-

Posts

3,494 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cathead

-

I partly have to decide sooner, since once I've placed trees in front of the backdrop I'm not easily going to be able to remove them again or get behind them to redo the backdrop. I agree, but I also relish the challenge and the distinctive look! Your photos look awesome. Yes, this is the general plan in most places. The most exposed seam will be where roads go directly into the backdrop and I have yet to decide if I'm going to try and have them blend into the distance or just go blank. The problem with a town scene in which most of the town is just behind the backdrop is that it feels all or nothing; if I paint on a receding road, there needs to be receding buildings, too, and I'm not sure I'm up for getting that right. Something that looks wrong is often worse than something just not being present, since the eye and mind will fill in missing detail but will notice wrong-looking detail. That's what I did...the bare bluffs receding on both the left and right sides use the same paint/pastel mix as the foreground plaster rocks. I'm pretty happy with how those transitions turned out; at the very least I don't think I can improve it. Another challenge in such backdrops is that viewers see them from so many different angles that there's no one "right" perspective. Viewed from one angle, a receding bluff line or creek can look great, and viewed from another angle, can be at an awkward angle. Very different from a true "flat" painting in which the perspective more or less stays the same no matter how it's viewed. For better and worse, I've mostly tried to orient the perspective from a trackside view, such that certain things look a bit "off" when viewed from a normal standing angle.

-

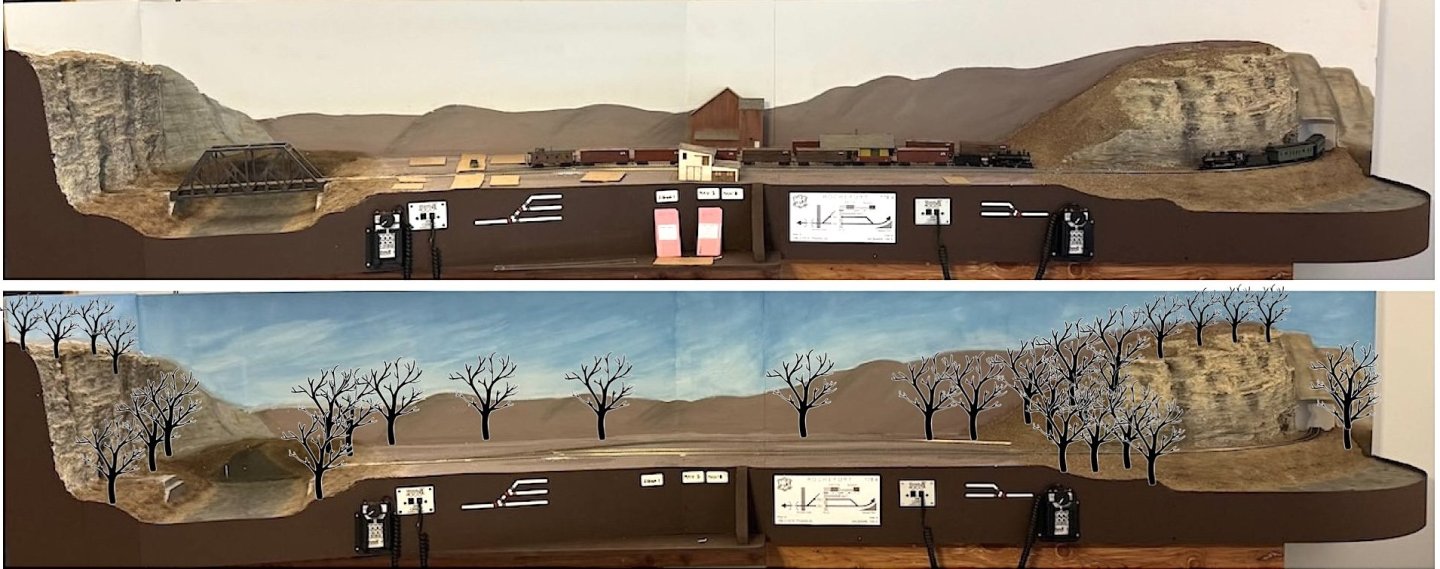

After posting that, I decided to do a little visual demonstration. It's easy to focus on the backdrop when it's the dominant thing you see without the foreground details in place. So I went back to the comparison photos I posted earlier, and added some basic tree silhouettes to give a better sense of how trees will break up the horizon and focus attention on the foreground. This is roughly the plan for major tree location: And this doesn't include the added effect of buildings, which granted will be no more than 1-2 stories except for the elevator, but will still further focus attention forward. What this suggests to me is that I shouldn't worry about most of the background and horizon, but that I might want to carefully draw in some suggestions of trees along the top of the left-hand bluff line receding away above Moniteau Creek, as there the foreground trees vanish abruptly once the bluff reaches the backdrop. Same for the bluffs on the far right. But that's (a) a much more narrow and doable space and (b) will only be needed in a handful of other places elsewhere on future backdrops. Thoughts?

