-

Posts

6,402 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Canute

-

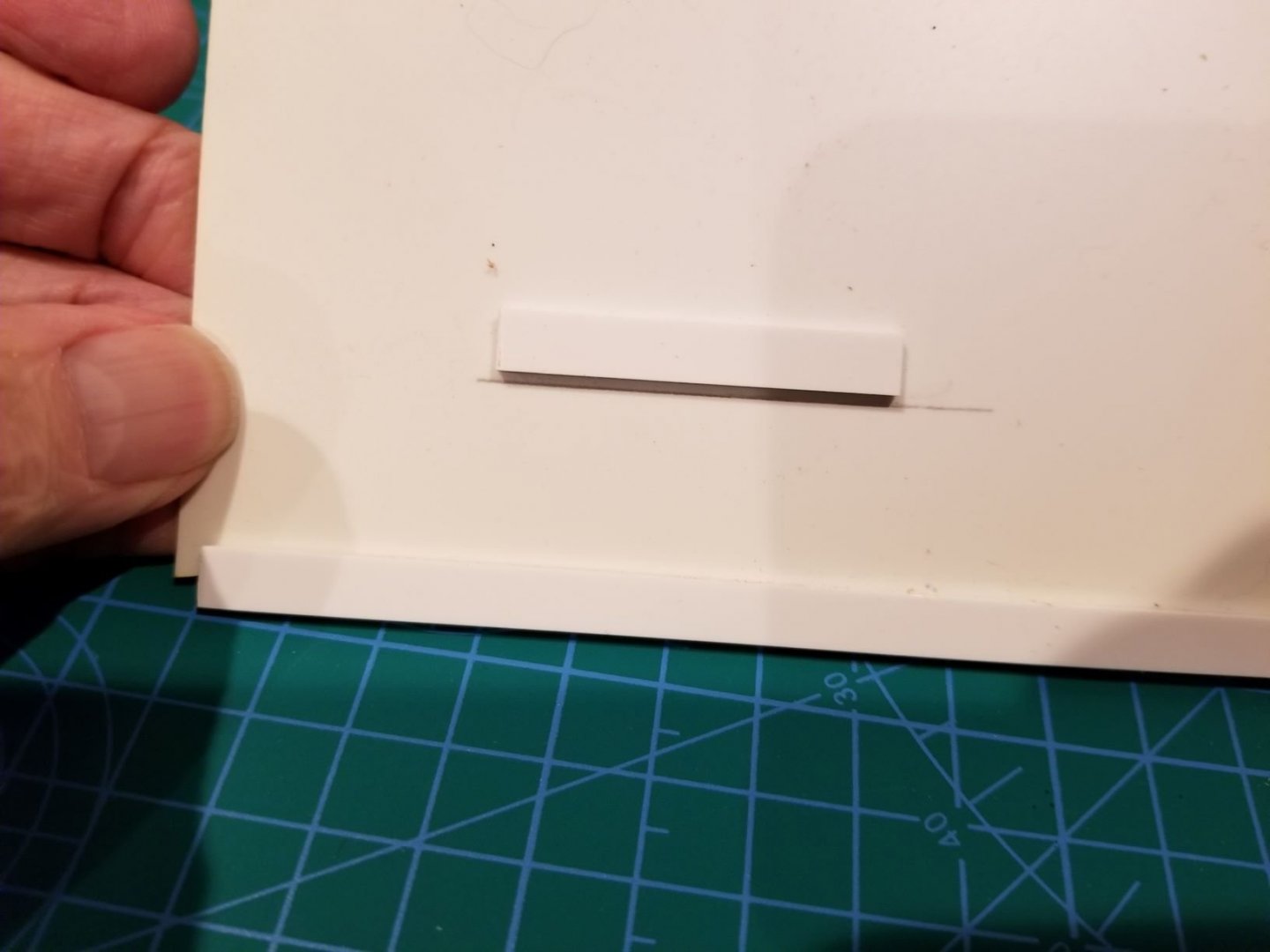

Finally decided to join in with the Medway Longboat project. I liked the lines, it'll teach me some fundamentals and it's designed by the Maestro, Chuck. The wood is excellent to work with and I've tried to keep my big mitts clean. I opted for the half lap joints to stretch my skills. I thought I did a pretty good joint and glued the stern together. Oops, it was bent. I figured out I only checked the thickness along the immediate outside edges but failed to check it was uniformly the 5/64" thick on each side. After an application of isopropel alcohol and dismantling the boo-boo, I made a little sanding fixture to keep the joints uniforms. Now, it's nice and straight. It's a piece of .040 inch styrene sheet with two .080 x .125 styrene strips. The .080 will allow me to get very close to the 5/64" dimension. I built up the keel and got it ready to add the bolts. I drilled the bolt holes with a #74 drill. Next step, wipe on poly. I worked on the floors and frames, making sure every one fit nicely, The fun will begin when I start fitting all of them into the keel. Bow frames. Stern frames I have to attach the transom, but have a question for the mavens. Do I remove the char in the groove to attach it to the keel. I cleaned up the char on the top edge and am contemplating how to keep the transom square to the keel. So far, it been a pleasure working with this wood.

-

Hmm, the Dragoons would be a good choice. I had considered reenacting a US Cavalry staffer at Gettysburg. Had the horse, but needed the rest of the gear. And time, which Uncle Sam was pretty stingy about allowing time off. The Cav at Gettysburg was in at the start, under Buford, northwest of that town, slowing the Rebs advancing on Gettysburg. And they were in there at the end, est of town with Custer and Stuart in one of the bigger cavalry clashes so far in that war. I'm a fan and student of the Cav in that war.

-

OC, while I like the alliteration you used, Ekis is correct. My given name has no Latin language equivalent. In my high school Spanish class, I used my middle name, James or Jaime in Spanish. Kenneth is pretty pure Celtic Irish or Scottish. The Scots had a King or two by that name. The Irish version, Kainnet or Canice, was supposedly an Irish member of St Columba's disciples on Iona. Alexandre or Denis would be a better name for M. Cuirasier. 😁

