-

Posts

691 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveRow

-

Wow that is some lift of the hull. Thanks for letting us know the source of the Build. I don't mind the pictures staying. All adds to the Endeavour 's ongoing History.

-

Hi Rod, Welcome, as others have said to the Endeavour Club. Doing a great job on the hull. Will follow with interest.

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi David, Happy to leave here in my log. Do you know which organisation built this hull ?

-

Hi Pat, Yes I bet the rope and block work is a memorable experience. I need to get back into it, keep the momentum up, as weeks will drag into months. Want to get this baby completed.

-

Hi their Greg, Actually the traffic I have experienced is pretty dam good. I am a TX driver, meaning driving Games Family Members(visiting nation dignitaries, managers), Comm Games officials about. A loot of work went into Games Lanes on a designated road network which I get to drive on. We have Comm Games vehicles to drive all shift. Done 7 shifts with 4 to go. Bit tiring, but meeting interesting people from other countries.

-

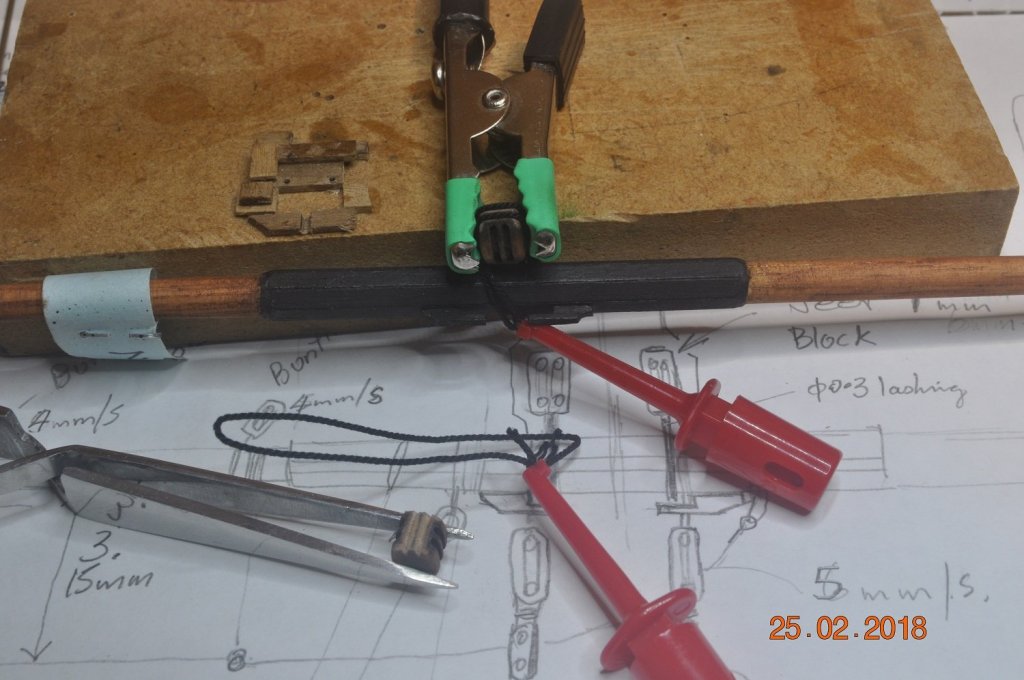

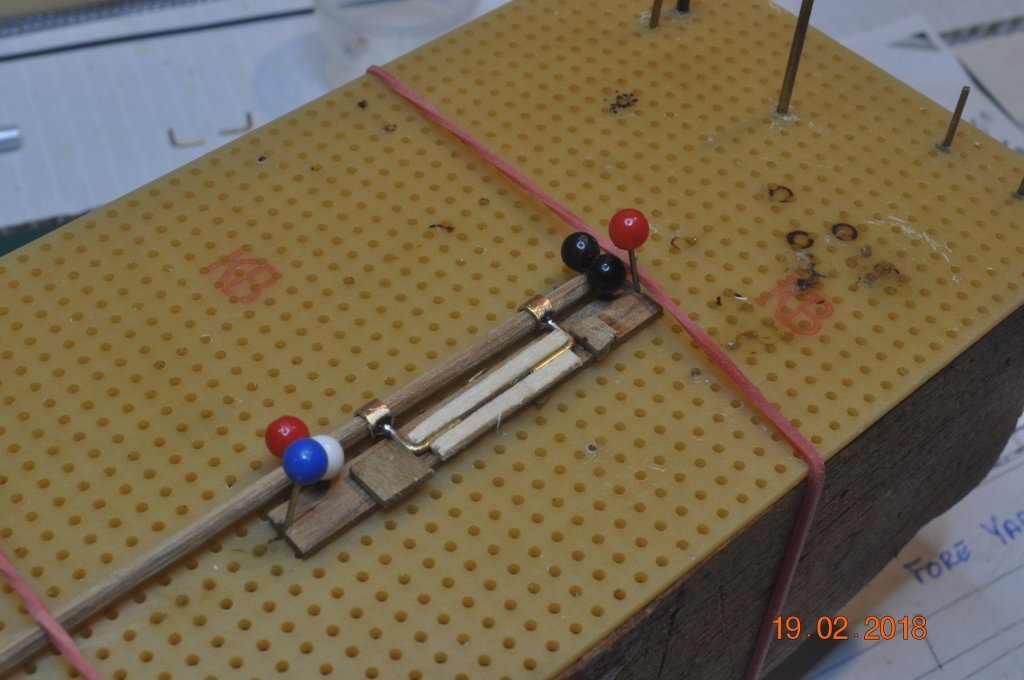

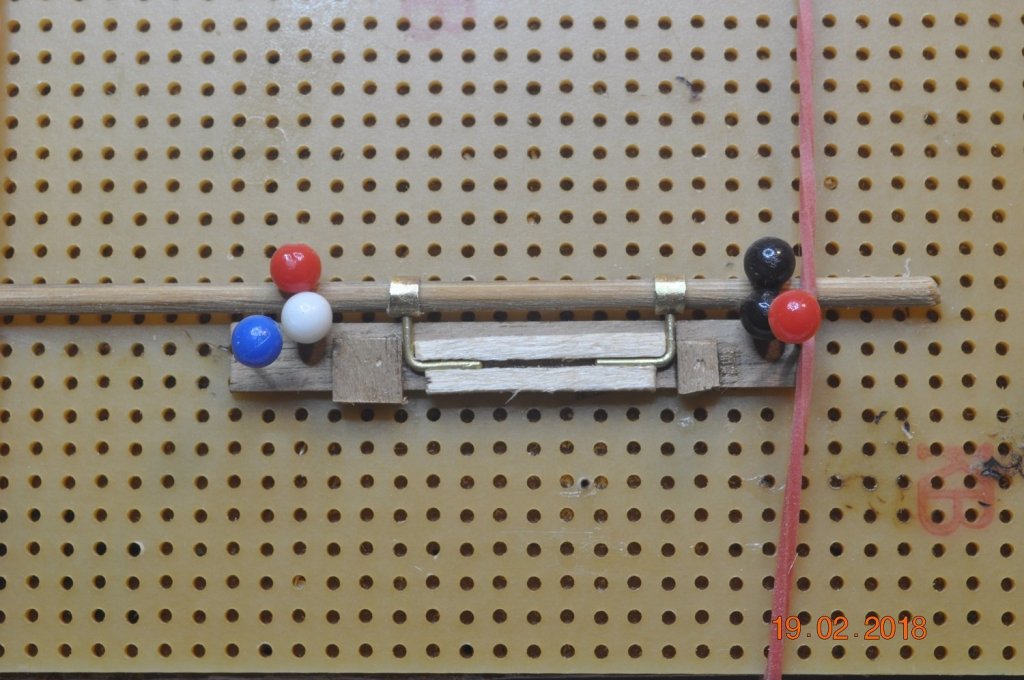

Shipyard Update: Fore Yard: Completed the Fore Yard a while ago. A few pictures of the final below. Well underway with a brass rod to set the length of the horse stirrups. Working at the Commonwealth Games at Gold Coast, so not much happening in the Boat Yard.

