-

Posts

2,170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JSGerson

-

-

-

- Blue Ensign, Jack12477, Martin W and 3 others

-

6

6

-

Also at that time, although not documented in this build log, the fabrication of the sling that suspends the Spritsail Yard from the bow sprit was initiated.

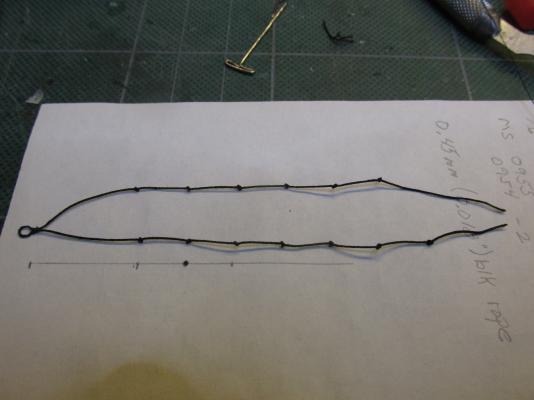

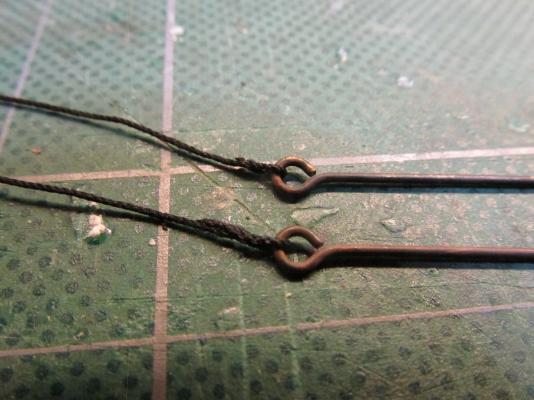

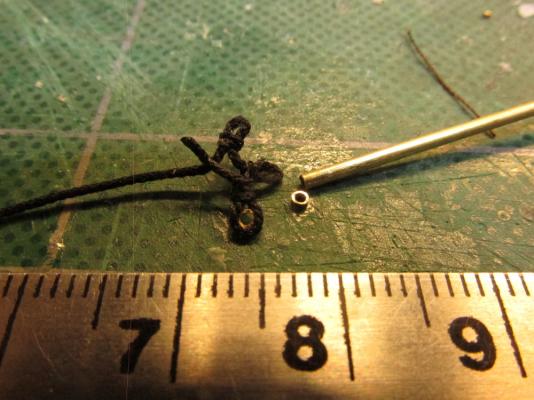

Basically what was done at the time was to serve a length of 0.40mm beige rope supplied from the Mamoli kit with black thread rendering the rope black in color. (No use in using my fine Syren rope if it’s to be covered in served line.) A seized loop was formed at one end, wrapped around the center of the yard and seized again to itself.

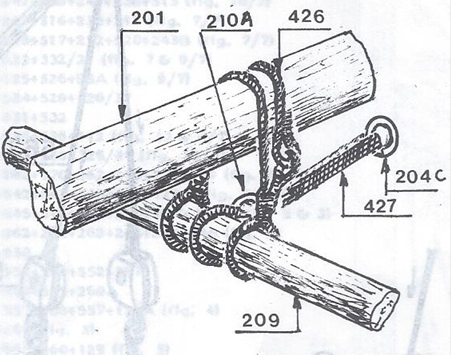

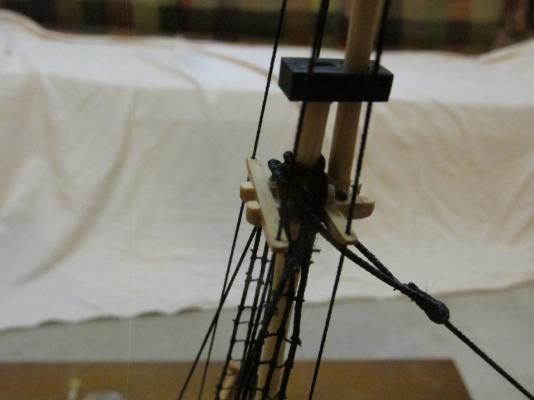

Coming back to it a year later, I realized that the loop was too bulky and large so it had to be done over. Using the technique demonstrated by Davis Antscherl at the last Nautical Research Guild Convention, I created a split loop which was smaller and a lot less bulky. Again the loop was seized to itself, wrapped over the bowsprit and under the yard and back where it was seized to itself, over the bowsprit again and through the initial loop and back. It was then seized to itself one last time. (No. 426 in the diagram below) Let me tell you that was no mean feat. Trying to thread the sling lines around the existing lines as well as the seizing thread lines without getting lost is enough to make you cross eyed!

