-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

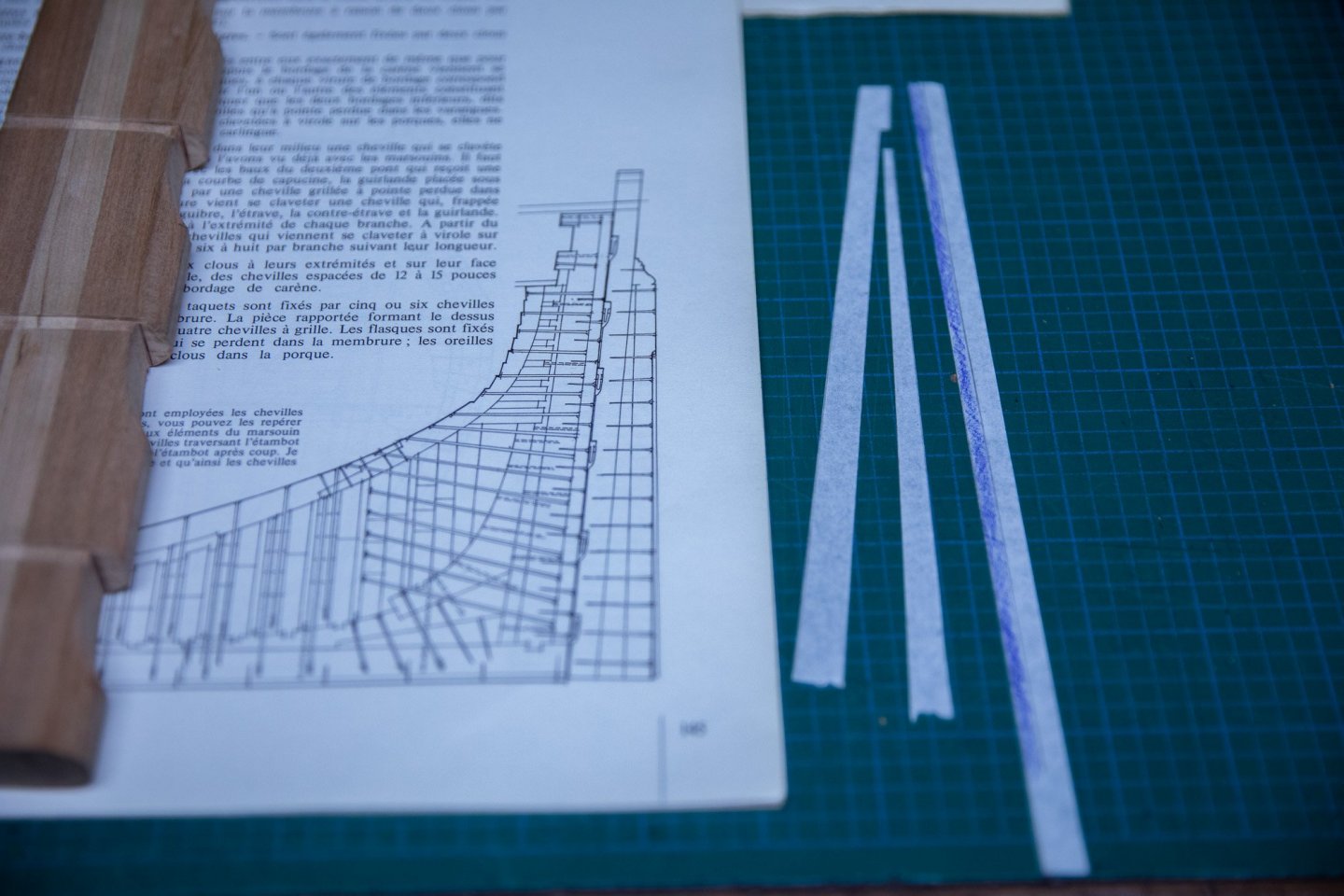

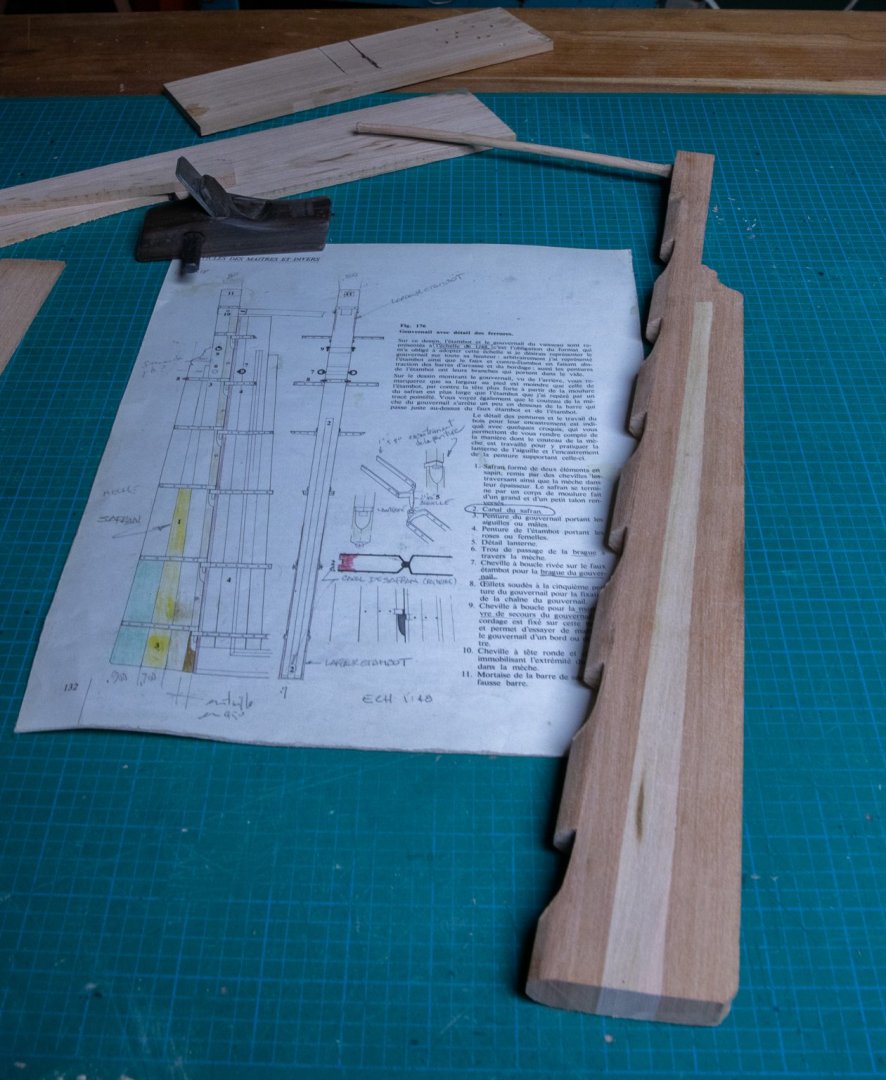

Thank you Allen, Karl, the rudder was made with 3 big trees like the 3 paper bands to the right. Big nails hold the parts together (The forth part would be fragile to these nails). The number 1 shows a 45 degrees bevel which also is drawing as if there was a fourth part. If you look the drawing from Boudriot, you will see that the hinges are at 45 degrees too. Jaager, I do not have the journal, if you could show us a picture, it could be nice.

-

I tried at least 100 kind of wood for model ship building... but at the end I use only cherry wood. I buy big quantities of cherry for model ship building. About 40% is suitable for planking. 55% is suitable for frames and the rest. Less than 3% is not suitable to use when the grain is perpendicular to the length of the planks. Easy to works and very easy to sand. It sands like European pear wood which is the favorite of many peoples, but is has no wood grain and wood by nature have a wood grain. But at the end, the choice of the wood is a personal taste and some wood, mainly the hard woods and the fruit woods, for their crisper edges and close grain are usually the favorites. The wood grain of the myrtle looks like good to use . In fact, most often fruit woods are good to use. The ideal wood would have a wood grain similar to oak but at a much smaller scale. Even if the real ships were made from oak, oak wood grain at smaller scale is way too big.

