-

Posts

213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegerber

-

I'm also with ... ... am looking forward to the first pictures! Best regards, Mike

- 1,083 replies

-

Wow, this is the flying dragon! -Brilliant work, Bob! - many congratulations!

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

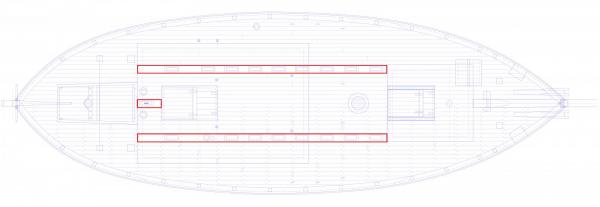

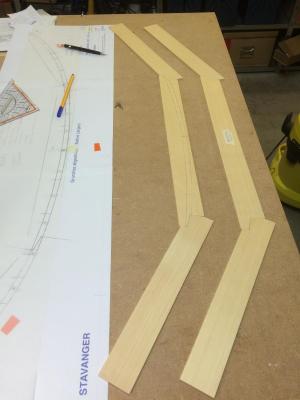

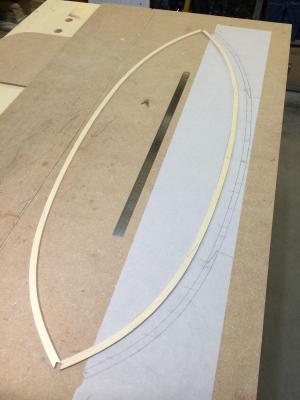

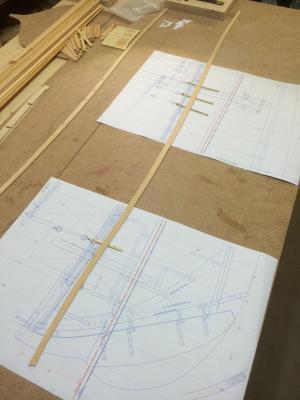

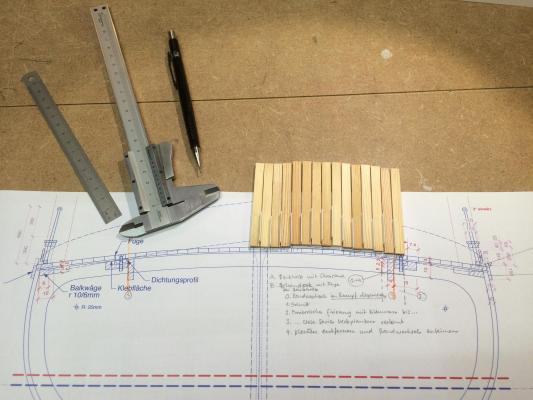

Hi again Thanks everyone who visited the shipyard, and thanks for all the likes. @Carl Many thanks for such a great feedback! ... “... well done ...“ – thanks a lot! ... “... something to remember ...“ – that would be a pleasure ... “... clever ...“ – maybe a little bit ... “... master mind ...“ – there are also other opinions – to this you have to interviewing my admiral ... The next thing that I must prepare are the double-width planks with the deck day-lights. To this I used a milling guide to obtain easily a high repeat accuracy (s. below) ... Location of the double-width planks Some experiments Making of the milling guide Get ready for milling First cut Second cut Post processing Best regards, Mike

-

Hi Nils Great idea with the plastic dinghies - from old make new and to this yet double-ender! ... ... yes! Double-ender for ever! I am incidentally pleased with every new KWdG-log - very well done, Nils! Best regards, Mike

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Igor What did you say, what scale is it? ... aha ok, scale 1:29, all right! ... ... I already thought I had read wrong - 1:290, something like this ... All the best, Mike

-

Hi vaddoc It all looks very good! - looks like the real and suddenly, I had still the suspicion that I look at a model, when I discovered the huge drill in the background! Best regards, Mike

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Hi Greg, Patrick ... ... as well as everyone else who visit "Stavanger's" shipyard. Many, many thanks for all of your feedback, comments and likes. Always greatly appreciated! In the following post I would like to document a do-it-yourself tool. In general, I swear on Proxxon tools - you can't win a war with it, but second to none is the price-performance ratio! ... Well, there is unfortunately no reasonable mini milling attachment for the IBS/E highspeed tool, but I need one for future cutting work on the semi-finished deck. So, I helped me myself ... Blanks before hard soldering Finished attachment with router bits Application with milling guide Best regards, Mike

-

Hi Kees It's great that we can have a look over your shoulders again! Best regards, Mike

