-

Posts

2,482 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JSGerson

-

-

If you look closely at Mustafa’s model. His stanchions fit into holes drilled into the top of the hatchway walls. For what ever reason, the walls on my hatchways ended up being too narrow to drill holes for the stanchion poles. To support the stanchions, I decided to use brass brackets on the inside corners of the hatchway. Hopefully these would provide sufficient physical support and glueing surface to hold the stanchions in place. Making the brackets was simple but installing them was a little tricky. Due to the installed beams, the most forward hatchway was the most difficult to access. My fingers were too fat to fit between the beams, so I had to do everything with tweezers. I couldn’t use CA glue because I couldn’t get the bracket into position, hold it there, at the same time applying minute drops of CA glue. PVA glue allowed me to stick the bracket in close vicinity of where it needed to be and maneuver it into the proper position (still not easy). Once it dried, then I could add more glue for proper strength. Once the brackets were in place, then the stanchion could be set into them. This was a time-consuming process because I had to wait for the glue to dry solid before I moved on to the next step. I also made a stairway plug to prevent anything from falling to the hatchway, like a loose bracket. Once anything fell in, there was no way I could get it out. It was a black hole.

- Stevenleehills, JeffT, mtbediz and 2 others

-

5

5

-

What to do? So, for my second attempt, I messaged Mustafa (mtbediz), the man who inspired me to do this over again. He very graciously gave all the details which I followed with some minor modifications.

First, He used exclusively 0.8 mm brass wire, but I stuck with the 0.81mm music wire for the stanchion for reasons mentioned above.

