-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

Proxxon or microlux

Gaetan Bordeleau replied to CPDDET's topic in Modeling tools and Workshop Equipment

probably Proxxon For micro milling not deep in soft metal or plastic or wood. To use a drill press for milling is the best way to see the vise dancing on the table. -

Does Belishi includes Working distance? If not, I would be skeptical to buy it! A comfortable distance to work with is usually greater than 10 inches, when it is too close, it is not very much user friendly.

-

Do a research (top right of the page) with "optivisor", you will find answers.

-

Byrne's Table Saw additions/add ons

Gaetan Bordeleau replied to blackjack40's topic in Modeling tools and Workshop Equipment

The only accessory I use is a modified fence that can be lift on 1 side to cut long strips. Micrometer stop... too slow to use. I measure between the fence and the blade with a digital caliper. -

Ship Building Workshop

Gaetan Bordeleau replied to Castos's topic in Modeling tools and Workshop Equipment

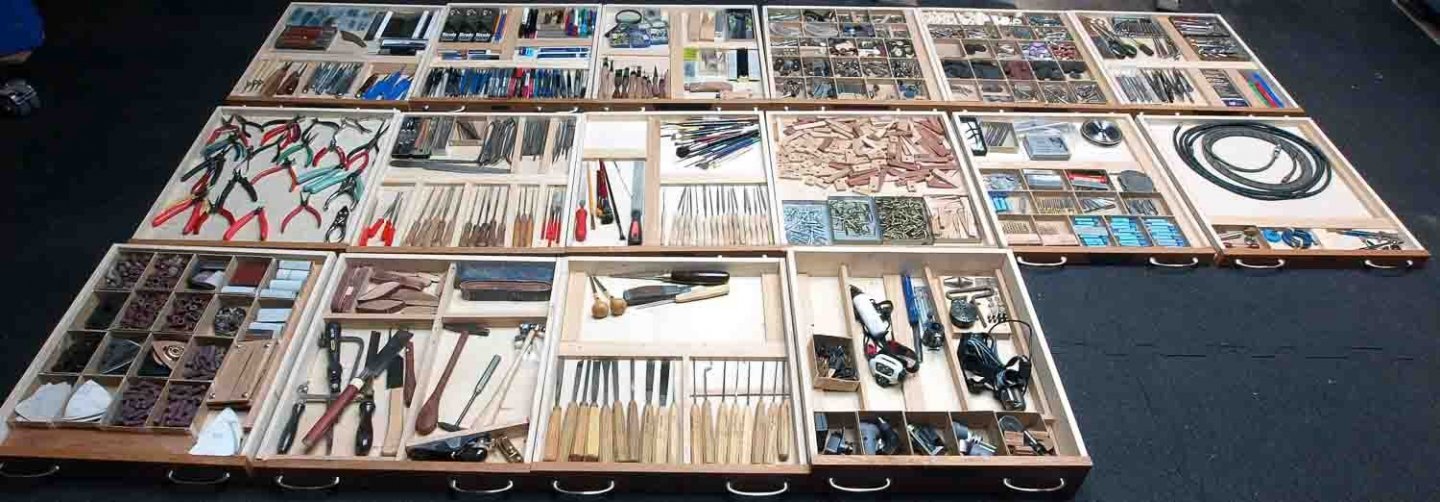

Except for the very heavy equipment near the walls, every others are on tables with wheels, the bigger the wheels, the easier it will be to move, so that you can change the set up as you need. The first one I would buy would be an electric height table and add wheels to it. Working at the good height, will improve the quality of your work and it will be less exhausting. Once you will realize this, you will always work with this table, and for every job, you will optimize the working height. -

