. Inner Tricing Line "in purple" is up near the Futtock for the hook to latch onto. The angle dangle of the Yard Arm Tackle. I'm now happy that this all works better and frees up the Clew Block for more ropes/work.

-

Hi Pat, I had three beads I had collected over time. Pic. below. The left is plastic ~3.5mm dia. which I sanded the 2 holes as they had dags on each end. Used on the 2 Main & Fore yards. The middle is plastic with a largish hole and was shorter than the dia. and I thought not really good for a parral bead. But I did use them on the Mizzen Gaff. The right was metal 2.5mm which I blackened is spherical and i used for all other smaller parrals. Used on other smaller yards. Each was consistent in size. I've since applied a clear varnish to the metal beads(shine them up) and 3D printed on the boat. brings them up a bit, any blemish, I'll take as sign of realistic wear from use. ! I got them from Art Supply stores. I drop into them when I see one, always looking for items to use. I'll look at for some if you wish... Not expensive.

-

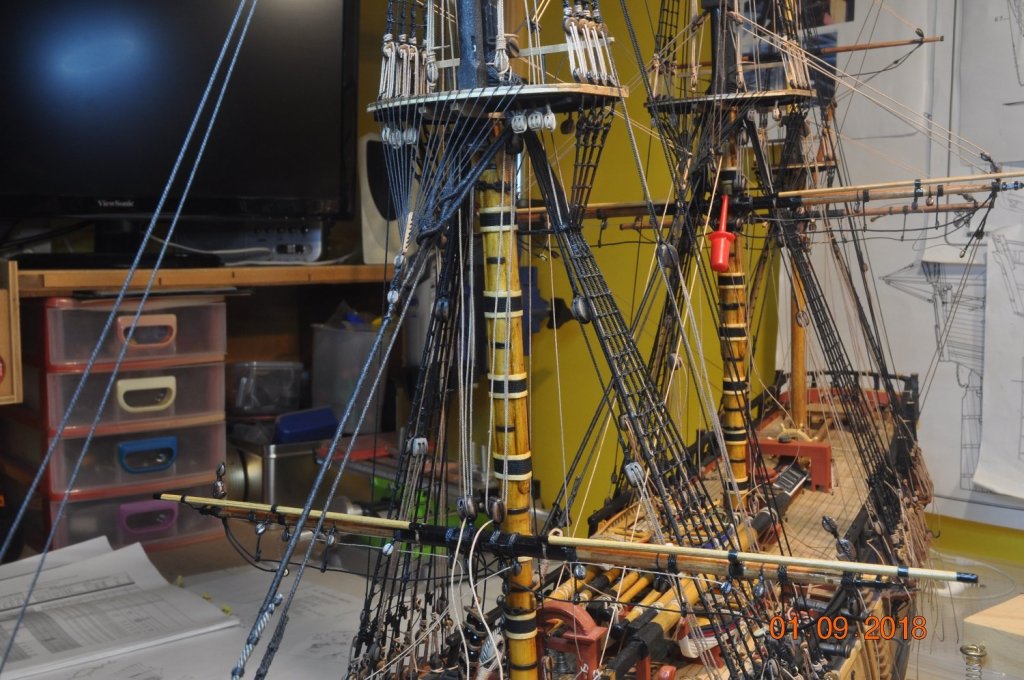

Shipyard Update: SpiritSail SpritTopSail Yard Rigging Took a while to rig all these ropes/blocks. All the blocks I had fitted have been used with a rope through each. Lifts Braces Clew lines Buntlines Jib Boom Outhauler and braces SpriritTopSail Halyard Above: Top view of the layout of ropes. All tied off at the back end. A few lines to work out how to spool/loop off. I count 15 ropes coming back from the front yards, Bowsprit & Jib Boom. Another wider view all them ropes heading back. Parrel on the Job Boom holding the SpiritTopSail yard below. Bunt and Clew lines on the 2 Spirit Yards Lifts up to the blocks under the Fore Main Mast top. Using a slightly lighter rope now, since I ran out of Chucks 0.45mm. On each side L/R the pair of Lifts tied off onto the rail. Bit of fun tying the knots with 2 pair of tweezers. View over the Jib Boom brace back to the SpiritSail Yard. Fixed at the end, run forward through a thimble. back to a mid yard thimble and back to bow. And now to devise a way to tie off all those rope ends.