-

Thank you very much Mark. You know, the best thing about trying to explain in writing a fact, is that it also helps you to understand. There is a groove on the back of the rudder. It is supposed to improve the efficiency of its control by maintaining the current of water in its extension. The rudder is controlled by the tiller. If the tiller breaks, a hand controlled tiller can be installed. The wood parts of the rudder are almost complete. The metal parts will be next.

-

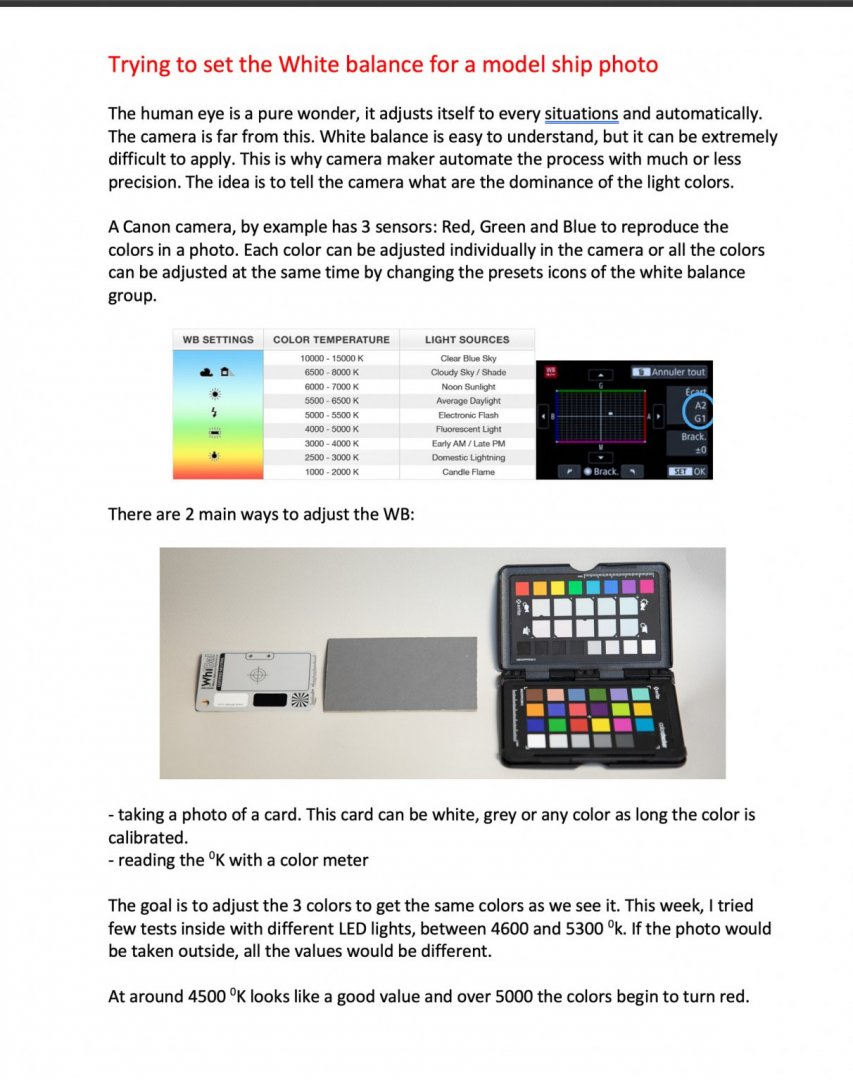

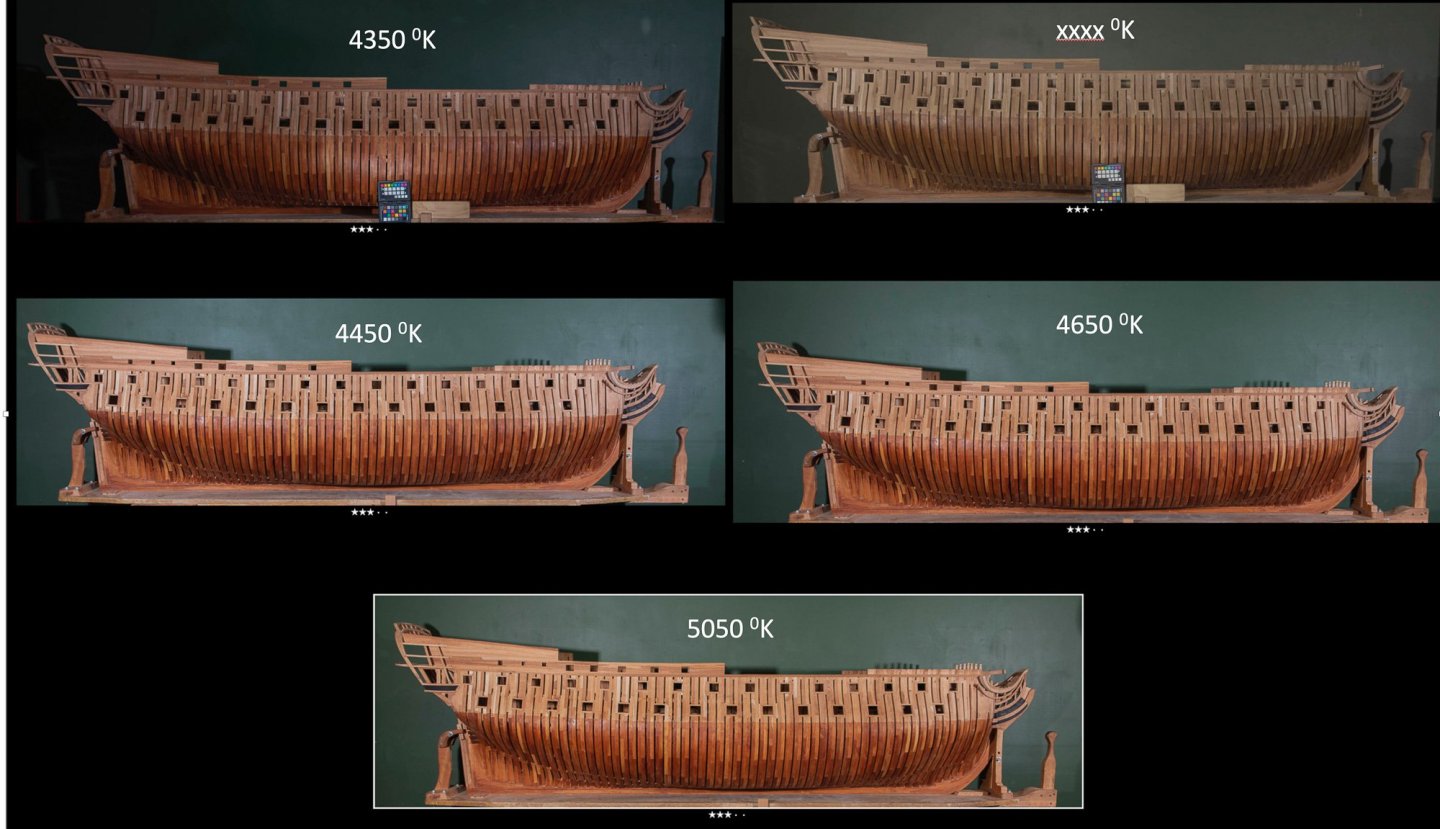

Ekis and Allan, thank you Allan, if I dare, This week was only to explore, again 1 aspect of photography: trying to match the color. To do this, I transform the workshop in a photo studio. Here is my easy way to transform a workshop into a photo studio: the big heavy are all around the walls so that the rest is in the middle. Everything being on wheels, it is easy to store when not needed. Also, I can make with this room a theater or a listening room where the sound does not sound too bad for 2 main reasons: concrete walls and a rubber mat. Over the years, I tried different floors and this one is my favorite. It acts as a anti fatigue mat and when I drop a tool especially those with a cutting edge, it does ruin the edge.