-

Spritsail Yard

Well, I’ve hit another milestone: the installation of the first yard on the model, the Spritsail Yard. If you may remember so long ago last October 2014, both the Spritsail Yard and the Spritsail Topsail Yard were completed and set aside.

- GuntherMT, CaptainSteve and Martin W

-

3

3

-

I know exactly how you feel Greg. Take a look at the second paragraph of my very first post for my Rattlesnake:

Jonathan

- CaptainSteve, thomaslambo, GLakie and 1 other

-

4

4

-

It's been a while since I last check in on you. Your model looking good. I thought I should point out to be careful about your gun port doors. I would have recommended that you install those at the last convenient point your could. I had all but one of my doors knock off during routine handling of the model. I won't put them back on till I feel I won't knock them off again or if I feel putting them on later would be harder.

-

Maybe I can answer that question for you Ken, per the instructions in Bob Hunt's practicum he states:

Two vital items are needed; a single edge razor blade and some very thin cutting disks. I'm not talking about those fat disks that Dremel makes for their Dremel tool. I'm talking about wafer thin disks. You can purchase these disks from a company called [Dedeco] International, Inc. Their address is Rt 97, Long Eddy, NY 12760 and their phone number is (914) 887-4840. You will need their super thin separating discs. You can buy a package of 25 (#5173) or 100 (#5183) and they also sell shanks for these thin discs.You might be able to get something like these elsewhere but this is where I got mine.He also states:You use your Dremel tool with the fine cutting disk in it to cut the profile into the razor blade. These disks are very fragile and easy to break so be careful and wear some eye protection.I can confirm, they are very fragile if you apply any pressure on the face of the cutting disc. -

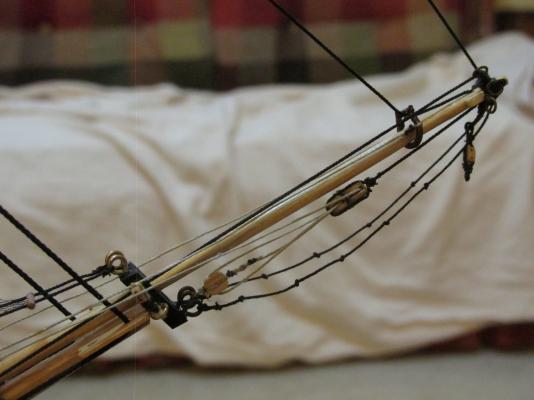

The footropes are supposed to be long enough to hang in an arc. According to Antscherl, the center of the arc is about three feet (~½”) below the jibboom. However, his footropes hang free because his model does not have a Spritsail Topsail Yard. On the Rattlesnake, it does have a Spritsail Topsail Yard which will be suspended in the middle of the jibboom. The plans show the footropes going above the yard. It appears the footropes slide (as opposed to being fastened to the jibboom) over the Spritsail Topsail Yard allowing the footrope to self-adjust as the yard moves along the boom. The footropes were installed with an initial three foot hang. How much they will finally hang down will depend how they drape over the yard once it is installed.

Note the last image of the jibboom tip shows how crowded it gets. I had hoped to show the detail in there, but the black rope just sucks up the light so you can’t see too much.

- CaptainSteve, KenW, Martin W and 2 others

-

5

5

-

- CaptainSteve and Martin W

-

2

2

-

-

-

The horses were further secured on the model to the forestay with a line coming off 90° from the horse. Here I used black 0.20mm Syren rope. They were attached to the horses with a pseudo splice. Since I didn’t know were along the horse it would secured, I left the splice unglued and the line excess uncut.

- Martin W, Jack12477 and CaptainSteve

-

3

3

-

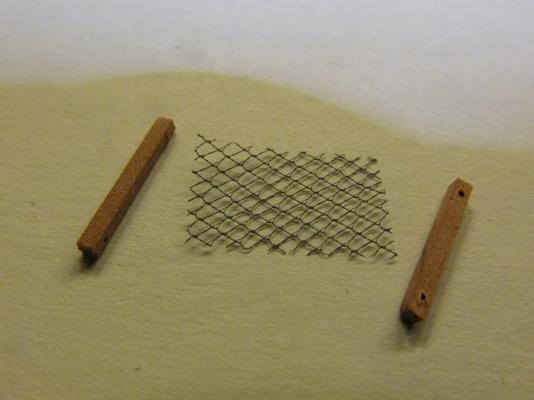

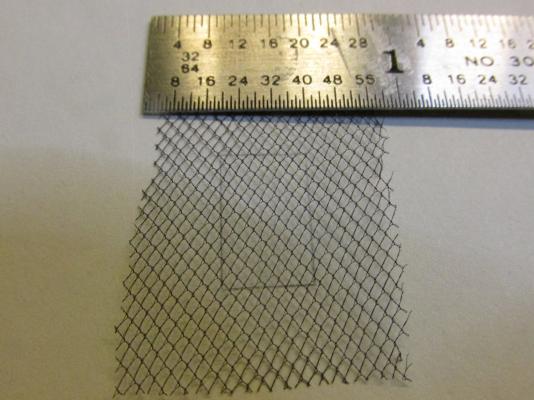

A pattern of the net was drawn on a piece of paper and the tulle was taped down at approximately 45° to the vertical of the pattern. My initial thought was to cut the tulle so that corners of the diamond pattern would form a zig-zag edge. Then I would wrap thread through the edge diamonds and then secure it to the staves and eventually the horses. As you can see from the close-up image above, the material is not just a simple crisscross of thread.