-

HMCSS Victoria 1855 by BANYAN - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi Pat, They look like they will do the job anyhow Pat. I was looking at how to roll a taper in the ends. Could you of cut the linen with a triangle each side, then when rolled(with tri's at either side) would of been thin on the ends ?- 993 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

I'm a beginner really. So many others I see on this site doing fantastic work/creations. Thanks for just looking in and you kind comments.

-

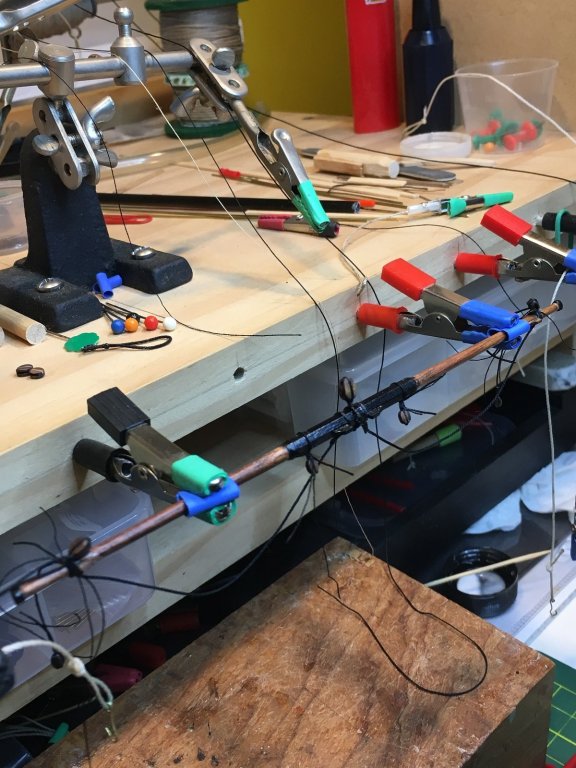

Hi Rod, When I thought of all the blocks and rigging to do, and that Banyan(Pat from Melbourne AUS) shared a Pic of a rigging station he had built, I decided a decent work station was needed(so ever grateful to Pat for that first pic). My Rigging Station has had a serious workout on this build. Main features which are real handy: - reels of rope and thread on spools at the back, all handy to pull forward - fixed shelf under for holding my 2 main boxes(timber blocks and metal eye bolts etc.) so their always handy - a sliding draw(black) at bottom to throw bits & bobs in - the main deck(!!) well it has all the bits that come in handy. There's a multitude of little caps to hold things, hooks, dowels, short ropes etc. that have gathered over time, each comes in handy at a time to hold, space, clamp when creating the various blocks and rigging. - But it all comes together between the 2 small clamps on the front to hold blocks, ropes etc. The space between the green and blue clamp(middle). The Essential Rigging Station