-

Great question. I don't plan on sponge painting as that's usually best for simulating foliage, which wouldn't fit for this late fall leaf-off setting. I'm still trying to decide whether I want to try drawing on a blend of bare trees or just leaving it as a hazy background. The challenge I see is that adding that level of detail would be all or nothing; if I can't get it the way I like, I'm going to have to repaint the entire thing because I can't just blend it back in the way I can with the current hills. And perspective/distance would be hard; the details of the trees would have to change from foreground to background or it'd look ridiculous since the way I have the hills painted represents quite a bit of depth (from right behind the foreground to miles away). In other words, if the backdrop were "flat" and just needed to represent a line of trees right behind the foreground scene, it'd be easier to add more details. But I'm not sure if I can get the perspective right with slowly blending fainter and fainter tree details as the perspective retreats back. You could argue that sponging would work for giving the faraway hills some texture, but I'm not sure how to blend that into more detailed trees in the near-ground. Partly just my artistic limitations since I have no real painting experience. And this is also why I'm not sure it's worth trying to super-detail the backdrop. It stands out right now, but once the town buildings are filled in, and there's even a handful of bare trees breaking up and obscuring the horizon, I'm not sure the extra detail would really stand out enough to justify the work. I'm less worried about making any still photography look photo-realistic and more about creating a setting that feels real and immersive when you're operating trains in front of it. The other consideration is that the current scene isn't meant to stand alone, but to be part of a larger layout eventually. So whatever design/color/detail style I define for this scene, I'm going to want to extend reasonably consistently to all the other scenes. IF I take this project to its full extent, I'll need at least another 50' of backdrop in addition to the current 11'. So do I want to be drawing/painting on complex tree details for another 50+ feet down the road so all the scenes feel consistent? In other words, whatever I do here defines the "style guide" for the rest of the potential layout, which creates different considerations than if this was just a stand-alone diorama. All of which is why I'm leaning toward leaving well enough alone, but have not actually decided. It's possible I could paint a small test-case panel off-layout reasonably close to the current backdrop style and see if I can create a more detailed style that's effective and efficient. Oh man, what did I just talk myself into when I just spent this whole post talking myself out of doing more work!

-

Thanks for all the feedback and advice! To be clear, I am familiar with the basics of photography and Mrs Cathead is a moderately skilled SLR operator. I just tend to use my iPhone on a day to day basis because frankly, it matches the SLR about 70% of the time and I personally don't enjoy using "real" cameras. I'm actually pretty good about adjusting phone settings to get good results when I want to (I do a lot of nature and landscape photography for both work and pleasure), and I tend to have a good eye for composition. I just don't always fuss with it when I'm doing basic model photography. Maybe (probably?) I should, but I don't. And for what it's worth, the nearest camera store is over 100 miles away! Here's a couple examples of phone photos I'm happy with. First one from a central Missouri prairie, second from a south Missouri glade. Neither has been altered in any way. I'll hopefully have another update this weekend.

