-

Posts

1,829 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tkay11

-

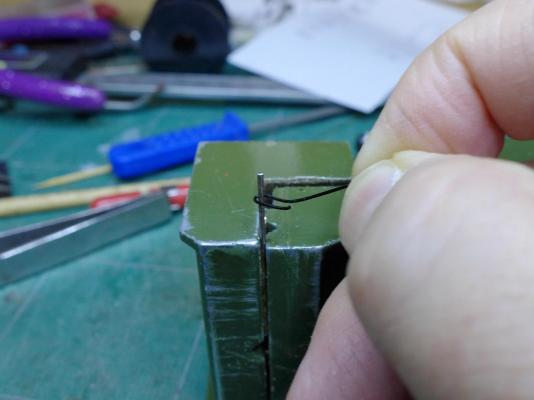

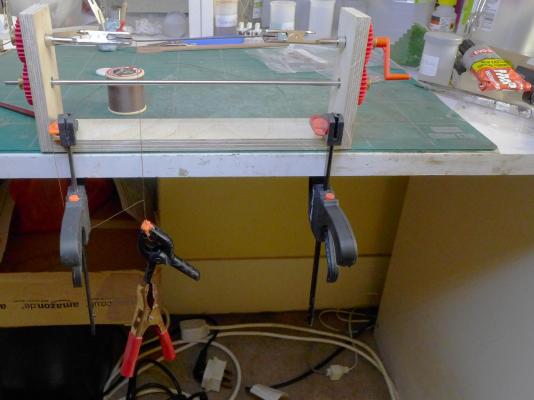

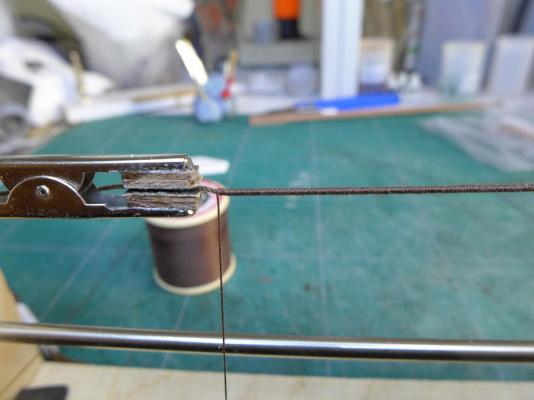

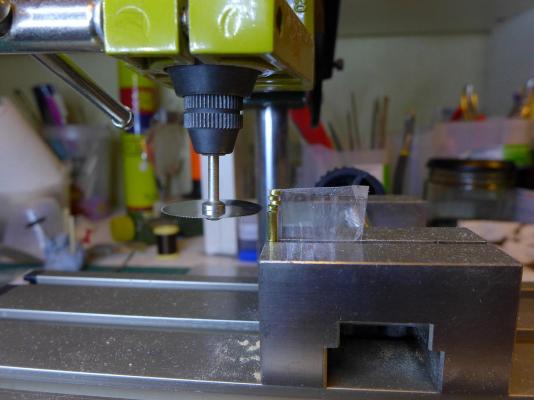

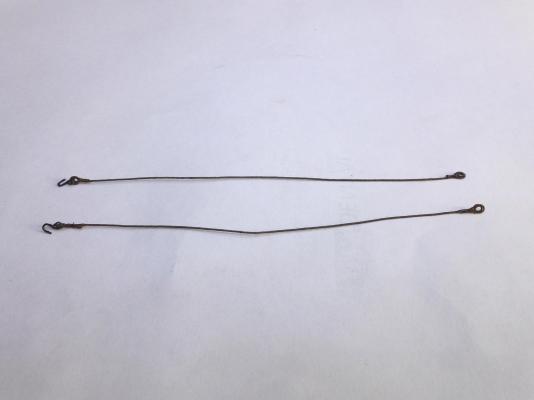

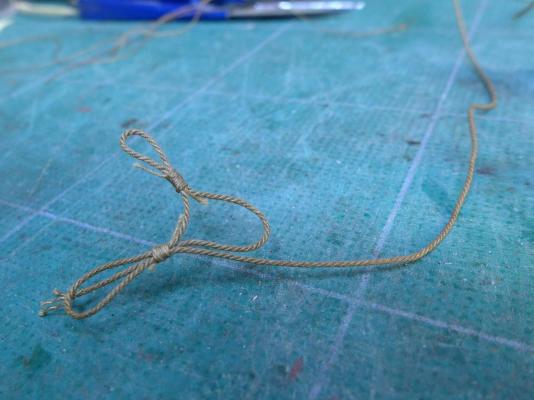

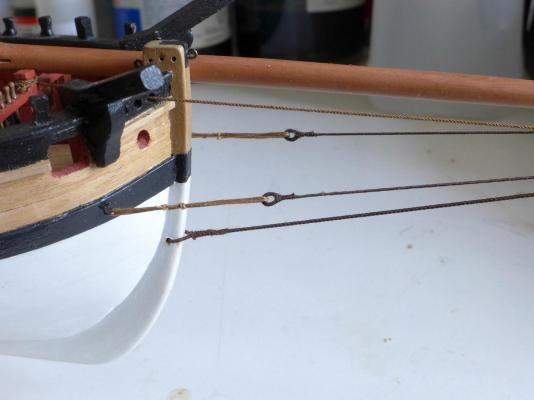

BOWSPRIT Well, as I suggested in my last log entry, I remade the bowsprit in pear as I was so disappointed with my attempts at staining the dowels from the kit. What a lovely wood is pear! This time I decided I’d look at how masts and spars were made, so I bought the low cost paperback facsimile edition from the Cambridge University Press of the first three volumes of Steel’s Elements and Practice of Rigging, Seamanship and Naval Tactics which I have discussed in another post at: http://modelshipworld.com/index.php/topic/9675-difference-between-editions-of-david-steels-books-on-rigging-etc/?p=291358 Using the measurements given by Steel, as well as by Biddlecombe in his 1848 book on the Art of Rigging, I started with square stock (instead of using dowel), used the lathe to cut it to the correct dimensions and completed it by sanding. FINISHED WITH BEESWAX AND TURPENTINE I then used a furniture cream made from beeswax and turpentine to polish it and give it a lovely golden colour. BOWSPRIT HEEL SHEAVE Reading Steel and Biddlecombe led me to a number of questions, such as how to rig the sheave at the heel of the bowsprit, which was discussed at http://modelshipworld.com/index.php/topic/9839-rigging-a-bowsprit-heel-rope-on-cutter-sherbourne-1763/?p=291354 I decided in the end just to make the sheave at the heel, and presume it would only be rigged when pulling out the bowsprit. CRANSE IRON I spent some time figuring out how to make the cranse iron at the tip of the bowsprit. Given the fact that I chose to have a bobstay, I had to make it with 4 hoops. You can see the discussion on bobstays at http://modelshipworld.com/index.php/topic/8646-bobstay-for-bowsprit-on-sherbourne/?p=256873 Initially I thought I’d try to silver solder hoops on to the iron, which I would have made from some brass tubing. However, it was clear that this would be very difficult to do since the heat from the torch would melt solder in hoops already fitted. I therefore decided to go the simple route, mimic the iron with black cartridge paper, drill holes in the iron, and glue hoops made from brass rod into the holes. You can see the sequence in the following photos: JIB TRAVELLER Then came the jib traveller, which was easily made from a brass rod and copper wire, silver soldered together, blackened, painted and covered with matt varnish: SERVING MACHINE Time to provide the blocks, hooks and tackle for the bowsprit. I made my serving machine using some steel rod from an old inkjet printer, some wood I found as scrap and plastic gears which I had to