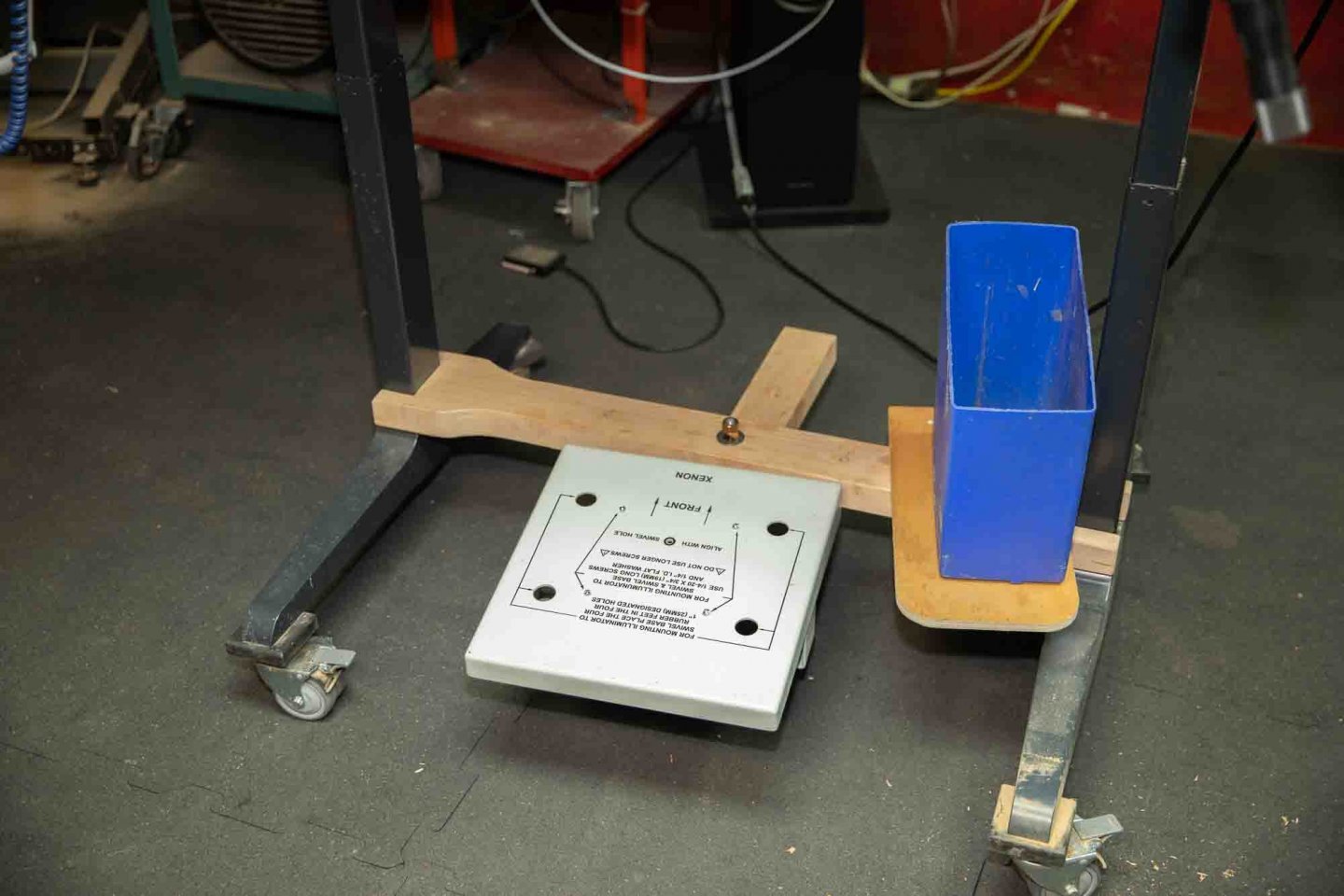

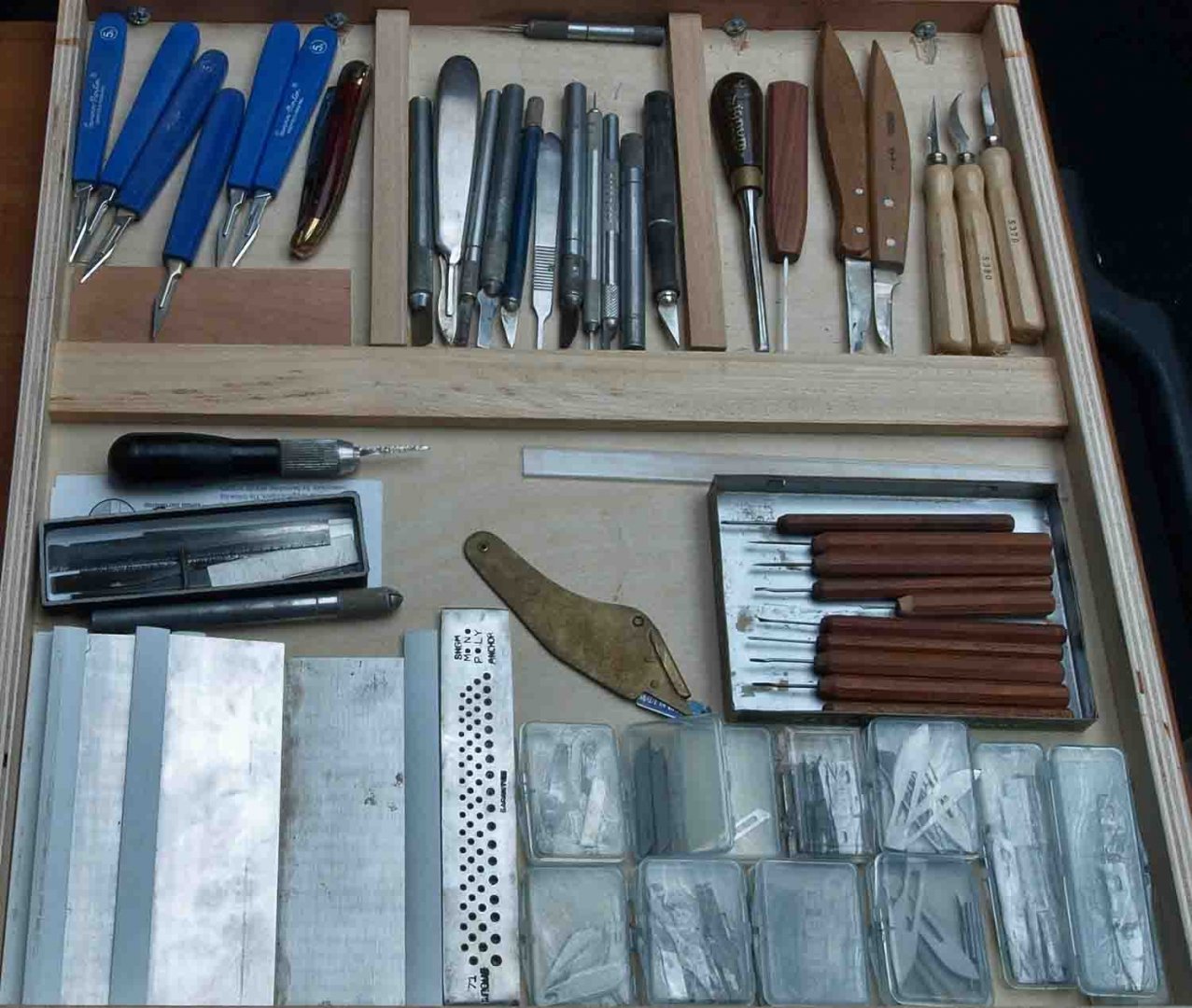

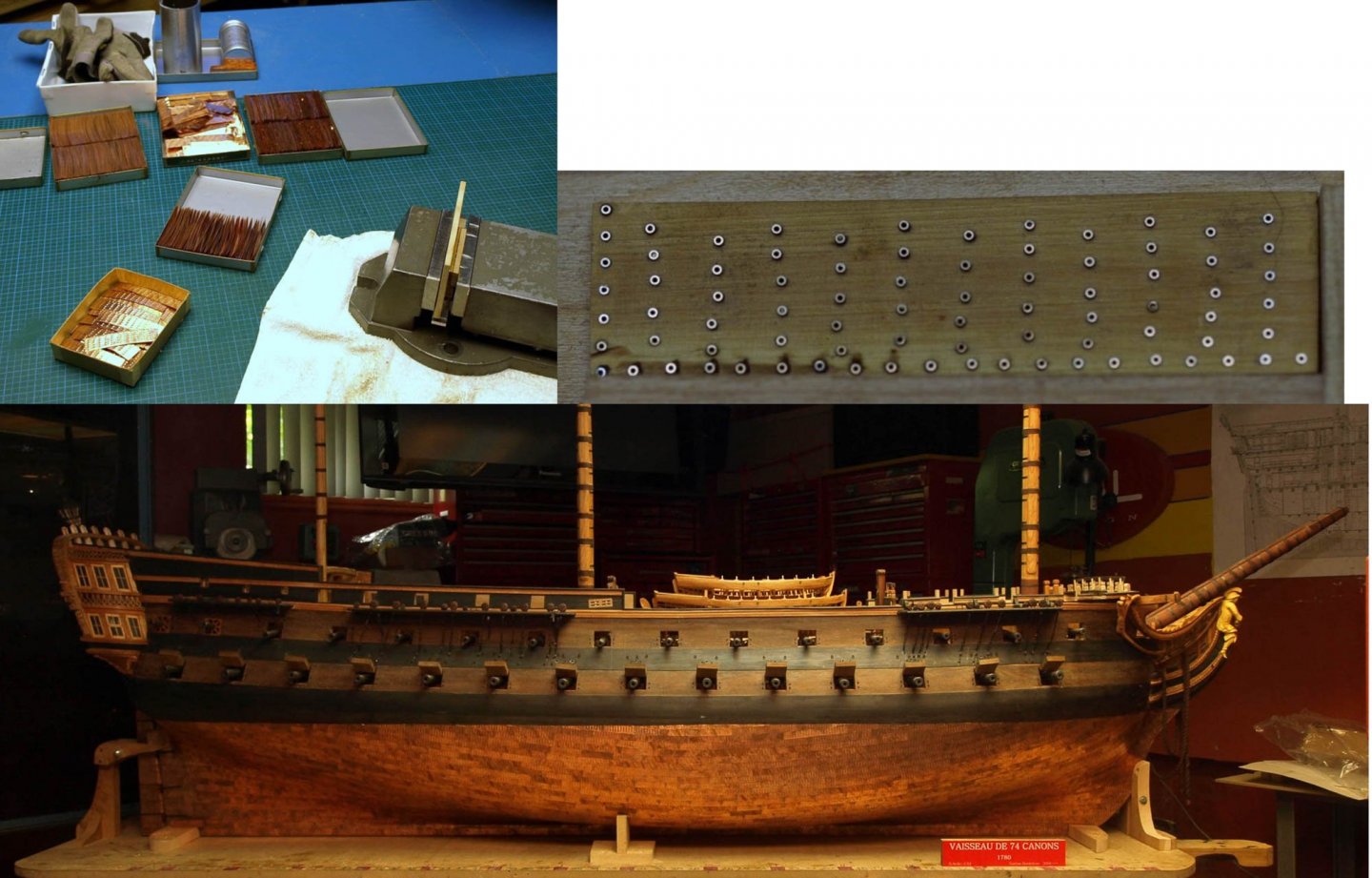

The big problem with one drawer is his height. Most of the small tools are, obviously small, often below 1/2 inch. Ideally there will be 1 layer of tools in a drawer. More than one would not be be user friendly. As an example, if 1 drawer is filled with tools of 1/2 inch of height in a 2 inches drawer: it means, that for every drawer, 1 1/2 inch will be lost for every drawer. This space is costly and it is lost! With this cherry chest, 16 drawers of about 21 by 21 inches give a surface of about 50 square feet. The blue chest is for heavy metal tools and the surface is even bigger. We need tools... and we also needs a lot of drawers.

-

size: 2000 X 2000 pixels * resolution: 240 pixels/ inch adapted for screen sharpness * If I remember correctly, MSW allows a generous size for a photo to be 2000 by 2000. Unfortunately, almost nobody presents "large size photo". When a photo is presented on Facebook, by example, in a "small dimension", It is like showing nothing, because there is insufficient data to appreciate the content. You can get a $200 camera to photograph with a resolution of 4K. You cannot post a 4K photo, but you can scale it down and show a good detail which is going to be profitable, not only for you, but for every