Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

3,377 -

Joined

-

Last visited

Reputation Activity

-

Cathead reacted to KrisWood in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Cathead reacted to KrisWood in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Thanks for the shout-out! I'll be eagerly following your build to see how it comes along.

-

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Standing on the shoulders of Giants

The choice of Longship came down to size, as always at the back of my mind is a sailing model.

On this count Billings won as it is, afaik, the largest Viking ship model kit on offer, and at 1/25 scale it makes into a substantial model

I had also read all the relevant build logs in the Kit section, and KrisWood's absorbing saga in the scratchbuilt Forum

I mean no disrespect by omitting excellent builders, but the Build Logs of Von Kossa and Jack Panzeca are the lodestars I am steering by - I cannot hope to achieve either their learning or excellent results, but I can learn a lot from them. Thanks guys!

Billings kit 720 Oseberg Ship 1/25

Double-sided full size plan (with ruler for scale)

In my view these plans are excellent. The instruction book is at the top of this picture

(Thank you Steven for the pic-shrinking tutorial)

The instruction book appears to be straightforward, but leaves a lot unexplained - hence my gratitude to the members who have posted their journeys of understanding and achievement.

the Kit includes all required for the jig shown apart from the base-board, and this seems to earn Billings 30 brownie points.

All is not, of course as it appears :

Obechi 4 x 8 mm is supplied to hold the keel, and I chose to pin these to the base board such that the keel is a squeaky fit and held straight

There are two parts in 4mm ply designed to hold the prow and stern timbers. They have a slot which does not fit any stage in the build, so they have been sleeved with soft balsa to be a neat fit

The build jig also neatly holds the hull inverted for planking and other fun and two formers are supplied to make a frame allow the hull to be clamped securely to the frame

The formers are shown (?glued) to the board using more 4x8 as a reinforcing block

To me this means that either the keel holding members or the formers have to be cut away to allow them to fit. No great problem, but why?

Next: Friday Kit

andrew

-

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Bill, you sound pretty laid back

You have it right: very similar expressions in the spectrum of discombobulation.

Louie da fly

Many thanks for the food for thought and references. I was aware that the Sutton Hoo ship was really a not-ship (or ship-shaped void) and I admire the early diggers recognition of what they had and calling in archeologists. I believe that the owning family had broken one plough too many on the stern or stem as they came near the surface, prompting the initial digging.

More later ; we moved to Vermont and are loving it.

Pronunciation note for our American friends. that's VER-mont here; not ver-Maant. but we have similar moonlight

Next: the experts I am following with this build

andrew

-

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Thanks for the Views, likes and contacts

Edwardkenway

I'm sure there are plenty of challenges ahead with the Oseberg ship; some of them stemming from the kit, and the rest from my skills and mind-set. I am a little reassured that many of the builders report the strakes assembling without too much difficulty.

And speaking of strakes and difficulty, here is Rødolm as she is now (probably a "he" in reality. I was told that the name means Red Dragon)

AHA - i b'lieve that I have found how to drag a picture into text

Every day, if you are not careful: you learn a new thing

The "works" Fixed carbon mast pivot which rotates 170 degrees with pulleys. mast slips over and is pinned to the base. Sail is fixed to mast and made of heavy drafting film.

Steering by steering oar (naturally) which was not in the box, but has a scale wooden oar painted on a large polycarbonate paddle-shape

keel splits round mast base and is pinned in place

Keel is 2mm polycarbonate and coarsly matted to make it less obvious

the strakes over blue foam are visible (I could not do extravagant sweeps up at stem and stern because of the Footy rules, same reason as why there is not a Dragon head (at the moment)

Batteries were 4 x AAA cells soldered up in pairs and painted to not stand out as they nestled in the cutouts

Enough about wee bits of history - onward with the real star of the piece

andrew

PS Picture sizing? is this tolerable/ about right?