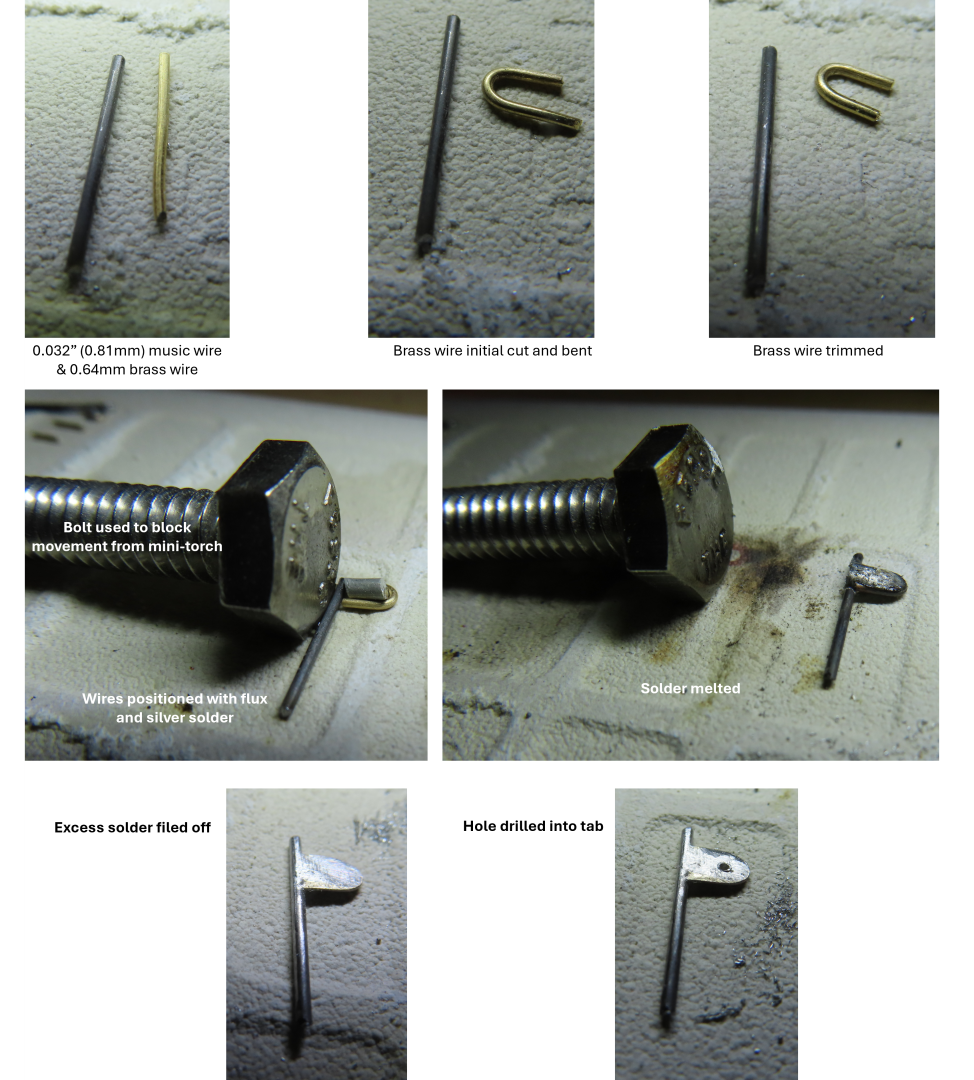

He used a short piece of 0.81mm brass wire to create the rope tab. I used a short piece of 0.64mm brass wire which was cut and formed into a U-shape like he did. It was trimmed so the ends were even and placed near the top of the music wire piece like a flag with the open ends of the brass wire touching the music wire.

Mustafa used lead solder paste (I believe) to fill the interior of the “flag” and secured the two pieces of wire in place with metal weights. I had silver solder paste but found mine wasn’t sticky enough to stay in place when I tried to fill the “flag” void (paste too old?). As a result, I used soldering flux and silver solder wire. The surface tension of the flux held everything in position. It was backed up with a bolt so it wouldn’t move during the heating process.

To heat the assembly so the solder would melt, Mustafa used a heat gun which I don’t have. I used a mini-butane torch which worked quite nicely. The excess solder was filed off and a hole was drilled through the solder without any problems. The stanchion were painted black, threaded with miniature rope.

