-

Posts

206 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by liteflight

-

Not only a stunning and beautifully built model, Steven, but also a journey of discovery through the Byzantine empire. Lots of unclear evidence winnowed and crystallised into the Dromon. You can be proud of it/her ( I have no idea whether Mediterranean ships are referred to as feminine!) Many thanks for sharing. I can safely say that no one who viewed your build log will ever pull a hose without seeing ( in their minds eye) a lateen yard rising steadily with three unfurlers ( Tom, Dick and Mustafa?) ensconced thereapon.

-

It seems to me that the Dromarch would be flailed round the head by the flag tails in any following wind. I hope Louie was spared that, or wore an anti-swooping helmet

-

Pics welcome! The problems you mention are mere breadcrumbs in the bed of life! You have surged past the bottlenecks/ breadcrumbs and are about to regale us with layers and pics Avanti!

-

The first step in the great journey to realise the hulk

- 186 replies

-

- keelless

- reverse clinker

- (and 4 more)

-

The spar is ( perhaps not surprisingly) a sprit. Probably a Dutch word I think, and pronounced “spreet” on Thames Barges. Gloriously the rope holding the bottom end of the sprit is the snotter. Beautiful work on the boat, Bolin. Extremely clean woodwork and a good result.

-

Apologies- you had shown us clearly that it is silly putty on previous posts Nice little boat, beautiful clean woodwork by you.

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

I plump for reason 4 as the true cause of the putty’s intransigence. It would follow naturally from Murphy’s Law. It is a well known fact that model aircraft fly perfectly and endlessly until a stopwatch is started. What sort of putty is this? Is it the linseed based ‘glaziers‘ putty?

- 72 replies

-

- fishing boat

- Barco Catalan

-

(and 1 more)

Tagged with:

-

So If the zylocastra had a means of communicating with the captain would that be a xylophone? very sorry, Steven. Failed to resist. Wonderful model and backstory. Getting better as you enter the finishing straight as well. I hope the little man lying down is feeling better in time to carry out his duties

-

I will re-read all the relevant Billings kit builds again tom see if a 1mm overlap on the strakes is a good aiming point. The strakes will end as marked at the bow and stern, so the 1mm overlap will govern where the midships strakes land. My plan is to: Mark the 1mm "land" on the GS, Mask the rest of the strake with masking tape Apply thinned glue to the land and allow to dry completely Clamp the new strake (already sanded with the scarf joint) in position Activate the glue with heat - applied with an appropriate electric device* Since the new strake will be clamped in place I will iron between the clamps, allow to cool and then remove the clamps and iron down those areas *Note: I will try this before spending money on a suitable heating gadget. The household Iron (with protection) or a modified soldering Iron will be used for trials. Good shapes of tool appear to be a Plank Bending Iron, a Covering Iron or a tiny craft/ travelling iron Amati Iron - good shape but expensive. Not variable heat, but a dimmer would take care of that. Covering iron for film covering. Good controllable shape to apply (a little) force. Excellent temperature control (said to be within 4 degC) I had one of these but gave it away as I do not use film! I'm an old-fashioned tissue and dope freak afficionado Something like this would be manageable. May or may not be temperature controllable (but a dimmer switch would sort that) I have many soldering Irons, including a solder station I do not use any more with a threaded (M6) iron tip. I think I can make this into a suitable device with a "shoe" threaded into the heater. To be tried! Sorry no progress photos at present - family challenges. But I can think and sketch while waiting! Thank you all for the "likes"

-

Louie, This is no the serious Burns unit! and no, also. No one has called me sleekit since birth, probably not even then. While I would still like to be sure that my planking will reach the gunwales triumphantly, or at least tolerably: I cannot see any good way to do this, so I am going to barrel in, damming the torpedoes. And yes, I do know what a torpedo was when this ship was hewn. Apparently they were used for electro therapy in the 19th century to treat distempered, hysteria and certain forms of mental disturbance. I am going to try the hot and neat clinker method and then dive in and plank. “Wi’ bickering prattle”