buy. The alligator clips were modified by grinding the teeth down until they were parallel when opened, epoxying wooden blocks into them, and then surfacing the blocks with carborundum paper for grip. As you can see, I used plastic clamps to provide the tension on the thread. The serving machine was also adapted for stropping blocks, but since then I have been stropping blocks just using two alligator clips embedded in a block. All the same, here are the photos: THIMBLES These I decided to make by cutting off 0.8mm thicknesses of thin-walled 1mm brass tube using my modified Proxxon which allowed me to adjust the height in increments. To stop the thimbles flying off into the universe, I first wrapped the tube in sticky tape. You’ll get the idea from the photo: The next stage was to figure out how to wrap the rope round them together with the hook. This was really easy. All I had to do was to make the hook from copper wire, silver solder it whilst the thimble was in, then attach the rope and seize it. THIMBLES FOR TOPSAIL BOWLINES Initially I was puzzled about how to make the thimbles as shown by Petersson for the topsail bowlines, so I posted a question at http://modelshipworld.com/index.php/topic/10181-how-to-make-circular-rope/?p=303151 The replies quickly pointed me to Jay Brent’s (modeller12) video at https://www.youtube.com/watch?v=WUrRb66VSSE which used the idea suggested by Bender at http://modelshipworld.com/index.php/topic/1056-tying-blocks-to-yards-or-masts/?p=17489 I therefore used this method to make the thimbles as follows: MAKING THE BLOCKS You may have noted that I’ve already tried a few ways of making blocks. I don’t think I’ll ever get it right. Nevertheless, I thought I’d try something else, using the same basic method suggested by Frolich which I have mentioned before. I found that using a straightforward pin was a bit difficult as I had to file it down to the correct width. Imagine my happiness at finding that Swann Morton no. 11 scalpel blades were only 0.4mm thick! Since the smallest hole I’m going to make for my blocks is 0.4mm, that’s perfect! All I have to do is provide wood of the appropriate thicknesses for the single, double and triple blocks. I used the tables in zu Mondfeld’s book on Historic Ship Models to determine the size of the blocks by working up from the rope sizes suggested by Steel and Biddlecombe. The following pictures show how I assembled and used the blades that are to score the sides of the blocks: Note that I ground down the very tips of the blades to provide a stronger tip. BOWSPRIT CAP ASSEMBLY I built myself a new motorised vertical ropewalk along the same lines as the Prosak developed by Alexey Domanoff and by Antonyuk (http://modelshipworld.com/index.php/topic/3593-hms-victory-cross-section-by-antony-scale-136/?p=133848), and put all these elements together. It was very satisfying: Next up: re-doing the belaying pins at the bow. Tony