- Nirvana, mtbediz, Stevenleehills and 2 others

-

5

5

-

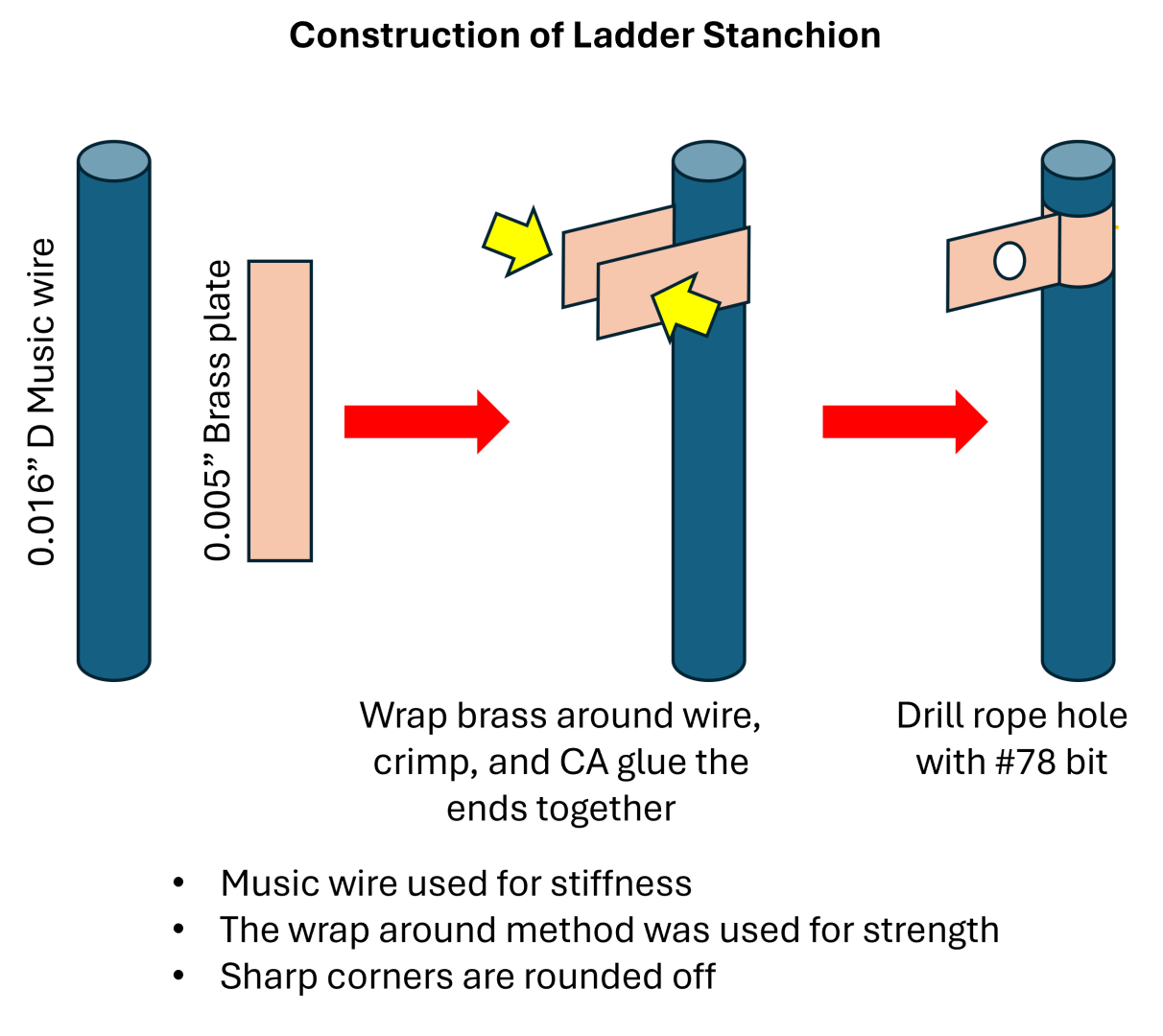

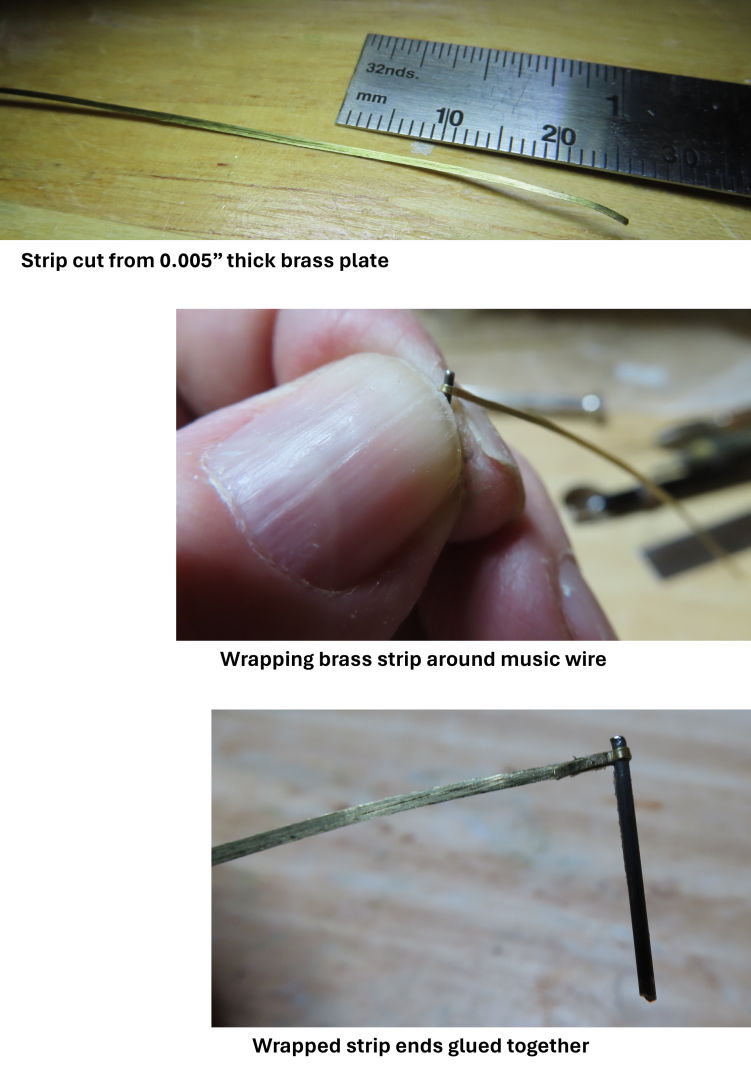

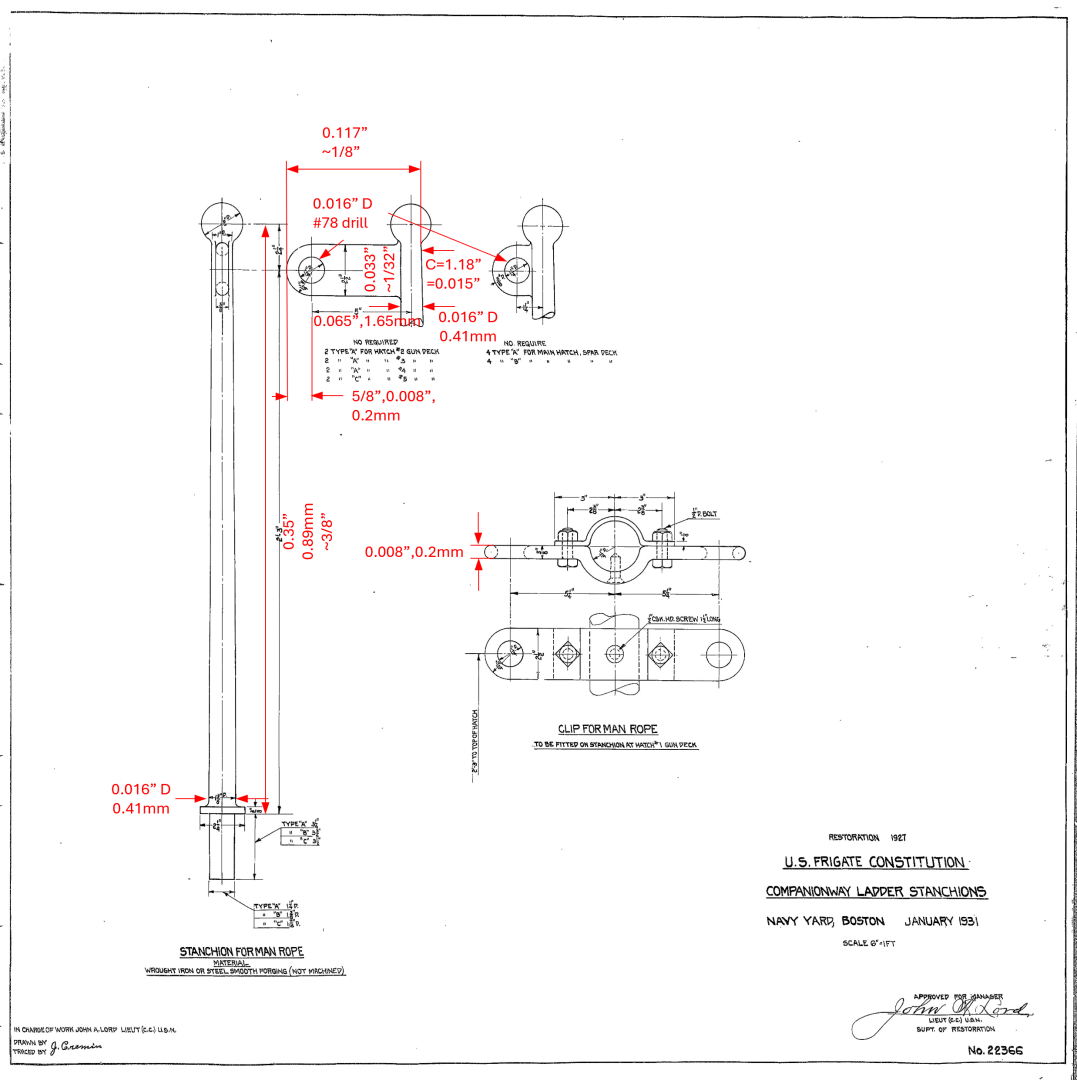

So, I chose 0.032” (0.81mm) music wire for the stanchion because it won’t bend with normal handling. For the rope tab, the idea was to wrap a 0.005” thick brass strip around the wire and then glue the ends together to form the tab. Lastly, drill a hole in the tab with a #78 drill bit to create a rope hole. Everything went according to plan…until it didn’t. For the life of me, I could not create the rope hole. My drill bit bent if I applied any pressure. (Cheap bits, I don’t know?) I tried creating a dimple into the brass with a needle for the bit to bite into, but all that did was deform the thin strip. I even tried using a very fine cone shape grinding bit but couldn’t keep it perfectly centered on the brass strip. It would drift and eat away one side or the other of the strip making the strip useless.