-

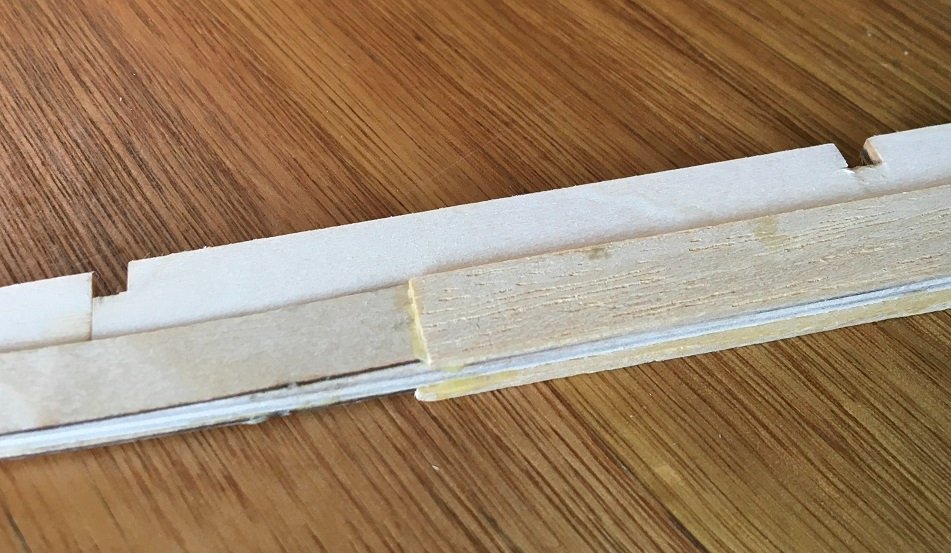

After a quiet week or two - alarums and progress! The Alarums come about because other notable and respected Viking shipwrights have run into problems as their clinker-built hulls have reached the upper strakes. Am I going to be in the same type of strife, I ask myself? Back to the Instructions - here they are: And this is the complete planking instruction. I have read - allow a 1mm overlap between planks and all will be well - but the writer had problems still with the top strakes not lying on the frames, nor forming a fair sheer. I can't really see any practical way of either calculating effective strake cover and marking that out on the frames, or laying out each strake with clamps on 1/4 of the ship (one side - half the length) But whatever happens later I still have to fit the Garboard Strake - so off we go: And immediately run into a small snag, easily overcome, that the garboard strake does not want to fit in the space for it. The frames fit to the keel to a position determined by the Billings LaserMaster. The Garboard strake (1mm thick ply) fits touching the frame and lies in the gap between the frame and the keel-reinforcing strip made from 1.5mm obechi (part 54) Fitting part 54 is one of the first operations, and I installed it (cunningly, I thought) so that the inside edge (which forms the planking rebate) was aligned with the shaped ply prow and stern doublers So that is what I did, and found that when it was time to fit the garboard strake (part 14) it would not quite fit in the gap left Sorry about the poor photo. This is the gap into which the Garboard strake (GS) has to fit, and for most of the midships frames, doesn't Easily fixed with my battery grinder and a diamond wheel. The fore and aft parts of the GS were cut to length, scarfed and glued in place This is the scarf joint (apologies to all the scarph spellers, I just happen to have settled on scarf and rebate, while liking and being aware of all the other spellings) I am pleased with how it went - what is most visible in the picture is the "fringe" resulting from sanding to a point - it will sand out neatly (I trust) So GS fitted successfully Now - how could I have avoided the need to grind the gap larger? 1) Not fit the obechi keel doublers until after the GS is fitted? Probably not a good plan - because the keel needs to be as stiff as possible during the processes of fitting the frames . Also the jig would need to be made to fit the bare keel (not a huge problem) 2) Fit the frames without glueing, and use a small spacer made from the strake plywood to mark the closest position for the obechi doubler 3) Do what I did, which might have been more serious for another builder - particularly anyone who cleaned up the laser-cut slots in the frames ands keel Next post - clinker planking without tears or glue cleanup, and a few more strakes added Footnote - "the best-laid plans of mice and men; gang aft agley" (Rabbie Burns; who was (briefly) a local farmer where I grew up, and knew a thing or two about plans ganging agley)

-

Hi, Balclutha I feel for your Viking ship and its planking! That is where I am heading and I hope that I am sufficiently wise and lucky to be able to side-step problems like this My (Billings) ship has no notches on the frames until the last 2 vertical strakes - and these certainly gave problems to my gurus (VonKossa and Jack P) But I find that 71 is an excellent age for life and problem-solving (with or without Tee shirts) Now only you and I know my real age, to others I only admit to seventy-mumble