-

For the last month, I turned and milled adaptors for photography. If I show my hands, you could not guess what I did for the last month. I do not have hands of somebody working with metals. For those who worked metals by turning and milling by example, you know that it is the best way to get dirty hands and sometime it is very difficult to clean. In fact, there is an easy way to keep clean hands. You need to wear gloves. In 2020, this the best solution. But not any gloves, you need gloves that fits... "like a glove". Nitrile gloves are a solution but not very durable. There is another kind:https://www.lequipeur.com/en/dakota-paquet-de-2-paires-de-gants-lite-enduits-de-pu-53768.html#53768=ASSORT This kind fits perfectly to the hand. These kinds of gloves have been on the market for the last 20 and are an industry standard used in many areas related to metal. To handle big peace of wood,I wear another kind of gloves: https://www.lequipeur.com/en/dakota-deerskin-gloves-32238.html?_br_psugg_q=gloves#32238=LEATHR I like these gloves because I can feel the wood grain. These gloves, in comparison with the other pair is more like a loose fit. This kind of glove would not be safe to use to work metal especially on the lathe. And again, some photos.

-

Actually,I am experimenting macro photography with a ring light around the lens.The 65mm and the 100 are useful for this. It is not every lens which are compatible. For the 74, the 100mm was used. By example, we can take photos of flowers outside. With the same set up, we can also take photos inside the 74. In a parallel project, I continue to explore ways to take photos inside the 74 in multiple levels at the same time. It is particularly difficult especially with the lighting. It is the kind of project which could be done easily with a 3D model, but this is not the road I want to travel.

-

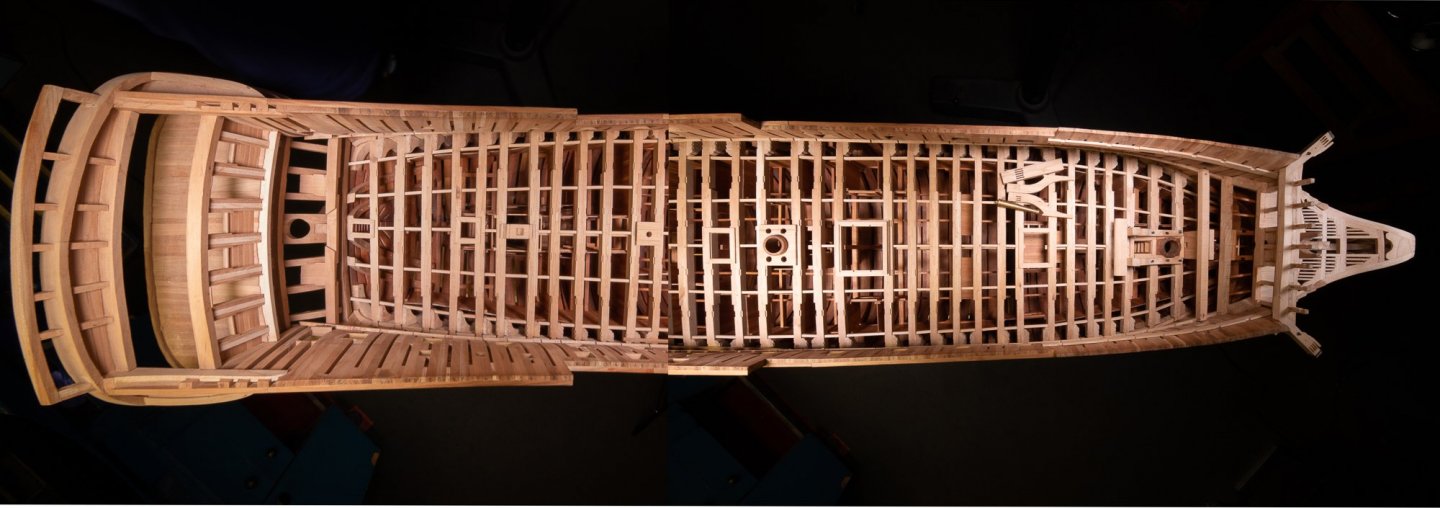

2 photos could be an option to get the model complete.I am not familiar with stitching images. I did not realize that I was missing the extremities, I was focused on the quality of the light. I did a fast try but to get a perfect match is difficult as you can see in the photo. I will do another try, focusing on taking the complete model. If the model is still too high, I will take it out of the dentist chair, this way I would get 3 more feet of distance and then it would be easy to get the full model.