-

HMCSS Victoria 1855 by BANYAN - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi Pat, The Funnel came out very well for 3D printing. Impressed I am. The printed surface, as you have found looks smooth, but rippled with the layering of the filament. I've bought small diameter nozzles to install on my 3DP, aim is for thinner layers > smoother finishes. All learning on this method. Cheers- 993 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

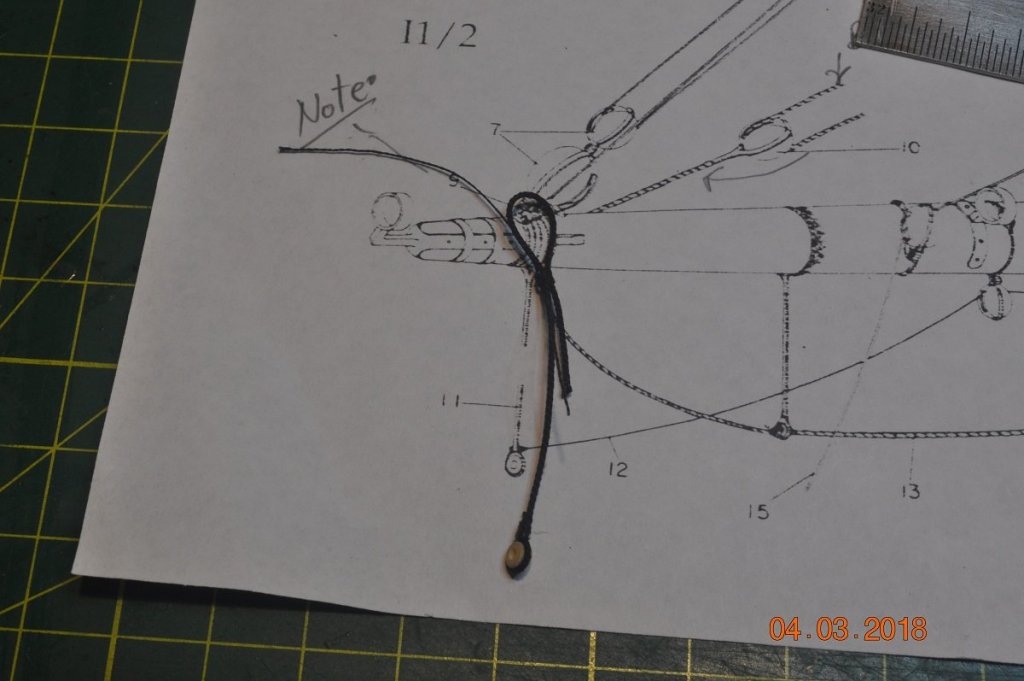

Shipyard Update: Main Yard Blocks: The shipyard has been working on the Main Yard, busy selecting the blocks, adding the rope work to each, then secure to the yard. Picture below of the Yard to date. Nearly ready to add to the Main Mast jeers and hoist away. Parrel and running ropes to add. Above: Main Yard; 12 single blocks, 2 double Jeers, 4 twin(2 blocks each) and 2 Pendant/thimbles. I actually have made all these blocks at the same time for the Fore Yard. Each loop tightened once in position on the yard. Yard Starboard end: Lift Block (4mm) & topsail sheet block (5mm) stropped together on top. Yardarm tackle pendant hanging from the end. Brace Pendant Block (5mm) on the far side. 1/3 length of the yard. Start of the Horse with stirrups wrapped 3 times around the diam. Outer tricing block (3mm) Leech/Buntline blocks (4mm) 1/4 way/point on the yard Yard Middle: Pair of Double Jeers(7mm) on top. Yard Block (4mm). Topsail sheet block (5mm) with Quarter block(3mm) stropped below the Jeers. Yard Port end; same as Stb. end And some detail shots of the blocks being made: Lift Block & topsail sheet block stropped together. 2 each for Main & Fore. Yardarm tackle pendant, 1/4 length of the yard. Quarter block with topsail sheet block stropped under. Onto the Fore Yard next.

