-

Posts

201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Leo-zd

-

-

the trouble is that i had a "few" photos (only this year something as 400 ... from 12 regatas ) here is the link to my space on photobucklet which I often use for posting images on nautical forum.

Most of folders are from sailing.

http://s364.photobucket.com/user/GRINGO_ZD/library/?sort=9&page=1

-

Hi Leo - I understand exactly what you're saying . Your wife is/should be the 'best thing in your life'. If not, then you're in strife. You now what they say - Happy wife, happy life! On another note, do you have any info/photos of your 1:1 scale model????

...................................Cheers

Patrick

you knew all (about wifes

you knew all (about wifes  )

)For the 1:1 , fortunately I'm not a owner (so I only have to sail

not to take care ) but I have two friends with interesting models

not to take care ) but I have two friends with interesting models

first is First 30 and when I am not on it I go with one Ufo 22

I don't want to spam your post so only few picks as I have a plenty of picks on my FB profile

-

Thk Patrick

In fact last half year or something more I was intensively engaged with a bit greater scale (1:1) and non-static recent models

Simply I had the fortune and the possibility to go on many sailing regattas, so in few weekends that I wasn't on deck was very politically correct to remember that I had also the best wife on the world (doesn't someone have OR could says that !? ) so the models are on stand by.

) so the models are on stand by. -

-

-

Great solution that was behind all but we didn't seen it :im Not Worthy:

And that give me a perfect idea for small scale (we both have a same feeling for soldering ), I will do it in styrene as in my scales it is to small even for plywood I use - 0,4mm aero , great :im Not Worthy: for idea and realization !!!

), I will do it in styrene as in my scales it is to small even for plywood I use - 0,4mm aero , great :im Not Worthy: for idea and realization !!! -

-

Nice work!

The mast is very nice, You can fill it, as it will be painted it will be OK.

About using the drill and sanding, one precaution, maybe You knew it yet, don't wrap the paper completely around the wood because the friction will be to high and something will be broken... Use the paper only bent for a half profile.

