-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

John, your work on the rigging is very inspiring, I hope that my own attempts will be as authentic as yours are in their execution. Would those backstays have been let out on the leeward side when running? otherwise it would seem that they would resrtict the travel of the boom. Michael

-

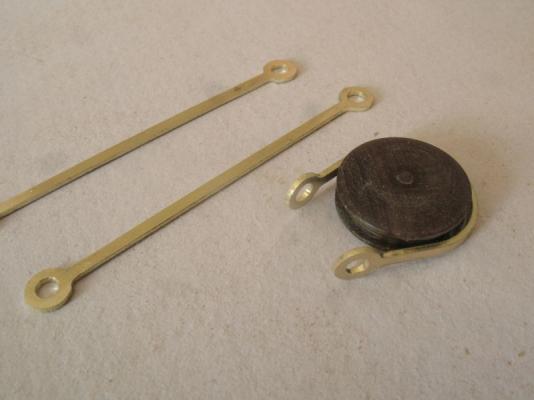

After folding the brass over the steel it was ready for the curve at the end I used a loop of the same hard rod, this had to be heated red hot to bend. the loop was hammered down to create thecompound curve in the rounded portion. the ends were filed even before folding the thimble closed a rope wrapped around the finished thimble with a shackle. now to make a few more. Michael

- 2,215 replies

-

John, Bob, thanks. I finshed the other three deadeye clamps. I used a couple of pins to set the level, this also ensured that both sides were even to the holes. This afternoon I worked on making some thimbles for the ropes. The fiest task wqas to cut some strips ofr brass 1/8 x 3/4 x 1/64 thick. These were annealed. Next I made a special benting jig out of some 1/4 x 1/4 square steel, this had a groove cut with a1/8th ball end mill. and then the end was shaped with some files. The brass was placed evenly so that a short area was laying over the grooves either side of the flat. the brass was shaped with apiece of .073 steel rod. the flat area allowed the ends to bend easily over the steel form ready for the final shaping. end part one. Michael

- 2,215 replies

-

Symiaki Skafi by stelios

michael mott replied to stelios's topic in - Build logs for subjects built 1851 - 1900

Stelios .6mm that is fine silver soldering, well done. Michael -

john thanks I noticed that the edge of the rail there needs a little refining too. Michael

- 2,215 replies

-

Not a lot to report, other than I am redoing the method of attaching the lower dead eyes. instead of a bent wire loop I am cutting out a sheet metal loop, I think it will be cleaner overall. Michael

- 2,215 replies

-

Alex, Carlos and Carl, thanks for your kind remarks. I have been away for a few days in the rocky mountains accompanying my good lady at the Library Conference. I had a great time no phone no computer, tons of good food spectacular environment, great accomodations. So I will be back in the shop tomorrow, back at the workbench doing a little more fiddling. Michael

- 2,215 replies

-

Symiaki Skafi by stelios

michael mott replied to stelios's topic in - Build logs for subjects built 1851 - 1900

Stelios the sails look great, I am taking notes because it will be useful for me later. michael -

Russ thanks. Mathew thanks for looking in. Bob, Jewelery now that is an interesting idea. Stelios, "when I grow up" :D Garward thanks for your kind words. Popeye, yes actual rigging. Germanus before I forget thank you for your comments regarding the need to balance the size of the shackles, I had realized this. If I missed anyone my apologies While this computer was doing the updating I did spend most of the day working on the shackles I set up a small travelling steady to cut the pins for theshackles after drilling the holes for them . Each shacle was placed on the wood bar and clamped in the mill vice to drill the holes.the holes are .073 inch the retaining rings were snipped off the ends of these compression springs from the spare springs box. I did make some from the .011 thou piano wire but they were a little too fine . Michael

- 2,215 replies

-

well I finally got tired of the explorer updates and cancelled it I use firefox anyway. and now it sweems to be back to a semblance of nomalcy. Michael

- 2,215 replies

-

Thanks John. It is still installing updates..... will this never end? Michael

- 2,215 replies

-

Daniel on my slow laptop, wow that is some impresive modelwork! now lets see some fine details :D michael

-

I woke up this morning to an unresposive desktop computer. seems that the keyboard and mouse were not responding. this being typed on my laptop which normally is not connected to the web, I just use it off line. so today I needed to get things updated and protected. needless to say XP found 122 updates for this laptop which it still installing it seems to be taking all day. also I had to purchase and download virus prtection. all this seems to be taking a great deal of time. The desktop is in for repair. So this is slow at the moment. I did work on shackles today Well adding that pic that took ten minutes so until qall th updating and fixing is finished I will wait to upload any more pics. the lock rings were cut off the ends compression springs in the spring scrap box I will respond to comments tomorrow when this thing has finished it's work. This is really frustrating, I cannot imagine how frustrating dial up is these days. Michael

- 2,215 replies

-

Symiaki Skafi by stelios

michael mott replied to stelios's topic in - Build logs for subjects built 1851 - 1900

What a fine looking model you are making Stelios. Michael -

John Thanks. Back at the block Factory, A long time ago I purchased a small board of Lemonwood or Degame to make some wagon type wheels, the blanks were cut but the wheels never got made. I re-cut the small curved sections to use for blocks. the wood is quite hard and takes a fine polish it is similar in texture to Boxwood but a little darker. I wont be using this many double blocks, after shaping the profile I will cut a number of them in half to make single blocks like the ones on the right. and a metric rule The big blocks are Lemonwood the small ones in the front are Boxwood I also worked on a maple one with a metal frame The pin is 3/32 in diameter the new block attached with yesterday's shackle Michael

- 2,215 replies

-

Russ, John, Mark, Bob, thanks for stopping by. Mark My plan is to make everything that would work on the full size boat, also work on this model within reason. I took a break from the winch this morning and finished another shackle this one with a ring instead of a threaded section. The ring is made from some .011 music wire. the pin diameter is .073" or scale 5/8th inch the gap is 1 1/4" in scale Michael

- 2,215 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.