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

Have a look at Dan Vad's blocks, Jack. He does these in the traditional way by hand after cutting lengths on a saw. Saw, scalpels, files, sanding. I am pretty determined to keep practising since it is clear some people can do it! Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

Yes, indeed, Druxey. The feeling was mutual. I really admired their enthusiasm and knowledge, as well as their friendliness. Nick already sent me a reply correcting a previous version of my post about Smokey Joe. I had thought the museum named it, but he told me that it came to them with that name. Further, as they were accompanying me from the museum, they took me round their store to see some of the enormous contemporary models (not of cutters) that they have in storage and then led me to some models they thought highly of in the museum proper -- including two very fine ships made from bone. Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

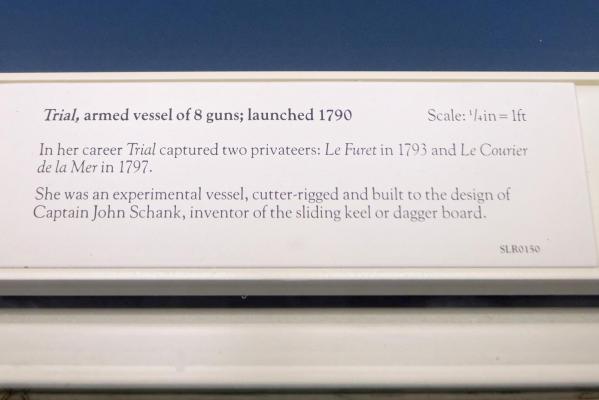

Jack, in addition to the dates provided for the models of the 1763 cutter, the 1777 Hawke and the 1790 Trial, the other two models are also said to be contemporary. The 12-gun cutter, as stated above, is thought to have been made as a model around 1820. Smokey Joe was thought to be around 1820 as well. Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

Cutter; 12 Guns. Object ID SLR0704. The description provided on the NMM web site is: "Scale: probably 1:72. A contemporary (?) plank on frame full hull model of a 12-gun cutter. The fact that the hull is planked in carvel fashion, (edge to edge planking), and that a square topsail is rigged would suggest a date of about 1820. Also the decoration on the stern indicates the name ‘Pelican’ although a cutter of this name cannot be traced either as a man-of-war or a revenue cruiser". The interesting thing here (for me, at least!) is that again the belaying rack at the bow is running fore-aft by the bowsprit. Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