-

HMCSS Victoria 1855 by BANYAN - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Lucky you. I've cracked the G Code, read up on how it works and adjusted it for my printer startup. I use "Simplify3D" to send the commands to the 3D Printer. So many settings in the program to fine tune the output, one can spend hours testing. Hope the Capstan turns out well.- 993 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

I will be waiting to see how it turns out from the 3D printer Pat. Did you buy a printer or you using a service ?- 993 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Poor Man's Lathe disasters

DaveRow replied to stevenmh's topic in Modeling tools and Workshop Equipment

Hi Steve, To add my experience of lathe work, esp. with small diameters. The dowel in the picture you originally posted(above), exhibits a twist in the longitudinal direction. This in MHO is caused by too much torque, either at startup or even when the motor is suddenly powered down at end. Meaning their is not enough dowel diameter to resist the rotational(torque) pressure on the dowel. A variable speed motor I have read should be used at startup to slowly rotate the work piece up to speed, then slowly reduce at end. I had several disasters after shaving down to a couple of mm. But my Lathe does not have a variable speed motor. -

Shipyard Update: Thanks for looking in on the progress fellow shippy's. Mast Yards - Parrels: I decided to create a smaller Parrel set for the smaller masts. The 10mm set seemed too big to wrap around the Main, Fore & Mizzen TopMasts and outer Bowsprit yard. Below is a 7mm version 3D printed in wood filament, with small 2.4mm brass trucks(balls). Above is straight off the bed of my 3D printer. I still get a drag of filament between each item, but it is easy to trim off. The back(the sacrificial bottom layer) just peels off. A few little holes, but a sand, stain and at the scale you don't see it. A Jig to hold the Ribs whilst the holes are drilled as before. A trial Parrel set made up. Ribs ready to drill at the bottom. 7mm Parrel wrapped around a 6mm dowel. Same 7mm Parrel around a 6mm dowel. Lots of blocks, ropes to go now.