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

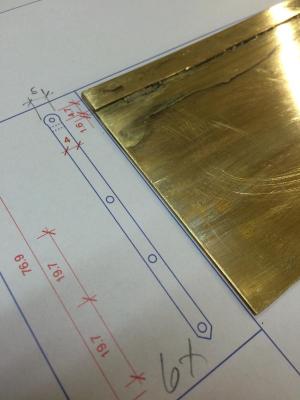

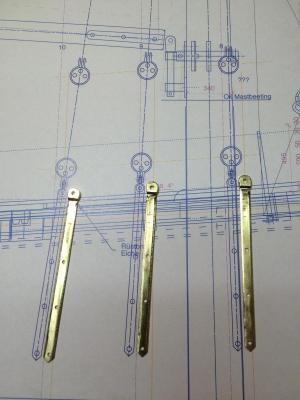

Hi Igor, Marc, Patrick, Michael, hi everyone Thanks all of you for feedbacks, your visits and likes! @Igor In Log no. 149 I falsely claimed that three different setups regarding jib sail consist. But you're right, there are only two versions of jibs (normal jib and storm jib), as shown on the sketch in Post Nr. 151 (Letter “F“ means the storm jib). Thanks for the hint. @Mark Thanks for your encouragement, but I am still not sure whether my RC design will holding - on this topic, I have to learn by trial and error ... @Michael and Patrick Yes, I will certainly report you success or failure about the draining system ... Patrick, this is really a funny story, this toilet installation of your father - the model boat that (let's say) all two minutes a WC flushing ejects ... ... back to the workshop. Concerning of the upcoming edge of the deck I worked on the chainplate. Last but not least, it was a welcome change to the wood work ... blank before and after hard soldering raw chainplates multiple calibration and constriction contour grinding chamfering chamfering chainplate's head done ... ... and not too much unlike ... Best regards, Mike

-

Hi Patrick Wow! Symphony was a real floating palace - very well done, looks super great! Best regards, Mike

-

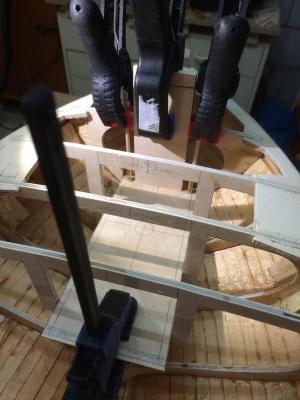

Hi everyone Thank you for feedbacks, all the visits and likes! ... one more update about the preparation of deck planking. It concerns the edge mounts of the locker doors and various reinforcements in the area of the deck beams. Til the next, Mike Below: - Various work steps

-

Hi Lextin This is a great serving machine - very well done! I really admire your ingenuity and look forward to every new post from your shipyard ... Best regards, Mike

- 366 replies

-

Hi Bob Your Dragon is maybe a little fire lady, but she looks really great! - I mean really great! Best regards, Mike

- 127 replies

-

- dragon class

- yacht

-

(and 1 more)

Tagged with:

-

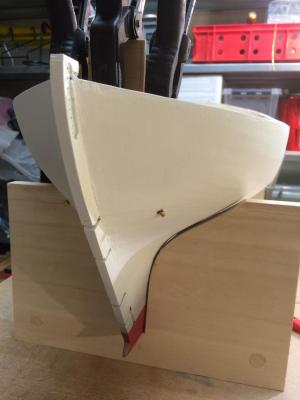

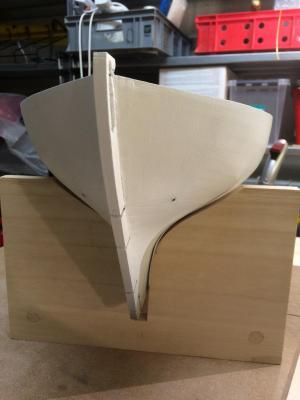

Hi everyone Thanks for all the visits and likes! ... it is following a short update with more preparations inside the hull, as there is: - Mounting of the main mast foot. - Mounting of the mizzen mast foot. - Mounting the cable hull with resin for the linkage of the tiller via wire. Til soon, Mike Below: - Various work steps

-

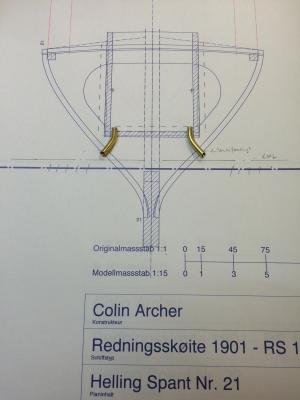

Hi everyone Thanks a lot for feedbacks, suggestions, all the visits and likes! ... well, here is a quick update from the workshop. Concerning the forthcoming step of planking the deck, still some installations are waiting. Colin Archers RS-boats all have self-bilge-cockpits. This self-bilge-system consists of two bilge tubes at the rear of the cockpit (s. below). In an upright position the cockpit drained due to gravity. By heeling, a hydraulic vacuum will be created on lee which sucks empty the cockpit through water flowing past at the discharge opening. I'm curious to see if this effect also works in scale. In the worst case I still can closing the tubes with resin. Best regards, Mike Below: - Self-bilge-system

