-

Posts

213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegerber

-

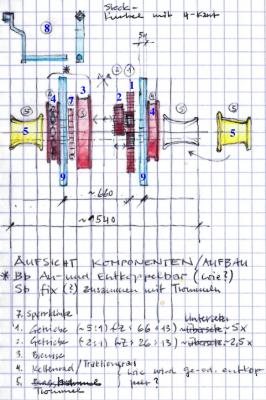

Hi Bob, Patrick, Timmo, Nils, Lawerence, Michael, all visitors Thanks a lot for your feedbacks and suggestions, all the visits and likes! During the holidays, finally I found some time to analyze the anchor windlass mechanics ... ... as far as I can see: 1) 1. Gear (reduction approx. 5:1) 2) 2. Gear (reduction approx. 2.5:1) 3) Break wheel 4) Chain traction wheel 5) Winch/rope drum 7) Ratchet wheel 8) Crank 9) Bearing stand Long I have searched in vain for a decoupling mechanism between chains traction and rope drum - conclusion: There is no (see photo below where the chain is off placed while using the rope drum) ... ... so the basic principle is now well understood. Nevertheless, I would like to ask you, whether someone is out there on MSW who knows further more about this windlass type. In particular I'm interested in the following: - Execution of the bearing stands (only bad visible on the pictures)? - Ratchet wheel mechanism? - Break system? - Brand or patent of the windlass? - Drawings? ... and finally the obligatory holiday image (Atlantic, Brittany, France). Til soon and best regards, Mike

-

Hi John ... wow! Just beautiful! Best regards, Mike

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Hi Patrick Thank you for the photos of the "replica" - But how did you bring in all this RC stuff with a full interior design - that borders on magic! ... and yes, absolutely. I remember concerning the fatal story of your loss - it's me a warning! til soon ... Mike

-

Hi Timmo You're doing a great job - looks really good! I like the clean processed raw build. One question: Do you applied soft soldering or hard soldering method for the hinges? Look forward to your further posts ... Best regards! Mike

-

Hi Mark I am happy about any additional plank on your build - comes really great! Best regards Mike

-

Hy Patrick It realy looks like a top-quality build! - congrats a lot! I'm looking forward to the final ... Best regards Mike

-

Hi Bob, hi Patrick For this time, only a briefly touch. I will check back in September on this log, giving you feedback and continue the reports - until then ... ... holiday! All the best, Mike

-

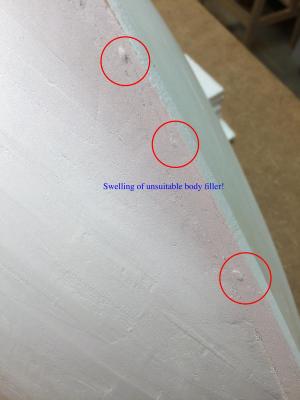

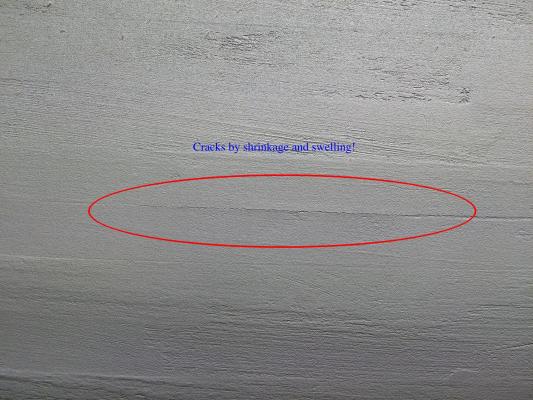

Hi all Thanks to all visitors for showing in and all the assessments with the like button. @Patrick Thank you for the nice comment and encouragement. Do you still have your RC boats? or maybe the one or the other photography? - about a possible post I would be very happy. @ Bob I also thank you for your comment. Yes, 'Stavanger's ' inner surface I have sealed with epoxy and fiber glass tissue. (see also below and post no. 121). As I have mentioned in the last log, the invisible hairline cracks in the wood of the keel were the reason for the water penetration. As the first corrective action, I have treated the keel wood inner side with an Epoxy layer – and after all, the big planked areas were seald from the beginning. But also the external coating has to be waterproof, this means the teaching of the lesson of swelling and shrinkage (see in last post). Therefore I decided to grind down the existing primer generously and to treat the whole outside of the hull with the real stuff! PRIMOCON (from International) is a one-component primer used in yacht building for the underwater area on all kinds of surfaces - as far as my assumption that what is good enough for the originals for the "little" is right. I have finally used acrylic paint to the final coating. Best regards Mike Below: Work flow as described

-

Hello everyone Thanks to all visitors for showing in and all the assessments with the like button. @ Patrick and Bob Thanks a lot for your feedbacks! – Bob, I suspect the question concerning "Vodka" came from Russia, yes? To the shipyard ... There was much detail work in the past few months concerning the preparations of the deck - I will report in the next logs. Among other things I spent a lot of time to gain clarity about the RC installation - or at least an idea of, before the deck gets closed. This is the reason for the long silence on “Stavanger's“ Log. First of all, the marking of the CWL (respectively painting line) was necessary. Second was the first swimming test ... it was a full setback! I had to realize that the hull was not ready for water at this time ... ... about my corrective measures in the next log. Till then and all the best, Mike