-

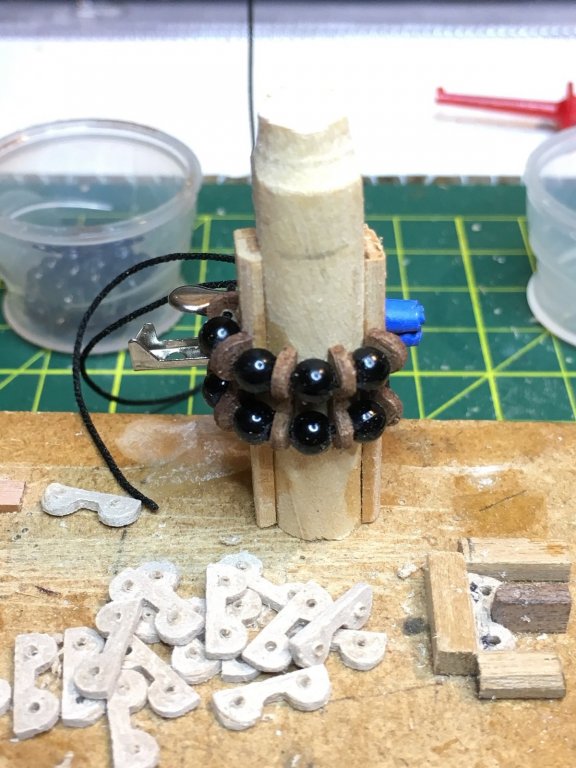

Shipyard Update: Mast Yards - Blocks and Parrels: A bit of an update the the Yards. Above are the 11 Yards with the various Tye & Stop cleats, Ferules on the ends, and the main & fore fitted with boom irons. I decided to paint the central areas Matt Black and the outer ends with a cedar wood stain. Next was onto the blocks, ropes and Parrel fit-out to the various Yards: What has taken a lot of time, was working out the sizes of the many blocks. Being my first model of this nature, learning a lot along the way, making it up as well... Many resources have detailed pictures and rope sizes, my kit plans were again useless again in this area. The AoTS indicates with scale the various attachments. Using David Steel's Rigging Tables, I hope I have worked out the block sizes to use. Jeer Blocks: I started with the Fore Yard Jeer blocks - 2 x 7mm double(7mm because this was the size I used for the mast blocks) Double strops derived from a trial fit around the mid section of the yard. One completed. 2 Jeers on the yard, temporary fit. The Parrels: My kit did not have any Parrel parts. Define parrel: a rope loop or sliding collar by which a yard or spar is held to a mast in such a way that it may be hoisted or lowered. I noted in Pay Banyan's log, Steve had dropped in a Parrels page from "The Anatomy of Nelson's Ships". The Ribs being 2' long and 8" wide. At 1:60 equates to !10mm x 3.4mm in frame size. 2" tick ~ 0.84mm Why not use my 3D printer with wood filament to create the Ribs. I won't go into the process, however printed 3 sets of Ribs, shown above. They are a bit rough on some of the edges, but after some sanding come up quiet well. Above the Jig for drilling of the rope holes. The top Rib is not formed well, so used as a drill template. The black beads(for the trucks) are 4mm dia, a bit larger than I wanted, and not oval as in the Parrels page from "The Anatomy of Nelson's Ships". However make use of what one has on hand. Above shows: 1. To the right a jig for drilling the 2 holes for the rope to pass through. 2. In front, some Ribs sanded and drilled. 3. Each Rib I stain and later will clear coat. 4. A test setup of the Parrel on a mock-up section of Fore-mast At this scale, all the little errors disappear. I am concerned though the scale is a wee bit too big, may be fine for the Main and Fore Yards. Might need to scale the set-up down for the smaller yards. Lots more thought to go into all this yard rigging and fit-out to go on with....

-

Love the detail you go to Ed. Masterclass effort.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

DaveRow replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Hi Pat, Thought I'd take break from my build and see what is going on elsewhere. The painted hull is looking great. How are you going to build the Capstan ? any 3D printing involved ? I'm jealous of a trip to the UK, visiting a number of the maritime museums. Something on my bucket list.- 993 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Hi Rob, Nothing silly going on hear. I use a Resistance welder, an American Beauty Super Chief 250, adapted to 220v for AUS. Works differently to a Soldering Iron(where the area around is heated up). Pat(Banyan) from Melbourne put me onto this system. Imported from USA to AUS. Not cheap. The 2 prongs(on the hand piece) heat up the area between the prongs in a flash(like in a micro second), and applying/regulating the amount of lead/silver solder creates the joint. Takes a bit of getting used to, however I am so impressed how fast it makes the joint/s. The system I have above. Kit from www.americanbeautytools.com Best results I find setting the parts up in a jig, flux the joint where I want the solder to end up. Touch the ends of the prongs to either side of the where you want the soldered joint. The current is via a foot peddle(like on a old Singer sewing machine) to activate the electrical current to the hand piece/prongs. I first starting using the resistance welder in March 2016. See my posts about that time for more info. Pat has info on his Endeavour build as well. Hope you don't mind Pat for the ref... And the type of lead/silver % solder makes a difference as well. Hope that all makes sense.

