-

Posts

213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegerber

-

Hi Patrick ... and I'm still wrong in the assessment regarding the scale - if your hand is displayed in the image - wow! I'm speechless ... just wonderful! Best regards! Mike

-

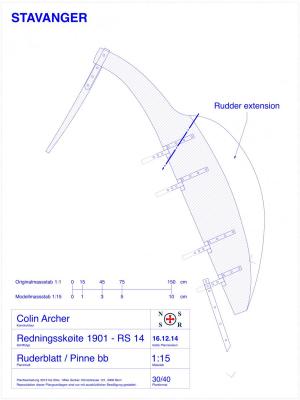

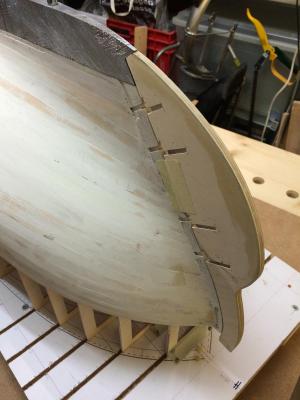

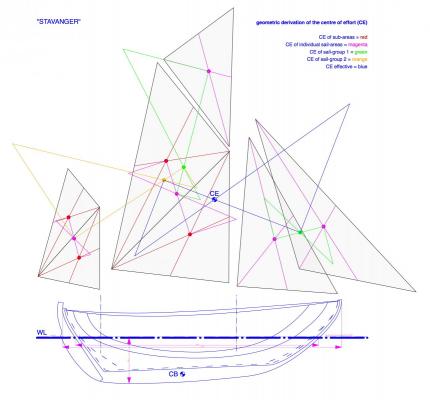

Hello everyone Thank you for all of your likes and for visiting „Stavangers“ shipyard - I am delighted whenever the "bell is heard“! ... So, what's going on in Colin Archer’s workshop? The hull as far is finished in its raw version. It lacks even the fine finish and the plasterwork and final attachement of the keel. Also the rudder blade achieved his raw state. Regarding RC technical reasons, the rudder blade is expanded in its area. Regarding the deck topic, I can tell you about the working status so far: Characteristic for all Colin Archer RS-sailors is the closed and heavily double-curved (concave-convex) hyperbolic shape of the deck. Thus shipped seas can be fast discharged. The original is made of pine planks of dimension 10/5cm. By aging, sun exposure, and dozens of surface treatments (probably pine-tar-oil), the look is anthracite-black. I've decided to forego a false deck. The problem is, that I can't manufacture a hyperbolic-shaped plane as a homogeneous element in any manner with reasonable effort - unless the false deck again would have joints, which were again to close and so on ... As all the tests with the deck dummies has showed, a simple and clean solution for this task is already foreseeable - in form of the elastomeric Sika-joints. The best thing is, that this is a way to solve everything in one single layer: Joint pattern, deformation, elastic connection, water resistance, ... Further I will plank the deck with pine/larch. Slow-growth pine/larch has a very fine and narrow drawing of annual rings - the scale effect will benefiting from this circumstance (see also Matija’s log on Pasara, page 3, no.32). I'll treat the deck in multiple layers with coloured pine oil. The appearance of the dummy is not yet there where it should be ... - but it goes in the right direction. Best regards! Mike

-

Hi together @Lawrence Thank you for the nice feedback - unfortunately, I have not always the feeling of serenity – but I'm already glad that it looks as ... @Igor Oh yes, I like this picture! - this is Colin-Archer-weather! As "Stavanger", "Christiania" is one of the most famous RS-boats and she has a moving story - see links below (report in WoodenBoat no.160, june 2001 and YouTube). http://www.woodenboatstore.com/product/WoodenBoat_magazine_issue_160_May_June_01 Best Regards! Mike

-

Papegojan 1627 by mati - FINISHED - 1/48

mikegerber replied to mati's topic in - Build logs for subjects built 1501 - 1750