body also. But like the mystery of the Exacto, even if we tell them that they could use a sharper knife, they continue to use only the Exacto. Of course, there is no need to drive a Ferrari when a Mazda will bring you at the same place.

-

A medal always has 2 sides. It is true that we see "new" imperfections with magnification and it is very frustrating at the beginning. The good side of it, if you take picture when you finish a section of the work, you will be able to see what needs to be corrected. We could call this tool "inspection by photography". After the make the small corrections, you take a second set of photography and you will be satisfy of your work. I think it is a good tool, to increase of one step, the quality of our work; but with miniature photos, it is impossible to do.

-

http://www.hocktools.com/products/knives.html is the best steel grade I tried for a knife blade already made. Vossiewulf , a member of this forum, bought many knife blades and he gave me a knife handle and a blade. I resharpened the blade and this one of my best knife I use. The shape of the blade is something like between an exacto an a surgery blade #11 by Swann Morton. Hardened at RC62, it will not break like the surgery blade. Finding a GOOD blade, is only half the battle, Sharpening is the other half. A good waterstone is very helpfull. With the help of Vossiewulf, we covered these subjects inside my build log: starting at p.15. Having a well sharpened blade automatically means that... you will not need to use an exacto anymore because, in comparison, an exacto blade does not cut. But even if I write these words, many peoples will still continue to use an exacto. I guess that a good way to learn is to go by comparisons. If you never try another brand of knife than exacto, you will always think that it is the best blade and this will remain true, until you try a better one.

-

Lee Valley has a very good green polishing compound. https://www.leevalley.com/en-ca/shop/tools/sharpening/compounds-and-pastes/32984-veritas-honing-compound It is use for a mirror bright finish and also it removes light metal fuzz created in sharpening at the apex (the meeting of the both sides of the blade).

-

I guess that when we begin to build model ship in kit, there are a lot of things to learn. One of the first tool we buy is an X-Acto at the hobby store. Then we come to the MSW forum and we learn that there is so much more cutting than this hobby knife. This subject comes back very often in the tool section and the day you will try, a Swann Morton scalpel blade by example, you will never go back to X-Acto. A good knife is the first step, sharpening is the next one.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.