-

Thank you for your comments. The wood camera studio stand is replaced by a metal one. I machined few adaptors for the final goal: to take a photo from the top of the model ship boat. This is a difficult task because the camera has almost to touch the ceiling to be able to see the entire 8 feet long model at a distance of less than 3 feet. Of course, a wide angle lens is required. Here is how it works; the camera transfer a live view image to the lap top and then the photo transfers to the TV. This way, I can easily see behind the camera.

-

I know that we saw some models made of paper but in my head there is something like of impossible. I must admit by seeing your results, it is very convincing and also, a very fast technic.

-

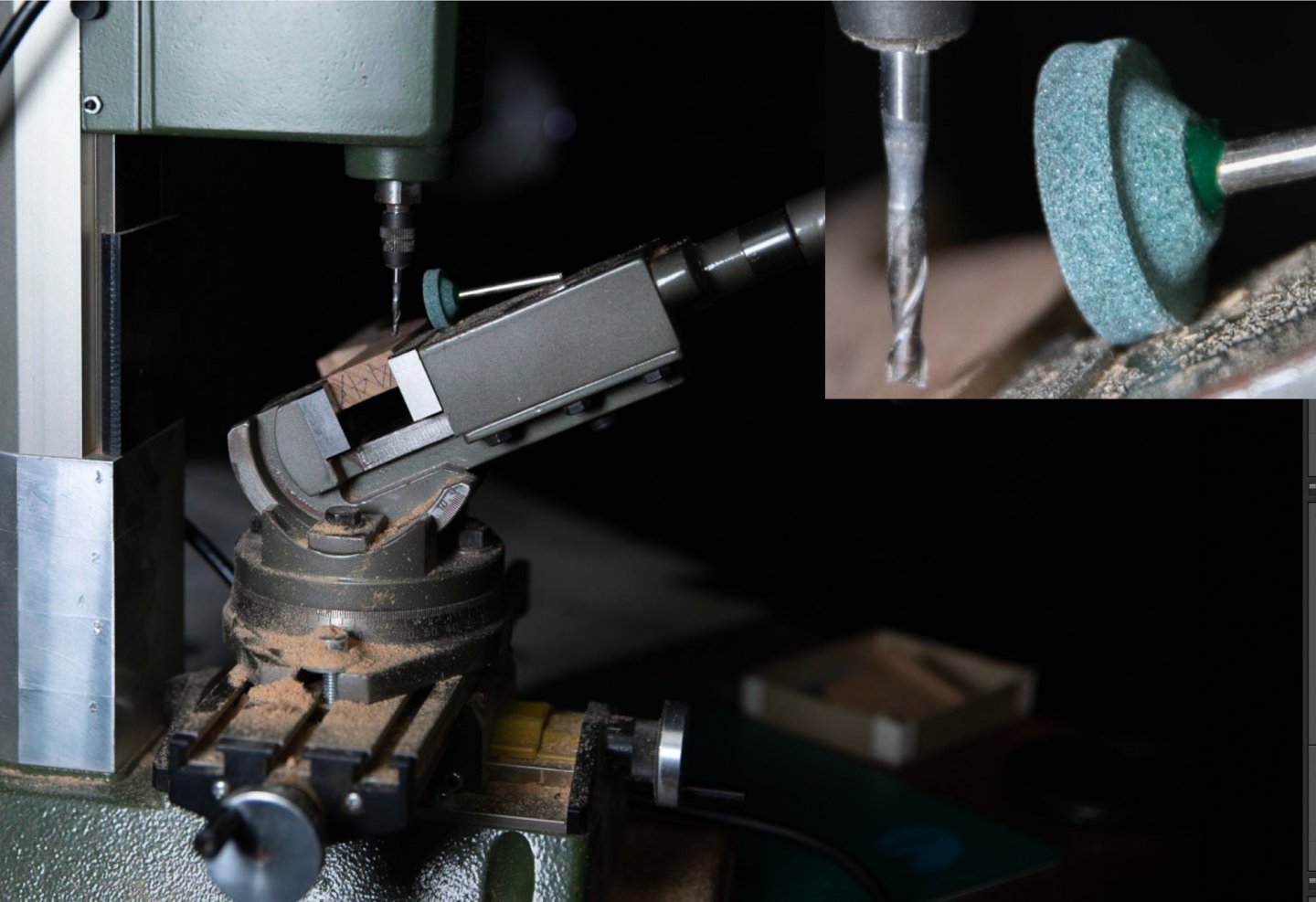

The midlle third of the miling cutter was grinded with a wheel for carbide. This way, the cutter has a smaller diameter than the diameter of the cutters. Before the diameter on the top of the cutting part was larger. This meant that the cutter could not go deeper than the area which is sharpened as a cutter. This also means that I could not mill through the wood part completely. Now, the cutter can go through completely.

-

dull number drill bits

Gaetan Bordeleau replied to BETAQDAVE's topic in Modeling tools and Workshop Equipment

just like a knife that cannot cut; sharpening is possible or may be buy a better quality -

Thank you GranpaPhil Sorry to disappoint you Chuck, but my name is not Gerard and yes I use 100% cherry wood. I f you look the second before last photo; half down is coated with tung oil and the top is not covered with anything yet. I tried many finishes and to my eye, for cherry 1 coat of tung oil is enough, 3 is too much. I bought many batches of cherry wood and never had 2 identical batch, always different color. for this batch, here is an example inside the model:with and without tung oil. In a way we could say that the "real color" comes tung oil. It is like aging the wood 100 years in 1 hour only.