-

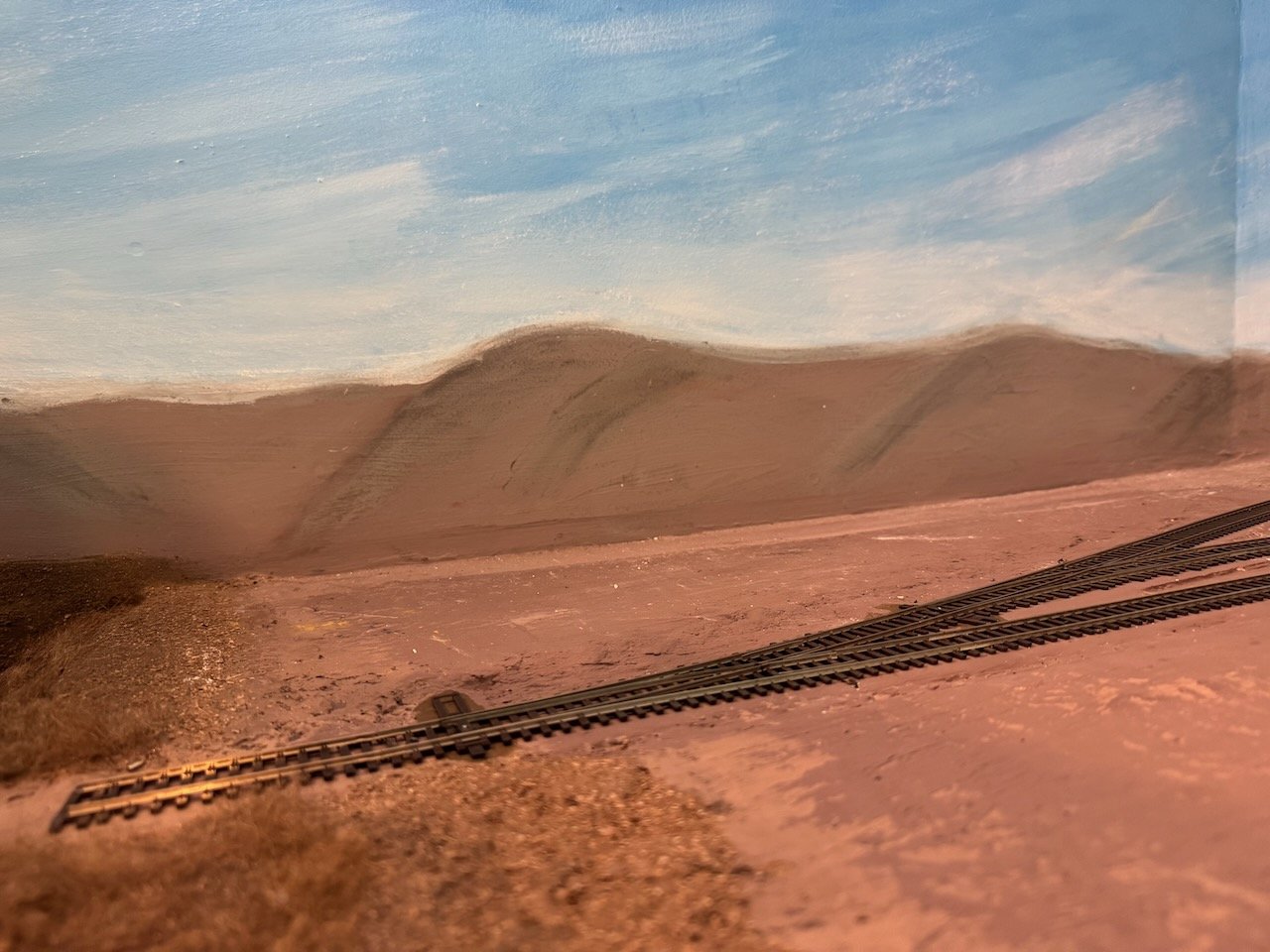

Yeah, I think it's the photo color balance. Here are a few closeup shots just to show what this looks like, partly since the camera "lies" from distance. These all have an odd, Mars-like red tint that demonstrates color balance oddities. These also show that, like many things in modeling, a sufficiently close look can ruin the illusion (the clouds look more like paint here) but I'm still pleased with the result. I also went through and touched up both the clouds, and the horizon interface with the hills, using pastels to soften some areas and blend sharp boundaries. I don't think you can tell the difference in the photo below but it looks better to me in person. I brightened this photo; the version below looks a little closer to the in-person view, and also closer to what it might look like when I get the overhead lighting installed. Thanks, Keith! And to all of you for the likes, comments, and interest.

-

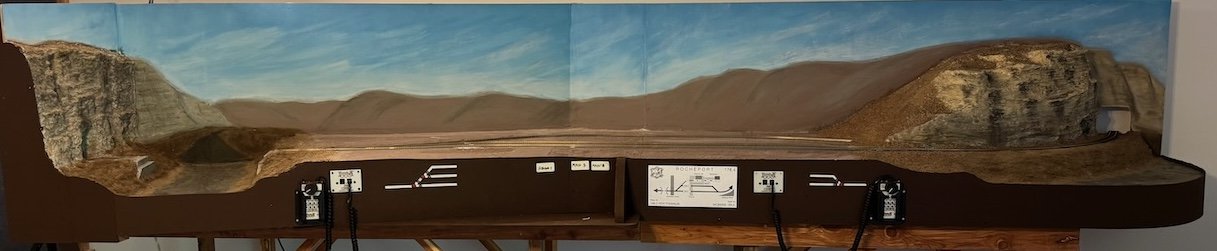

Here's a quick update on an upgrade. I finally made time to properly finish the backdrop. Although I did kind of like the bland threatening overcast look of the base sky color, I had planned on a different look. Some of my favorite Missouri winter days are those with clear skies but a haze of high clouds portending a change in the weather, like these reference photos from the Rocheport area in January: And here's a before-and-after pair going from the background to the finished sky: Thoughts? I'm trying to decide (a) how well it matches the reference photos and (b) whether I do in fact like a more overcast, threatening look. You'll note that I was historically accurate and did not attempt to recreate contrails... EDIT: Just realized I didn't describe HOW I did this. It's a technique pretty common for model railroaders; for example searching YouTube for something like "paint model railroad backdrop" will get lots of results. Basically I laid down a fresh roller layer of blue paint, then started brushing white in from the bottom, blending the wet paint upward to go from hazy near the horizon to brighter blue higher up. Then I started using brush strokes to develop the elongated hazy cirrus-like clouds, going back over everything with the roller now and then to blend things in. I actually ended up nearly done and then started over, because my first version was too blue and not hazy/cloudy enough. I also made things hard for myself by being over-perfectionist and trying to keep touching things up as the paint got too dry, which makes blending harder. One other thing I did that you shouldn't do, is paint the foreground hills before the background sky. It's a pain to try and blend sky into pre-existing hills; much easier to start from the back and work forward. But that's not what I did and it just made the job a bit harder. You can't see it from the distance of these photos, but I need to go back through and use pastels to blend in the horizon/hill interface a bit. No excuse; I just got ahead of myself in being excited about scenery and didn't take the time to do the sky first. Oh well. I think it came out pretty well.