-

-

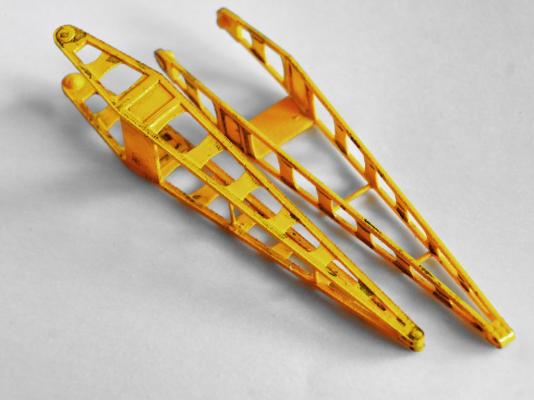

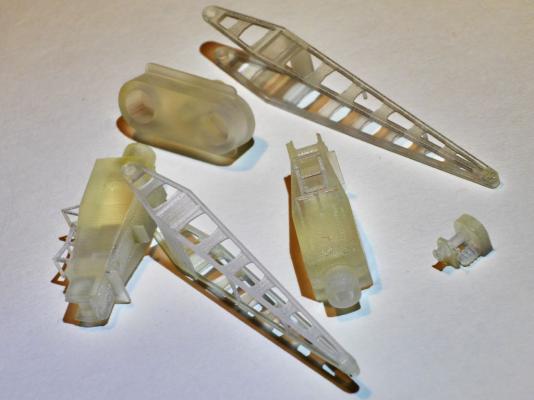

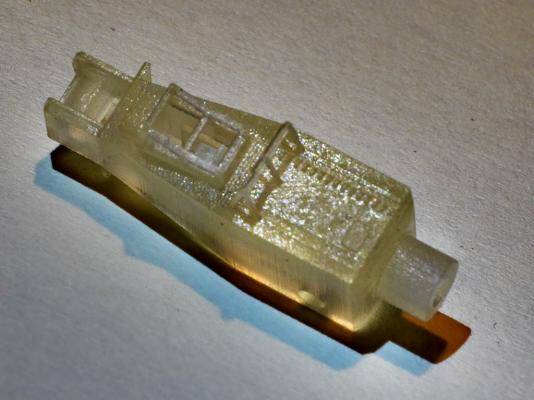

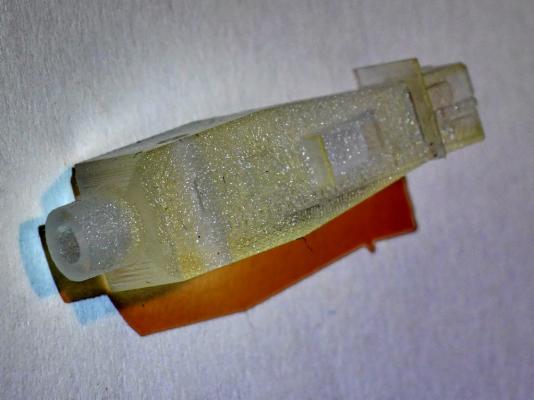

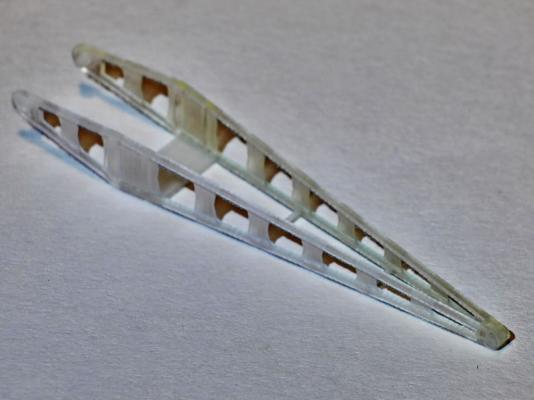

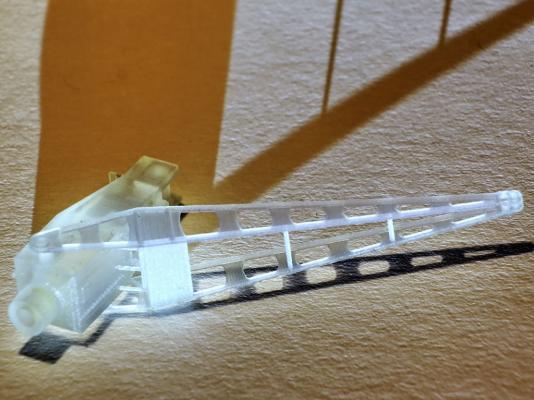

Hi, it was printed by Shapeways with material Frosted Ultra Detail because this was the test print, probably the friends will order with Frosted Extreme Detail which have better resolution. anyway the limit is 0,1 mm as the smallest dimension.