-

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

Cathead reacted to liteflight in Oseberg Viking Ship by liteflight - Billing Boats - 1/25 Scale - 9th Century

First model ship kit build: First build log on MSW. Be still my beating heart!

The Kit:

Billings large model of the Oseberg Ship (1/25). This turned out to be Billings part number 720 and has plywood laser-cut shields, and laser-scored scrollwork in ply

(More on the laser and ply later as the build commences)

The kit was a Christmas present (2018) from my lovely Admiral, and was ordered and obtained from our local model boat shop Float-a-Boat. It took about 6 months to arrive but this was not a worry, as we both had plenty to do since we had just moved house. By the way, "Oseberg" in Australia is pronounced "Osssburg"

I'm sure I could have obtained it cheaper and faster, but the end cost would be huge, as real model shops will not be there unless we use them

I failed to take the ceremonial unboxing and layout on the carpet pictures. Sorry

Not much in the box, as longships do a LOT with a little material.

Some dowels, stripwood - all obechi as far as I can see, sail material, build instructions (which make IKEA instructions look encyclopaedic by comparison) and a double sided full size plan, which includes (some) dimensions for the build Jig

Why a Longship?

I love them!

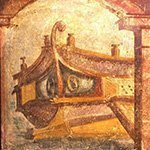

I went to see the Sutton Hoo museum in Suffolk, UK and was smockraffled by the model of the reconstructed boat in the entrance. It's about 1.5m long and I remember seeing it's bow from water level and realising that I want to make one of them.

So since that I have been reading about the construction - actual and model.

I have learned of the wide range of boats in this style of construction then and now.

I can remember walking round Stavanger harbour in the 1980s and seeing small boats whose construction and fastenings are clearly cousins of the Oseberg ship

Confession. I have Previous Form

In the early part of this century I raced Footy Radio-control (sometimes) yachts and progressed from state-of-the-art carbon masterpieces designed by Angus Richardson (he designed the 507 Footy still sold by Melbourne's RadioSailingShop) to satisfying scale gaff-riggers such as Presto (https://www.woodenboat.com/boat-plans-kits/presto-footy)

I was asked by Angus to make him a Drakkar to the Footy rules to act as his Admiral's barge on ceremonial occasions, so I made one, learned a LOT and made him the requested Drakkar called Rodolm with an Angus-designed pattern on the sail (photos follow if anyone is interested)

The lower hull was carved blue foam (to the sections of the Gokstad ship) with about 3 strakes above the foam to make the hull. The keel allowed a removable polycarbonate keel with lead ballast to be inserted. Mast was exactly in the centre of everything and sail was fixed to the mast. Both rotated up to 180 degrees to allow close-hauled sailing on either tack.

Now regrettably Angus had poor sight, and Rodolm had low and symmetrical prow and stern (as it had to comply with the Footy rules) and sailing her turned out to be a challenge for him. I added a staff and mylar streamer to the stern to help him with orientation and wind direction.

Info: "Footy" yachts have to fit in a Box 12 inches long x 6 inches wide x 12 inches deep. (Rodolm did)

I am aware of venturing into a huge forum of skilled experts with diverse knowledge.

Please feel entirely free to dive in and comment, help, suggest solutions and/or request more (or less) information

To come in next post:

The build so far

Mine is a Friday Kit

Decisions about Floor levels

There will be no Ply edge visible!

The Giants on whose shoulders I an planning to stand

andrew

-

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

With the dog days of summer here I've been maximizing outdoor time and haven't done much on the boat in recent weeks.

But the other day I decided to take a step forward and glue the garboard strakes. I first bent them with the water immersion technique mentioned above, and the result seemed pretty good. This is where she sits right now.

(Starboard side view, bent port side plank sitting in front)

With this bending technique - soak, clamp, glue, clamp - I can only do max one strake per day, and since that won’t happen it will be well over a month before the hull is planked. I’ll report back then.

Being my first ever build, at this point I have no idea how good of a job I’m doing or if things will turn out well. Perhaps that’s makes this hobby seem like an adventure!