-

I mean, I'm regularly floored by your work, so I might as well floor along!

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Great start, sorry I missed this when you launched. As one of the resident steamboat aficionados here (see my signature links), you've made a great choice of kit and subject and I'm super excited to see how you progress. If it's of interesting, @kurtvd19 has a really great set of extra instructions and context that can help you get even more out of this model. Hopefully mentioning him here will summon him to make contact with you. Welcome to MSW!

- 23 replies

-

- sternwheeler

- Chaperon

-

(and 3 more)

Tagged with:

-

For what it's worth, if my memory and understanding are correct, there were hand pumps on even larger riverboats like Arabia for just this sort of scenario (priming boilers when the steam was down). Granted, that was in the mid-1800s, so by your era any sensible crew may have told the idea of a hand pump to take a long walk off a short barge and installed a gas pump like you're suggesting.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

I started hearing the theme from Jaws as soon as I saw that. Very cool idea to add that. To be honest, I thought it was a loudspeaker when I saw it and wondered why you had a tornado siren on there. It's nicely done, it's just a lot bigger than the one in the original photo. So I'd agree with you on redoing that one. Everything else looks great!

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Well sure, you'd think so, but the reason I got involved in this particular theme was that one of the earlier kit images you showed had what sure looked like the wrong Cyrillic letter, or at the very least a really poor rendition of one, so I was just celebrating that the part you showed this time was right.

-

Here's a bit of fun historical background. I was finally able to make a trip to the State Historical Society research center, where they have all sorts of cool stuff. The item I was after, which I'd perused before but not taken detailed notes from, was this: This is a thick volume, published by the railroad, that lists summaries of every town along its entire system covering Missouri, Kansas, Texas, Oklahoma, and Louisiana. These summaries include population, primary industries, descriptions of the surrounding country and its agriculture, and so on. The volume then goes on to list, in exhaustive detail, every business or businessman having a relationship with the railroad in an extraordinary variety of classifications. For example: That last one cracks me up. Language is always changing. So I was able to slowly go through the entire volume and note down every business that dealt with the railroad in my focus towns like New Franklin and Rocheport. Here's a summary of the businesses operating in Rocheport in 1912 that the railroad felt were worth listing in its business directory as shippers or receivers, curated for the entries I felt were most relevant. Yes, I'm focusing on 1900 instead, but this is the only year the research library has and it's close enough for my purposes. Hotels Grossman Hotel Agricultural implement, vehicle and wagon manufacturers and dealers W.W. Scobbee Apple and potato dealers, buyers, shippers, and growers George Roberts, apple grower & shipper C.D. Hill, " C.C. Bell, " H.J. Fieschman, " Luther Grigsby, " Sid Challies, " L. Torbitt, " C.S. Jenkins, " Coal & wood dealers T.J. Canole Drug dealers B.F. Dimitt E.H. Chinn General merchandise dealers E. Inman J.B. Challis H.R. Harris Grain Elevators, flour, feed, corn, grist and rice mills Rocheport Roller Mills, flour, 125 bbls daily Rocheport Elevator, 10,000 bu Hardware and mill supplies F.E. Bysfield Hay and alfalfa dealers and shippers T.J. Canole Lumber F.E. Bysfield Stock yards and livestock dealers and shippers Basque & McMillan Rapp & Little D.C. Steckdaub Note some of the interesting overlaps: TJ Canole is both a wood/coal dealer AND a hay/alfalfa dealer. This is pretty fun, since when I was first trying to figure out what that giant hay barn was, I thought it might be a lumber yard. It may still double as a fuel dealer and that means I can spot cars of coal there (Missouri has several major coal mining regions that were quite active in this era, including a major field along the MK&T mainline in SW Missouri). Also noted that FE Bysfield is listed under both hardware and lumber; that's also a pretty sensible combination. The sheer amount of independent businesses in a town of 434 is fascinating. Not to mention the far more diverse agriculture. Nine independent growers and shippers of apples from a town that size! I knew this area was once vibrant with orchards but even so that's a vivid picture. I'm strongly resisting the urge to get political here with regards to the decline in small towns, manufacturing, and independent communities and the resulting socio-economic problems. So all this is very interesting if you're a complete local history nerd, but why is it relevant to this modeling project? Two primary reasons. (1) It lets me use real names for local businesses. I can now call it the Rocheport Elevator (creative name, I know) and put a sign for TJ Canole, hay dealer, on the larger barn wall. I can give the commercial buildings in town the names of real enterprises. It adds a layer of realism and context that I think is pretty neat. (2) It makes operating sessions more interesting. Having all these names for local shippers lets me set up specific orders for cars. For example, maybe one set of stock cars sent to the stockyard is for a consignment being shipped by Basque & McMillan to one destination, while another set of cars is for Rapp & Little being sent to a different destination (for example, Kansas City vs St Louis, both of which had major meatpacking establishments), instead of just "two stock cars". I can have different boxcars spotted to be loaded with apples from different farms being sent to different destinations. I can have shipments for a given merchandise or implement dealer set out, rather than just "spot boxcar 123 on track 1 loaded with general freight". Operators switching in Rocheport (or anywhere else) will have a much richer sense of what the railroad is doing there, and that's part of the joy of modeling railroading, the ability to really recreate the actions (not just the look) of a setting. Another aspect of (2) is the value of planning a model railroad based on real settings. I laid out my version of Rocheport based on the actual track arrangements and what I could see in contemporary photographs. For example, there's only one siding and only two physical destinations for freight cars on that siding (the stockyards and the hay/grain complex). Model railroaders building something more freelanced would want more physical industries in a scene this size, and would be adding factories and other sidings and so on. I stuck with what I could see. And the reward is the evidence that Rocheport DID have a lot of other industries going, it's just that most of them didn't have specific loading points. I left room in my track plan for two spots where freight cars can be spotted for general loading/unloading (called "team tracks", since traditionally a wagon drawn by a horse team would pull up there, and still called that today even when served by modern trucks). I didn't have a specific plan for what would ship to/from these points, I just felt certain they'd be needed. And now I have a massive list of specific businesses that would be using those team track points, from outbound apple shipments to inbound farm equipment. It just makes the whole setting so much more vibrant. In a future post I'll talk more about model railroad operations but this is enough writing for one post. I think it's some pretty cool context and maybe you will, too.