-

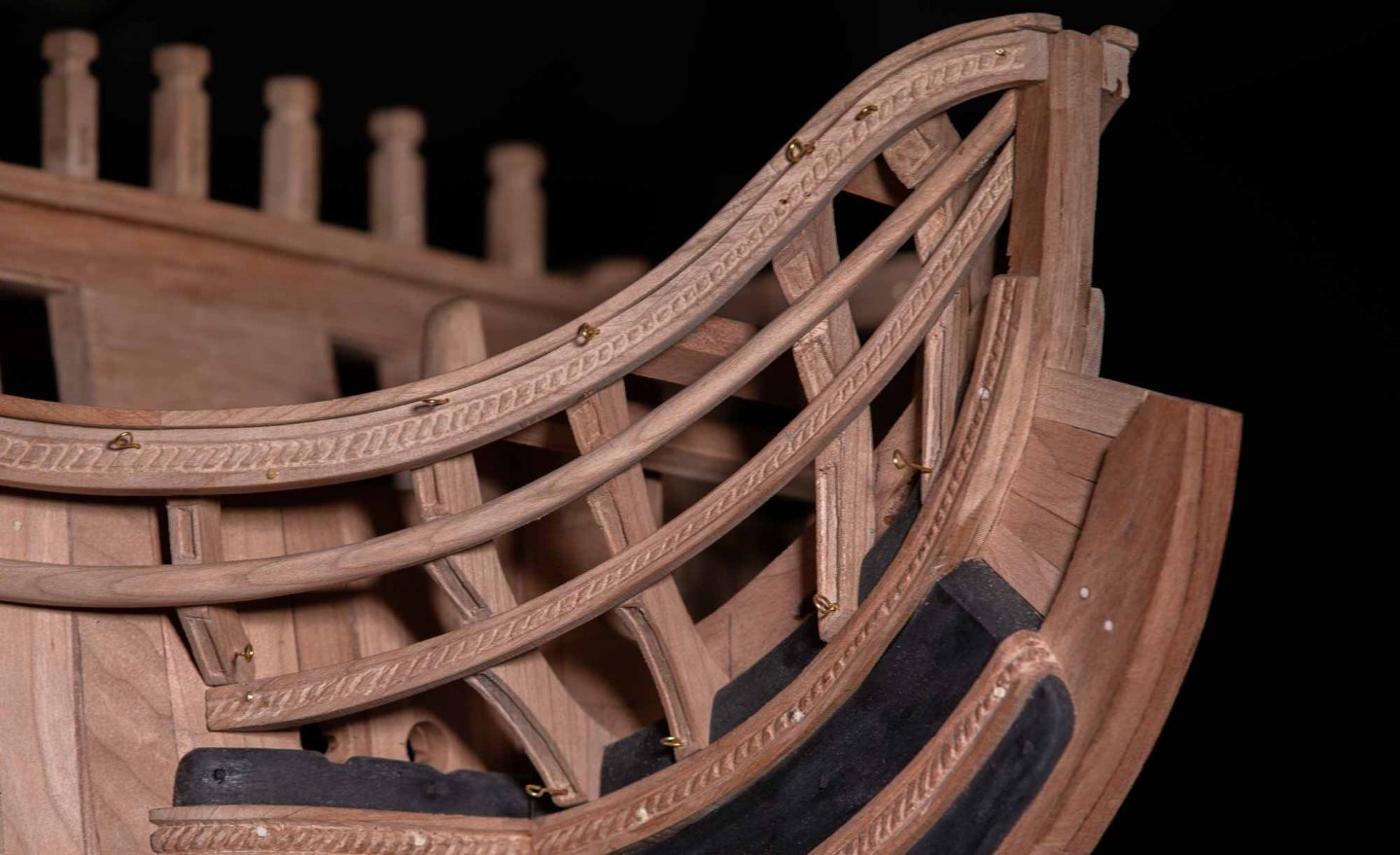

Thank you Richard Are these complicated curves, I do not know. I think that what is complicated is that you need to constantly refer to what is on the construction site. I also think that plans for this section are almost impossible to follow at exactly 100% because for every part that a slight variation it does affect many other parts. For now, it is enough with this part, I think I will come back on decks.

-

Byrnes thickness sander vs Micro Mark's

Gaetan Bordeleau replied to twintrow's topic in Modeling tools and Workshop Equipment