Smokey Joe, Object ID SLR2631 The next one I saw is an unarmed cutter, probably acting as a pilot cutter. Its standard of construction is not as good as the others, but there are interesting details. Its name, Smokey Joe, is thought by the Museum to be fictitious, although very appropriate given the appearance of the model. Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

Trial 1790, Object ID SLR0150Next was a model I had previously seen on display at the NMM in Greenwich. Its name probably refers to the fact that it had an experimental sliding keel. It is really beautifully constructed, but Nick said that it might have had some re-working at the museum. Its original caption at the NMM stated: The other photos really just show the beauty and detail of the construction Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

18th and early 19th Century cutter models

tkay11 replied to tkay11's topic in Nautical/Naval History

Cutter Hawke 1777, NMM Object ID SLR0314 Next of the models I saw is the model referenced by Goodwin in the AOTS book on the cutter Alert. Unfortunately, when the model was taken out Dave Lindridge noticed that someone had damaged the topsail and had put it back in position totally out of place. This is something they will fix, but as the details are so interesting I am still posting the pics for those who have a particular interest in the Alert. As I mentioned previously, this was the only cutter with the topmast aft of the main mast. It is interesting that there are many details quite at variance with the Alert shown by Goodwin. See, for example, the shrouds. Tony- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

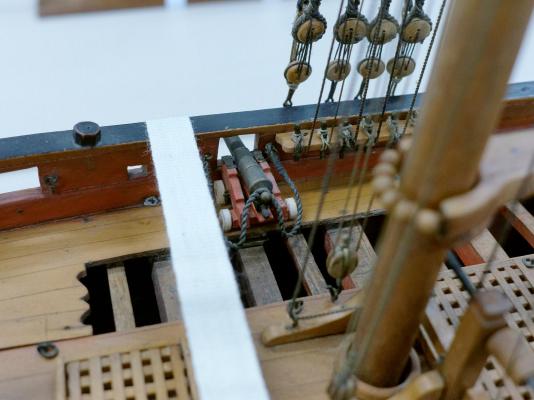

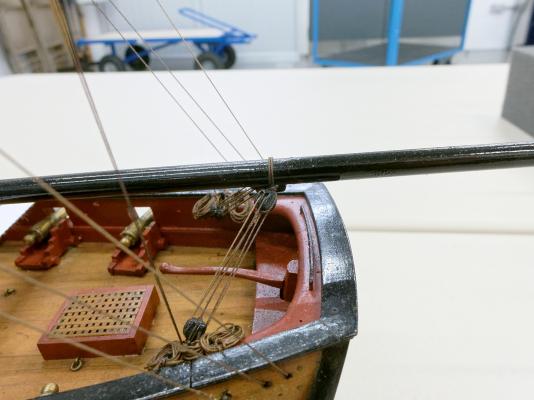

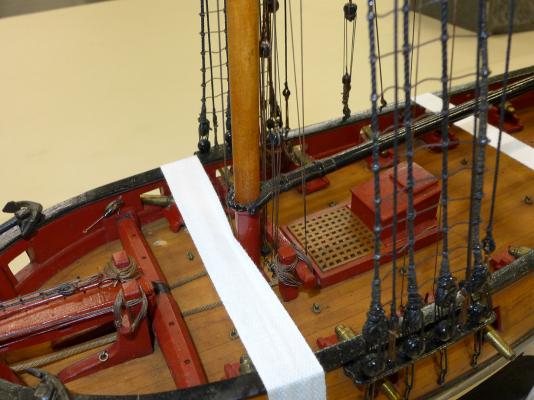

In order for me to understand better the rigging practices for cutters of the 18th Century, I wrote to the National Maritime Museum asking if I could see some of the cutter models they have in storage, now that they no longer have a model display at the Museum in Greenwich. Nick Ball, the Assistant Curator of Ship Models, wrote back very quickly saying that I would be welcome to visit and could see all of the models I had requested which are now stored at the Royal Historic Dockyard in Chatham -- except for one which was stored in another location less accessible to the occasional visitor. He, together with Dave Lindridge the Store Manager, gave me a very generous amount of time to look at and photograph the models that they had taken out for inspection – during which they provided a lively discussion about their jobs and the models they were showing. In fact Nick said he was pleased to show visitors the models because it gave him more of an opportunity to review models in their vast collection. I asked Nick about permission to post my pictures and he told me it was fine as long as I made it clear the pictures were from the NMM collection. He also asked to be provided to the links of the photos as he himself (as a trained naval archaeologist) was very keen on the details and would enjoy any discussion that ensued. I will post the photos of the individual models under different messages, this post deals only with the first of the models. I just need to add that I am enormously grateful to Nick and Dave for their patience and generosity with their time for this visit, which for me was invaluable. 1763 cutter NMM ID SLR0510 First off is their cutter referenced in the NMM as Object ID SLR0510. It is described there as “a full hull model of a cutter (circa 1763) Scale: 1:48. The vessel measures 53 feet on the main deck by 20 feet in the beam and is armed with twelve 3-pounders. The model was donated unfinished and was completed in the Museum in 1960”. For me there were four main points of interest, apart from the fact that it is dated the same year as my Sherbourne. The first is that the fore belaying pins are arranged fore-aft beside the bowsprit. Gregor, Dirk, Kester and I have been trying to figure out how the belaying pins would be set given that the kit of the Sherbourne provides no plans for such a belaying rack. Each of us have provided our own particular possibility – with Dirk going for an arrangement such as that on the AOTS book of the Alert, and Gregor going for a rack right on the stem. I had made a rack that was parallel to the windlass. However, now I have seen the arrangement on the NMM cutter SLR0510, and, as you will see, the 12-gun cutter I saw had the same arrangement, I have changed my own rack accordingly. The second is that the topmast is