I didn’t have any thread fine enough to come close to the thread in the tulle and what I did have (polyester mono filament thread which came the closest to being thin enough) was very stiff. Trying to hold these tiny parts and manipulate them to conform to what I wanted was like trying to herd a bunch of drunken cats while on crutches…at night. I gave that idea up soon enough.

At this point I went to the Nautical Research Guild’s yearly conference, which this year was held at Mystic Seaport, CT. I had a good time. There, I saw an award winning model (forgive me, but I did not record the model or its maker) with the fore topmast staysail netting. He just glued the net in place. If he could do it, so could I.

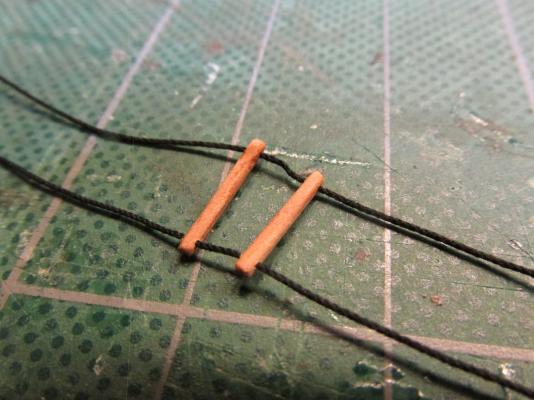

The assembly was taped down and the netting was glued to the stretchers using G-S Hypo Fabric Cement I got from Model Expo. It has the look, feel, and smell of airplane glue, but dries clear and is flexible.

- CaptainSteve, Jack12477, KenW and 1 other

-

4

4

-

- CaptainSteve and Martin W

-

2

2

-

-

Bowsprit Horses and Fore Topmast Staysail Netting

Continuing to follow David Antscherl, now was the time to create the bowsprit horses, and although not shown on any of my plans, the fore topmast staysail netting. The netting is used to store the topmast staysail and is located on the bowsprit horses between forestay and the foretopmast preventer stay. Mr. Antscherl was very clear that the diagrams in Darcy Lever’s The Young Sea Officer’s Sheet Anchor, Lee’s The Masting and Rigging of English Ships 1625-1860, and Peterson’s Rigging of Model Ships¸ were incomplete. They only showed the initial zig-zag construction of the netting and not the final result which was a diamond shaped netting. David went so far as to reproduce this netting for his model; I, being of sound mind and body, elected not to. Instead I bought some tulle in black and off-white at Hobby Lobby. It’s a sheer often stiffened silk, rayon, or nylon net used chiefly for veils. It’s not perfect, but it was all that I could find in my area. Both pieces set me back a grand total 0.30 cents for more material than I will ever use in a lifetime.

-

Martin, I'll be heading out next Tuesday and checking in Wednesday. I'll see you Wednesday or Thursday!