-

- Mike Y, thibaultron, mtaylor and 2 others

-

5

5

-

-

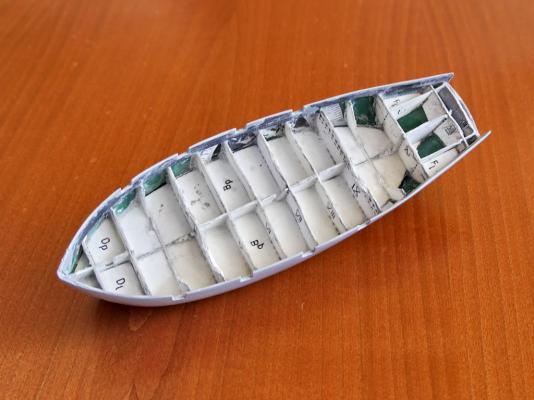

Today's visit to tailor's shop

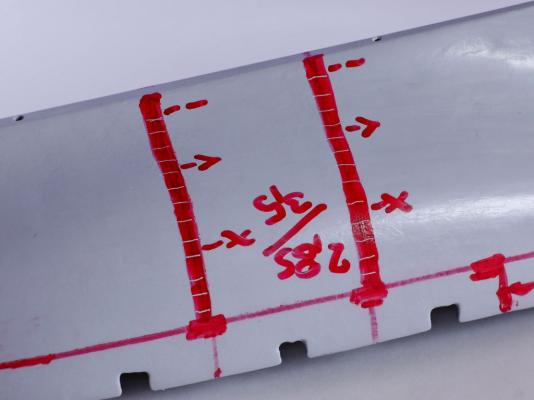

But the tailor, instead of calk, used the marker so the signs remained.In fact the marker was too big so at the end used it as a base and scribes the division on the hull.

In the middle it is 14 sections of 2,85mm (in fact 3,5mm for the overlapping of the klinker) at the ends it is 2,5 and 2,7 mm without klinker.

-

-

-

Another project..

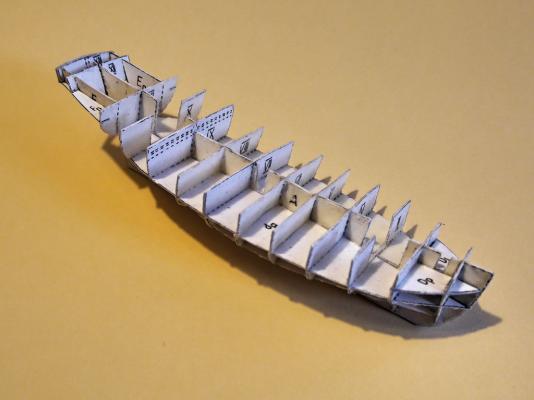

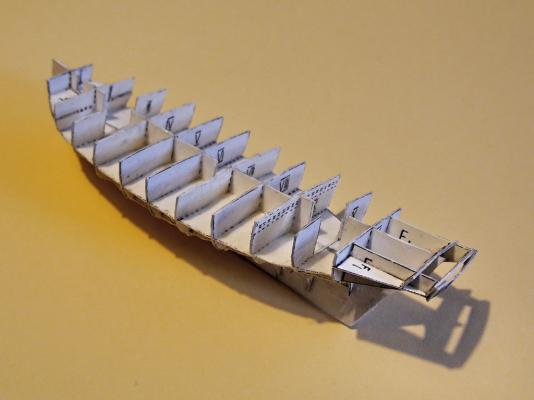

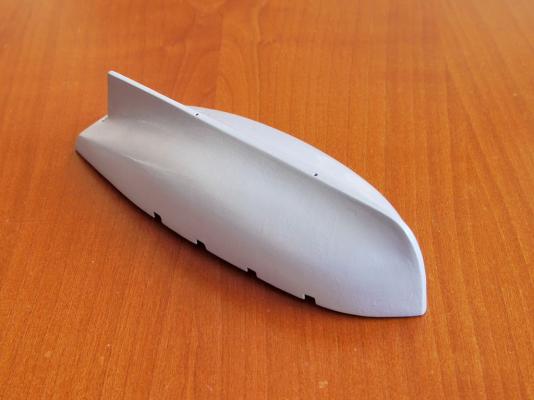

Better to say a bit of experimentingTime ago I found the paper model for Le Coureur, and for the first I decided to made the hull, to see the lines and how do the paper works in this case. In meantime I found drawings from iconography, in small scale, but my intention is to made a small scale.

As I started with LN in 1:120 (in fact 1:119) I decided that it will be my standard scale so reduced the drawings .I haven't the requested paper but used some envelopes and made some copies, glued together.

For fast and straight gluing I use PVA glue and the iron for faster work. (also with iron prevent the elements to deforms due to the water from PVA glue)

I made the skeleton and that was like a playing.. but the lines seemed nice so I decided to continue.

But the hull made from paper wasn't too nice, many panels are deformed like on the real steel boats.

