-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

Roughly Le Fleuron is 50 years before the 74 guns ship. Comparing some details, like the stairs, it often look like if the difference in time was very much longer. Nothing beats experimentation to progress in design.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

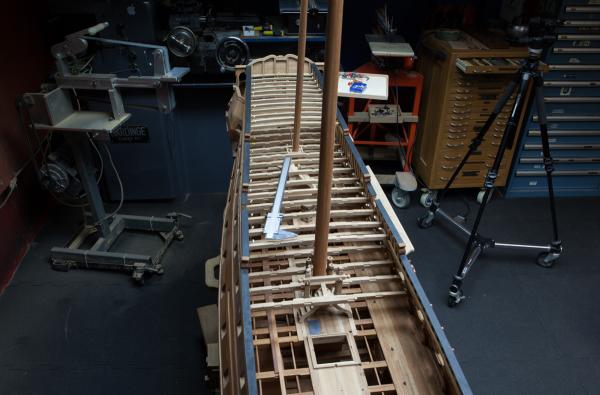

To convince you that the scale is really 1/48, I put a ''standard measuring tool on the deck. Strange form of staircase in the last picture.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Workshop Set Up Question

Gaetan Bordeleau replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

The main advantage of a garage it is easy to bring the big tools. But I prefer the basement, it is easier to control a stable temperature all year. In your case it would depend first can you bring every tool in the basement. For the Hardinge lathe a Hiab was use to bring it at the good level,so for every tool there is a solution. At your place I would choose without hesitation the basement and install a suspended ceiling especially to pass all the wiring easily. Installing drywall is an easy job. You are not sure if you want to breathe it or spread saw dust in the basement, it is effectively a disadvantage, there are air cleaning systems but even with this there are some dust going up and your wife will not like it. Even with that disadvantage there are more advantages in the basement. In the garage the floor will probably be left unfinished and always be cold. Even if it is the same surface in the basement for the floor, you have more choices to finish it etc etc... -

Jeweler's Tap and Die

Gaetan Bordeleau replied to Landlocked123's topic in Modeling tools and Workshop Equipment

-

I had anchor cables done from previous works and they match. Cable circumference is breadth/24 : 41.84/ 24, C : 2pi r, Diameter:6.64 inches and at scale 1/24 :.28 inch. I am sure that if they had micrometer during that period they would have measured not the circumference with a rope but the diameter. During myfirst professional job, I bought a camera. Up to now Olympus was always my first choice and I was happy with it. Now I will experiment with a full frame Canon camera. They are very strong with the light sensibility and they have a wider variety of programs for the photos manipulation.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

The first table saw I bought about 25 years ago was a Dremel and it still works and this table does things Byrnes table does not. You get what you pay for. Dremel are low cost tools, and for that price they are good tools. Foredom is better quality, much stronger, in fact even too strong and the shaft reduces the maniability, and for that reason I do not use it anymore. The best quality I use Gesswein, price 10 times Dremel, so you see Dremel is not expensive. Last year they replaces bearings for $140, and it was worth.

-

Beeswax dangerous fact or myth? Here is what I just read on Internet; Yes, beeswax becomes slightly corrosive when exposed to UV. It's because it's a biological material and UV degrades the molecule releasing natural acids. In my opinion, the corrosive effects only really matter on a really long term scale and with fragile museum items. New work such as ours won't have the capilliary system of damage and corrosion that ancient pieces have so the risk of new acidic compounds entering the piece on a microscale is not such a concern. It's the reason microcrystalline and renaissance wax was invented because the V&A realised this fact after a century of applying beeswax to protect the nation's most precious and ancient artifacts that they had, unbeknownst to them, been applying slow acting acid.

-

Work table height?

Gaetan Bordeleau replied to rtropp's topic in Modeling tools and Workshop Equipment

1- Jewellers and watchmakers workbench are very interesting in their concept. The height of the bench brings the work close to the eyes making it easier to see. 2- The other watchmaker workbench is even more interesting because it offers an additonnal feature electric height adjustability of the workbench. Having the work at the good height simply makes the work easier to do. 3- Inpired from a jewellers workbench, finally discarded because it was too heavy to move. 4- Modelship workbench based on a watchmaker workbench, electric table, when it is easy and fast to change the height, you often adjust at the good working height and you are not oblige to work with the restrictions of only 1 height which in certains circomstances can be painful. More lower drawers added to suit little tools. When drawers are too high a lot of space can easily be wasted. Small tools are easy to reach. -

Work table height?

