-

Posts

441 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael101

-

Hello Roberts, Great question you asked! Its nothing to dill with the fairing process but the reason is : You can look at wood as a breathable and living material that changes in relation to the climate and humidity of the room in which it is located In summer it expands and in winter it shrinks For that, in order not to have any distortion problems in the future The best way is to seal the wood (keel and bulkheads) with paint! Best regards, Michael.

-

Hello Bob, I have the one with the side holder (for holding the vice to the table) and very pleased with this precise tool Best regards, Michael.

-

Very nice job Roberts ! about the twist at the bow you will not be able to fix it after gluing the bulkheads ! take your time to fix it now, just don’t run ,rushing is not the name of this game the best thing is to take the L supports from one side out and draw the rest of the line until the end of the bow , and make a big L supports to hold the beginning of the bow between them (put it in the very beginning of the bow to be able planking the ship without disconnect the supports , BTW I did the same thing also at the stern ) The next stage is to work on the bulkheads ... and after glueing the bulkheads in place put som wood supports between the bulkheads for holding the shape permanent you can see it in my build log but we will talk about it later on when you will be at this stage ... Best regards Michael.

-

Hello Roberts welcome to the journey of building the HMS VICTORY im calling this project a "life project" ! there is a lot to learn and think before each step ! so take your time and enjoy the moment about the bulkheads .. before starting anything you must make a stand for the keel to insure straight keel .. made it by using a plate of birch plywood and 90 degrees L supports from the picture you uploaded I can see that the keel is not straight (its very normal when having very large keel ...) but you can fix it by making the stand ... also if you asking me when you will have the stand ready .. don't glue the bulkheads from inside the slots just dry fit them and glue them from outside by using timbers of 10*10mm its a bit hard to explain but you can see my build log (my model its a caldercraft one , but the first stages are the same ) you can check the pictures at post no.2 and post no.11at this link and if you need anything you can pm me best regard Michael.