-

Chris, here's another question about accuracy, as a former student of Russian. In the "what it's supposed to look like" photo, the stern has what's obviously supposed to be the ship's name in Russian, Phoenix (феникс). But that first letter looks totally off; it looks like a plain "o", not the Cyrillic "f", "ф", which can be scribed various ways but must have a vertical line through it. Sometimes it looks like a sideways 8, sometimes a circle, but always the vertical line. What they show would read as "oenix" in English. It really threw me until I realized it was an incomplete f. Unless I'm missing something about 18th century Russian script, which I admit to not being familiar with... What does the lettering look like in your kit?

-

I would have said the same as Other Keith; black makes a good undertone but the way to weather it is with shades of grey that tone down its ability to soak up light, and reveal some of the surface texture. Another reason I like pastels, because they inherently leave some texture on any surface that scatters light just a bit.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Me, too, though I kinda can't wait until the next revolution comes and locomotives become self-contained with battery power. I'd be thrilled to eliminate all track wiring. Sound does add an extraordinary level of immersive realism. Yeah, the car card boxes will be right at that shelf for easy use. This way this scene is designed, it's all but impossible (or at least highly inadvisable) for any paperwork to get put on the layout because the tracks are set back a bit with scenery in the foreground. There will also be a track diagram with spotting locations labeled, I'm working on developing that now. That'll be a future post.