Hi Mati I stumbled today on your log ... ... and I almost can't believe what my eyes see - MSW really knows some superlatives - but looking at your site, I'm speechless! With pleasure, I will follow your workshop. Best regards! Mike -

Hi Igor ... "the idea of Colin Archer in a bottle doesn't leave me" ... My recommendation: "Let's do it!" Best regards! Mike

-

Hi Igor Looked up just your last post ... ... simply keeps me amazed, that something is doable - unbelievable! Absolut great work, Igor! Best regards! Mike

-

Hi again Many thanks to everyone who posted comments and likes. @John ... yes, thank you! I am myself surprised how well it works! @Igor ... many thanks for feedback. It is Larch wood which I'm testing - from the beginning on I had provided something like that, but I got final confirmation by studie Matija's Pasara (see Pasara's page 3, log no.32). Stavangers's planks width measures 6.6mm, thickness 3mm. @Nils ... I'll watch out! @Patrick ... of that I'm not afraid, that will take time. Best regards! Mike

-

Hello everyone Please find enclosed a short interim report regarding the state of the hull after the first primer application ... Regards Mike

-

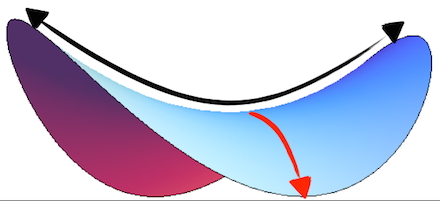

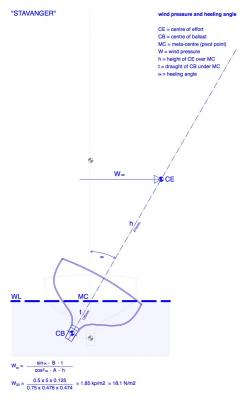

Hi all Thank you for participating, your feedbacks, and all the likes. @Bob Thanks for your funny statement - I like your sense of humor: “... using caulk to simulate caulking ...“ - wonderful! Incidentally, the joints on my build are 0.5mm wide - but I'm sure, with the spatula you get this stuff into the smallest joints - we need to test this necessarily also on smaller scales ... @Nils Thank you for your appreciation of my log. The lead keel weighing about 5 kg - regarding to the considerations of the scale effect (see log no. 14) I've done the subsequent calculations to the subject of wind pressure and heeling angle. The formula is simplified, therefor ship weight empty, center of lift are disregarded for example (see below). With the 5kg ballast and wind force Beaufort 3 (~18N/m2), the model will heel about 30°. Taking into account the scale effect, Beaufort 3 corresponds to a veritable gale! @Matija Thank you for your great feedback. Yes, you are right, planning is my profession - but as we all know, it is also not always helpful to think of everything in our heads - hence my newly discovered joy of model-making, here I can also create something with my hands. Below, a few more pictures of the deck dummies and first experiments with surface treatment - more on that later ... Best regards! Mike

