-

Posts

1,218 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Overworked724

-

-

Still plodding along. Taking my time on the deck due to work conflicts but making steady progress. Thinking ahead to the haws holes and prepping the rudder pintles and gudgeons before I jump into coppering.

Also thinking into how I want to make the carronade blocks which hold up the carronade. Those little laser cut pieces are not homogeneous...I think I can do better.

-

22 hours ago, Justin P. said:

I think Im getting a bit saturated on this build and need a break. Not from modeling, but perhaps from the type of modeling demanded by Syren.

Totally agree with you on this one. My job has been pulling me in multiple directions lately, and the time commitment to 'get things done' on my Syren has been a bit of a challenge. Kind of hard to start-stop-start in spurts and sputters. I actually was looking at starting a side project as well to give my confidence a bit of a well needed boost! Take a break and enjoy your hobby!

-

-

4 hours ago, WalrusGuy said:

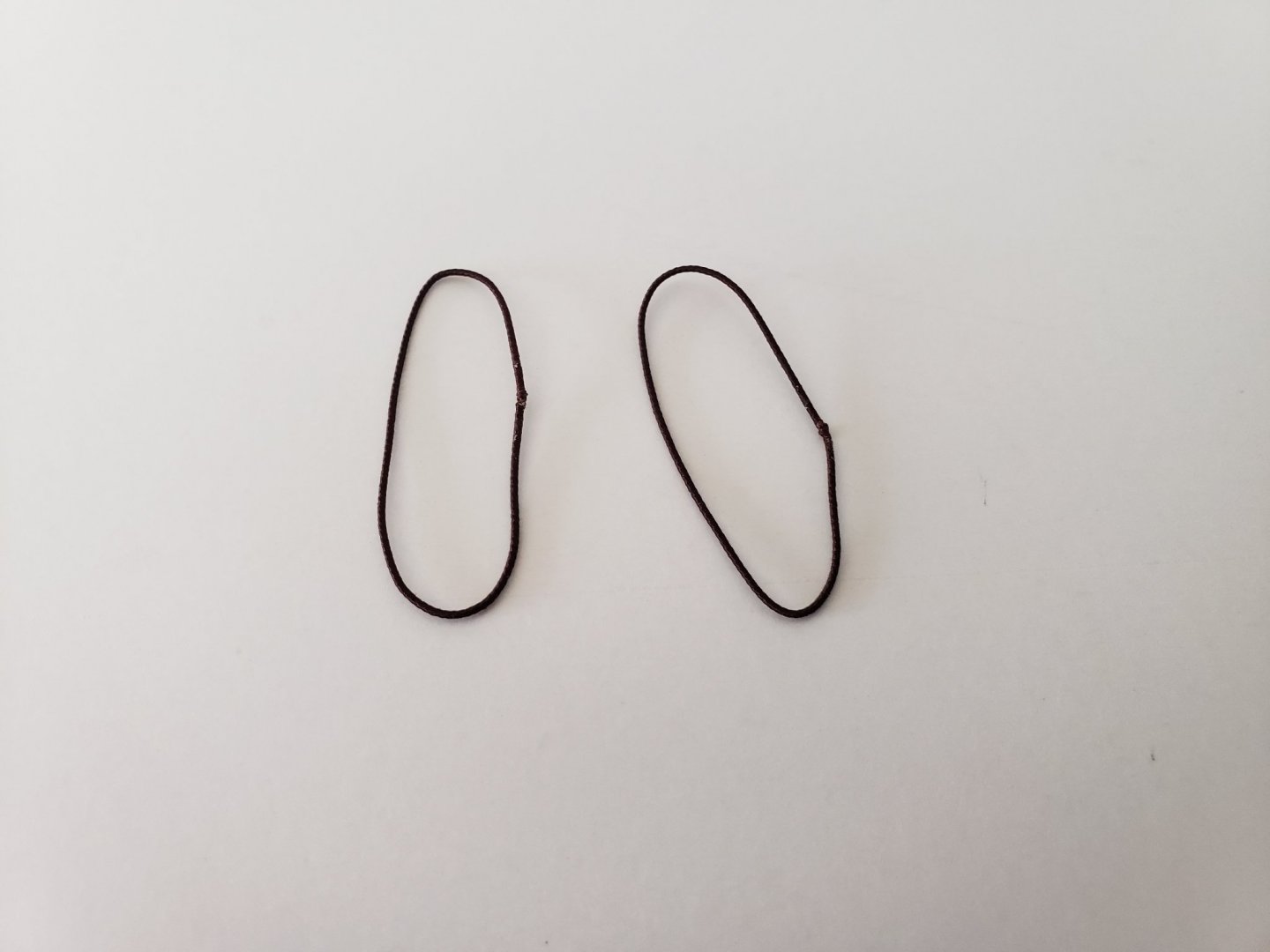

Great tutorial and stellar work. But I’m not certain exactly what you mean at this point. Having a hard time visual what you were doing after you formed these closed served hoops. -

-

Well....that’s the problem. I joggled 3 planks on either side a bit and I was doing pretty good, but my margin plank was glued in. Lesson learned. It was at joggle #4 that I noticed the spacing on either side was off. I think when I glued in my margin I had created a slight shift in alignment. If the margin isn’t symmetrical on both sides, the joggling is asymmetrical...something I was NOT really aware of. Again, some good experience and useful for next build.

