-

Posts

384 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by thomaslambo

-

Matt, I feel you, I've got a box of way to many reject prototype parts myself, and this is my first build...I think of it as my battle with the dark side Great finish on the battle station, love the aged/worn look....and sweet looking weapons for the Ranger (thanks for the penny in the pic)

-

Matt, Beautiful work as usual....I use my desk lamp magnifier as well, just can't get comfortable with the head set. I also bought a higher strength pair of reading glasses that really help for close up work. Keep up the excellent work my friend

-

Hi Bob, I like to follow as many of the AL builds as I can because I'm in the middle of one myself. Looks like you're off to a strong start. Having followed several AL builds I've noticed they all tend to have some shaky spots in the build instructions....mine is no exception However, I find my kit to be very true to the original ship design....and the overall quality of the laser cuts, wood and other parts to be quite good. I'l be following your build with much interest, and good luck

-

Hi Mike, Just beautiful work as usual....and the stand is looking great. I've yet to do any Rigging so it's a nice tip for me to see how you assembled the masts on a separate board. Also, I missed the fact that you're donating the ship and display case to the Library....definitely a kind and generous thing to do on your part

- 230 replies

-

- victory

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks much CaptainSteve, Thanks much for the encouragement my friend I'm going to start doing prototypes on different plant ideas and see what I come up with (some bird just whispered in my ear to try Sushi plastic garnishment greenery - nice) Also, using my new scale ruler (compliments of Matt's build log) I discovered the pots included in the kit are larger than the pots used on the Bounty. According to the Anatomy the real pots were 6 and 8 inch dia. along with some tubs and boxes (approx total pots was about 774). The pots in the kit are 12 inch scale. I'll probably stay with them because it'll be easier to make the plants and see the display with larger pots. Only detail freaks like us will ever know the difference However, I may put twice as many pots as the kit provides....and I've also got some other ideas that will raise the bar in the Green House

-

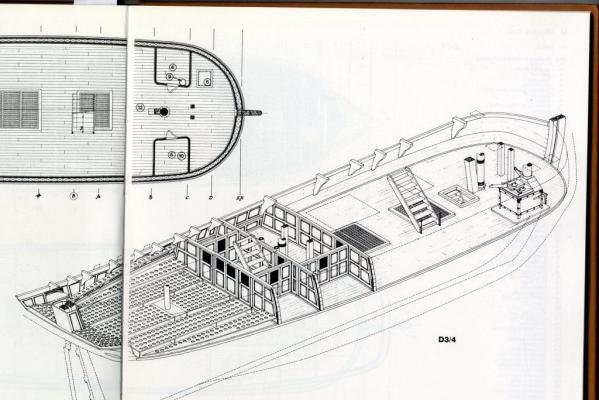

Yes, they really did a number on the Bethia to convert it for the Bounty's purpose....taking out considerable rooms for the crew to accommodate the tree plants. Check out these pictures....one of the things I'm wrestling with is the scale of the racks and pots (in the kit) let alone the size and look of the trees. Two pictures are worth a 1000 words Converted Green House 3 month old bread fruit tree which is supposed to be what they transported....pic came from Captain Al's build log

-

Captain Al, Thanks so much for stopping in and the kind words....I really appreciate your support And thanks for the heads up on the main deck alignment. I've already spent some time with the main deck (made a full size template with the planking pattern I'll follow) so I'll carefully check the hole sizing as you recommend. And stay tuned for the modifications on the middle deck which will be considerable...and I'll actually build some furniture myself LOL