-

My first reaction is that they would be livelier than a flower class corvette. The extreme rocker and rounded cross section would, I suspect, allow it to pitch and roll like a good’un. But reverse clinker would facilitate the banana shape, if I have understood the issues. I still Look forward to hearing the other advantages 😄

- 186 replies

-

- keelless

- reverse clinker

- (and 4 more)

-

You are excited, and the wood is looking forward to being transformed into a thing of beauty

-

Aaaah! I have acrylic Matt medium in large quantities for painting in acrylics - I will give it a whirl and see if it’s close to the acrylic varnish I have not been able to find this side of the world. thanx, Druxey I tend to use a synthetic/ cotton mix for sails of radio yachts because it cuts with a very hot soldering iron, getting sealed into the bargain. I would not propose anything so venal in this august gathering. Such a practice would deprive hundreds of sailmakers hours of fun couching boltropes round sails and cringling where cringles are called for Dromon looking increasingly fit for purpose, lovely realisation of your research, Steven

-

For stiffness you cannot do better than carbon fibre, and the version I am thinking of is carbon tissue. It has no mass or thickness (yes, I have been told not to exaggerate a million times) and would bond between two sheets of paper to make a usefully stiff shield. I use it a lot in my aircraft builds, and had a sq metre or so, but it didn’t get to Australia with me. I get mine from Mike Woodhouse in the uk. He posts everywhere and is an all round good egg and free flight guru. https://www.freeflightsupplies.co.uk/files/carbontissue.pdf And this is the relevant page of high tech materials: https://www.freeflightsupplies.co.uk/index.php/products/hi-tech-materials/cloth-tow For some reason I expect that Mike is not rushed off his feet by orders from MSW In fact, if this is of any interest the best and cleanest laminating method would be to spread carpenters glue on one side of two bits of paper, allow to dry then heat-laminate the sandwich together with a suitable heating device ( use baking paper to protect the surface of the iron, or suffer the wrath of the Admiral). I have no idea what this would do to pre- printed shield patterns!

-

Great pictures of the reverse clinker in action. I can see now one advantage - it makes the upsweep not only possible but rather more straightforward. There is a lot of overlap on each strake, and plenty of nailing “meat” I think it makes for a strong and heavy hull, and would be less flexible than the Nordic tradition. And correspondingly, under these circumstances you cannot be lost. But a Catnav would be handy

- 186 replies

-

- keelless

- reverse clinker

- (and 4 more)

-

Sorry, I am still learning Australian, eh? THAT type of bodging in the UK involves chewing gum and baling wire, and more recently WD 40 and duct tape I really like the carved shinners, and appreciate the skin shading you have painted. They would have some grip on the robands, but it’s a steep climb. I think that big and strong are not the ideal physical combo for the degasketting crew. All the photos I have seen have been of slight, young grinning lads. Dunno if dromons have anchor cables, and therefore need nippers. But I suspect there would be a small mob of younkers who carry water to the rowers, basically facilitate everything for the crew (and release the gaskets) Do you know anything about brailing as applied by dromons? And what is the plural? Dromonai?

-

Castles to avoid the “bare” look, and possibly a cherry each end? Or how about the little trumpeters as shown on one of the seals? The whole shipbuilding world is your lobster, until and unless someone finds a wreck, as-built plans or a time machine. The thought has just come to me that there is probably more information and representations of the toothed sea-monsters available, than about the hulc!

- 186 replies

-

- keelless

- reverse clinker

- (and 4 more)

-

Seaography! Like it, but the lettering is a bit ephemeral. I suspect that flumenography comes into it as well as we are discussing a rivermouth, or “os” I like Steven’s convincing parsing of the Pune, or play on worrrrds. Dick, whatever style of reverse banana you build, it is in danger of becoming the only physical representation of a hulc ( or is it an hulc?) and therefore cited in learned treatiseseses for ever. If Steven can present evidence from any 3 random planks, you have a golden ( or possibly gloden) opportunity the recreate the hulc and Gift it to Posterity!

- 186 replies

-

- keelless

- reverse clinker

- (and 4 more)

-

I feel that I should point out that your remediation was not technically bodging, as that profession works with green timber. But we know what you mean, and I am being pedantic Did the repair involve sawdust and glue?

-

Wonderful, Louie! Very glad you decided to carve the active men in the rig - they are shaking out the furl and loosing the gaskets, I expect. Well carved. I expect that you mentioned the wood you are using. It looks home cut and dried. Pity about the ankle; but I realise that if it was all easy it would not need your talents

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.