- JeffT, Ryland Craze, Nirvana and 3 others

-

6

6

-

Waaaaayyyyy back in July 2018 when I was first installing ladders from the gun deck down to the pseudo berth deck level, I made and installed the associated ladder stanchions and hand ropes. They didn’t last long due to my inadequate fabrication and installation skills; and they were being battered about by handling the model installing other stuff. Well, due to my admiration and inspiration of Mustafa’s (mtbediz) fine workmanship of his model, I’m giving it another go. If I’m going to do it, it must be now before the gun deck becomes too inaccessible for this detail.

My first attempt, I tried to maintain the scale based on the US Navy’s plans and I wanted my stanchions to be robust enough to handle any jarring due to my manipulation of the model.

- Ryland Craze, JeffT, mtbediz and 2 others

-

5

5

-

After I finished my Rattlesnake (Hunt practicum), I wanted a change of pace before I started with the Constitution. I decided to work on the Conny's boats first. They were a lot of fun and you can load them up with as much or little (especially if you're going to cover them when they are finally installed on the ship) detail as you want. I relied a lot on the US Navy plans for the details. Surprisingly, the MS plan details were very close to the US Navy's. They were like eating potato chips - "you can't just eat one."

Jon

-

It's beautiful. You should be proud of yourself. Well done!

Jon

-

-

I saw your comment to mtbediz today and thought I would give a welcome aboard from a bunch of us USS Constitution active builders. We've been sharing our knowledge and comments with each other and we range from beginner to the more experienced. Although, as near as I can determine, there aren't many Mamoli builders for the Conny at present. There is one active (last post in January) builder, Oscardeuce and an excellent builder, Bill Edgin (Robnbill) who completed his Mamoli kit in 2021 that you might want to check out as you work on yours.

Good luck and have fun

Jon

- Bill Morrison, Gregory, mtbediz and 1 other

-

4

4

-

-

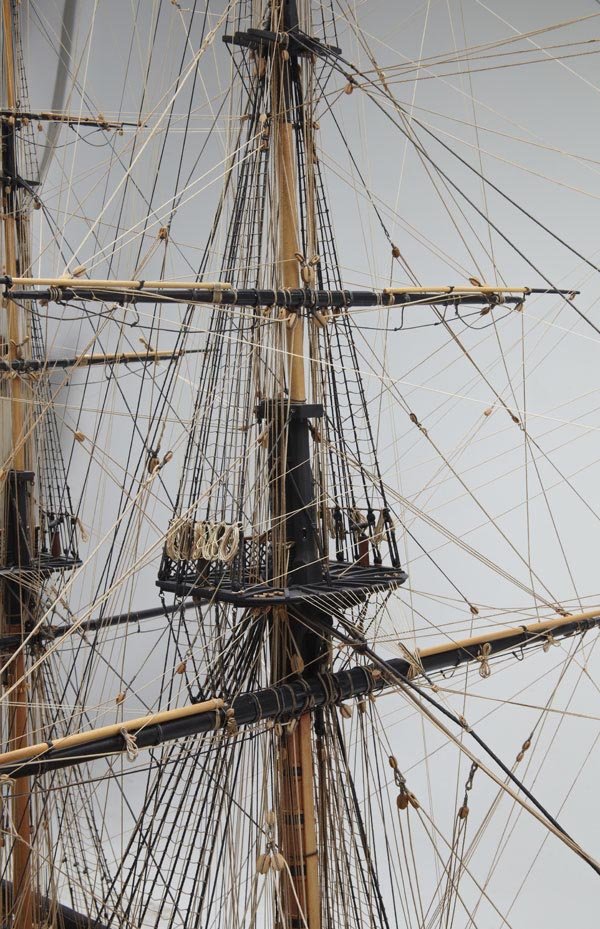

Peter, I found the images of this model by Mark Antczak on Shipmodel.com, a company that sells boat models. Unfortunately, this model is not displayed any more at this site. However here is a limited blurb about this model from this Shipmodel.com at the time I down loaded the images:

QuoteOne of Mark Antczak’s greatest achievements was his ¼” scale (1:48) full hull model of the USS Constitution completed in 1990. This model was on display in the Carew Tower Arcade and the well know Exactitude art gallery in Cincinnati. It was acquired by a local business man, but was subsequently put on loan to the Maine Maritime Academy in Castine, Maine where it was displayed for a several years.