fore of the main mast. I had understood that earlier in the century the practice was to place the topmast aft of the main mast. In fact the cutter Hawke (which I also saw at Chatham and whose pictures follow in a subsequent post) was the only one of these models to place the topmast aft of the main mast. The third point of interest was the windlass. The original NMM plans for the Sherbourne showed this type of windlass, and Gregor has already made one in the same style, and I followed his example – rather than following the type of windlass provided for in the Sherbourne kit. The fourth point of interest is that, like the Trial that you'll see in a subsequent post, the lower hull is painted up to the wales, and not to a waterline. The following were the other pictures I took of the1763 cutter, all of which will have details which will be picked up by those more knowledgeable than I am! Tony

- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

-

Thanks for letting me know about your experience of blackening, Clare. I had a chuckle of sympathy when you described how you began to feel more confident once you started up again. I have the same experience with each new step of the model. At first I believe I simply can't do it. Then I start thinking how I might do it. Then I experiment and find I can do an approximation of what I'm attempting. Then with a bit more practice I find it actually looks ok. Then I start worrying about the next step and start all over again! Tony

-

Perhaps of more general use would be a razor saw and mitre box set, of the type you can see at Cornwall Model Boats. I have never used one of the square cutters, so can't comment on how good they are. Maybe others will chip in. Tony

- 29 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

Nice idea, Wefalck. The prices for the cotton-covered wire are not bad either. Tony

-

There are quite a few modellers who have gone for a weathered look. You could search for 'weathering' in the forums. One I have been following recently is Riverboat's work on the Krick kit of the Alert. You can find it at http://modelshipworld.com/index.php/topic/6400-alert-by-riverboat-krick-125th-scale/?p=186050. Most of the weathering is in the later pages. Railway modellers seem to be very big enthusiasts for weathering, and their supply shops are full of special paints and techniques to do that. Tony

- 18 replies

-

- gjoa

- constructo

-

(and 1 more)

Tagged with:

-

Thanks, Lextin. That's very similar to Modeller12's and the one I'll use as it allows for snug fits as well. Tony

-

If you are thinking of getting into scratch building, you might want to look at building 'La Jacinthe', a French schooner of 1823. The monograph produced by Ancre is excellent, as are the plans and instructions that go with it. It is POB, but you can go as detailed as you like and several modellers have made it plank on frame. Because of the combination of instructions on building, list of the materials necessary and the excellence and details of the plans, it lends itself to a first time scratch builder. The author claims he gave the monograph to a 15 year old boy who was able to make it himself -- albeit with a little help from the author. The book is available in English as well as in French. If you speak French, there are also lots of builds that are beautiful on the French model ship fora. You can also see several stages of a POF build of La Jacinthe by Frolich in his book 'Art of Ship Modelling' which you can also find from Ancre books in France. You can see details of the monograph at http://ancre.fr/en/monographies-en/52-monographie-de-la-jacinthe-goelette-1823.html. There is also a very nice model of 'La Chaloupe Armee' which is very much simpler but has a very different method of construction, which you can also find through Ancre at http://ancre.fr/en/monographies-en/31-monographie-de-la-chaloupe-armee-en-guerre-1834.html. As these come from France, you have no import duties at all and all the references to lengths are in metric. An additional perk is that the Euro is extremely low against the pound, so these monographs and plans come in at a very reasonable price. I myself have bought the monograph and plans for 'Le Rochefort' -- which is a POF build. Otherwise, as has been said, there are plenty of lovely builds you can follow on this forum, including the cross section builds of Triton and Echo -- both of which are also great ways of learning about POF building. (Not that I know anything at all about building from plans or POF since I am only on my first model build). Tony