Honestly, I could rip it all off and start over, but I’m so close to done, I’m curious to know what it will turn out like. 😊

-

-

-

-

32 minutes ago, Redshadowrider said:

Question @Overworked724 I have been trying to find a source for the .009 cutting discs shown in your log. So far it seems that I can only get them from Dedeco. I tried Amazon and they require a business account and a healthcare license. Can you tell me where you got yours?

I got them direct from Dodeco.

-

-

-

-

-

If you microwave the piece while it’s bent across a former (I used a wood block) it holds its shape really well.

-

-

Yep. Snapped a bunch. I ended up scaling down width as well. Made it easier.

-

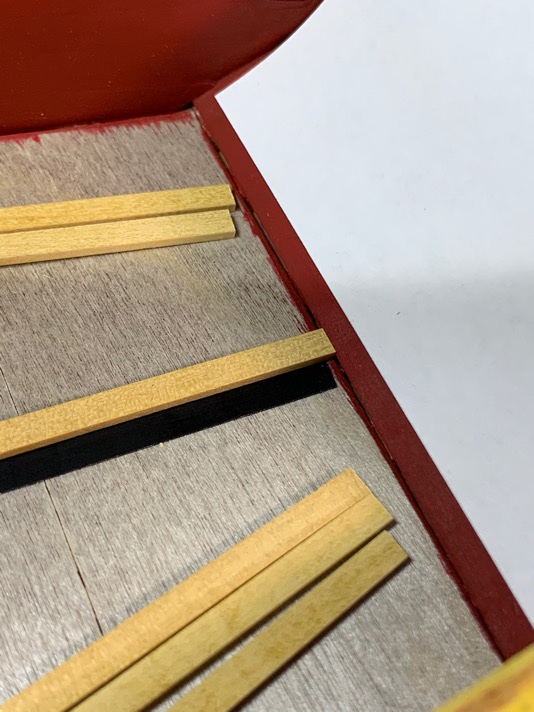

Took a break from work to put in the remaining sections of the margin plank. Was all excited...until I measured the remaining planking widths at the various frames...and of course, the starboard side measures slightly narrower (about 1mm) across the main section of the ship. I’ve been measuring constantly, and it’s fine at the extremes (stern and bow frames), so not entirely certain where the discrepancy lies. Probably when gluing the margin in there was some ‘minor give’ (straightness) in the plank which I removed by pressing into the bulkhead curvature.

Live and learn!!!

-

14 minutes ago, CPDDET said:

Could cherry or mahogany work? Both are easy to work with and readily available.

I do have some cherry...but thought that color contrast would be no different than using the Swiss Pear. Maybe it’s worth cutting strips for the pear and cherry to compare to the two types of boxwood. 👍🏽 -

5 hours ago, Justin P. said:

Maybe it won't be so dramatic when you've got more of it complete? What will you use for the waterways? That would be an opportunity for a third color - worth considering.