-

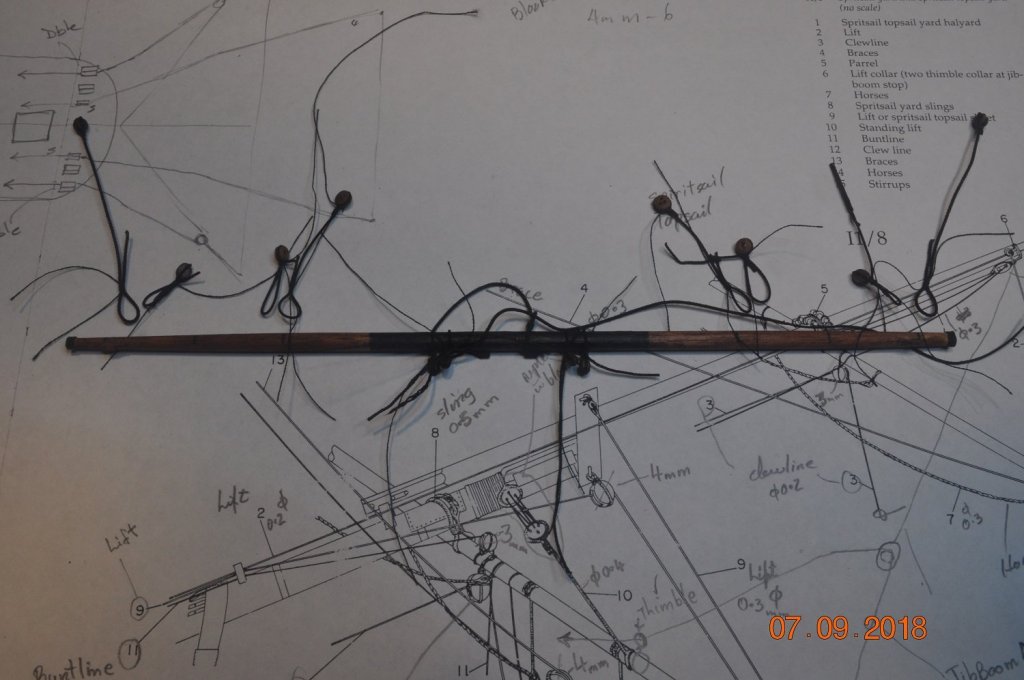

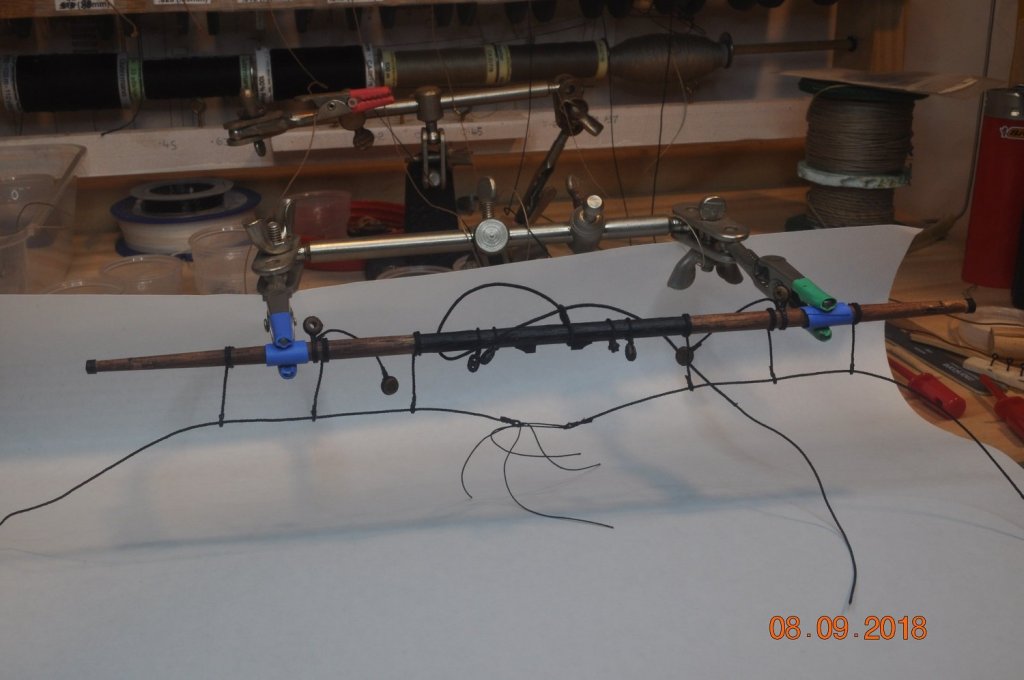

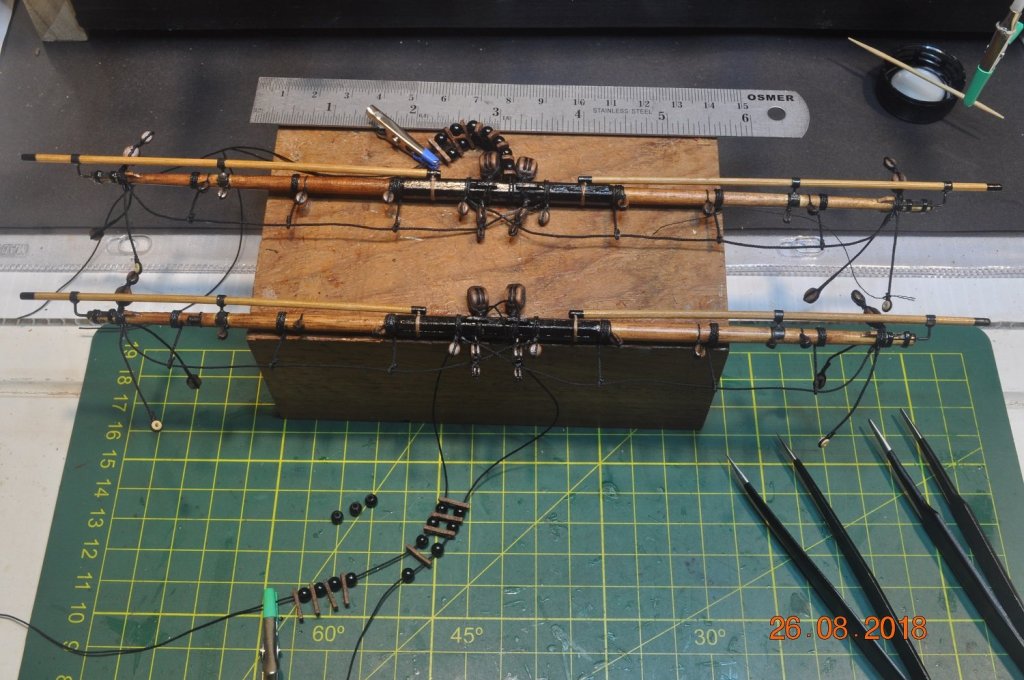

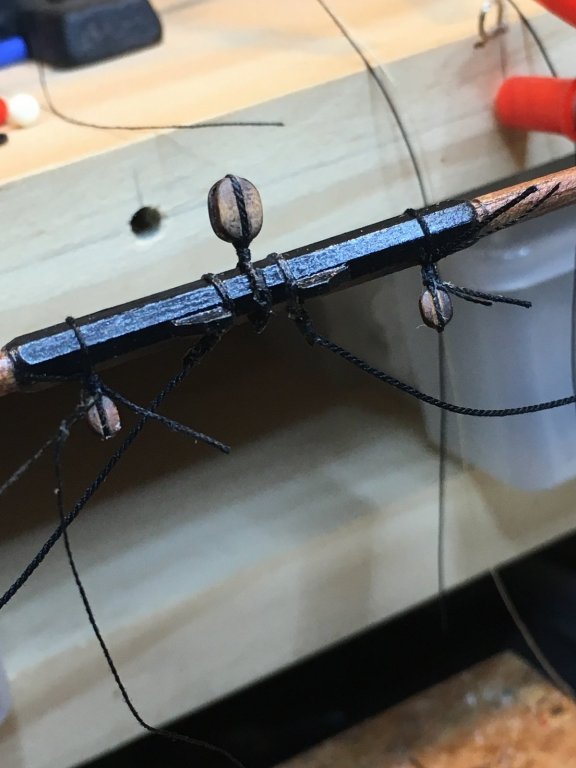

Shipyard Update: SpiritSail Yards Recently been working on preparing the SpiritTop and SpiritTopSail Yards to attached and fit-off to the Bowsprit. The following of the SpiritSail Yard Made all the blocks off the yard. Started to attache each to their respective positions. My markup page from the AoTS underneath with my scratchings(what goes where and sizes). This mess, I've attached all the blocks, now setting up the horse stirrups with a brass rod 15mm(900mm full size) below the centre of the yard with weights to set each stirrup straight. Just realized the picture angle, all 6 are behind the clamps drying. I'm sure you get the idea. ! Threaded the horse rope through the stirrups, ready to tie the ends to the yard. This is the SpiritTopSail Yard fitted out with blocks and horse. Above the Spirit Yards are fitted to the Bowsprit and JibBoom. Next to run the various ropes to and off these yards.

