-

Posts

671 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by hornet

-

-

I get my Birchwood Casey via EBay. Jaycar electronics sell a lot of soldering stuff. They do online orders as well.

-

I agree with Brian, that's how I do it too. I use brass or stainless screws.

-

-

I built the Corel version. I wouldn't recommend it unless you are very experienced.

-

Rick, I think you are right about the boats. They look identical to the ones supplied with the Perseverance and Mermaid - which were plastic. I think this may be the case with other manufacturers as well though. The Caldercraft Supply ( my current build) did not even come with a ship's boat. I actually used the plan from the Modellers Shipyard Sirius Longboat (which I reduced to a length of about 8cm on a photocopier) and scratch built it. It turned out really well - better than anything I could buy.

-

I think you may be right Frankie. I checked out the Sirius Website and there is a good diagram of the bow section. The bowsprit on the model does seem to be a smaller diameter than the one in the diagram. ( link below)

-

This kit is not 'new.' Modeller's Shipyard (modeller's central) was selling it some years ago. The rumour was that it was that it was taken off the market due to design faults - I'm not sure if this is true but it looks like they have resurrected it - they must have fixed the problems that existed in the earlier version ???????? This kit is considerably cheaper than the original which (from memory) sold for around $1100 (AU)

-

Hi again Cabbie

Yes the outer stunsail boom rings are attached with brass tubing (1mm) which I bought cheaply on ebay. However you could do the same thing with brass wire. The copper sheeting I used was about 0.2 mm thick. I can't be exact as my vernier callipers aren't the new fangled digital type and I got it quite a while ago and don't remember the thicknesses. However even the thicker stuff bends very easily and can be moulded into all sorts of shapes. I have two thicknesses of copper sheet, one is a little thicker, probably 0.3 - 0.4mm. Both are good and easier to use (in my opinion) that brass. Silver soldering isn't hard and adds another dimension to the hobby.

-

Hi Cabbie

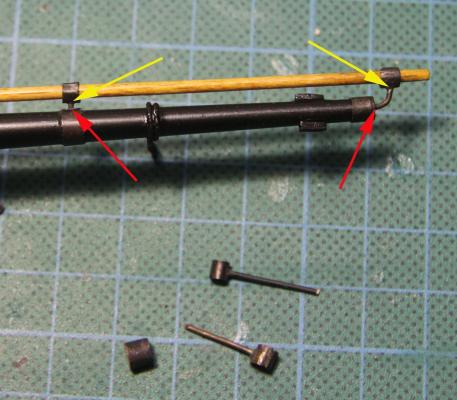

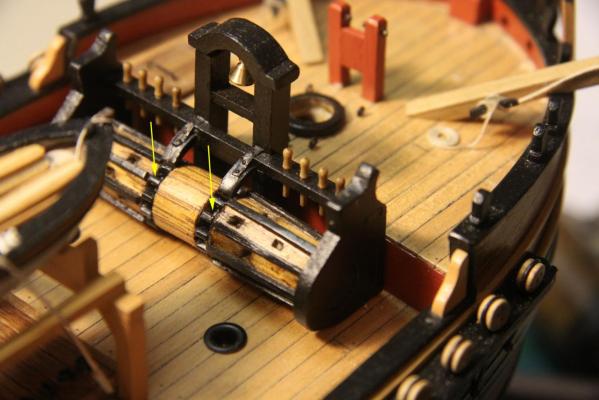

Welcome from a fellow Aussie. I have to concur with DocBlake in regard to just drilling a hole and using the whole eyebolt. I might add you may wish to consider buying a sheet or two of copper (quite cheap on ebay) and using it instead of brass sheeting. I have found that is easier to bend, blackens easily as well and is very easy to silver solder. I have done a number of jobs where I have silver soldered copper sheeting to brass wire or tubing. The pic below shows some scratch built inner and outer stunsail boom rings. The joins arrowed in yellow have been silver soldered ( brass tubing to copper sheeting) the ones arrowed in red were drilled through the copper and directly into the dowel. I found that the silver soldering blackened well using Birchwood Casey Brass Black.

-

If you are going to plank your deck after gluing in place, a good result can be gained by marking the deck where the bulkheads line up under it, predrilling (about a 0.8mm drill bit) through the deck and bulkheads, applying glue then nailing deck in place with pushpins or chart pins. I have found chart pins such as that arrowed below work better than standard push pins because the heads don't break off when nailing. Pins are easily removed when glue is dry.

-

My No 11 blades have a very short life expectancy. I find that I regularly snap the tip off them. This often occurs while the blade is still sharp. For this reason I tend to buy my blades in packs of 100 and I don't get too attached to them. In saying that, checking out how other's sharpen their blades sounds interesting.

