-

Posts

172 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alangr4

-

18' Cutter by Maury S - Scale 1:48 - SMALL

alangr4 replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

This is a great little photo exposition of how it is done Maury. Thanks for sharing it with us. Alan -

Stunning work Remco and a wonderful lesson on recovery. Alan

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

It is coming along wonderfully Ben. Well done. Alan

- 889 replies

-

Mark I think you will find that they have not done an english translation for Belle Poule. I am translating bits and pieces of the monograph but it is a long and laborious process. Sorry Alan

-

Remco Your build continues to provide inspiration Remco. Pebbles just has an eye for detail. Hang in there. Alan

- 1,214 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Version 2 is looking good Grant. Incredibly fine work. Bad luck about Ver 1 but will store away the hair clips usage. V clever. Alan

-

Umm Ed I know I was concerned the other day about how they got the goods in and out of those decks but did they have RoRo in the 19th century? You don't have to cut through the framing on my account. Great job. Alan

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

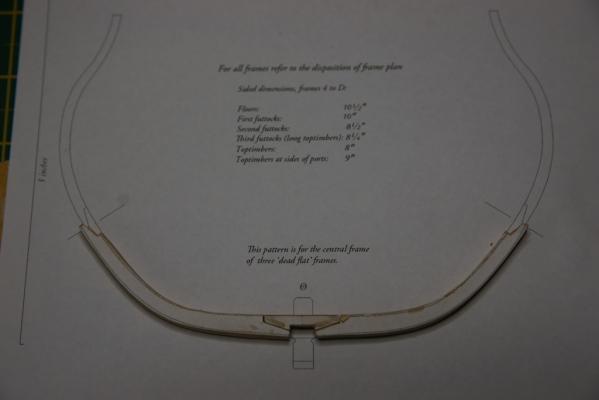

Back on deck after a period of writing and taking care of a couple of other commitments. As you may have gathered from my last framing post, I wasn't entirely happy with my opening framing performance. It was to my mind a bit hit and miss and I was still very much in the mind set of building a kit. I am finding this to be a completely different exercise. Fun but different. Suffice to say, over the interlude I went back to school and re-read the relevant chapters of the books of David Antscherl, Ed Tosti and Bernard Frolich. Also invested in a couple of new tools: - some perspex which I have cut up into rigid sanding blocks of different shapes; - some ultra reverse blades from Flying Dutchman for the scroll saw (thanks Ben); - a Veritas honing guide to help sharpen the chisels. In the past I have not been a great one in maintaining my chisels. I am now! I have a wonderful scroll saw but these reverse blades make cutting a joy and I am starting to get a tighter tolerance on my frame components. I am not yet close to the masters such as Antscherl, Tosti or Frolich but I am working on it. I found with my sanding that I was using a soft mat underneath my sanding which was causing me to roll my corners, particularly on the chocks. The perspex ( which ideally should be plate glass) is giving me a bit more "squareness" (if such a word exists) in my sanding. Also trying to rely more on the chisel to give me my edge rather than a sander. The following pic suggests that not much progress has been achieved since my last post, but I am more comfortable with fit, particularly around the chocks. Fortunately, there is plenty of spare timber. I figure if I can get my approach right here, it will stand me in good stead later on. Still a little work to be done to assemble the frame but we are getting there. Alan

-

Master Po and Kwai Chang Caine I have watched your journey, "young" grasshopper with great interest and enjoyment. One thought which you may have already considered, Chris Watton (a member of this august order) did the design for the Arrogant kit released a year or so ago by Amati. I wonder whether he may be able to shed any enlightenment on the quandary you are currently in? I hope you find the answers you seek. Alan ‘Never assume that because a man has no eyes, he cannot see.’ -Master Po

-

Great pics David. They really do capture what it would have been like being a wharfie in the 19th century stacking these holds. A tough way to earn a buck although I suspect they weren't getting a buck for their labours. Again Ed your build generates so many questions and research topics every time you post a new pic. Well done Alan

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Wonderful lines Ed. It is fantastic to see her taking shape. It looks like it would have been very difficult to load and unload from those two decks? What would YA have usually carried on those two decks during her working life? Great pics. Alan

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Mark Licorne is coming along nicely. Well done. The piece of ebony for the false keel will look terrific when finished. Will you be using ebony for the wales? Alan

-

Ed Your industry and creativity knows no bounds. A wonderful set of photos. Alan

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Sounds like my type of Birthday Mark. Congratulations. The deep dish apple pie sounds like just the ticket. The smell of the cinnamon is wafting across the Pacific. Alan

-

Well done on completing the cutter framing Grant. The scale would have presented a heap of challenges. I doubt I would have had your patience in applying the isopropyl. Looking and sounding great. Alan

-

Welcome back Ben. A great set of pics. Great work on getting the bollards carved and set up. Those supports you built to get the angles right seem to be working a treat. Regards Alan PS Just ordered 6 dozen of those reverse blades you suggested. Thanks.