-

Hi Rod, Below is the process I use for making: 1. block at the end of the rope and 2. block with a rope loops to go over yards etc. (One will see what I do know is leave a short tail on the rope about the block) Description below each picture below: First I groove a blank block where the rope is to go, so it "lies" in the groove. Next I clamp the block with rope so I can work where the seizing is to go. I clamp the 2 rope ends with an electrical clamp. Next I use sewing tread. coming from the right I bring it past the clamps and hold it to form a loop, bringing it back(to the right) over the and behind the 2 ropes between the clamps, bringing it under and forward. At this stage, you could dab some 50/50 PVA H2O mix between the ropes, where the seizing is to go. Note: for block at end of a rope. The tread is wound around min 3 times to form the seizing. The thread is then "threaded"(pocked) through the loop on the left(created earlier). The thread on the right hand side is slowly pulled, whereby the loop is slowly closed up. The aim here is to pull the left thread under the "rings" of the seizing to "hide" the interlocked left and right threads(like if you were to interlock your index fingers) Hope that all makes sense.... !! Above the thread is under(or at best tightly locked) the seizing. From here you/I would use 50/50 PVA/water mix around the seizing, let it dry. Later cut the short rope end back to the seizing. At times another seizing can be added a little further on and short end cut. Now the other Pulled Loop Version: Above all the previous steps have been applied up to this stage. Note: no glue applied at all. It is hard to see, however the red clamp has 3 ropes clamped in place, 2 from the block and another from the blue clamp to the right(where the loop was made(clamped) This pic. above shows things clearly, as the red clamp is removed, showing the short rope from the block(this is the end that you DON'T want to go under the seizing when the loop is tightened onto a yard. When attaching to a yard, I clasp the sort end(with tweezers) whilst pulling the rope(on the left) to close the loop onto a yard(or what it is intended for) Pulled out of the clamps. I don't trim the thread off till on the yard, PVA mix dried. This a recent looped block on the end of a yard. ready to be tightened. I'd pull the rope on top up, whilst holding the sort rope with tweezers, or sometimes I clasp the seizing enough to let the rope pull through. Never has the short rope end run back under the seizing. The above is 2 items: thimble and a pendant attached to a yard. With some practice(after a few dozen, hundred !!) the loops/blocks end up pretty neat. Well Rod(and others), I hope I've explained the making of blocks with ropes well enough. Works for me.

-

You have been busy Rod, Nice paddles. The remake >> better than all brass.