-

Hi Patrick Thank you very much for the Photos of your funny tin - by my little girl I've already get a print job for tomorrow ... Actually, you can put that tin in Symphony's salon as a micro model on the sideboard ... ... by the way, Symphony's salon with the fireplace looks awesome! All the best. Mike

-

Hallo Patrick In this log also and again, you showing us the emergence of a small work of art - absolutely great! ... ... and I have to admit what I also like is the consistency and the aesthetics of your photo galleries and the presentation of your logs. They are very beautiful and inspiring - they seem to me like a still life - for example, there is this fruit bowl in the background or the box with the funny elephant (which my little girl loves so much) or also the small blurry screen of the laptop - I like that! Keep it up! All the best! Mike

-

Hi Igor This is probably the "Flying Norwegian" - am I right? Looks fantastic! Best regards. Mike

- 154 replies

-

- colin archer

- lifeboat

-

(and 2 more)

Tagged with:

-

Hi Patrick As always your builds are a class of their own - simply fantastic! best regards Mike

-

ancre La Salamandre by tadheus - 1:24

mikegerber replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Hi Paul That looks super! Well done - perfect craftsmanship as always! Best regards. Mike -

Hy Igor I like very much this last Pictures - Scale and detail solution make again a stark contrast! Very well done! Best regards Mike

- 154 replies

-

- colin archer

- lifeboat

-

(and 2 more)

Tagged with:

-

Hi Vaddoc Courage, you will fix it! - You're doing a great job on this model, I am looking forward to each of your posts! All the best Mike

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

ancre La Salamandre by tadheus - 1:24

mikegerber replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

... Looks super great Paul! I'm looking forward to future posts Best regards. Mike -

Hello Kees Your KW49 looks absolutly great! Wonderful and Congratulations! ... and the scenery is also true. I already look forward to your next build. Best Regards. Mike

- 205 replies

-

- kw49 antje

- trawler

-

(and 1 more)

Tagged with:

-

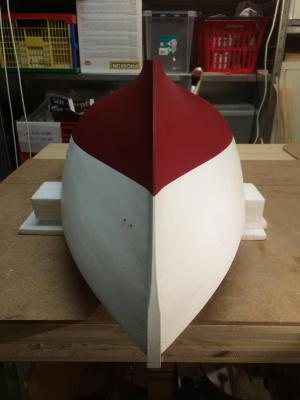

Hello again I would like to thank for all the many likes, which has received the last post! @Igor Thanks a lot! ... and of course I am pleased repeatedly on news from your RS1 shipyard. @Parick Many thanks to you too! ... In addition I have embedded a thin glass fibre tissue in the epoxy layer - I think that will hold. In the meantime the primary color concept is finished (see below) - there will be water resistant acrylic-based paints. @Lawrence Thanks a lot for the great feedback/comment and so many likes! - It means a lot. @Bob Thank you Bob, for this valuable tip with the rubbing alcohol (Isopropyl alcohol?). Again and again I'm amazed about the vast of know how that is cumulated on MSW- there are answers to so many technical questions here! I should get used to ask more questions about unknown topics of mine ... Best Regards. Mike Below: Some considerations of the colour concept. Flag of the Norwegian Society of Sea Rescue (NSSR) Todays colors of the NSSR Lineup of RS Boats with the todays colors "Stavanger" with her specific colors The current color samples for the model

-

Hello everyone Thanks to all visitors for showing in and all the assessments with the like button. @Patrick ... „Onwards and upwards now“ ... – Yes! After long back and forth I decided to attach a waterproof epoxy layer only inside the hull - I've to much concerns, that by a external application, the wooden nature of the boat will suffering. Either way I hope that now everything is tight - a leak test will be done. Best regards. Mike Below: To days state of the hull with epoxy layer inside.

-

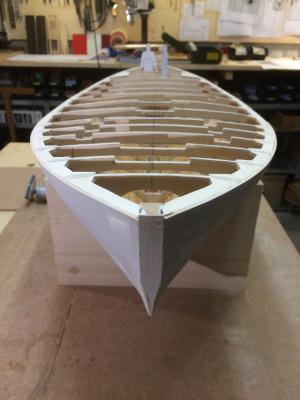

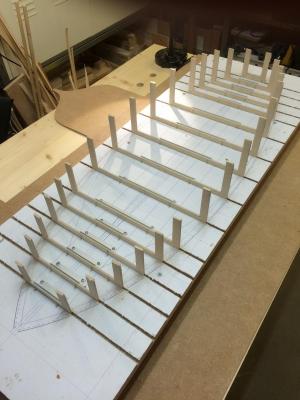

... and what's happen in the workshop? It was a great moment for me: To see her released from the jig! Best regards. Mike

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.