Gaetan Bordeleau replied to rtropp's topic in Modeling tools and Workshop Equipment

To have a height adjustable chair is limited to let's say 4 inches. Why not think the other way around by having a height table adjustment system. You can work with every chair. 4 inches is not enough a big height difference. When working on small parts , it is a lot easier to work and to have the parts closer to the eyes. Table height 30 to 48 inches high. You can work standing which is very interesting occasionally. -

Thank you Greg for translating the opinion of this new member. Gloaguen, on some pictures wood grain can look a bit strange, but you should look at more than 1 picture before writing anything, just to give you a better idea. Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi David, effectively off the model, it is easy. But there are parts especially around gun ports which are not so easy. I tried many solutions and what I find difficult is to keep homogeneity in the entire process, there is often an area which do not want to dye as well as the rest. This is particularly visible when taking photos. Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi Chris, Wales are black on 1 side only. Stain not dark enough. I tried Dye with black ink or shoe dye, good color but if you use a tape the dye is not stop and goes under the tape also. Matt water base paint is better because it is more controllable. Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Beams of the second bridgea are not fixed yet, some notches are still to be made on all beams and it is a lot easier to do it on the working table. A brass rod held in the Dremel picture 6 will be turned to a door knob. Shaping is done with a metal cutting wheel of the other electric pen.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

The construction of the Frigate Hermione began in 1778. The 74 gunship is in 1780 and has copper plating. Copper plating began in France in 1778. At his neuvage (when new) it was not copper plated. It was copper plated only few months after. Copper plating of Hermione began in november until december 1779 and needed 1100 plates.

-

Thank you for your nice comments. HI John, This is sold under the name bitumen. In Canada, it is sold as Natural Bitumen by Waxine. You can find in 2 kinds of store artist paint products and wood finishing products. Depending of the % you add, the darker it will get and yes it does the trick. To answer, your second question. My father was building houses, so I learned at young age to use woods. This is why I have a long experience with wood. When I broke a finger around 15 years ago, I stopped model building and began to machined steel and aluminium tools in a continuum to build more and more complex tool. When the day arrived where I had no more tools to build, I came back to wood ship models. I am surely not the best modeler, but I know the road to build it. HI Mark, Thank you I now understand the problem.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Thank you Ian. If there is no fix for this, I am wondering: Am I going to change build log every 20 pages if I want to be able to print the entire log???

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Bolts for the first deck Photo 1; the red rectangle with a shoulder is slightly thinner than the bolt and is used a guide to make a hole always at the same place. The parallel holds the guide in place. Photo 2-3-4; preparing the planks for the channels Photo 5-6-7; ouside bolts and the rest inside I cannot print my log anymore! I lost the print icon at the bottom of the page. Same thing for others, but not all the other subjects. If someone has an idea I would be glad to hear it.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Very nice work and even nicer when we see where you display it. Karl, did you decide which model is going to be your next build?

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Greetings Carabrente Bitumen is an instant Aging solution. Depending of your application many varieties can be applied. bitumen allows beewax molecules to bind and make the asphalt more neutral asphalt: Was used by the egyptiens for embalming Oil suluble pine resin: Gives plastic properties and can form a varnish if mixed with alcool natural soap: probably for the oils in the soap turpentine: Fluidity and solubility of the mix siccative of cobalt: shorter drying time, max 10% of total mix. Not recommended with linseed oil, the reaction with linseed oil induces at long term crack and separation. There are many receipes, this means you can can mix one that suit your needs just like a parfume. The simplest way asphalt plus tung oil. If you want to increase solubility, add turpentine or alcool which as a bonus will act as a fixative. Add asphalt to your mix make a test add continue until you obtain the desired tint (maximum % of asphalt 40%, if you add more it does not dissolve and sinks in the bottom. Asphalt must be applied in thin layers . Do not apply in thick layers as a painters would do, it would be too hard to dry and would probably crack. After drying, you can reduce the tint if required with 000 steel wool. Wax slows drying time softens the color and make it more transparent. Another possibility (for the hull by example, for large surface » Bee wax with turpentine to make a paste like shoe wax. Just these 2 elements makes a good finish on wood. You can also add asphalt progressively until you get the color you want. Another example, asphalt plus turpentine to dissolve asphalt rest for 15 minutes (chemical reaction continues to fully dissolve). Add tung oil. To accentuate the details of a bow figure to make it look deeper, you can apply the mix especially in the deeper parts. Finally, to complicate the process, you can add by layers. By example, apply and wipe to give patina at your taste and when finish apply wax or oil as a finish. Simplest way to use it. Asphalt plus tung oil, and for the hull, I like to add bee wax plus turpentine. This should cover the subject.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi JP, I like what I do, so I have no problems to stay there. Unlike what we could think, I try to have as little tools possible on the table. The idea is to have more space and also it is much easier to keep the room dust free Hi Mark, It is from the same batch which I paid $2 pmp, the batch has mainly darker wood than this plank. Plank had many cracks, but tis no problem if I saw in correspondance with the cracks. I would estimate that over 60% of the wood is lost in sawdust. It takes some luck to find a good batch. The most important factor for me, the color: the darker the better. Previously to this batch, I bought another batch, also at the same price all 1 X 5 inches fresh from the planer but that batch was much lighter in color. I did offset the color by adding asphalt in powder in the mix with tung oil. Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.