russ

Members-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by russ

-

Sam: In a 1928 article by a correspondent from out of town, he got to sail aboard a schooner in the regatta. He wrote that whenever he tried to raise up from his prone position on the deck to take a photograph, the rest of the crew told him to lay down because he was slowing them down. That is how seriously they took their races. Russ

-

Popeye, thanks for the kind words. Sam, the captain would kneel for a couple of reasons. In any event, the wheel is set very low and it would be uncomfortable and perhaps impossible to stand and steer. In many cases, the wheel box is set forward of the rail so there might not be a place to sit either. In races, everyone stayed low. No unnecessary wind resistance. Russ

-

The hull is shaping up very nicely so far. Good work on the bulwark framing. Russ

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Bob: Here is a photo of the bolt rope detail from a Biloxi schooner in the 1920s. Note the relative sizes involved. That mast is probably 9-10 inches in diameter and the sail hoops are probably about 1 1/2 inches thick or thereabouts. The halyards there are probably not more than 1/2" diameter. I would say the bolt rope is fairly large and prominent. Russ

-

That looks pretty good. I would suggest leaving it for a day or so and then come back and look at it with fresh eyes and see what you think. If you like it then, all well and fine. If not, well it is your call. You are the one who must be pleased with it. Russ

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

I agree that the outer windows need to come down or the inner windows need to come up. Russ

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks. The windlass needs a few more details, but it will get there eventually. The windlasses normally seen on local schooners are generally much simpler affairs than those found on schooners up in the Eastern seaboard for instance. However, I seen several different types used down here, so it really pays to research old photos to see about what was used in any given instance. Russ

-

Bob and Frank: Thanks for those kind words. Frank, there are many things about this model I like, but I can also see all the problems. Granted, most people will never see them, but it will always bug me. However, it is all a learning process and hopefully, some of things wrong with this model will help me make the next one better. Russ

-

Brian: The damage to the subdeck is really not that big a deal. It just needs a patch and it will not matter how it looks so long as the deck planking lays flat. On the stern frames, do the laser cut windows have an angle to them that they will fit between the angled stern frames as shown in the plans? If they do not, then you would not be able to fit them in between the frames if you installed them on an angle. If you are going to install the stern frames on an angle, then it is a simple matter of properly beveling the upper and lower ends of each frame. As for the two that are next to the false keel, there is little to be done there. It would be difficult at best to try and bevel their outboard faces to get kind of angle you want. I would let the laser cut window frames guide you on this issue. If they are not angled, then install the stern frames perpendicular and build the stern up accordingly. Russ

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

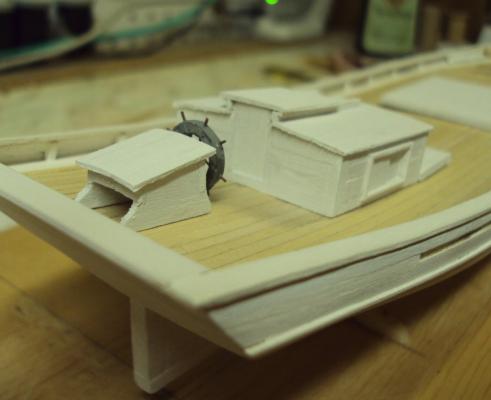

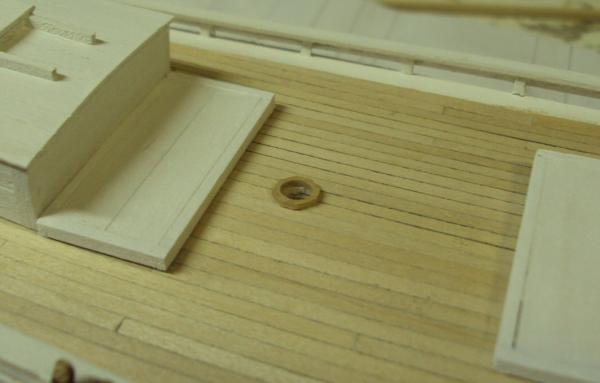

Here is another update. Some progress has been made on the deck fixtures and fittings. Here is a look at the wheel box which still needs some sanding and another coat of paint along with a peek at the wheel. The mainmast collar and the aft hatch is also nearing completion. The windlass is getting there, but still needs a few fittings added and the axel trimmed. The bitts will be painted after the windlass has been fitted but not attached. Questions and comments welcomed. Russ

-

Larry: The deck looks good. I generally do not put any finish on the deck before I get all the deck fixtures in place. I like to use hidden dowels in the bottoms of deck fixtures so that they will be fixed in place on the deck. I can remove a hatch coaming and know that when it goes back it is in the same place every time. Russ

-

Congratulations on a great build. She looks beautiful. Well done. Russ

- 139 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

John: It looks great. It is really good that you did not need any bilge stringers to stiffen the hull. Looking forward to the hull planking. Russ

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

The metal work looks very good. There is a lot of it on small workboats like this and you are doing very well with it. Good work. Russ

- 113 replies

-

- model shipways

- willie l bennett

-

(and 1 more)

Tagged with:

-

So far, the fairing looks like it is coming along well. Keep at it. In my experience, just when you are sure you have it faired, go back and check again. The moment you are sure about it is when the rug is likely to get pulled out from under you. Russ

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Good work so far. Is the bottom of the hull supposed to have any fore and aft curve in it? I think it should, but it is something to look at before you get too far. Russ

- 19 replies

-

- skiff

- Midwest Products

-

(and 2 more)

Tagged with:

-

Nice work on the halyards. Good solution. Russ

- 139 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Frank: The planking job looks pretty good. I have also had one those repair jobs and it is always good to get it done. Nice work. Russ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.