-

-

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

Cathead reacted to tlevine in Swallow 1779 by tlevine - FINISHED - 1:48 scale

I reached a milestone today: the first planking belt has been completed. So far, I am pleased with the appearance. For anyone toying with the idea of building a clinker- planked hull, I am finding this a lot more difficult than carvel construction. There is no room for error and edge-bending that last half-millimeter does not work the way is would on a carvel hull. I have found that the easiest way to secure the planks during gluing-up is with planking screws, placing a piece of scrap between the cross-piece of the planking screw and the plank to prevent denting. My layout has a butt joint at frame M. I decided that this was too far forward and placed a basswood filler between frames K and M.

The first belt has four rows of planking; the upper two belts will each have five. So far it appears that a stealer will not be necessary but I will have a dropped plank in the upper belt.

-

Cathead got a reaction from hollowneck in Schooner Polotsk 1777 by Mike Y and his daughter - Master Korabel - 1:72

Cathead got a reaction from hollowneck in Schooner Polotsk 1777 by Mike Y and his daughter - Master Korabel - 1:72

Daria,

Mrs. Cathead (who is a scientist) thinks it's fantastic that you're interested and engaged in such things, as do I! I've been sharing all your updates and photos with her. There isn't much in the nautical way out here in the central US, so I quite envy you the chance to work on such a Viking ship (especially as someone of Norwegian descent).

-

Cathead got a reaction from hollowneck in Schooner Polotsk 1777 by Mike Y and his daughter - Master Korabel - 1:72

Cathead got a reaction from hollowneck in Schooner Polotsk 1777 by Mike Y and his daughter - Master Korabel - 1:72

Daria and Mike,

What a lovely project this is! I'm fascinated by the Russian kit, as a former Russian Language major in college. It looks quite interesting and well-crafted, and I would probably have fun trying to translate the instructions.

And I can't say enough about how lovely it is to see a daughter-father project like this. Daria, you're doing excellent work so far and I hope you won't mind a random American following along to learn from what you're doing.

Looking at the bow in that photo, did you feel that the kit provided enough internal support for the planking? There don't seem to be any filler blocks. Are the planks well-spiled enough to fit smoothly without any further support or aid?

-

Cathead reacted to travis in Virginia 1819 by Travis - FINISHED - Artesenia Latina - Scale 1:41

Cathead reacted to travis in Virginia 1819 by Travis - FINISHED - Artesenia Latina - Scale 1:41

A little more carronade rigging done. I also decided to ditch the pot metal goosneck saddles and make my own that are more accurate. Rather than the one piece version, I mad the saddle with the two halves, nailed on and then even include the "shoe" (??) in between with a wire to allow it to actually pivot against the mast when the boom would be raised and lowered. Turned out pretty well for the first one.

-

Cathead reacted to Siggi52 in HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

Cathead reacted to Siggi52 in HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

Hello,

and many thanks for the many likes and nice comments. I do my very best to satisfy you.

@Karl, as Greg already mentioned, you could see these red muzzles on many models of that time and also at paintings. Not only at english ships, but also the „Wappen von Hamburg III“ has that future.

Lt. Gabriel Bray

At least I did't post here for a long time. I got the Corona Bluse, but good luck not the infection. Because the summer here in the northern part of Germany is more or les cold it is much colder in my basement. So I'm fixing this and that at my house and garden, and when the sun is shining I relax in the garden and doing nothing. 😊

So, Mark, you did't miss anything.

Stay all sound

-

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

I started working on the head rails. The start only was already so tricky, no idea how I'll do the rest 😶

To start this chapter, I went through all the build logs to see how everyone approached it..

I began by carving the outside edges. With basswood being basswood, this was not fun... Then seeing Thomas Gahm's log, I saw he glued the two parts of the cheeks prior to installing them to make it look like one piece. This helped a lot to make it look neater.