-

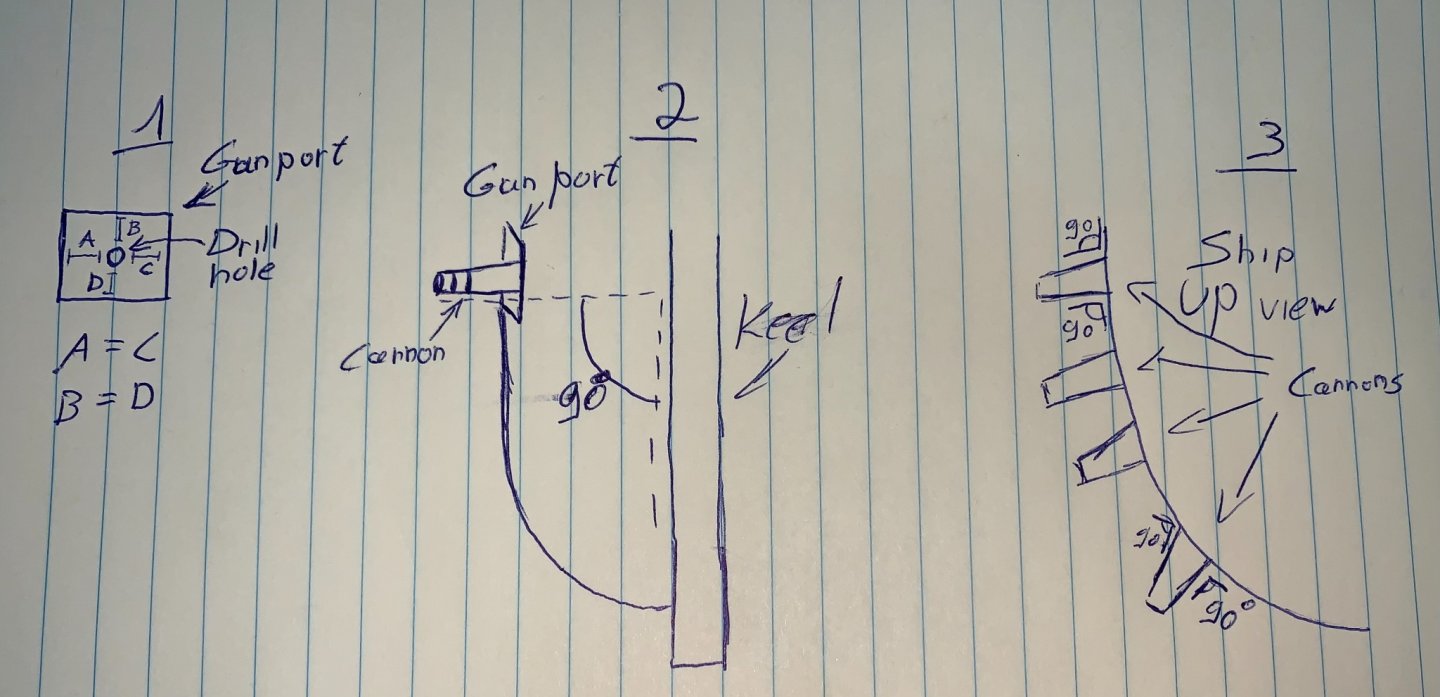

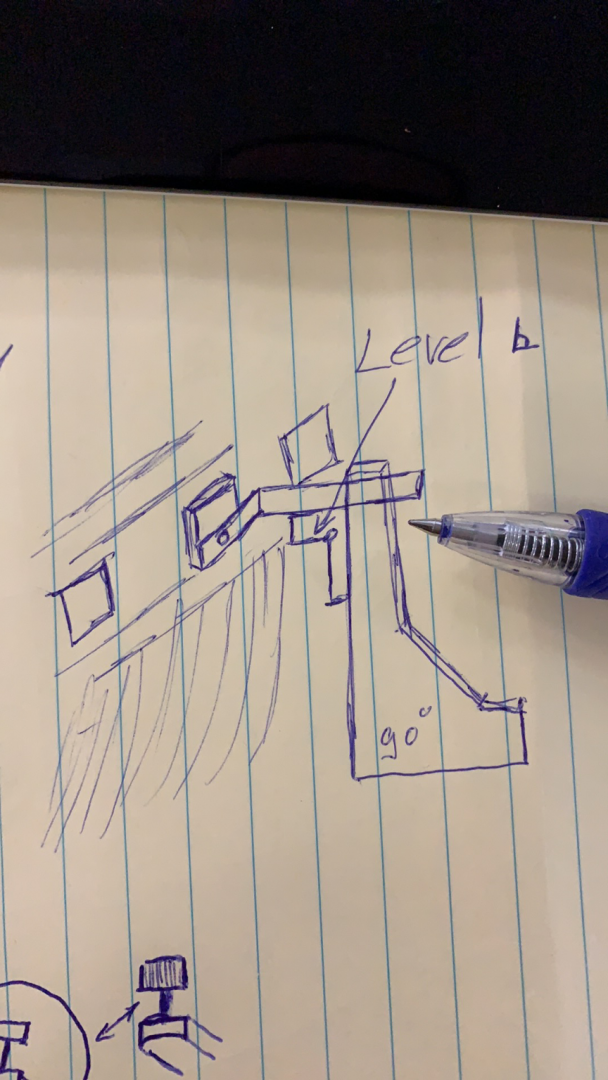

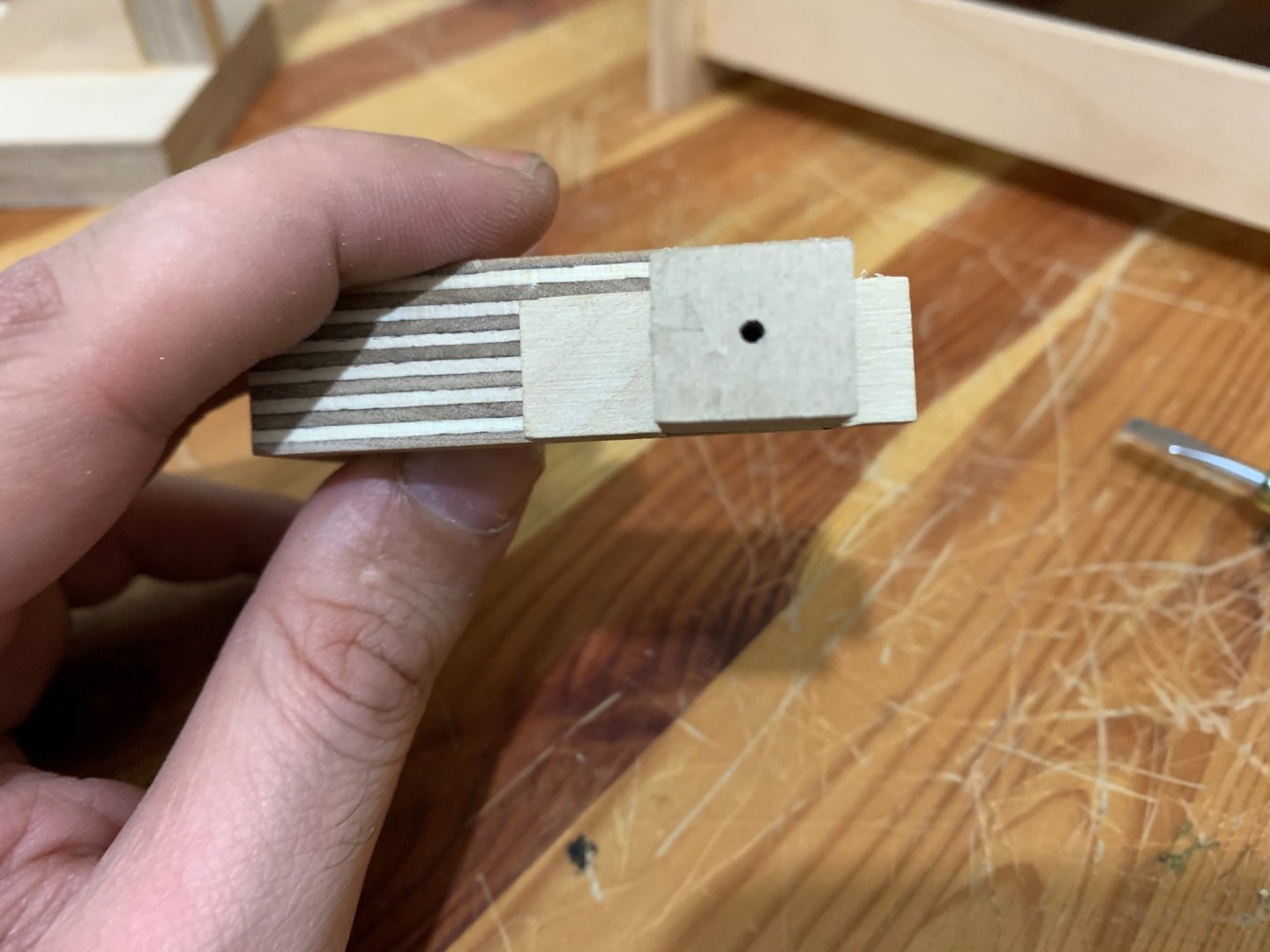

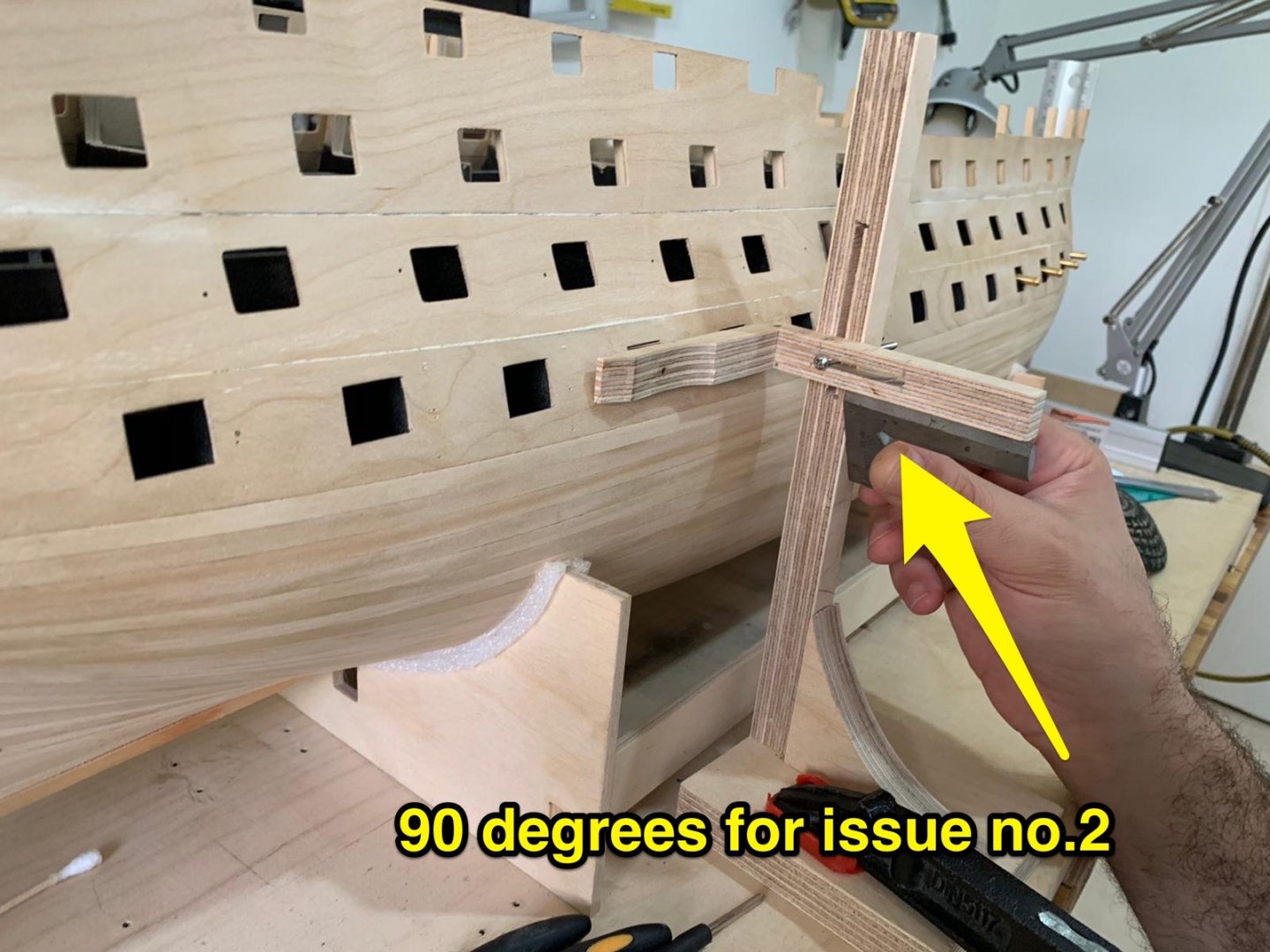

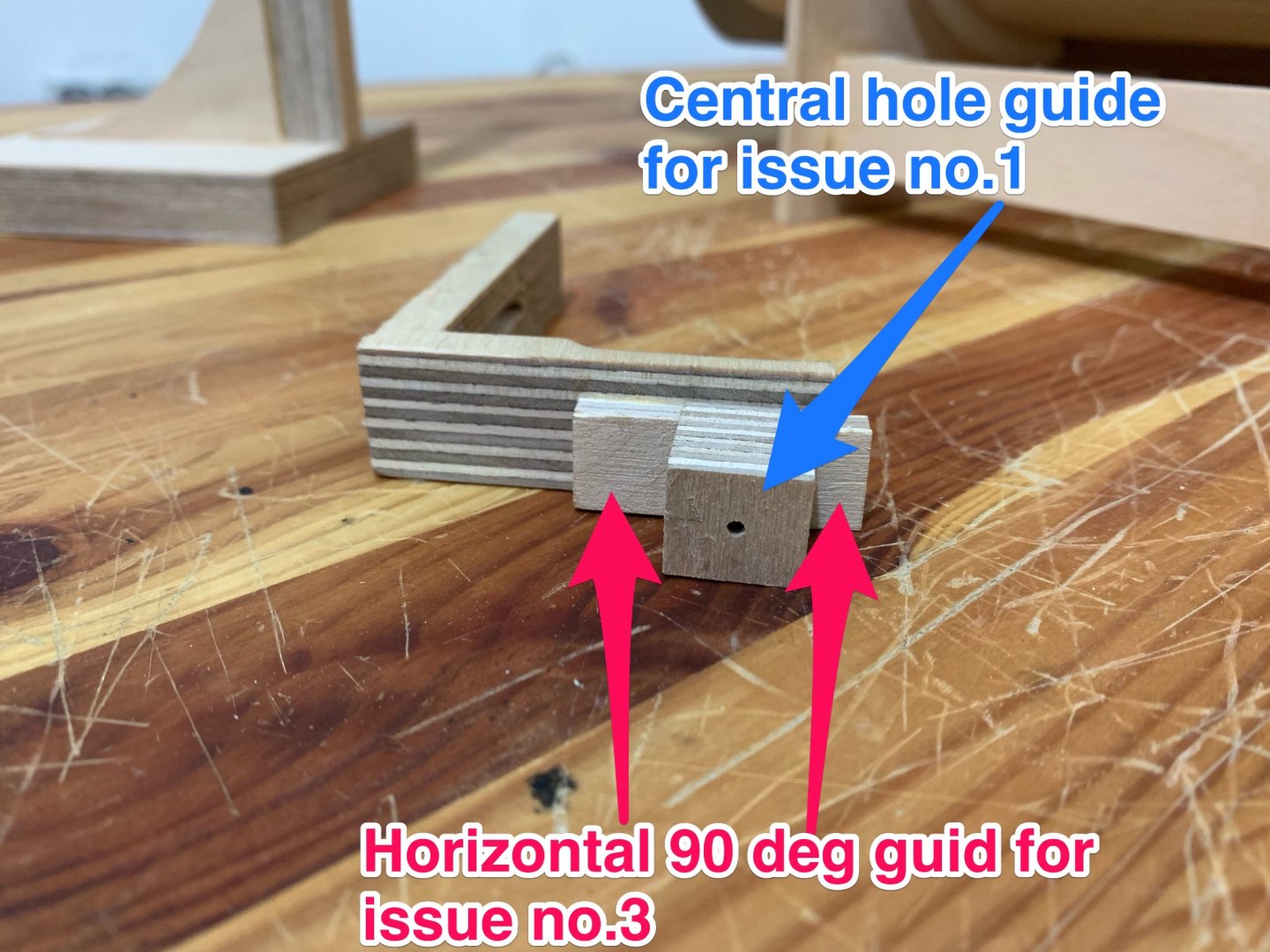

Hello friend ,I hope all of you are well and safe at this days Here is a little update for my build log, I have done it a few month ago but not had the time for sharing with you So now before starting the next stage on my victory I had to share with you guys a new method for drilling the holes in a perfect way inside the gunport for the cannons until now I saw a lot of beautiful build logs and a lot ways for drilling this holes for the cannons but I wasn’t happy with non of them I saw some people who used a water level and other who used the stand of the proxxon drill but you can’t get the perfect central hole in the middle of the gunport with this methods....(and there is also other problems with this methods ,I will speak about them later,) So before starting expanding what I have done I will start talking about the issues in this matter The cannon must be in the middle of the gunport The cannon also need to be 90 