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

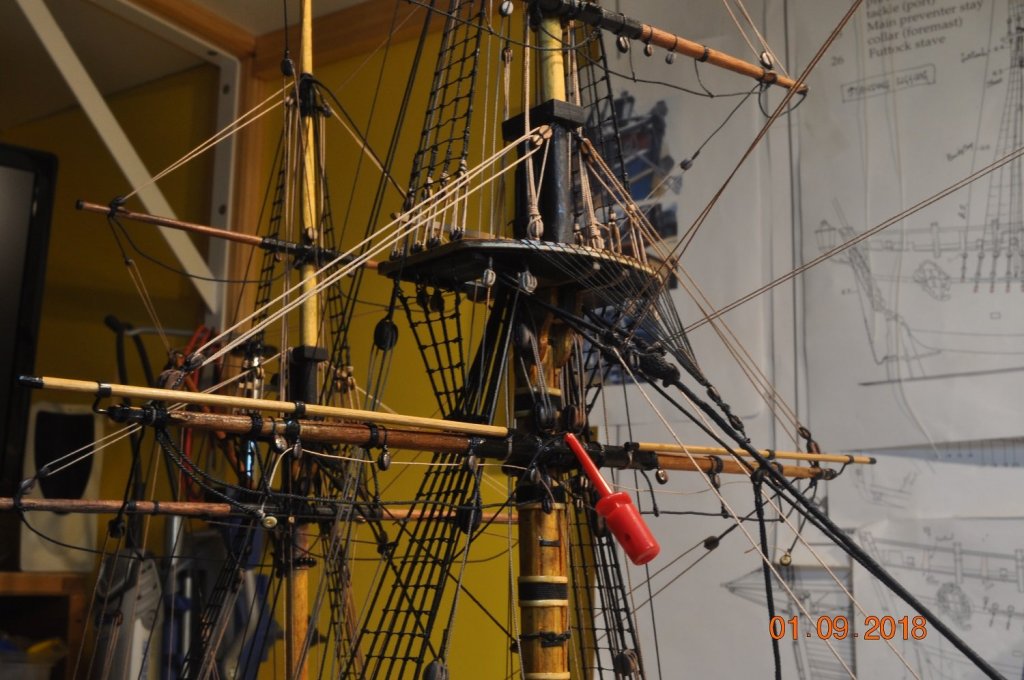

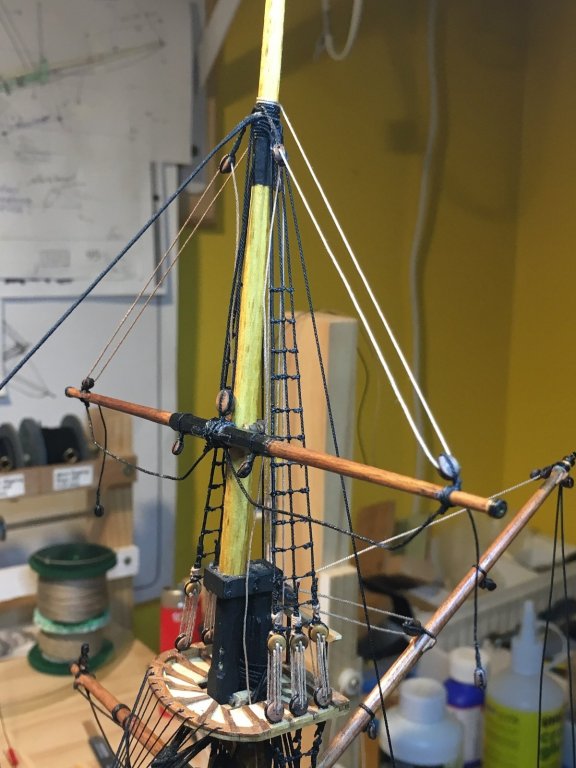

Shipyard Update: Mast Yards General Pic of the port side mast yards. Have now attached - to Mast Yards: - Braces - Reef Tackle Pendants - Lifts - Outer Tricing Lines Many more i can do, maybe look at some after the 2 x Spiritsail Yards.

-

Thanks Fernando, Pat and Rod for looking in recently. This rigging stage is quiet testing on the hands skills, and I just do a bit at a time.

-

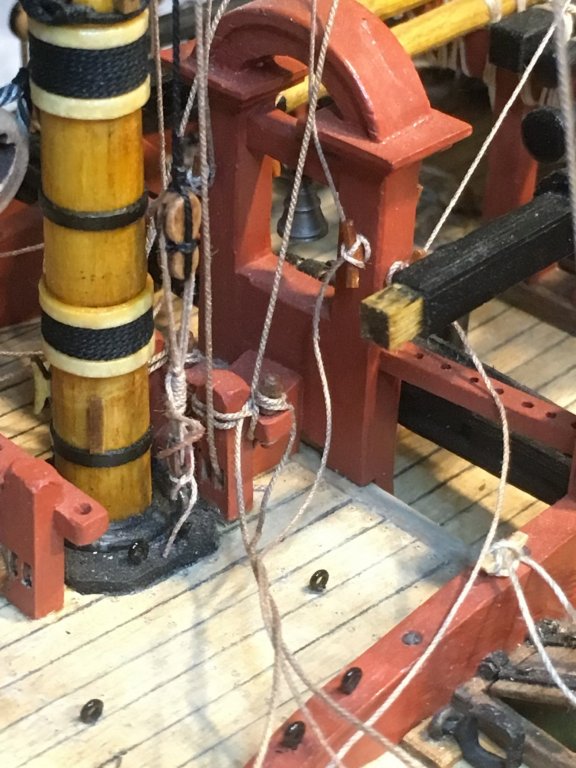

Shipyard Update: Main & Fore Main Yards Been a little while for a post. I made the Main and Fore yards, what seems a long time ago. I added the studdingsail booms and game each a coat of clear varnish. Set each up with the Parrel. Also added the Outer Tricing Line now, to cut down the "tweezer in the air" duel. Hoisting the Fore Yard up into position. Used a electrical clip to hold the Parrel rope ends tight while the glue dries. Added the Lifts in this Pic. Back of the Parrels (Main ones in this shot/Pic) Fore Mast Yard: Bit tricky, but I got the Jeer halyard through the Sheeve in the Bit. The hole and sheeve I had allowed some years ago, was just big enough. I ended up using CA on the end 10mm of the halyard, let it dry then tapered it so I could feed it in through the bit shaft. Was then able to pull the halyard though. Main Mast Yard: Jeer halyard through the Sheeve in the Bit.