-

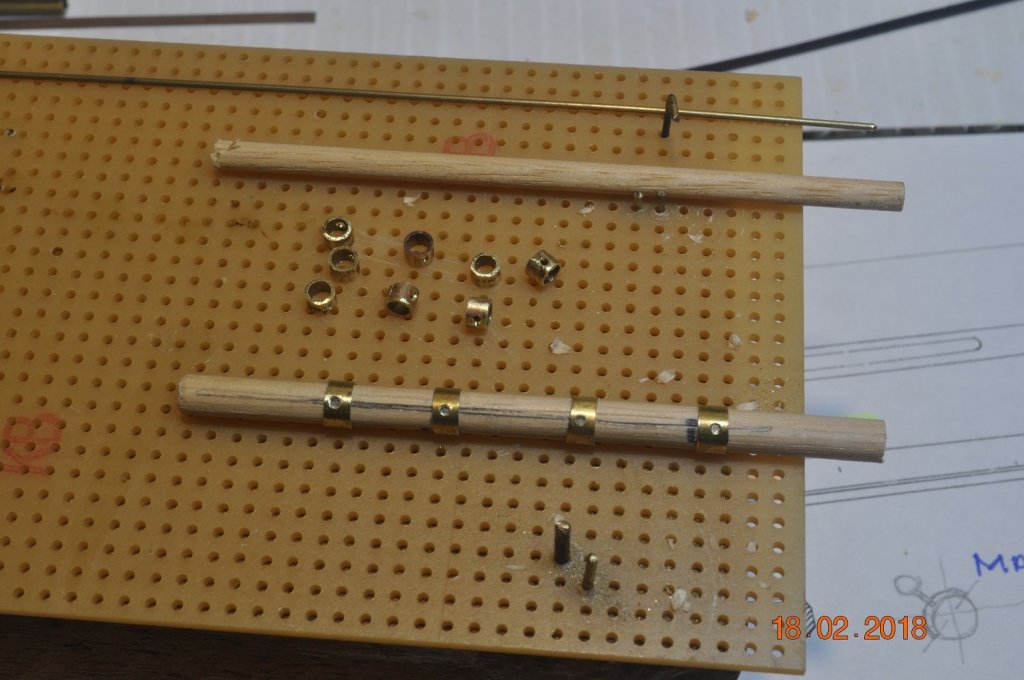

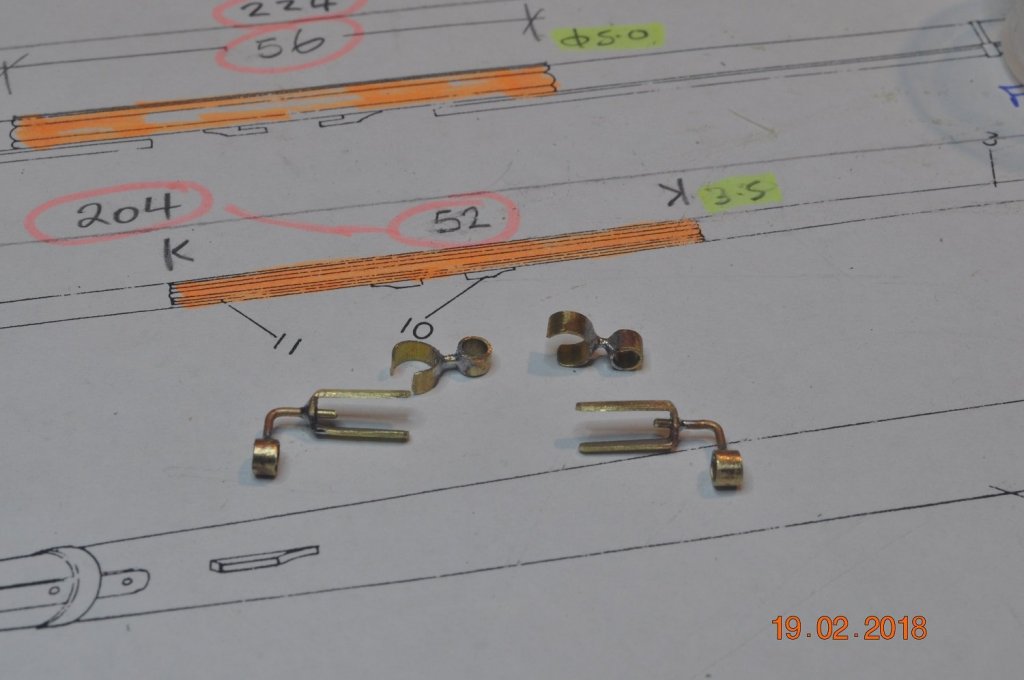

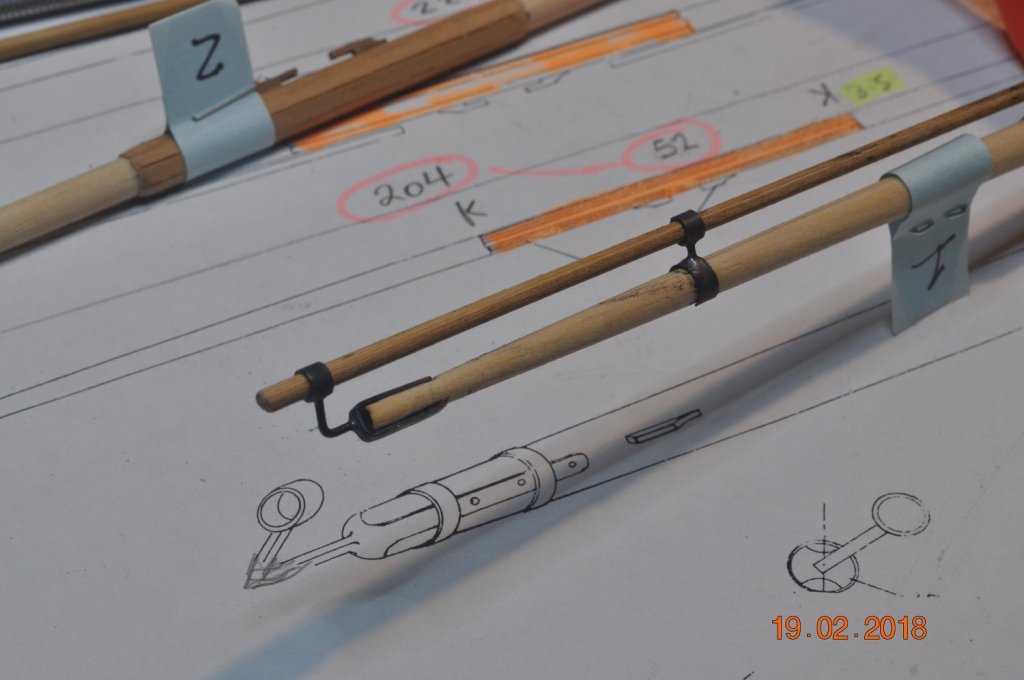

Shipyard Update: Mast Yards - Studding-Sail Boom Irons: The Main and Fore Yards have Boom Irons fitted to hold the Studding-Sail Booms. Above are the Inner & Outer Boom Irons fitted to one end of a Yard. The parts and process: INNER BOOM IRONS: Two(2) sizes of brass tube were cut to make rings, 1 for the Rings(for the studding-sail boom to slide through) and the other for a collar onto the yard itself. 0.8mm bar was used for the neck to join the rings to the yard. According to "Dave Steel" the neck was a square bar, which I did not have. Rod instead. Each ring and collar has a hole for the neck rod to fit into. I made a jig to hold the 3 parts together for welding the 4 assembles together. Welds complete. OUTER BOOM IRONS: On the end of the yard/s a same size Ring, 90deg. neck and straps are fashioned. Another jig top to weld a pair of rings/neck bar for consistency. Set ready to be welded here. After welds done. Above are the 4 Boom Irons for 1 yard, removed from the yard ready for blackening. Test assembly on 1 end, blackened boom irons fitted. 2 hoops to fit over the end straps.

-

What... your not chopping the hull up into sections like the real deal ?? Looks like another great job ahead for you.

-

Thanks Pat, I realized after reading Dave Steel - Mast Making section last night, the yards with battens in the middle, the stern/rear batten should be longer. Will anyone notice once they are painted black ?