-

Nice points, Robin, and sorry if this is detracting from Chuck's log, but could someone let me know, or give an illustration of, how the mast would be placed when 'cockbiild'? This is purely my ignorance, so I apologise again. Tony

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks! I was just checking, Chuck, because I am slightly confused about when shrouds are served and when not in the building of the Sherbourne. Is it the case that the foremost shrouds are fully served whilst the others are only partly served? Or are they all fully served? And backstays? I agree about the 3D modelling being not only very interesting but helpful too. Tony

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Are the foremost mast shrouds served in either the 3D version or the model to come? Tony

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, John. Just like Modeller12's your site is something I had marked previously but had forgotten about. Thanks very much for bringing it to my attention again. The site is really great. Tony

-

Aaaah! Thanks, CaptainSteve. That's exactly what I wanted! He's been really helpful on a whole host of questions but I didn't know him as Jay Brent. Tony

-

Thanks, Pieter. It's a great video. Funny enough I already had a link to Bender's original post but had totally forgotten about it (I had been looking at stropping blocks when making the cannon a year ago). It's at http://modelshipworld.com/index.php?/topic/1056-tying-blocks-to-yards-or-masts/#entry17489. I was looking for J Brent's excellent videos on this forum, as I remember he posted several of this type, but I can't remember his forum name. Tony

-

Don't worry, you're doing fine. The gun carriages from the kit are indeed a problem. The brass wire that goes across the carriage serves two purposes: one is to strenthen the carriage, the other is (if it were true to scale) to hold the bed for the quoin. Unfortunately the kit carriages are not built to scale and don't really resemble the real construction of a gun carriage. You can get the plans for a 3-pounder on this site in the 'Ship Modeling Database of Articles' in the section on 'Armaments' at http://modelshipworldforum.com/ship-model-armaments-and-cannon.php. That will show you how the quoin should fit in reality. If you are finding that your quoin won't fit, then you can file it down or make a new one. I eventually discarded the kit carriages and guns and made my own. Tony

- 23 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks a lot, Dziadeczek, Henry and Druxey. All great comments and ideas. I'll start practising today. Tony

-

Ha! Having posted the question, I came across a couple of suggestions in Longridge's book on the Anatomy of Nelson's Ships. On page 217 he suggests two methods. The first is to wind fine thread three or four times round a dowel and then use a needle slipped between the dowel and the thread to serve the thread. The second is to make hoops of fine copper wire, silver-soldered, and serve the thread round the hoops. All the same, should any one come up with other suggestions, I'd be very interested. Tony

-

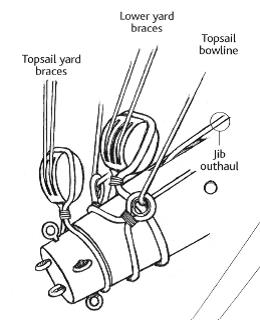

I am at the stage of putting blocks on the bowsprit of my Sherbourne cutter (1763) to hold the various bowlines and yard braces. Going by Petersson's book on rigging fore and aft craft, as well as by the AOTS book on the cutter Alert, the strops require a rope to go round the block and the bowsprit and the middle section of the rope is spliced together and tied between the bowsprit and the block. The following diagram from Petersson's book shows what I mean: I've had a quick search through the forums and can't find a reference to how to make rope for such a purpose. I can't recall any discussion about it either. So my question is how to make the circular rope? I have thought of butting the ends of a rope together and stitching or gluing, but that seems very likely to produce visible joins. I'd be grateful for any suggestions as to how to go about this. Thanks Tony

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.