I will post the seven addition photos of this model that I have on your blog so as not to intrude too much on Mustafa's beautiful instructive blog.

-

-

When in doubt with fillers between bulkheads, do more than less. It can't hurt to have extra filler.

Jon

- Scottish Guy and SUBaron

-

1

1

-

1

1

-

Quote

Workspace

I’m curious about the work/hobby stations folks use. I’m fortunate to have a workspace in the sunroom - it allows me to work and still be sociable. I suspect folks probably like getting some Q/T in a remote shop/space - but I prefer it this way. I do have a vacuum “wand” that I use regularly after whittling and sanding. My garage has the few power tools capable of being utilized for this hobby; Scrollsaw, lathe and an old Central Machinery combo 6” belt & disk sander.

Here is my work area. It's the "bonus room" above my garage. What is seen in the photo is about 1/3 of the room. My major power tools are my Byrnes saw, Byrnes thickness sander, 50 yr year old Dremel scroll saw (very noisy and vibrates), and a small wood lather which are in the garage. You may also notices my astute "assistant" sleeping on my chair who periodically allows me to sit there and work.

-

-

Getting back to the gun rigging, I decided to plunge in and complete the rigging once and for all. I just wanted to get it over and done with. Adding 22 fully rigged guns was no simple task. I made the following calculations and was staggered by what it revealed. From start to finish, adding eyebolts to the interior of the gun deck, to fabricating and assembling the gun trucks, and then rigging them, I got the following numbers:

There are 235 separate parts per gun port or 5,170 parts for 22 fully rigged guns not counting brass blackening, painting, and do-overs. Most of these had to be fabricated from scratch. That breaks downs as follows:

Gun & Truck = 26 pieces/gun = 572 pieces total

Item Quantity

Gun 1

Sides 2

Axials 2

Wheels 4

Transom 1

Breast Piece 1

Quion 1

Quion Handle 1

Quion Bed 1

Trunnion cap 2

Eyebolts 8

Rings 2

Gun Ropes (including excess waste)

Ropes/gun: 10 cut pieces/gun = 220 pieces of rope total

Recoil Rope. 1-6” piece 0.030” (0.76mm) dia./gun x 22 guns = 66 pieces = 132” = 11’ = 3.6 yds total

Tackle Ropes w/coils 7” piece 0.018” (0.45mm) dia. + 1.5” (for double block)/tackle + coil = 8.5”/tackle + 1 rope coil x 3 tackles + coils/gun” = 7 pieces of rope/gun = 3 Tackles +3 coils/gun @ 25.5”/ gun = 154 pieces of rope = 561” = 47’ ~ 16 yds total for 66 tackles + 66 coils = 3,388 pieces total

Rope Seizings/gun: = 21 rope seizings/gun = 462 seizings total = 3 yds thread total

Recoil rope seizings 6 seizings/piece = 24” of thread = 2’ total/recoil rope

Tackle seizings 5 seizings (@4”/seizings) /tackle = 20” thread/tackle rope

3 tackles/gun = 15 seizings = 5’ thread/gun = 3 yards thread total

Note: rope coils made from excess rope and supplemented with additional rope

3 Tackles/gun = 6 blocks/gun = 132 blocks total

3/32” Single blocks 1/tackle @ 3 tackles/gun =3 blocks/gun = 66 blocks total

3/32” Double blocks 1/tackle @ 3 tackles/gun = 3 blocks/gun = 66 blocks total

Block hooks 6/gun = 132 hooks total

Gun Ports = 12 parts/port = 222 total

Eyebolts: 10/port = 220 total:

Recoil Rope eyebolts/port 4 = 88 total

Tackle double eyebolts/port 2 = 44 total

Idle eyebolts/port 3 = 66 total

Deck tackle eyebolt 1 = 22 total

Recoil rope bulkhead pins 2/port = 44 total

All gun deck guns are now rigged!!! Whew!!! As I promised, an OSHA nightmare.