Speaking of neat, the start of mine looks so messy, glue everywhere... Things kept sliding and was very frustrating loll. Half way though installing the bottom cheek I realized I needed to steer away from one of the holes on the stem knee, and make sure the figure head fit, both of which didn't so had to deconstruct and do it again. Again, this was very messy....

Here are some pics of testing the pieces:

Here are pics of them glued in:

Figure head is not glued in yet, so it keeps sliding down, but fits nicely I think..

Next I'll be making the hawse holes. I don't know if it's just me, but everytime I have to drill into the hull I get extremely nervous...

-

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

Cathead reacted to joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

I've been working on both the staircase and the boiler

-

Cathead reacted to FriedClams in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Cathead reacted to FriedClams in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

I've been following along on your build Brian, and for a first-time scratch builder you're remarkably attentive to accuracy and the workmanship is clean and careful. And you've picked a great subject. I've always been somewhat of a "Western Theater" Civil War buff and I find this period of U.S. history endlessly interesting. A great start on an interesting and unique model.

I realize that you have decided to go with printed paper for the brick work, but for future reference, there is a company called New England Brownstone that manufactures Hydrocal brick wall slabs in 1:48 and 1:87. They are made in the American bond pattern with tie header courses. You have to color the slabs yourself (they tell you how) and it is not a cheap product, but with careful execution they produce the most realistic brick work in those scales that I have seen.

Looking forward to future updates.

Gary

-

Cathead got a reaction from FriedClams in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Cathead got a reaction from FriedClams in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

On the brickwork, I think I used printed brick paper (from model railroading) on the Bertrand and made my own wooden bricks for Arabia. I don't think the former would hold up at your scale. There are a lot of model railroad molds out there intended for casting various building parts in plaster, I wonder if a brick pattern mold could be found that would look right? That would give you a nice 3D effect without having to cut out and shape lots of bricks.

-

Cathead got a reaction from GrandpaPhil in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from GrandpaPhil in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Next step is to add bracing to the top of the frames to hold the whole assembly stiff while planking. This is another example of the instructions being really vague; they refer to using a numbered part for this, but there's nothing in the laser-cut sheets or plans with that number. The kit comes with various strip wood, but there's no parts list to tell you what's what or what it's intended for, and all of it seems to be nicer wood than I'd use for throwaway temporary bracing. So I just used stuff from my scrap bin instead.

I did the bow and stern first, using shorter pieces so they'd stay near the outer edge of the frames:

Then filled in long straight strips in the middle:

Next step is to remove the hull from the building frame and start planking. I'm trying to decide if I want to build/adapt a new building frame to hold it firmly upside down, or just work on it freehand.

-

Cathead got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Hah, good point. It would be cool to simulate some of the stone ballast, maybe I need to leave some of the deck planking off. Someone's log also has a super-cool real-stone anchor that I want to copy.

-

Cathead got a reaction from GrandpaPhil in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from GrandpaPhil in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Time to add the false decks. It took quite a while to carve the frame slots out enough for these to fit properly, but I got there eventually. Part of the slowness was the need to keep sliding the decks back inside the frames to check the fit, which is a delicate process.

Once I felt they'd fit, I worked out how to hold them in place while the glue dried. Several people have used various combinations of rubber bands and clamps, but I drew on some resources from my geology background. First, I spread a thick layer of glue on all the keel/frame surfaces, as the fit isn't perfect in a few places, not worrying about spillover since none of this will be visible from any angle:

I then used rock samples between each frame, which seemed to work nicely with a minimum of fuss. I did one half of the frame first, then the other.

So far so good.