-

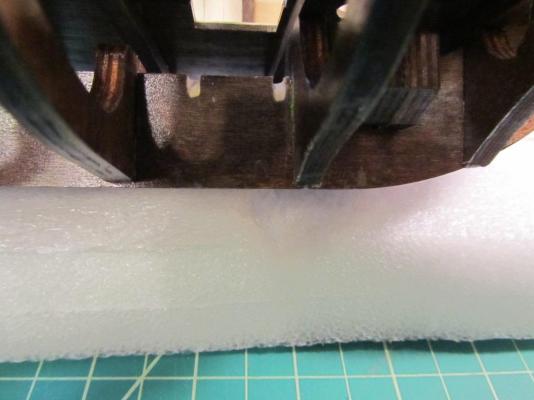

Part two - Middle deck planking and installation (basically step 12 in the instructions). Deck Alignment - First off, prior to installing the middle decks I needed to spend some time aligning the masts, bilge pipes and support beams (also using the main deck). This required some careful sanding and fitting. Modify Ladder Opening - I had to move the stern ladder opening two planks toward the starboard side to accommodate the lower stern cabin additions (required minor mods to both middle deck pieces). Planking Decks - I used the same technique described in my lower deck planking (exception being I refined the nail pattern – using a pencil instead of a marker pen (a bit too dark IMO) and only simulated nails at the butt joints). Install middle decks – this was fairly straight forward after dry fitting and doing a bit of sanding and trimming at the frame joints. I did rough sand the decks and cross beams where they join together for better glue adhesion. Then I just clamped and weighted down the decks while the PVA glue dried. Install Bow and Stern Ladders – simple and straight forward as they had already been fitted. Install the Bow Balustrades – again, straight forward as they had already been fitted. Note; I delayed installing the lower and middle deck mast rings until I actually install/glue the masts in place. Here are pictures of the finished details…. Aligning the decks with masts, bilge pipes, etc prior to gluing up the middle decks Top view of middle deck planking Full front view, note the veneer edging on the false decks on both lower and middle decks to cover the ply edge Bow additions with ladder/stairs, note I left off the veneer edge on the right most frame (middle deck) to show the difference between ply and finished edging Lower deck Balustrades installed, note the Boatswain's Storage Room wall additions on the right Railings will be added once the middle deck balustrades are installed. Stern additions with furniture. Ladder/stairs will also have balustrades and railings installed

-

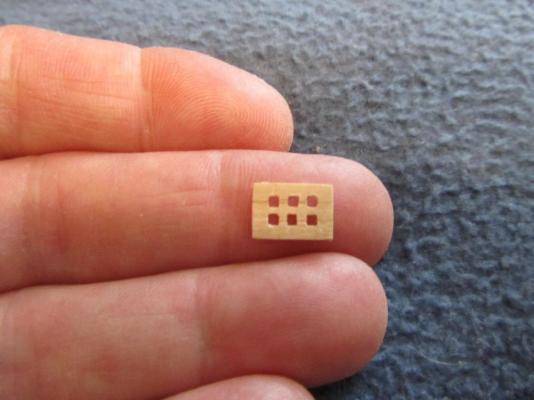

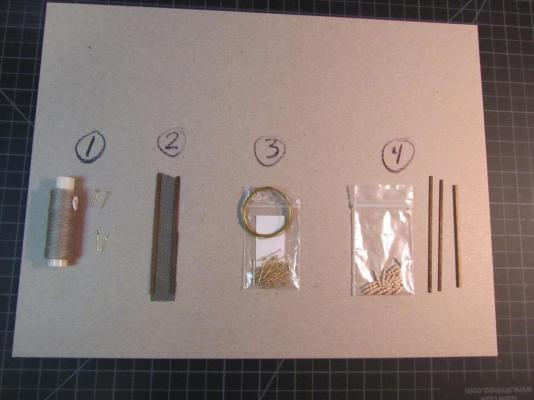

I’m going to report my latest progress with two posts (First; narratives on the detail work I did with a few supporting pictures, and second; another very short narrative with several pictures of the end results). Part one - Lower deck detailing I finished up most of the details on the lower decks (basically steps 1 – 11 in the instruction manual....and the additions/modifications I planned to do. Cabin Door Grid Windows - I decided to add grid type windows to the cabin doors for a touch more detail. I cut the windows from 1mm thick maple sheet. Very delicate process, I broke 3 windows while building 5. Finish Boatswain’s Store Room - I completed what I call the Boatswain’s Store Room (added two walls to close off the room in the Bow area). Build Ladders - I needed to build the short ladders used on the lower decks to be able to design and build my balustrade and railing system (the ladder assembly would normally be addressed in step 19 of the instruction manual). While I was at it I went ahead and installed the lower Bow hold ladder. Balustrade and Railing - I completed the design and construction, as well as a dry fit on the middle and lower decks. I spent some time to decide what type of design I liked. Basically I came up with four options; 1) brass hooks and thread – AL kit, 2) wood rails with netting, 3) brass stanchions with brass wire rails, and 4) wood rails with wood balustrades). I ended up using option 4 and spent considerable time to design and build the system. As a byproduct of the above design activity, I came up with another idea to add further detail to the model. Option 2 (wood rails with netting) will be used for a storage system inside the hold areas.…kind of like a racking system using nets, rails and ropes to hold assorted barrels, boxes, sacks, supplies, etc. Veneer Edging - I also added veneer edges to the lower and middle false decks to cover the ply edges (cut from the .5mm x 5mm basswood strips included in the kit). In addition, I lined the inside edges of the three port side middle frames with .5mm x 6mm walnut strips (not included in the kit). I’ll use this same material to cover all the frames exposed on the starboard viewing side as well. My intent is to rid the model of most of the exposed ply edges to give it a more finished look. Floor Molding - I also added additional floor molding under the door frames and a couple other areas. Furniture Addition - And the last touch of detail was to add a table and chairs to the Stern middle cabin/pub. The plastic furniture was purchased on line and then painted with a mix of colors to simulate wood. Here are some pictures of the detail work (pictures of the finished work will be include d in the next post).... Cutting out the the windows from 1mm maple sheet Close to complete....little more sanding and then the stain Installed grid windows Needed a touch of filing on the keel to fit the ladder Installed ladder View from the top....also note upper right hand corner of the pic is one of the Boatswain's Room wall additions Material options for ladder railings Drilling the holes for the balusters Finished balustrade and railings parts for Bow ladder/stair (lower and middle deck)