I use 2 by 72 belts and the best ones are blue, last for months. -

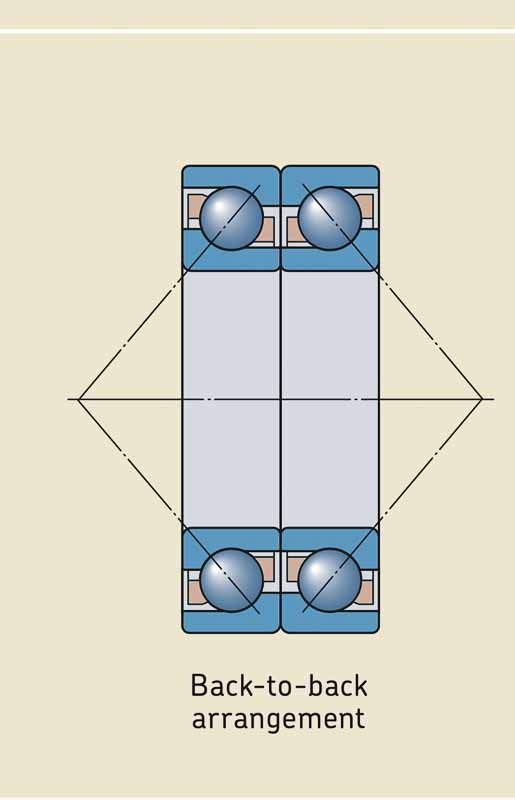

I did fix the last parts and we had the first real nice temperature this week... I did some maintenance on the milling to increase the spindle precision. One of the most interesting facts is the difference between a press drill and a milling machine. The spindle of a press drill has standard bearings. The Bridgeport has angular contact ball bearing with the main line at 40 degrees. This is why the spindle can work in more directions than the press drill.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.