-

Nails and Glue

Canute replied to Neil10's topic in Building, Framing, Planking and plating a ships hull and deck

I'd like to read some ideas on what grade of CA to use on wood. My past experience makes me not want to use it as a glue. The black monofilament fishing line is a technique Chuck Passaro used in his 1/24 scale longboat, here on the site. His kit include 10 pound and 25 pound line for simulating bolts. The light line simulates bolts thru hull planking; the heavier line is used for the bolts in the boat's keel. I think it all comes down to the scale you are working in and how visible nail heads are in the scale. And too much of a color difference could make it look like a case of the measles. -

Delahaye 135 by CDW - FINISHED - Heller - 1:24 - PLASTIC

Canute replied to CDW's topic in Non-ship/categorised builds

Great looking car and an outstanding finish. Too bad the manufacturer didn't build a test model before the kit was released to see the discrepancy. -

Preformed sizing for dead eye installation

Canute replied to Runnymede's topic in Modeling tools and Workshop Equipment

I'm not a fan of paid sites for info I may not access on more than an occasional basis. Thanks for the efforts for digging the info up. -

Preformed sizing for dead eye installation

Canute replied to Runnymede's topic in Modeling tools and Workshop Equipment

Moab, it's now a drug pedaling site now. The site was saved on a Pintrest site now, which I'm not a follower. -

Preformed sizing for dead eye installation

Canute replied to Runnymede's topic in Modeling tools and Workshop Equipment

Do you have a link for Hubert's seizing? -

Your work with the kit PE is nicely done. Looking forward to seeing some more of your work.

-

Delahaye 135 by CDW - FINISHED - Heller - 1:24 - PLASTIC

Canute replied to CDW's topic in Non-ship/categorised builds

Thank you, sir. Looks like a good color for some stainless passenger cars, too. -

Delahaye 135 by CDW - FINISHED - Heller - 1:24 - PLASTIC

Canute replied to CDW's topic in Non-ship/categorised builds

Coming along nicely, Craig. Is that paint an acrylic or lacquer?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.