-

Nice, it does print out perfectly. I'll use card stock and then laminate it for durability.

-

Hi Don, I missed your first post, so welcome aboard the HMS Bounty AL club It's a nice model and IMO the quality is quite good for the price. Some of the instructions are a bit mixed up due to language translation....but combined with the picture book and plan sheets it's doable. Captain Al's thread has some great suggestions as you probably know and you'll find a third build that unfortunately the builder (Capt.Fisher) dropped off shortly after the hull planking (but some good info none the less). Here is the link to the third build: http://modelshipworld.com/index.php/topic/6241-hms-bounty-by-captfisher-148-artesania-latina/?hl=%20hms%20%20bounty Also, KeithW has some very nice finished pictures of his build in the Gallery. Good luck with the build

-

Ken, I think you're probably right about scratch building (or lack of) in model Railroads. Don't get me started on the RR hobby....a magnificent money pit to be sure Mark, thanks for the link to the conversion chart Matt, I'm wrestling with scale on my Bounty build as we speak....I'm down a couple of detail rabbit holes thanks to you and CaptainSteve

-

Matt, Wow, I didn't pay attention to the size of the Ranger...a challenge to be sure at 18 inches. FYI - I actually started the Mamoli Lexington (also 18 inches) and put it down after planking the hull because I wanted something larger for my first completed build. At some point I'll probably go back and finish her as you're doing with the Ranger. Thanks very much for the picture, it definitely puts things into perspective...I've seen some very very small chains at the jewelers Boyd

-

Yes, I find the Dremel to be one of the most versatile tools ever made....so even more accolades are deserved for being resourceful Thanks, Boyd

-

Matt, Really fine work on the Mortars What lathe are you using? Also, would you mind taking a picture of one of the mortars next to a coin so I can gauge the exact size. Thanks much, Boyd

-

Matt, I'm going through the same thought process....so far I've blackened every brass part on the ship but I'm heavily considering leaving the cannons brass just for the nice contrast (really not going for historical accuracy on my build - I think the viewing audience would like the brass look). And nice progress on the mortars...looking forward to the end result on both weapons Boyd

-

Al, I think so, I've had some issues as well.

- 265 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

-

Al, I've been using CA for years on model airplanes and RR models. Loopers work well. Here is a link: http://www.creativedynamicllc.com/new-v2-looper.html I've also been using tooth picks and needles very effectively with CA. You just need to experiment with applying it until you get comfortable with how much ends up on what you're gluing. Get some small pieces of scrap wood and play around for an hour or so and you'll have it wired I use CA on almost all my very small parts with excellent results. The goal (very difficult in deed) is the viewing eye should not see glue on the model...which is very hard to cover up or remove after the fact. I've tried many brands of CA, some dry instantly and others give you some limited time to set the parts (not all CA's are created equal ). I make sure all my pieces are clean and ready to be glued and then I rehearse putting them together quickly. In many cases I use stabilizers to get them squared and straight quickly. I also lay most of the parts on wax paper so they don't stick to my work surface (tape the wax paper down). Here is a link to my favorite CA (I also use their thin product on occasion): http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXPT39&P=ML I get about 10-15 seconds to adjust parts with their Medium product. If you read Chuck's latest build log he comments that he uses CA exclusively on his planking jobs....which I would say is one of the finest planking jobs I've seen in my very short career of wooden ship modeling Good luck

- 265 replies

-

- finished

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.