I have found a use for broken No 11 blades. See glue scraper on following link.

http://modelshipworld.com/index.php/topic/4679-the-kit-bashers-guide-to-the-galaxy/page-7

-

-

I used Zap-a- gap CA glue to copper the hull of my Sloop Norfolk. It was my first attempt at copper plating. Up until this time I had never had any health problems with CA glue. Even though I did the coppering outside on a deck, I too came down with symptoms similar to flu. In fact I thought I had a very bad cold and ended up taking a couple of days off work. The Admiral suggested that I may have been suffering from the effect of CA fumes. At first I thought that this could not be so as there was no warning on the bottle. However, after doing some research, I discovered that this was a fairly common problem. I now never use CA - even a very small amount - without a face mask.

-

Every time I browse this site, I learn something new. LOVE IT

-

I use polyurethane matt and satin but dilute 50/50 with low odour turps. On small areas I brush it on but on larger areas such as decks, I apply with a single action airbrush. I find this gives a smoother more even finish that an aerosol can. Because the poly is thinned, I usually apply at least 4 coats. It tends to dry a lot quicker than 100% poly. I agree with Geoff, Admiralty paints are excellent both for brush and thinned in an airbrush.

-

To Kurt's philosophy I would also add the following:

He who dies with the most toys WINS!!!!!!!

My Chopper II works well on anything less than about 2mm in thickness. After that I find that the blade tends to flex and a square cut is difficult to achieve. This is when my little Proxxon KS 230 circular saw takes over. I have found the chopper to be most useful for repetitive jobs like cutting deck planking.

-

Brick75 and Jparsley.

Buy or make yourself some planking screws and use titebond or quick dry PVA when planking. CA is more trouble than it is worth when planking. Home made planking screws shown on thread below.

http://modelshipworld.com/index.php/topic/3734-planking-screws-moved-by-moderator/

-

Being half way through my Caldercraft build of HM Supply, I too found many differences between the Caldercraft and the Artesania kits. After close inspection of the build by Dan Vadas I noticed the model seemed more `rounded' than the Caldercraft kit. When comparing them both to the Powerhouse Museum model, I could see that both kits had some similarities and some differences to this as well. Things became even more confused for me when I looked at a contemporary painting of the HM Supply (see below)

I think that the overall `shape' of the Caldercraft version is more accurate, but many other details are more accurately shown in the Artesania Latina kit. The Caldercraft kit was reasonably inexpensive and this may account for some of the omissions (like a ship's boat). With a lot of `bashing' I have ended up producing a hybrid of all four configurations. It may not be entirely accurate but I am having fun with it.

-

I too am fascinated by Shackelton's amazing feats of endurance. I purchased the reprint of his book 'South' as part of a Time Life Series - 'Classics of Exploration' many, many years ago. The story and the B/W photo's in this book are remarkable. I am very interested to hear that a kit of the 'Endurance' is coming out at the end of the year. Does anyone know who is producing it?

-

I have also found Admiralty Acrylic Paints to be excellent. The colours are authentic and they work very well when diluted for an airbrush. Even though they might not be considered 'cheap,' the fact that they give excellent coverage makes them, in my opinion, very economical. I also love the new lid which is a flip top and has a small lip at the rear which prevents paint spilling down the side of the bottle when opened.

-

-

I purchased Alexey's motorised serving machine some time ago and made a modification which allows the reel of cotton used in the process to be mounted on a rod at the front of the machine rather than just sitting on the bench top. I have found it to be a useful addition. I also found greasing the shaft where it goes through the supports with fishing reel grease makes the whole machine work more efficiently. Check out the link below if interested.

http://modelshipworld.com/index.php/topic/7712-domanoff-rope-serving-machine/page-2

-

Hi Bryan. As you move forward with your second layer of planking, you may like to consider using PVA wood glue instead of CA (superglue). The use of wood glue such as titebond, or my preferred glue a quick drying PVA from Selleys is not only much easier on your fingers because it is water based but is a lot more economical and has no toxic fumes - as CA does. You can use a gel type CA (this is not runny) on the end of the planks to help hold them in place while the PVA glue dries ( only a couple of minutes in the case of the quickset PVA). Using PVA allows you to move, adjust or even remove an reshape where necessary. CA is much less forgiving.

-

When you think about it, buying from Germany is no different from buying from the UK if you are buying off the net. Unless the dealer is within a reasonable distance you are unlikely to go to their premises.

Also, if you pay via credit card then the card company are equally responsible as the dealer that you buy from if anything goes wrong.

Proxxon appear to be a reputable company so I wouldn't think twice about buying from them.

Derek

Thanks Derek, but I was actually interested in John's ( Neptune) take on the warranty issue. I'm sure that purchasing from Germany would not be an issue if you were in the UK but could be if you are a zillion kilometres away in Australia.

Ship rigging book

in Masting, rigging and sails

Posted

Cabbie,

I have found Petersson's books to be very helpful. This Aussie Online seller has good prices too!!

http://www.thenile.com.au/search?s=Lennarth+petersson&x=0&y=0