-

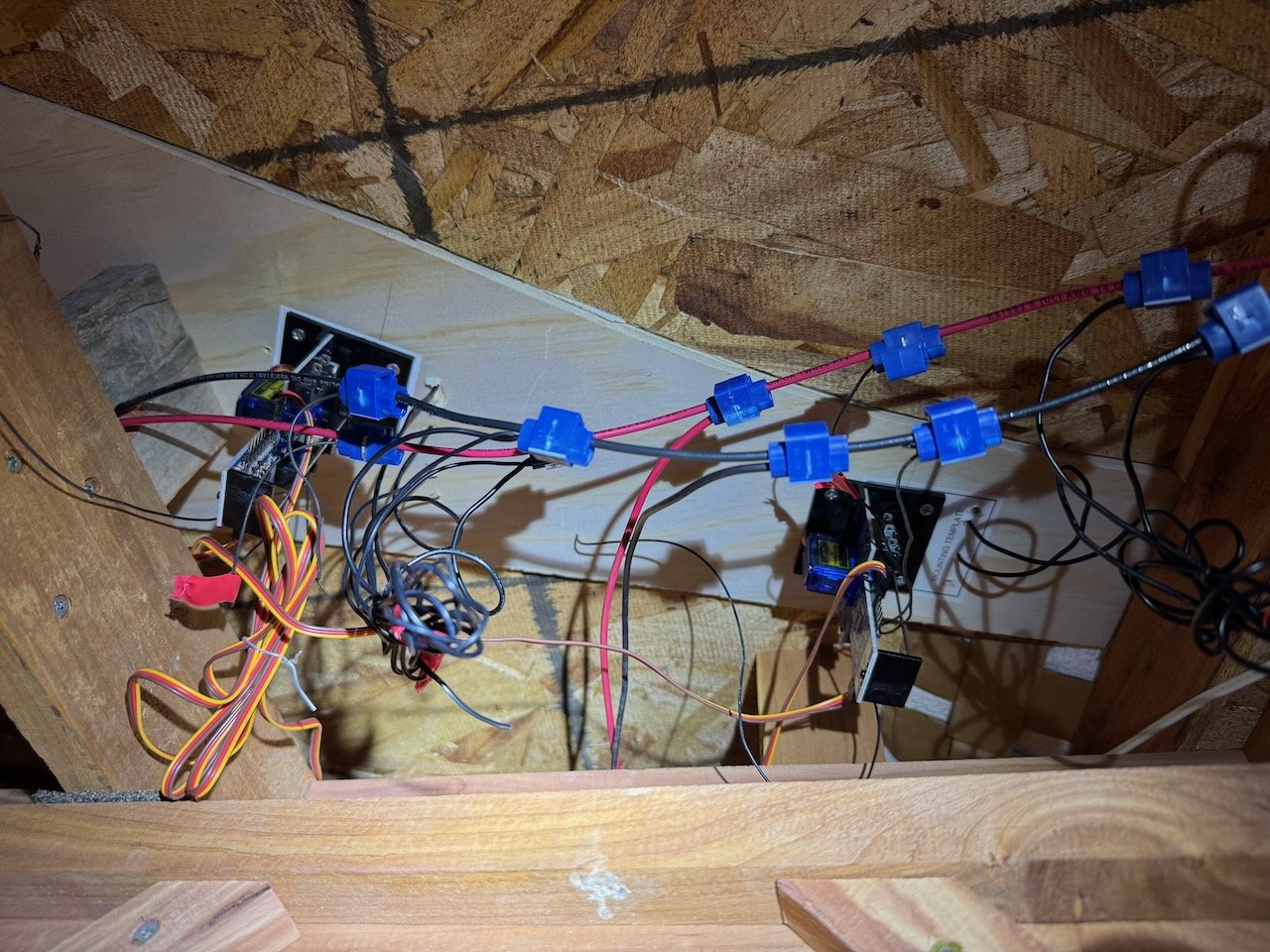

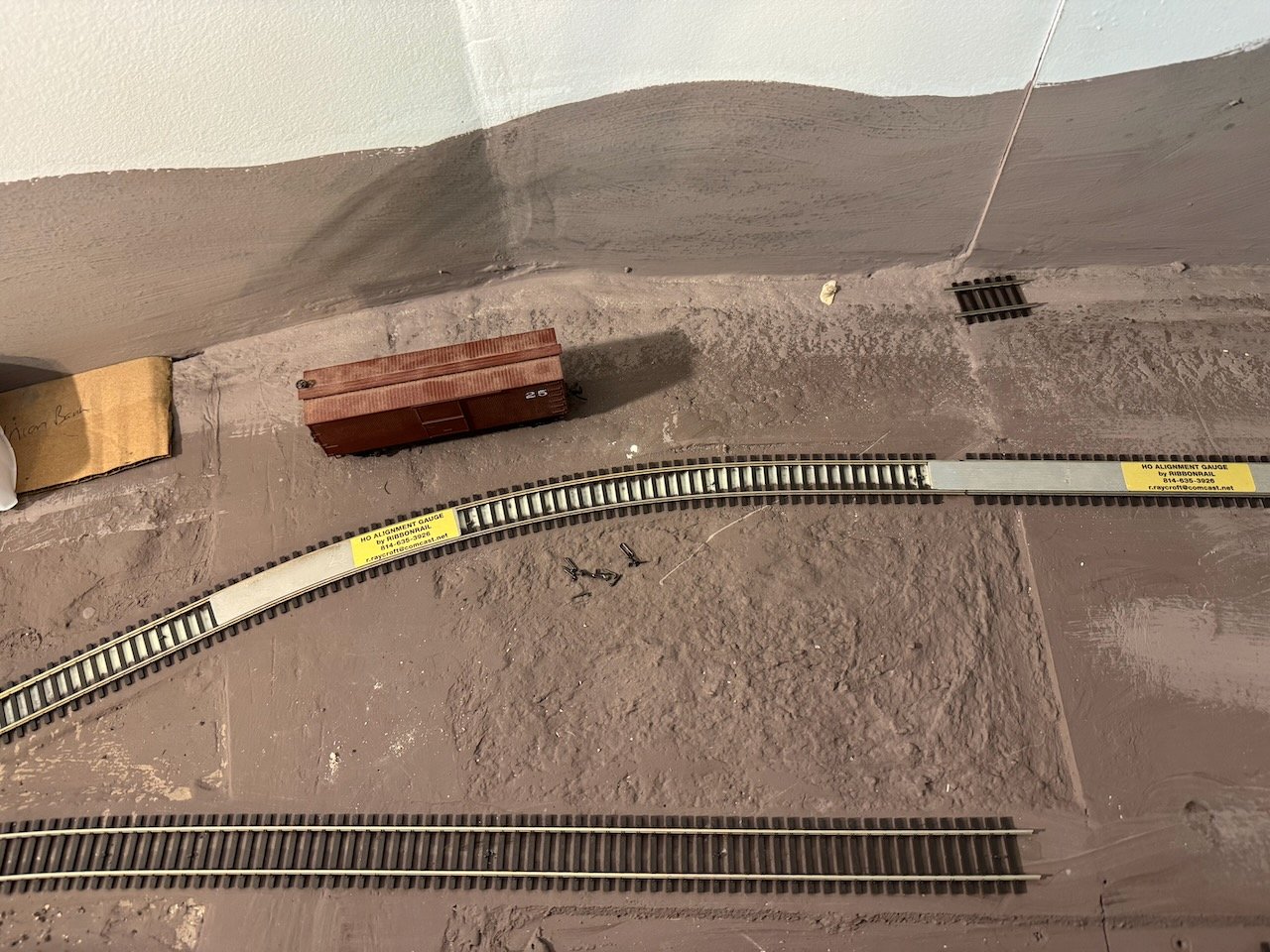

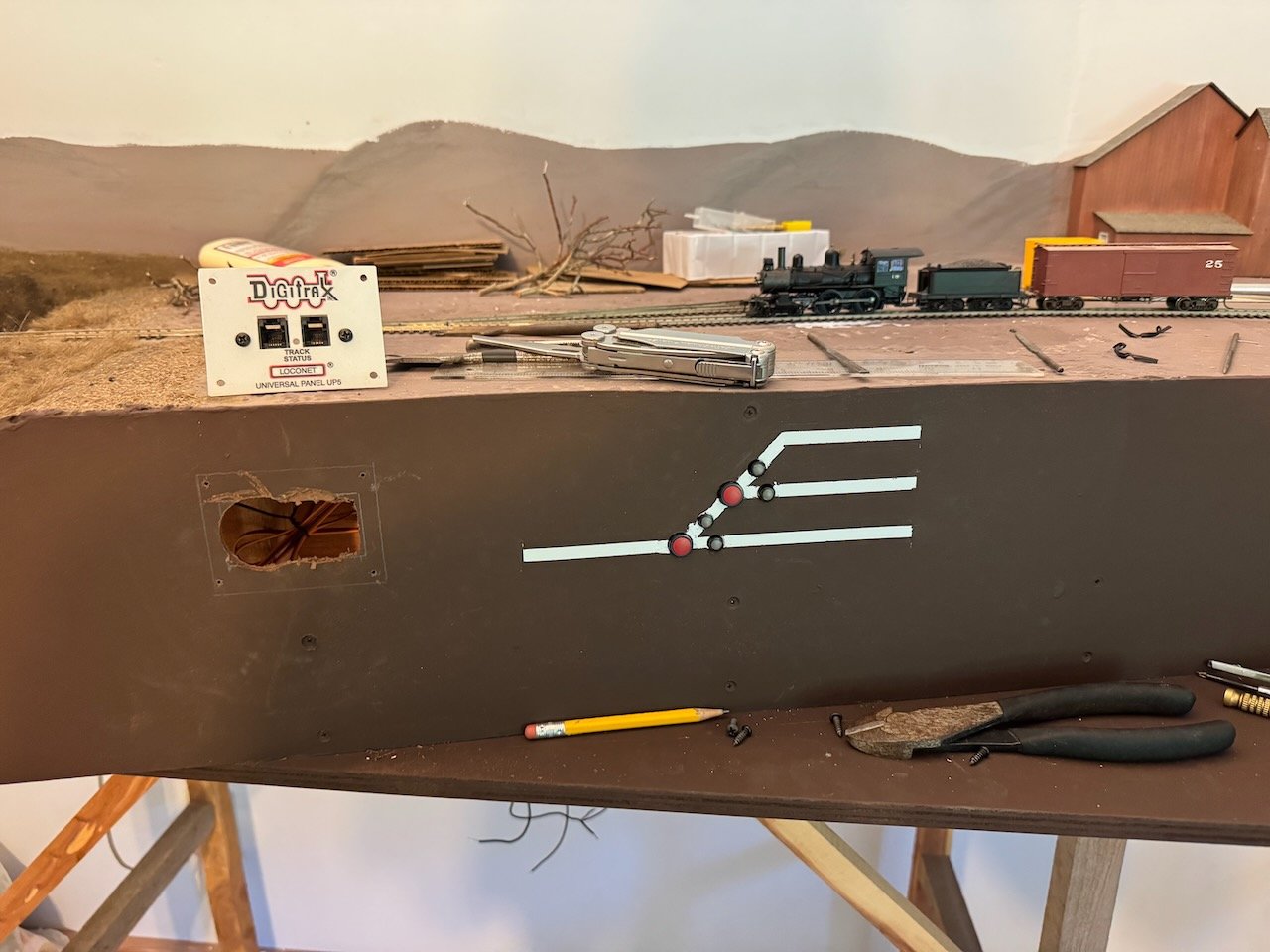

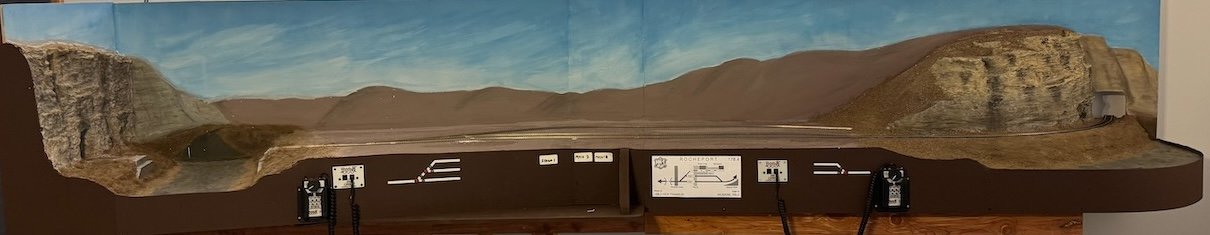

I continued on track-laying and wiring for part of today. Here's what the wiring under the two west-end turnouts looks like. It's not as scary or chaotic as it seems, like wires are actually neatly bundled together and nothing's soldered, meaning it's easy to adjust if needed. Thick black and red wires are the bus wires that carry main track power, smaller wires branching off from them carry power to individual track feeders, and yellow/brown/orange wires are the control wires for the turnouts. This is by far the most complicated section because of the turnouts and the throttle panel. Here's a detail of track laying. I lay a thin smear of glue down on the roadbed, then use these nifty metal track spacers to set consistent curves or straight runs; these hold the flexible track in the right shape while I use a few small spikes to hold the track down until the glue dries. And the really cool news is that the track-laying and wiring are all done! After a small amount of trouble-shooting, everything appears to work smoothly and I can operate all across the layout. It's super-exciting. In celebration, here are some broader context shots with more trains staged for appearance. It's so cool to reach this stage. It'll be back to scenery for a while now, but I can actually run trains! I don't think we can upload video or audio clips directly to MSW, and I don't really want to start posting layout stuff to