So I fixed the paper with CA glue and then applied the mono-component car's putty (IMPA) which regularly is used on plastic modells

Few repeating of sanding and applying the putty, final coat of liquid fine putty Mr Surfacer and sanding with paper 1000 to obtain clear surface.

The next step will be the second layer of boat's hull, it will be done with styrene strips

-

My attempt to made winches and cranes for mercantile ships in 1:350.

The longest piece, crane have about 5 cm (2 inches) and the winch on biggest dimension is about 8 mm (0,3 inches), the photos are taken on plain fine paper

-

-

Thk..

The second hul is Le Coureur, time ago I found (download) paper model for this boat.

Al started as a play, I wanted to see how is to made a paper model.(in fact I like the hull forms)Nturaly I reduced to 1:120 , and printed on first harder paper I found (You can see that on internal part is something printed, I think that was one envelope for assurance contract or similar).

It's interesting to work with paper

, naturaly, as the paper wasn't the adequate thickness although i glued two together the hull's first layer wasn't as I expected.

, naturaly, as the paper wasn't the adequate thickness although i glued two together the hull's first layer wasn't as I expected.

So I impregnated it with CA glue and then covered with mono-component car putty (IMPA) which dries relatively fast and it is pretty strong and easily sanded.

When finished with that putty coated with liquid fine putty Mr Surfacer , sanded with water card 1000 and polished with piece of cotton and nail laquer remover (with acetone)

So the play became serious and probably I will open a thread

-

- Dubz, GrandpaPhil, mtaylor and 4 others

-

7

7

-

-

The bell is reduced, painted and put on its place, I also put the piece of rope underside.

I decided to made a stove, in fact just a chimney tube because fortunately nothing can bee seen inside.

I used styrene tube , external diameter 2,4mm and piece of styrene strip for the base.

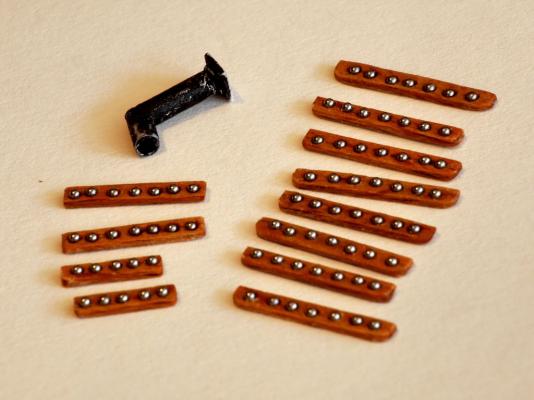

As this is armed cutter, the cannon without ammunition are useless so i decided to put the cannon balls.

Fist options were the balls in cartigge for hunting rifle but the smallest are 1,5mm and that is so big.

I chosen the steel balls from ball-bearing, the smallest one is 1 mm diameter, approximately the dimension I needed. It was a bit laborious to made the wooden support (1*2 mm) and as could see it isn't perfect but it is so small that I think it will be OK.

The problem is the brightness and color of balls, but wasn't possible to color so small and glanced surfaces.

Maybe the mat transparent coat will got better appearance.

At last one photo with the laptop monitor just to indicate the real dimension and the fact that in reality all is much smaller than on the screen( especially errors and imprecision)

- Tadeusz43, GrandpaPhil, Siegfried and 6 others

-

9

9

-

-

Thk

No, the bell is made from styrene, first glued with CA strips of styrene on steel rod than put it in styrene tube, and glued/molded styrene together with Tamya cement - green cap . that was the worst part of job.The rod is used as the axe and put in minidrill and worked with fine sandpaper for the shape, for polishing i used the "wrong" part of sandpaper (the paper) and the minidrill at high speed. Just take care to do all gently, very gently.

As is all so small I used two small wires for the bell's eyes.

I hope I explained (not because the operation was complicated bur because my English......

Genesis by Omega1234 - FINISHED - 1/300 - 49 m Mega Yacht

in - Build logs for subjects built 1901 - Present Day

Posted

How big fingers You have !?!?! 😆

Fantastic micro works !!!