-

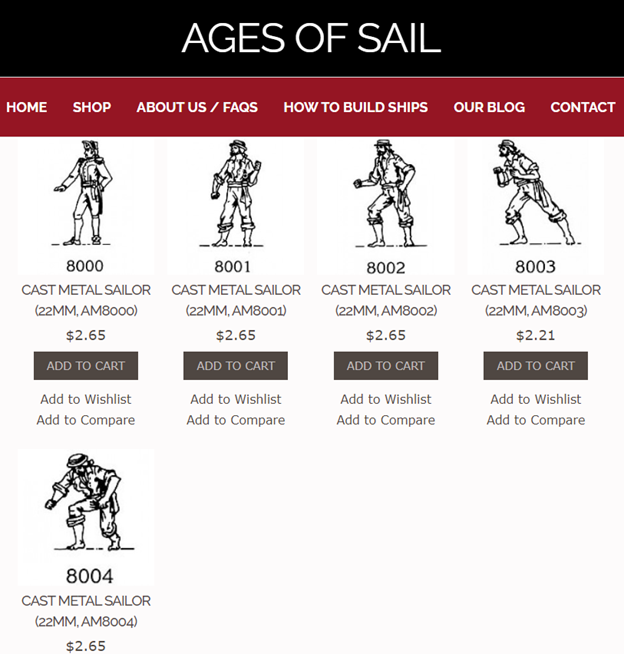

While continuing to work on rigging the guns, I took a diversion from this tedious task and once again went looking for figurines to be placed on the model later to add some scale. I added figurines to my 1:64 scale Rattlesnake which I finished in 2017 which worked out quite nicely and I want to do the same thing with the 1:76.8 Constitution which I started in 2017, but I’ve had no success finding any suitable figurines.

For a typical 5’6” (165cm) tall man, I needed something around 0.841” (21.34mm) at scale. I was seriously considering modifying HO train figurines when I finally found five 22mm 18th (?) century sailor figures at Ages of Sail. I’ve checked this site before numerous times and even got the 25mm figurines for my Rattlesnake (1:64) from them some 8 or 9 years ago, but I never saw the 22mm ones until now. Strangely enough, the two sizes do not have the same figures, and are totally different from each other. Still, I immediately bought all five and it may be years (at my rate of speed) before I’ll need them. Who knows how long they will be available?

- mtbediz and Stevenleehills

-

2

2

-

- Stevenleehills, MajorChaos, SUBaron and 2 others

-

4

4

-

1

1

-

-

I grew up in the Boston area and left to follow the paycheck in 1977, but I was fortunate to have visited the Constitution a couple of times before I left. I now reside in South Carolina where the paychecks ended, and I retired. My last visit to the ship was in November 2015, just before her last restoration which ended in 2017. I have mentioned in several other builders’ logs, that I had been collecting photos of the ship starting a couple of years even before started building the model. They range from the very earliest images (1857) to the present. Obviously, most of the 4,000 odd images I have, accumulated from a variety of sources, are not of the post 2017 restoration. The few photos you posted of your recent visit to the ship are wonderfully taken. They are sharp, clear, and well composed. (I was a serious amateur photographer in an earlier life). So, if I may impose on you to share any more photos, it would be greatly appreciated.

If you (or anyone else) need an image(s) of something and can’t find it on the internet, I may have the image you’re looking for. Most times when you put in a search request for “A.” you may also get “B,” or “C.” If they are remotely relevant to the ship, I collect them because should I need to find them later, searching for “B” or “C” may not give me those particular images. Hence, I’ve got some rare or difficult to find detail images.

If I may offer one critique with the photo of painting the waterways, if possible try to make sure you background is unobtrusive. Now I know you are a food and wine aficionado.🤫

Keep up the good work.

Jon

- SUBaron, GGibson and Scottish Guy

-

2

2

-

1

1

-

Now I know, thanks!