Not a bad idea but my options are limited. Pear wood be too stark a contrast and I refuse to use basswood. So at the moment I am planning to use the same wood as the margins but will go ahead and cut some strips from English boxwood to compare. -

The one thing that bothers me is the margin plank and the planks themselves are considerably different in tone. The castello boxwood the margins are made of is slightly beige where the planks are cut from English boxwood which is more yellow. I hope the color difference doesn't stand out too much...regardless...will continue to press on...

-

-

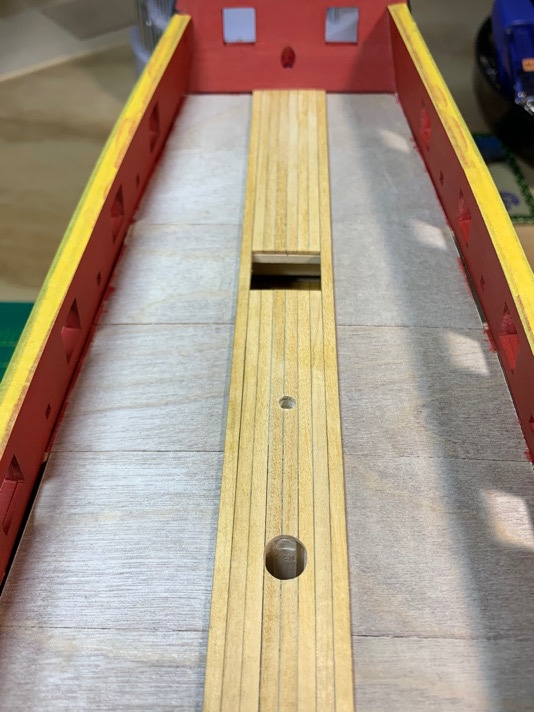

Plodding along. Decided to stop overthinking and used some vinyl striping tape to nail down the center line. The thickness of the tape makes a good backboard which you can use to set in the initial center plank.

You can see below that I gave myself a bit of a gap (~ 1/64”) above the faux deck at the transom. Makes for a clean seam when setting down the planks at the stern.

Made sure I carved out my two mounting holes (which will at some point be hid by gratings) and the two mast holes. Better to do it now rather than later. 👍🏽

Moving on....slowly!!

- John Cheevers, WalrusGuy, davec and 5 others

-

8

8

-

On 12/31/2020 at 4:54 PM, Bill Gormley said:

1 - Should I address this or will it not really show up under a coat of paint? If it should be fixed first ... wood shim or better to use filler? Wood shim might be more supportive and you can sand it down.

2 - Are the sills supposed to be sanded to the same thickness as the frame? What I'm showing here is my sills are a little bit wider. I think the practicum addresses this. The lower part of the frames can be a bit wider.

3 - It's hard to see in the photo, but this is a shallow divot where I wasn't careful with my sanding stick. Should I fill and restore this divot (and others like it)? Not sure whether it will cause trouble later on when it comes time to plank the deck. Uniformity and symmetry are important. If there is a gap in the deck the planks will not lay true. I'd fill it with a shim or filler and ensure there is continuity between the frames...otherwise you will have a dip

4 - What do you use to get nice straight cuts? I have been using a razor saw which cuts the wood easily enough ... but is there some basic technique or trick to get a straight cut? A chop saw or table saw...something automated rather than manual.

5 - I'm about ready to paint the gun ports red and I was planning to use either Tamiya or Life Color paint from my plastic modeling stash. Do I need to prepare or seal the wood first? I used Tamiya paints without issue. But I am woefully horrible at painting. I'd research this and come up with your best solution and ensure you are conformatble with it before throwing it on the ship...see my blog and the recent screw up I needed to address with regards to painting the bulkheads....

Thanks for reading this far ... all input and feedback welcome!

Bill

Hope this helps, Bill. Happy New Year!!!

- Ryland Craze, CiscoH, WalrusGuy and 1 other

-

4

4

US Brig Syren by Redshadowrider - Model Shipways - Scale 1:64 - First wooden ship build

in - Kit build logs for subjects built from 1801 - 1850

Posted

Those trim pieces turned out very nice, Red! Hope the scraper was easy to make.