-

- CaptainSteve, Jack12477, GuntherMT and 2 others

-

5

5

-

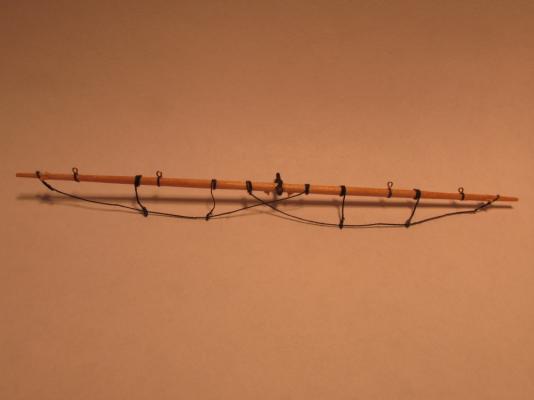

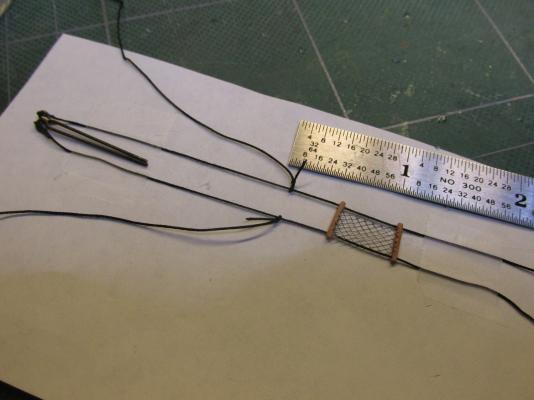

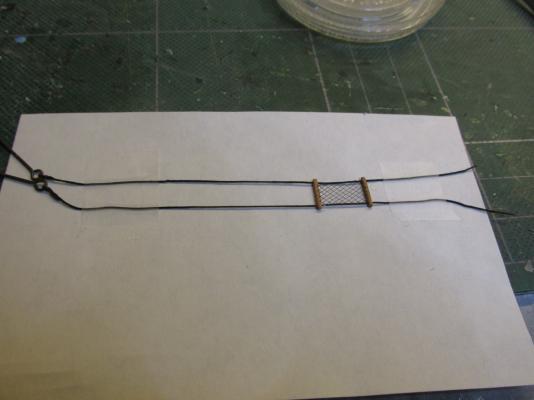

The first to be attached was the block assembly, followed by the double eyelets, and finally the triple eyelets. The block assemble was attached with a loop through an eyelet and pulled tight. The multiple eyelet assemblies had to be installed in steps. In actuality, the rope ends were spliced or lashed together which at this scale was impossible to do. First, an assembly was orientated to the proper position and then a touch of glue was added at the top to hold it in place. The two ends were cut so that they would just meet under the bowsprit and butt together. First one end the given a touch of glue and then the other was made snug and glued into place. The fourth item, the footropes was not added at this time but will be added later. That will be made from thick thread so there is just enough room left to secure it.

-

-

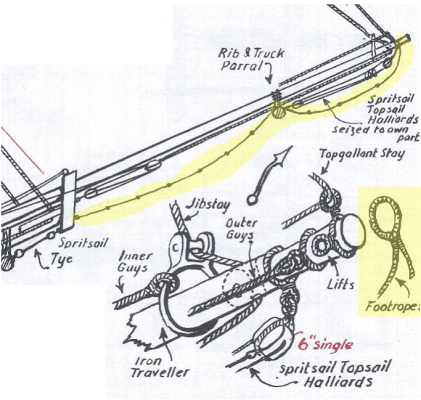

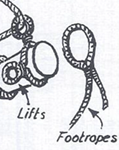

The Topgallant Forestay was next. It starts at a pair of deadeyes coming off the bow, goes through a ring attached to a thimble at the tip of the bowsprit and is attached to the top for Fore Topgallant Mast with a line eye slipped over the mast. But, in order to do this, one of the corollaries of Murphy’s Law is that “No matter what you have to do, you have to do something else first” had to be complied with. In this case, it was on the tip of the bowsprit. There are four items there and two of them had to be completed first. They were (aft to forward): Spritsail Topsail Halyards Block, Outer Guys (two eyelets), Lifts and Stay (three eyelets, and the footropes. The Mamoli plans show different portions on the bowsprit depending on what is being rigged. They also have a complete image but without all the detail. The image below is from Model Shipways. As with everything else, it seems nobody can agree on how things were done. The Mamoli plans show the order as: Lifts and Stay (three eyelets), Outer Guys (two eyelets), Spritsail Topsail Halyards Block, and the footropes. I chose to follow MS for no particular reason other than I like their diagram.

-

Thanks all, your flattery er... opinions are greatly appreciated.

Finally, we come to the Fore Topgallant stays. The backstays start at the mast top, pass through a previous drilled hole through the cross tree, looped around the top of the mast, back through the crosstree and finally anchored at the top. The anchoring at the top is by lashed rings off of the outside deadeyes. The looping at the top of the mast is seized and both the ends and the loop were served. In the picture below, the lines have not been tightened and finalized.

- CaptainSteve and Martin W

-

2

2

-

- CaptainSteve, usedtosail and KenW

-

3

3

-

The excess rod was trimmed. I initially planned to epoxy the rod on the outside face because didn’t want to reheat the assembly and risk having everything fall apart. I didn’t have multiple solders of different melting points. But as it turned out, no glue was necessary as there was enough friction to hold everything in place. Comparing the two travelers, you can see my second attempt gave a much cleaner part.

- KenW, janos and CaptainSteve

-

3

3

Rattlesnake by JSGerson - FINISHED - Mamoli - 1:64 - Using Robert Hunt’s practicum

in - Kit build logs for subjects built from 1751 - 1800

Posted

QUESTION

I have to fasten double blocks to a stay as shown in the diagram below (red arrows). As indicated, it appears that the blocks just have a simple stropping loop at the top which goes around the stay. That would mean the blocks are held in position and have enough holding power to counteract the forces applied to it by pure friction. I don’t buy it. There has to be some mechanical method to take the load.