-

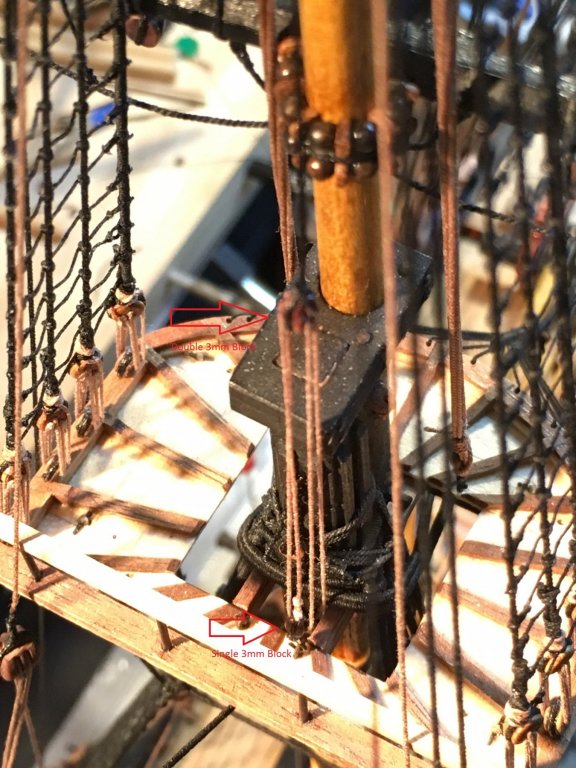

Shipyard Update: Lifts, Braces & Reef Tackle to the Upper Yards Main and Fore TopGallant & Topsail Yards Mizzen Topsail & Crossjack So the boys in the shipyard have been busy adding the Lifts & Braces to the above, along with some Reef Tackle pendant & falls(to the Topsail Yards) Some blocks were already on the mats(e.g. for the Main Topsail braces on the Mizzen) Many have been added by making single or double sets in 3mm, 4mm or 5mm blocks. The Topgallant in 3mm Topsail in 4mm and the Main Yards will have the 5mm blocks. Below are 4mm and 5mm sets Below are various shots of the recent additions: Fore Topsail Yard with Lifts, Reef Tackle & Braces back to the Main Mast, Main Stay Main TopGallant braces back to the Mizzen Main Topsail Yard with Lifts, Reef Tackle & Braces Mizzen Topsail yard Lifts in the background. Mizzen Topsail Yard with Lifts & Braces back to the end of the Gaff. Gaff with Lift. Main Mast Cross Trees: 3mm single blocks added for the Fore Topgallant braces which run down the Stay to 2 more blocks(below shot) 2 x 3mm single blocks added to the Main Topmast Stay, where the Fore Topgallant braces run down to cleat - on side of Bell Belfry. Fore Topsail Braces back to the Main Mast, Main Stay Main Mast, Main Stay blocks(in RED) 4mm for the Fore Topsail braces. Additionally have already added(in Blue) a 5mm for the Fore Yard braces. Mizzen Mast: over the Crossjack are the pendent for the Main Topsail braces(in RED). Crossjack pendent blocks(in BLUE) for the braces(in GREEN) which run froward to the Main Mast rear Shroud Mizzen Topmast, 2 x 3mm blocks added to forward shroud for the Main TopGallant braces to run down. Fore Mast TopGallant Yard braces back to the Main Mast, Stay blocks. Port Main Shroud Cleats: Braces are tied off to the cleats on the shrouds. Bit messy, a lot of cleanup to do down the track. I added another set of cleats on the rear(6th) shroud for the Crossjack Yard brace. Starboard Fore Mast shrouds: Cleats for braces. I added another set of cleats on the rear(6th) shroud. you can see the different lashing used. Bottom of the Mizzen Mast, cleats filling up. Next will probably add the 2 Main yards.

-

HMCSS Victoria 1855 by BANYAN - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat, Your doing a fabulous job on her...- 993 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Hi Blacky, Looks pretty dam good that 2nd planking. A sand should bring it up nicely. Looks like you will glue the Wales over this layer ? Not sure for the OcCre Kit, the channels on my Corel kit(not that it was that great for details) and AoTS show a thicker timbers, the same depth as the channels, in line for the 3 x channels per side. How you going to attach them ?