-

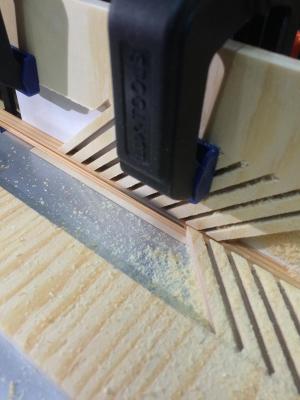

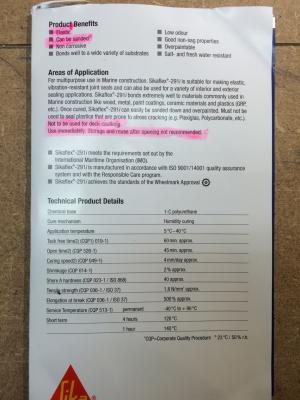

Hello everybody Thank you for visiting this workshop and all you encouragement with your likes! @John, @Patrick, @Dimitris Many thanks, I really appreciate your assistance! Currently, I'm heavy busy with the manufacturing processes for the deck. I'm on the way to prepare various dummies for these. So I wanted to try different things: The choice of wood and the whole appearance with color, the producing of the caulk joints, but also the functionality such as water resistance and so on. To do this, first of all I need to modify my old Proxxon table saw, so that I can produce identical planks. Further on, the pending decisions concerning the caulk joints is one of the most important question I have to answer. So I asked myself: Why not just do like the originals? ... Sikaflex-290i DC Is a one-component sealant based on polyurethane and designed specifically for application on Rod deck joints. Sikaflex-291i Is a strong adhesive 1-component polyurethane sealant, designed specifically for all marine applications. ... My choice much on the Sikaflex 291i, because it seems to me, as a strong adhesive elastomer, very suitable for model application (although, it is not recommended as such for rod joints in full scale). I apply the sealant with a spatula. Here I recommend you a good processing in the longitudinal direction of the joints. After drying, the surplus material gets scraped and sanded off. I'm thrilled by the result! - it looks quite fine and is further on to develop ... Best regards! Mike

-

Hi everyone Many thanks for all the like buttons and for visiting this workshop. @Igor ... quick, get a few spaghetti to the pan and make use of the bottle of oil, so that she gets empty! - fun aside, take your time. ... and thank you for posting the flickr links - I've also discovered this great image source. @John, @Dimitris Thank you for your continuous attend and great feedback! @Row Thank you for this great feedback! ... yes, no stealers, no drop planks, the planking is equivalent to the original - up to a few blemishes on proportions. But I have my joy at the result and have learned a lot here. Best Regards! Mike Below: ... always still raw, but done!

-

Hi Igor I just like this diversity on MSW - someone builds in scale 1:8 and the other in 1:600 - but all speak the same "language"! great work, Igor! Best regards! Mike

-

Hi Igor ... This is a fantastic idea and I would be extraordinary pleased by such a project! - you could count on my support (if you need and wish) ... Best Regards! Mike

-

Hello Kees I want to tell you, that your skills impressing me very - it is very inspiring! ... and I especially like the detail work on all of the fittings and little parts! I'm looking forward to more ... Best Regards! Mike

- 205 replies

-

- kw49 antje

- trawler

-

(and 1 more)

Tagged with:

-

Hello everyone and especialy Patrick, Igor, Lawrence, Michael, Crackers (avsjerome2003), Row. I like to thank you very much for all of your feedback, support, encouragement and also for all the like buttons! ... that always drives me forward! ... and yes, I also want to see this thing finished planked - soon! Best Regards! Mike Below: - present state

-

Hi Patrick I am realy fascinated! - Your ability to show us the wealth of details, lead us also the generous dimensions of these “J“-types before eyes - great work! Best regards! Mike

-

Hi Patrick I love it! ... and now you will cover the Cup with gold leaf! Best Regards! Mike

-

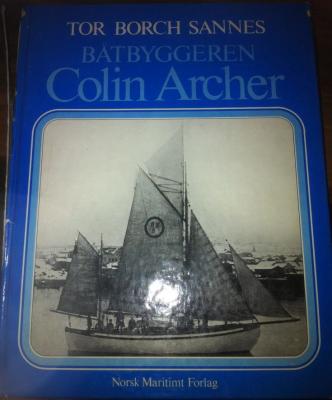

Hello everyone Thanks all of you for the like-buttons and for your visits in this workshop! @Igor Thank you for posting this beautiful sketch. Although I already knew this sketch, I not knew that it is from the book of Tor Borch Sannes, because I not own this book. I'm not sure, but I think it's only antiquarian available - once I will do some searches about that ... ... "Stavanger" has done some slow progress, but the planking is yet still not finished. So, I can show you only some pictures of these unfinished state. At the time the build is progressing slowly, but I have invested much time in strategies to the topic, how I can achieving my expectation concerning the deck - I like to report more about that later ... Best regards! Mike Below: Here now a small photo gallery ...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.