-

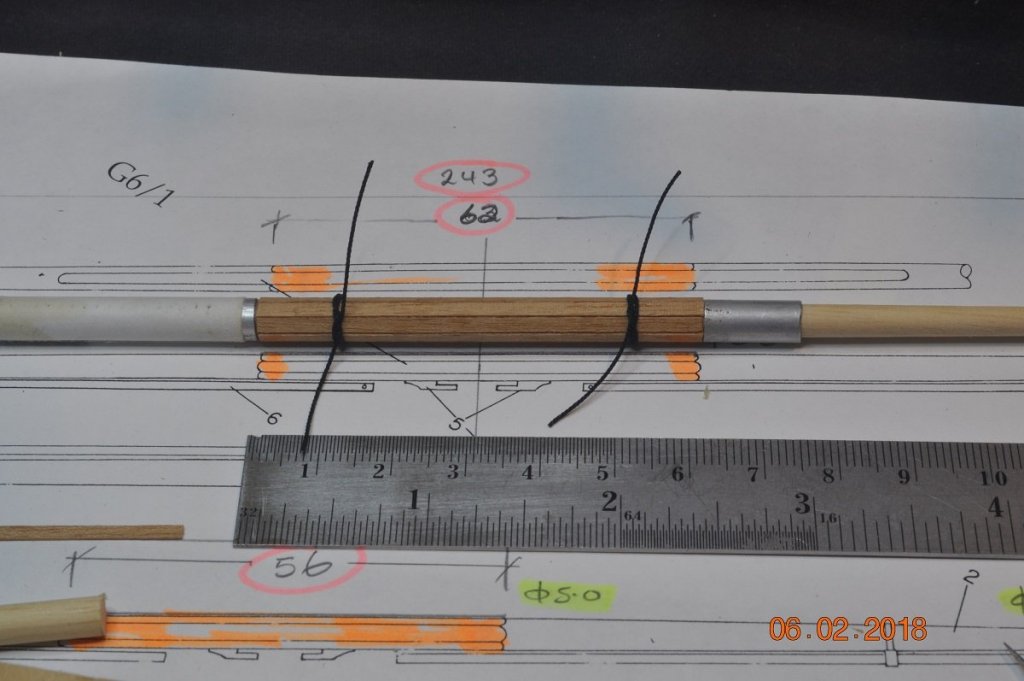

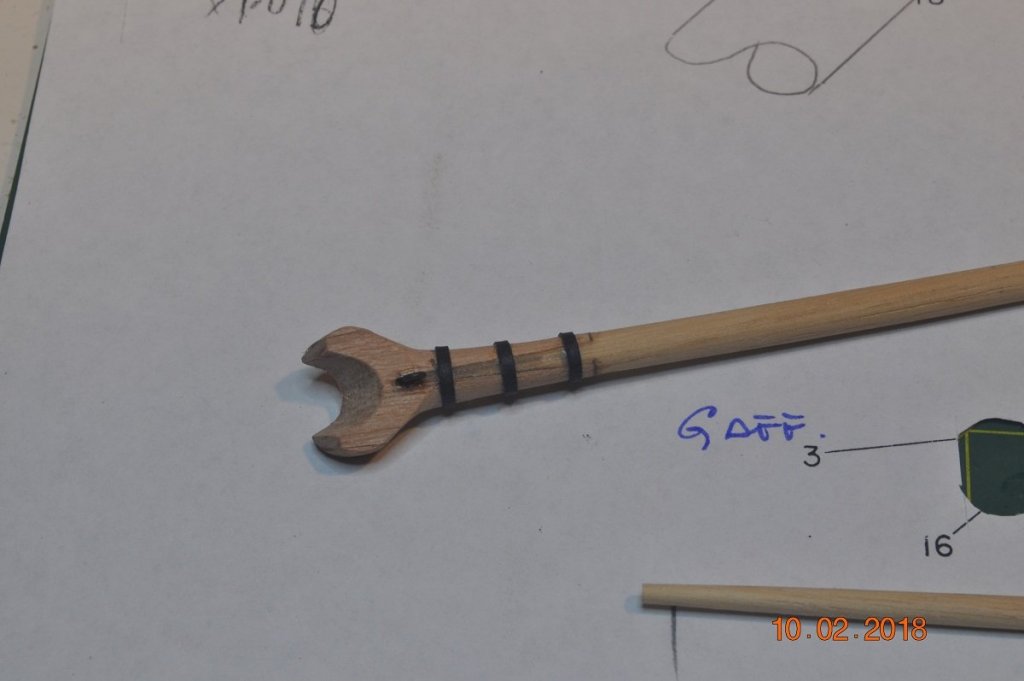

Shipyard Update: Yards are on the build: We're underway making the yards. All(11) of the Lower, Top-sail, Top-gallant, Spirit, Spirit-topsail & Gaff(off the mizzen) Yards on their way. I added a block to shape for each of the Stop cleats and Tye cleats. Yet the construct the outer and inner boom ironwork. Next task. How I added the battens to the mid sections of the Lower & Top-sail Yards. I used a section of Aluminium tube to square of either end - before round sanding the batten edges. I shaped a dummy mast section to shape the jaw, for a snug fit. Couple of pictures of the lower end(jaw) of the Gaff, scarf joint with hoops(a wrap of thin black card). Detail as per AoTS p93 Next to fashion the Boom Ironwork for the Main & Fore Lower Yards. Must ensure the hoops face forward(eh Pat !) for the studdingsail booms.

-

You've crafted a nice collection there Greg. Love the paint-jobs and detail is amazing at that scale.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.