- 45 replies

-

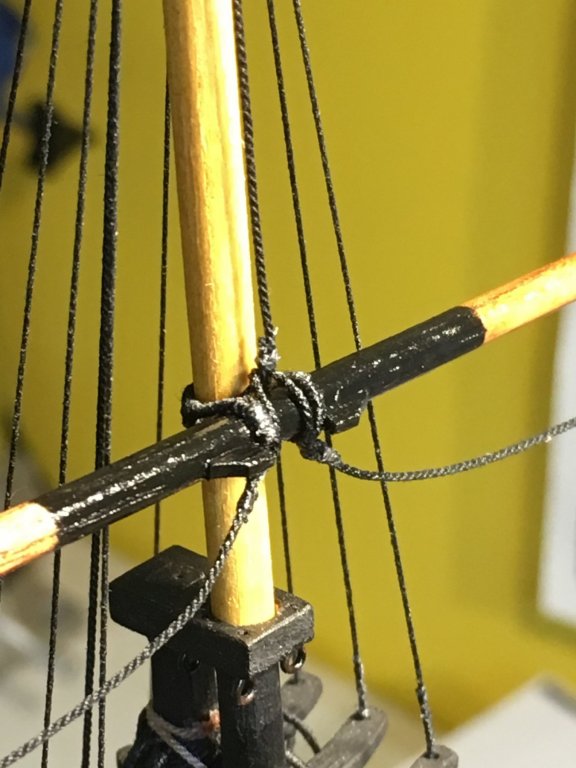

Shipyard Update: Top Gallant Yards for Main and Fore Masts. Got the boys to hoist the Top"G" Yards. Each had: - brace arm at each end with a toggle hole - Sling Parrel: the "loop" end was lashed onto the yard before the fitment to the mast-top - one of the horses was attached both sends(onto the sling-parrel loop and outer yard end) - the other horse just to the outer yard end, the inner end of the horse attached to the lashing end of the sling-parrel - the halyard with double block run through the back of block under the hounds Above: Fore Top Gallant Yard in place Above: Main Top Gallant Yard in place Above: Top Gallant Yard - middle of the yard with Sling-Parrel, horses and halyard attached. Above: Top Gallant Yard Halyard - each as a block and tackle, 3mm double block attached to the lower end of the halyard, tackle with a 3mm single block with hook at the bottom to an eye bolt into the Mast Top. the tackle rope down to Mast Bits. Above: Halyard Belaying - tied off to the middle of the Mast Bits(Main and Fore) to Belay Pin. What a job that was. Onto Main Yards. Had them made months ago, time to get them on I suppose.

-

Shipyard Update: After some time fiddling about, I came up with Anchors, Bumpkin and Fish Davit on the Starboard Bow - below. All just sitting there, not glued in place yet, as not sure or happy with the layout. And I'm confident I can postpone the final arrangement, continue rigging and fit this lot later on towards the end. So all coming off and going into storage. Move onto the Main and Fore TopGallant >> Yards.

-

Thanks for looking in Pat, Not sure about "nearly there now". So many more blocks and ropes to go.

-

Shipyard Update: Change of tack. Back in early to mid 2016 I made the Anchors and Bumpkins and Fish Davits. Before I potentially "lock myself out"(access), thought it time to fit the above on the bow area before ropes and other work is done. So Rope added to the Main anchors and a final coat of matt varnish. Will be attaching the above to the Bow next, along with the smaller 2 Anchors.

-

Shipyard Update: Mizzen TopSail Yard. Previously I made reference for the above as the Mizzen TopGallant Yard, which was wrong. I had also made the yard as a TopGallant, which has been rectified. Below are pictures of the new fit-out. Fitting the blocks and ropes to the Topsail Yard. Above: Left to Right > Yardarm Lift Block, Tye-Block(Clew blocks at sides), Parrel being added. TopSail Yard in place with Yards and Tye lifts. Main TopGallant brace Blocks added, tied to the front Shroud(either side) Plenty more for the shipyard to get no with. Chop Chop.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.