-

Hi Mark Thanks for your comments and questions. ... yes, you are right as far as that the jib sheets run about the forestay, but “Stavanger“ has no stay in front (end) of the bowsprit. Three setups with different sizes of jibs are known to me in this context: - normal jib - storm jib - “Handkerchief“ (sorry, I don’t know the exact term of this sail ...) ... however they have no stay. They carry themselves and in strong weather, normally the bowsprit will be fully eliminated and has its secure place on deck (s. pics). sprit in secure place ... and yes I agree with you, I have a problem with the overlap of fore and jib concerning the geometry of my mentioned RC-Layout - ... the jib sheet which runs across the forestay – trouble! ... my next model is probably a static one. ... so, this problem is detected but not yet solved. How Bob has allready noted, it is Jerry Todd who shows us a possible approach in his "Constellation"-log no. 72: (http://modelshipworld.com/index.php/topic/3244-first-class-sloop-of-war-constellation-in-136-scale-by-jerry-todd-radio/?p=205356) Maybe I have to check a adaption for my case ... At this time, I'm very anxious to realize all additional parts as light as possible. If I'm right with my estimates and if I don't will punish the ballast keel, it will only stay about 2kg weight of material for deck, superstructure, masts, rigging and sails available after installing the RC system. ... what you're saying about the ballast will be correct for a local, low-hanging ballast arrangement. In terms of inertia, wobble and rolling action, I'm almost entirely sure, that I have done, with a long lead keel, a maximum in regarding of a optimized scale effect - so my hope (compare log Nr. 14). til soon and best regards, Mike

-

Hallo again ... @Igor ... yes, Johan Petersen is a well known name in so many report about RS14 - and thank you for the initiative on FB – that would be really great, if he would get in touch ... @Nils ... Thank you for your feedback and the question. As far as I can, I had played through that topic intellectually, that you mention (elastics, circulation sheet, a.o.). I have to say, that I can speak to this topic only from real sailing experience, and not as "RC-Sailing-Pilot", therefore my previous design is to consider only as super provisional. I have excluded the circulation sheet system for me. It seems hardly feasible without RC sailing experience. Another disadvantage is the additional weight of the necessary substructure. For my planned system, I will use elastic cords if necessary to the single sheet ends of main- and mizzen sail. At the servo arm all sheets will led on roles and operate in "Roll cages". Further, I intend to led jib- and fore sail sheets double (Ps and Sb) . Therefor they are fix mounted only at the Clew of the appropriate sails. This sheets behave more or less like a kind of circulation sheet – what is given slack at one end, is taken taut at the other end and on the servo arm this sheets also run around on roles. In addition, I will lead the sheets tightly at the insertion fairleads on the front wall of the cockpit. So I hope that at a jibe-maneuver the sheets only beats slack over deck and not below deck – either way before jibing a maximum of taken taut will be necessary, if I will not endanger the rig (and the crew). @Bob ... Thank you for share your valuable experience – I see, I have to rethink once again thoroughly the thing with sail winch vs. sail servo and I will also take to heart Jerry Todd's logs. Bob, Nils ... ... you see, so far my theory – it is well aware that the practice will instruct me to a better - probably I have to approach me to a valid solution step by step. @Carl I hope, that it is possible in the further course of my reports to clarify a thing or two – and thanks for the visit, it's good to know you in the audience of this workshop ... Best regards, Mike

-

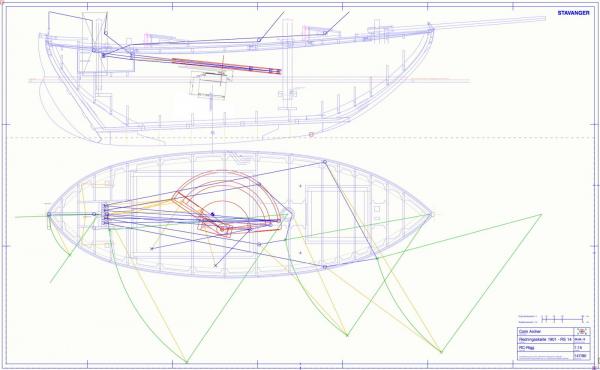

Hi everyone Thanks a lot for feedbacks, suggestions, all the visits and likes! @Patrick ... as always I'm pleased about the dialogue with you – thanks for the info from your RC shipyard. @Igor ... thank you for your feedback - i had of course already discovered www.colinarcher.no on my internet searches. But still up to now, I hadn't found the courage to "knocking on" there with my questions – on this, I have to give myself a "jerk" – will tell you about ... In the meantime I have made some thoughts about the RC layout, so that I can close the deck in a further step without having a bad conscience. At least theoretically, I'm almost certain that it would have to work, controlling all sails on one single sail servo (s. sketch below). Therefor I need a long servo arm, thus different rope lengths can be realized. Here, an analog sail sevo with a torque by approx. 250Ncm will fit quite well. What I don't know yet, whether the servo speed can be controlled by the above mentioned RC technology?! All maneuver have to be done slowly (Scale-speed). Maybe a RC specialist on MSW knows more about this? – Suggestions are very welcome to me ... Regards Mike Below: - RC layout

-

Hi Lextin It all looks really good! I am pleased to see you back in the shipyard. Looking forward to future posts ... All the best, Mike

- 366 replies

-

Hi Timmo I am by far no expert in soldering technology. Anyway, I had some fear to soft solder the hinges for a function model. Maybe you like to check hard soldering with silver solder - it is not that difficult ... 1. Degreasing of parts 2. Flux on it 3. Some silver solder pieces to 4. Flame on it 5. Done All the best, look forward to future posts ... Regards, Mike

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.