donrobinson

-

Posts

1,909 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by donrobinson

-

-

I just ordered the Joitka/Caldercraft one yesterday from my good friend Rick Shousha at "Modeller's Workshop", it will be interesting watching your build. Looking forward to seeing more.

-

-

-

-

Richard,

Thanks

I am not sure of the grade, next time I am out in the shop I will check to see if there is any kind of grading on it. I bought it at a local hardware store, so I am sure it is nothing special. I had no problem milling it, although, I will say my end mill bit was brand new which I am sure helped also. Cutting it to length with a hacksaw was no problem either so I am thinking it is not that hard of a grade.

I am new to this and do not know my metals that well, but I will check for you.

Have a Good Day

-

Hi Merchen: I have just recently found this topic and I can say I am really impressed with your wood supply. I would like to ask what the history is on that boat and even the table it is sitting on. The boat is absolutely beautiful and the carvings are fantastic are these something you have made?

-

-

When is she scheduled to be completed?

-

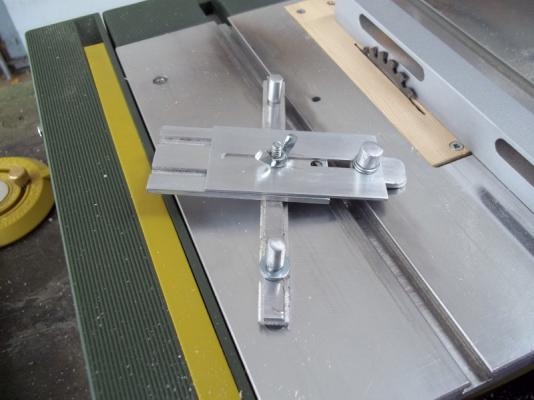

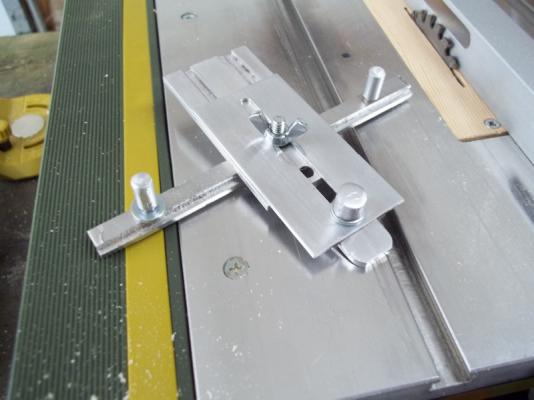

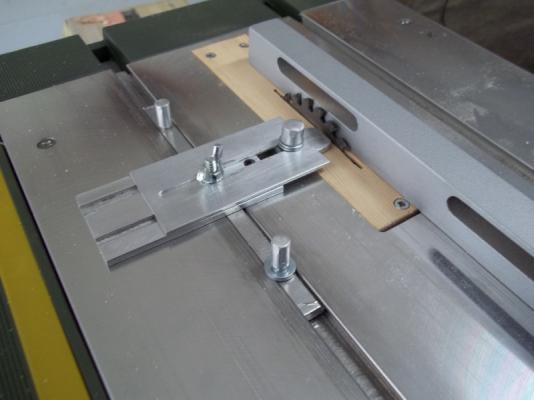

I just realized I have posted this on the wrong topic, please move if necessary. This planking jig was made using my Sherline mill and lathe(my first attempt on a real project), it is a copy of someone else's here that was made of wood(I apologize for not knowing your name).

I used 1/4" aluminum for all the sliding parts and some 1/2" round stock for the thumb screws.

I avoided using a ball bearing on the end, as was on the original, as I was worried about thin stock sliding underneath it. The only flaw is that I am limited to approx. 13mm(1/2") in width, which should not be much of a problem. When in use the stock slides by with no binding and appears to be quite accurate in maintaining a consistent width throughout the entire length.

It is a bit of a pain adjusting fence for every plank but for the sake of safety a little more time taken is well worth the effort.

The original one was used on a Byrne's saw, I believe, and he used a spreading system to lock his in place, I have a Proxxon which has a "T" slot making for a little different locking system as you can see.

There are no patents on this so feel free to copy(lol), if you want any measurements or more info feel free to ask.

Again I apologize for posting in wrong forum.

- CaptainSteve, Mahuna, cristikc and 6 others

-

9

9

-

Congratulations, enjoy your new bundle of joy. Glad to hear everything went well, any name yet?

-

-

Hey Martin good to see you back. That "precious Paper" sure changes the looks I love it. I just took my Pegasus kit down from the shelve last night thinking I would start it next but now I am having second thoughts.

Congrats on your windfall, I did the same when I got my retirement windfall this year and "tooled up". I bought the Proxxon table saw for the same reason you are thinking(shipping charges and also exchange) it is a fairly good saw but you are limited as far as accessories go ie: blades and attachments. After buying the Byrnes disc sander and thickness sander I wish I would have sucked it up and bought the table saw also.

I am not familiar with Toolco so can't speak on that, however, Brian(from this forum) turned me onto Sherline tools, they have excellent tools, I bought their mill and lathe and am really impressed them. And what is really great about them is they have a full line of accessories, it is worth while checking out.

Well I hope this helps spend your windfall

-

Nice start, looking forward to more

-

-

-

-

Might be a little big, I don't think it will be all that noticeable though.

If you feel you need to refine them more,try taking a piece of your dowel(6mm) then get some planking(,5 -1mm thick) cut this into 1mm wide strips(length is up to you) glue these strips onto the dowel. Now wrap your bamboo over this and that should give you a better diameter, or at least one that you can control or change. Plus you are freeing up a pen

-

-

Very nice work, Dominic. Looks real nice

-

-

Lots of work but worth it. Looks as though it was fairly well built and would have looked not bad at one time. I am really looking forward to this restoration, but what I would really like to see is the look in their eyes when you deliver the final product.

- mtaylor, CaptainSteve, GLakie and 3 others

-

6

6

-

-

I have just recently purchased(two weeks ago) a Sherline mill and lathe. They are both great machines and I would advise anyone thinking of buying a mill or lathe to buy a Sherline, they are a quality "made in America" product. Unlike other products on the market Sherline has an extensive line of accessories available that make the possibilities of what can be achieved on your mill endless.

On my current build(AL Mayflower) there is seven different pin rails to be made, with the mill I was finally able to drill all holes exactly centered and spaced. This job is virtually impossible on a drill press, and with the proper bit(which didn't have) it would have been possible to cut each one to the exact length. I mounted a piece of stock in the vice and drilled out all the pin rails at once then cut them to length later on my table saw.

With the mill and a index block it is also possible to cut perfectly square sides on a dowel, such as a mast or spar.

The mill, although I am a novice on it, with the proper accessories can be thought of as a drill press, router, scroll saw, lathe and even a table saw to some extent.

In my mind, with it's versatility, the mill is second only to the table saw in this hobby.

The last thing I would like to mention if anyone is thinking of buying one from Sherline check out the "packages" they come with enough accessories that you can start milling right away.

- xken, Canute, Landlocked123 and 2 others

-

5

5

-

I have the AL Mayflower kit 1:64(3/16"/ft) it comes with sails, I could scan them and e-mail if you want. let me know, would be happy to help

Unicorn by ameletters - Corel

in - Kit build logs for subjects built from 1501 - 1750

Posted

What's happening with the Unicorn?