third-party sites like YouTube. So I'm not sure if I can do that. I do agree I'd love you all to see and hear the actual operation, it adds so much. I'll give this some thought, there may be a solution down the road. Thanks to all of you for helping me get to this point! EDIT: I forgot to add this image, which is a first rough take on recreating the historic photo that inspired this whole project. Pretty cool! The actual location of the real shot is actually west of the tunnel (layout left), so it'll appear if/when I extend this to the next module. The layout shot is actually along the bluffs in the background of the historic shot, just east (layout right) of Rocheport. But it's close enough!

-

Yesterday featured a landmark occurrence: the first movement of a train on this project: OK, fine, it was just a quick electrical test of the first bits of track laid. But it was still a very exciting moment! This locomotive is sound-equipped, and the huffing of exhaust along with a triumphant whistle blast brought Mrs. Cathead in to see what was going on. Here's a broader view: I really hate doing electrical work, it's easily my least favorite thing about model railroading. But it needs to be done so I'm doing it. I already showed the turnout controls; another step was to install the panels where locomotive throttles plug in. These involve drilling out rough holes in the fascia to accomodate the circuitry behind these panels, them screwing them in place. You'll also notice that the left-hand track diagram is now painted instead of taped, as agreed on by the community. I then installed throttle holsters as well. So now the front-facing part of the electrical work is done, and it's time to start doing all the fiddly under-layout wiring along with additional tracklaying. I've already found something I need to troubleshoot and hope I can figure out. Did I mention that I hate electrical work? But the good news is that it directly leads to some really fun stuff (operating trains). A few more status shots. It really is starting to look "official" with the fascia infrastructure near completion. And one final shot down the tracks:

-

My leaning was also the painted version, both for permanence and appearance (I think the thicker lines look a little child-like and overdone). As Rik said, harder to get right in the first place but worth it in the long run. And I could always paint wider stripes but I like the thin ones. I'm using the turnout control system made by Walthers. I've used the Caboose manual throws before but I'm not a big fan of their out-of-scale appearance and I just felt they weren't entirely reliable. Plus, the fascia controls give operators a better sense of how routes are lined, potentially avoiding mistakes. Especially on something with a through-running mainline as opposed to a switching layout where the manual controls make more sense. I should note that the backdrop still isn't done, I need to do some additional sky painting. But I do like how the background hills and bluffs came out.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpeg.7d464e4407dc6f4b2f1f88eec9d1b7b9.jpeg)

.jpeg.bed2a9378df2699d53e4db071c867e16.jpeg)