Jon

- mtbediz and Der Alte Rentner

-

2

2

-

-

Ok, here's what I got. The first picture is a "Harness Cask," (I don't know how "harness" is defined on a ship) the second is the "Grog (watered down rum) Tub," and the third is the "Scuttlebutt" (contains water). I do have US Navy plans of the scuttlebutt and the harness cask should anyone want them.

Jon

- SUBaron, mtbediz, Stevenleehills and 3 others

-

6

6

-

She was deployed October 21 1797.

- mtbediz and Stevenleehills

-

2

2

-

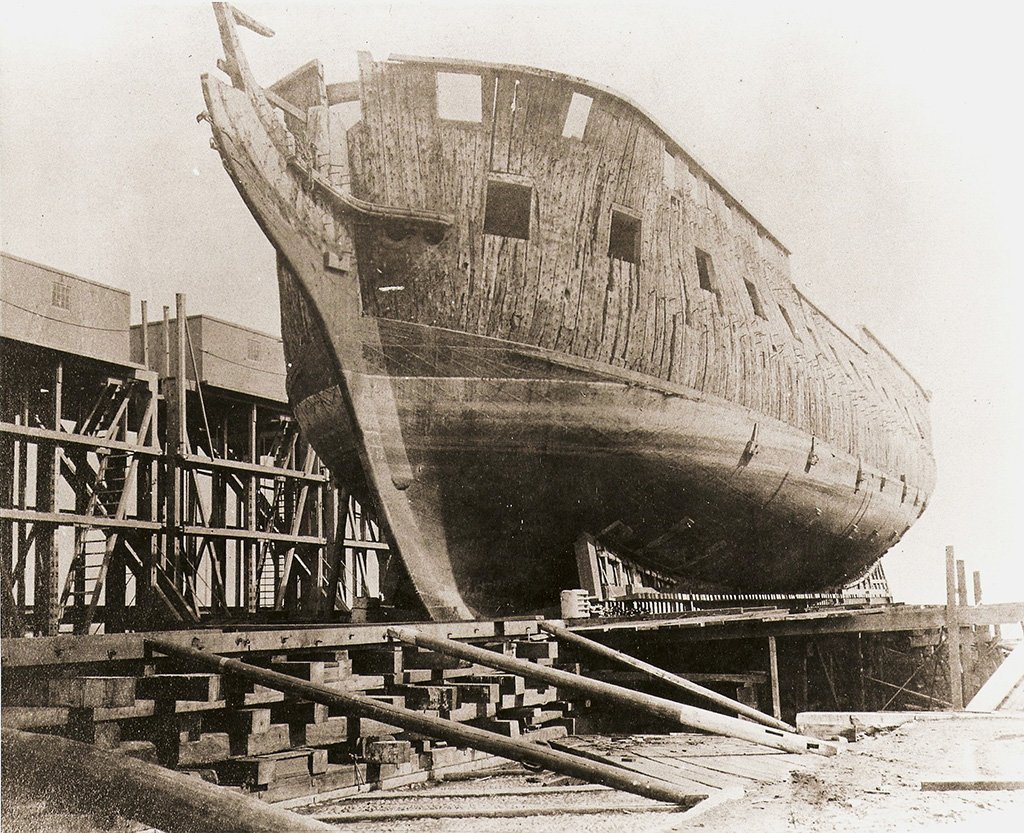

I'm not surprised those auxiliary beams inside the ship obscure the gun deck view. This war ship, although made of wood (obviously), was built to take punishment. If you look at the photo below from the 1873-77 restoration, you can't even see inside the ship with her hull planking removed. The hull frames were so close to each other, the ship looks solid. To take a phrase from an old Timex watch advertising slogan, "it takes a 'licken' and keeps on 'ticken,'" No wonder they called her "Old Ironsides."

Jon

- GrandpaPhil, SUBaron, mgatrost and 2 others

-

5

5

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

in - Kit build logs for subjects built from 1751 - 1800

Posted

The stanchions were stung together with 0.12” (.30mm) black rope prior to installation so that I wouldn’t have to thread them on the model. Mustafa used tan rope which I must admit looks great, but the real ship uses black rope; but it doesn’t have the visual impact like the tan. So be it. It was slow, tedious, tricky, and time consuming That one stairwell down, six to go. Hopefully these will get installed quicker.