degrees from the keel ( vertical ) and the problem is- the gunport is not square with the keel and each ship has his shape .... And also the cannons need to be 90 degrees horizontal from the sides of the gunport (before at issue no.2 I was talking about the 90 degrees from the keel and I was referring vertical ! and now in the second issue I’m talking about the horizontal way means the cannons must run smooth with the curves of the bow and the stern ) here you can see the issues : So like I said I saw who the builders dill with the drill holes some of them used a water level but this level can’t be precise for our needs , also I saw other who used the stand of the proxxon drill ,that one maybe can be ok only for the issue no.2 but not good for the other problems .... All those issues above made me to think a lot about the solution and after a lot of thinking I made this jig for my drill who going to resolve all those issues I will cut the words and will show you some pictures - And after all here is the result : I hope this guide will help you out Best regards, Michael.

-

Busy Box for my baby's birthday by michael101 - WOOD

michael101 replied to michael101's topic in Completed non-ship models

Thank you 🙏 -

Busy Box for my baby's birthday by michael101 - WOOD

michael101 replied to michael101's topic in Completed non-ship models

Thank you 🙏 -

Accurate Triangle metal square

michael101 replied to michael101's topic in Modeling tools and Workshop Equipment

Thank you , i prefer the flat ones but like i wrote before i dont know why but there is a lot of bad comments in AMAZON about different company who making this ruler im still keeping searching for a good one so if someone hear has a accurate one i will be more than happy to know hat company is it.. -

Accurate Triangle metal square

michael101 replied to michael101's topic in Modeling tools and Workshop Equipment

yes ! i think the drafting one can do a perfect job for that .. correct me if im wrong -

Accurate Triangle metal square

michael101 replied to michael101's topic in Modeling tools and Workshop Equipment

I have found this tool who got a beautiful reviews about the calibration !!!! here is the reviews: https://www.amazon.com/product-reviews/B073YGVQT3/ref=cm_cr_unknown?ie=UTF8&filterByStar=five_star&reviewerType=all_reviews&pageNumber=1#reviews-filter-bar and there is also a store how sale that in Europa: https://shop.kinexmeasuring.com/en/precision-triangle-kinex-250mm-45-90-csn-25-5162-csn-25-5163-p9002369c22c189/ you can also get with it CALIBRATION PROTOCOL now im wasting to the sore so send me the shipping cost .. ---- but again if someone still can recommend other tool i will be happy to hear Best regards Michael. -

Accurate Triangle metal square

michael101 replied to michael101's topic in Modeling tools and Workshop Equipment

i have a few and im used them at the moment but like you know you can easily scratch the edge then you loosing the calibration.. -

Accurate Triangle metal square

michael101 replied to michael101's topic in Modeling tools and Workshop Equipment

Thank you ! i need it to be a perfect straight without any bend and also to be a perfect 90 degrees for caliber my proxxon machines like a table saw scroll saw disc sand act.. so your beautiful tool cant help with that because it not has a sharp corner but thank you anyway !

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.