- 889 replies

-

Thank you David B, Druxey and Ben for your information. The itinerary for our first non-work related trip to the US and Canada continues to grow. My wife Annemaree is particularly taken by the sound of Mystic Harbour. She has taken over google to check out their quilting potential. Annie was in Washington a few weeks back and bought back pics of the Smithsonian's boat collection. Another must see place to get to. Ben, thanks for the tip on the blades. Will check the local hardware shops first to see if they stock them. Google is currently locked up dealing with Mystic Harbour quilting tour questions! Well done Druxey, Annie says hi and reports 19th century dress making classes figure in Mystic Harbour as well as Patchwork Murder Mysteries! What more could I ask for! Back to the frames. Regards Alan

-

David A stunning example of the craft. Thanks for sharing it. Wondering too how many frames might have made up a full schooner? Excuse what is probably a dumb question, but what is Manitowoc? I have seen it crop up a few times over the last few years. Thought initially it was a place but wondering now whether it is the name of a boat show or maybe a place and a boat show. Thanks again. Alan

-

Many thanks to you all for your gentle feedback and encouragement. I hope my post didn't leave you with the impression that I am losing enthusiasm. Absolutely the opposite . I am getting a great deal of enjoyment from this little exercise. Just kick myself occasionally that I should have known better. Ben: The Ultra reverse blade sounds like a nifty little blade. Does this fit all machines? Like your latest challenge, Indefatigable - as if you don't have enough challenges already. The Ultra reverse blade sounds like the ideal tool for 'Razeeing' a 64 down to a 44. Your analogy of this feeling like a mountain sometimes is quite apposite. The last time I took on a mountain (this size), some 35 yrs ago, they bought me down on the back of a yak and an oxygen bottle! I do enjoy my mountains! David B: Any chance of seeing a pic of the Great Lakes Schooner? Thanks Druxey for your guidance and encouragement. Means a lot. On to version 4 of the frame! cheers Alan

-

Well, put the final coat on a side table I had been building for my folks and have swung back to the framing. After a couple of practice runs on some scrap and then once using Jeff's wood have learnt a number of things and left with a few questions. First, switched blades on the scroll saw as suggested by Druxey. Moved to a no 9. Certainly better control and reinforced that I dismiss Druxey at my peril. Thanks Druxey! Second, I underestimated the role and importance of the chock. Making sure that I follow exactly the plans in cutting out the chocks is critical. I spent far too much time, I think, sanding and fairing the chock to fit rather than using a chisel and getting that fit accurate to begin with. Three, I am in a quandary about how much spare I should leave outside and inside the frames. I think on reflection in all three attempts I cut and sanded far too close to the line on the plan whereas I should have left a bit - maybe around 1/32 or 1/64 so that I have a bit spare when I come to fairing the completed set of frames. - I have found in the past that I am an inveterate fairer once the framing or planking is complete. This may be something I have to get out of my repertoire if this build and any further scratch build efforts are to be a success. Four, rushing the framing is suicide. Yet it was taking me a good three hrs to get as far as I have - which is not far. Again to my mind spending far too much time sanding to try and get the frames, particularly the joints right. Five, I was in two minds whether to cut from the whole plank that Jeff supplied or cut a smaller piece covering the quantity required for the first futtock and chock. Decided on the latter. My mistake was not leaving enough for an adequate hand hold particularly for the chock that you can grab onto and steer. Life becomes quite interesting when one is cutting a chock sans handhold on a scroll saw running at 1200rpm! Anyhow, a couple of pics follow. Suffice to say I am going back for a second attempt once the temperatures have warmed up a mite. Druxey: please note surgical knife in pic 1. Your pliers worked a treat. cheers Alan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.