-

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Got all the frames installed, looks pretty cool:

I started test-fitting the false deck that gets inserted within these frames, and immediately found the next problem: it doesn't line up straight with the frames and keel. It has slots that are supposed to fit over every frame, but if you line up the deck's centerline with the keel, the slots are at an angle to the frames (i.e. the frame don't fit into them), and if you slot all the frames into the deck, the deck doesn't line up with the keel. Here the latter is shown; check the centerline at both ends:

Detailed view amidships:

Detailed view at the bow:

This problem is consistent throughout the deck; all the slots fit neatly around the frames, but the whole deck is off-kilter. So this could have two explanations: (1) I got the angle of the frames consistently wrong (not square to the keel) when gluing them in or (2) the deck slots aren't cut quite square.

I double-checked all the frames relative to the keel using a square, and they're all as square to the keel as I can determine. I then placed a strip of wood across one of the frames and placed a square against it to check the orientation of the deck's centerline, with this result:

You can clearly see the off-angle there, which seems to imply that the deck slots weren't cut quite square during manufacture (option 2). Even if I installed the frames crooked, if the deck slots were cut squarely, the deck's center line should be at 90° to the frames when they're fit together (the measurement above is independent from the keel).

Does that seem like the right conclusion, or am I missing something?

Either way, it seems like the best answer is to file the deck slots wider until the deck fits properly and squarely with the keel. As this gets covered with another layer, I don't think it matters if the slots are a bit loose.

-

Cathead got a reaction from Canute in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Cathead got a reaction from Canute in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

On the brickwork, I think I used printed brick paper (from model railroading) on the Bertrand and made my own wooden bricks for Arabia. I don't think the former would hold up at your scale. There are a lot of model railroad molds out there intended for casting various building parts in plaster, I wonder if a brick pattern mold could be found that would look right? That would give you a nice 3D effect without having to cut out and shape lots of bricks.

-

Cathead reacted to mbp521 in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Cathead reacted to mbp521 in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Eric,

Thinking about it, the printed paper method might just be the right idea. Most of it will be hidden under the boilers anyway. With the exception of the ash pit, I may just do that then shape and paint the ones that will be seen. No sense in going through a big expense for something that won’t really be seen.

-Brian

-

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Next step is to add bracing to the top of the frames to hold the whole assembly stiff while planking. This is another example of the instructions being really vague; they refer to using a numbered part for this, but there's nothing in the laser-cut sheets or plans with that number. The kit comes with various strip wood, but there's no parts list to tell you what's what or what it's intended for, and all of it seems to be nicer wood than I'd use for throwaway temporary bracing. So I just used stuff from my scrap bin instead.

I did the bow and stern first, using shorter pieces so they'd stay near the outer edge of the frames:

Then filled in long straight strips in the middle:

Next step is to remove the hull from the building frame and start planking. I'm trying to decide if I want to build/adapt a new building frame to hold it firmly upside down, or just work on it freehand.

-

Cathead got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Next step is to add bracing to the top of the frames to hold the whole assembly stiff while planking. This is another example of the instructions being really vague; they refer to using a numbered part for this, but there's nothing in the laser-cut sheets or plans with that number. The kit comes with various strip wood, but there's no parts list to tell you what's what or what it's intended for, and all of it seems to be nicer wood than I'd use for throwaway temporary bracing. So I just used stuff from my scrap bin instead.

I did the bow and stern first, using shorter pieces so they'd stay near the outer edge of the frames:

Then filled in long straight strips in the middle:

Next step is to remove the hull from the building frame and start planking. I'm trying to decide if I want to build/adapt a new building frame to hold it firmly upside down, or just work on it freehand.

-

Cathead got a reaction from mtaylor in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

Cathead got a reaction from mtaylor in USS Cairo 1862 by MPB521 – FINISHED - Scale 1:48 - American Civil War Ironclad - First Scratch Build

On the brickwork, I think I used printed brick paper (from model railroading) on the Bertrand and made my own wooden bricks for Arabia. I don't think the former would hold up at your scale. There are a lot of model railroad molds out there intended for casting various building parts in plaster, I wonder if a brick pattern mold could be found that would look right? That would give you a nice 3D effect without having to cut out and shape lots of bricks.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)