-

Posts

1,253 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Overworked724

-

-

-

Those kit dead eyes look great!

-

2 hours ago, niwotwill said:

Very nice Patrick. If I take mine off will you make me some? HA HA HA

Regards

Will

Not so fast!! The jury is still out on whether these are going to look good mounted…much less work as I hope!

Fingers crossed!!

-

11 minutes ago, CPDDET said:

Thank YOU, for sharing your techniques. You're a huge help / mentor to us newbies.

LOL! Dave, even on your bad days, I think your work far outshines mine! But I’m glad you can find some new ideas in my build log!!

- Ryland Craze and CPDDET

-

1

1

-

1

1

-

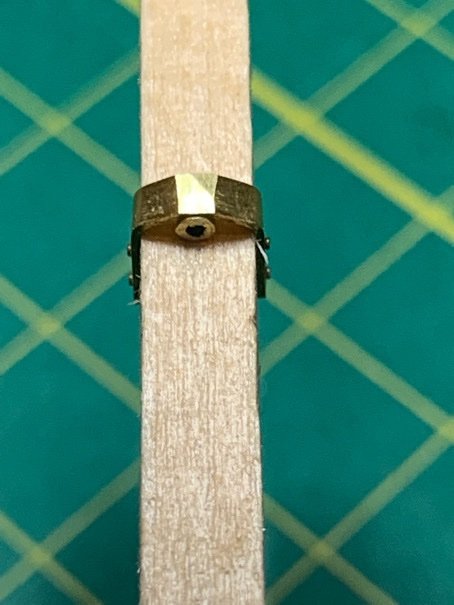

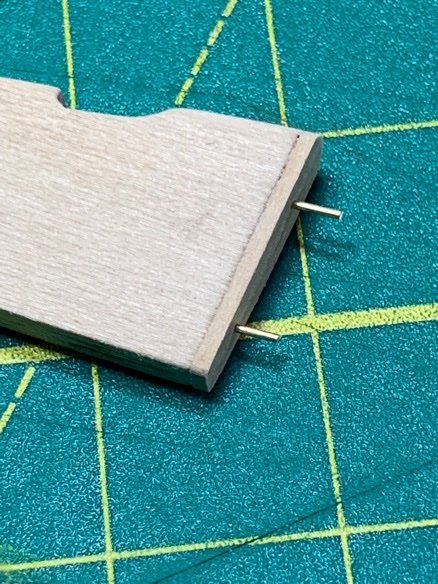

It occurred to me when trying the P&Gs on scrap basswood piece (same width as sternpost) that the width of the brass strap needs to be considered when the pintle and corresponding gudgeons are aligned (i.e. opposite direction of each other). So I decided to sand off a bit of the brass at the ‘peak’ where the hollow brass tubing sits.

Also tried the small brass nails to lock it in place…and that sucker does not move!!

Moving on…

- Gahm, CPDDET, Ryland Craze and 1 other

-

4

4

-

Dear @CPDDET Dave,

Thanks again for the kind words. You and the other shipmates kudos always keeps wind in my sails!

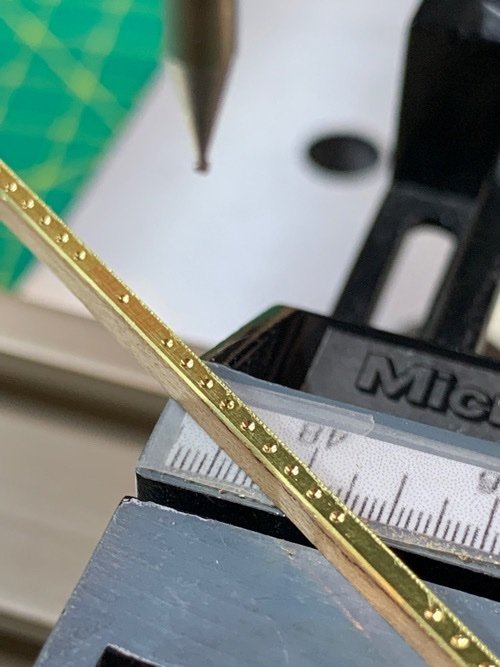

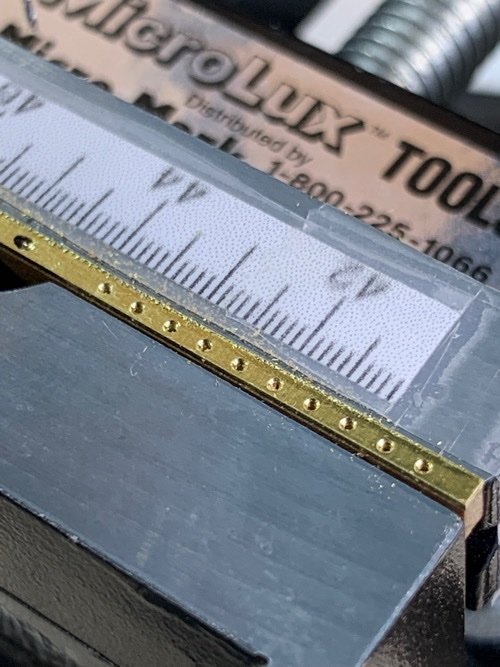

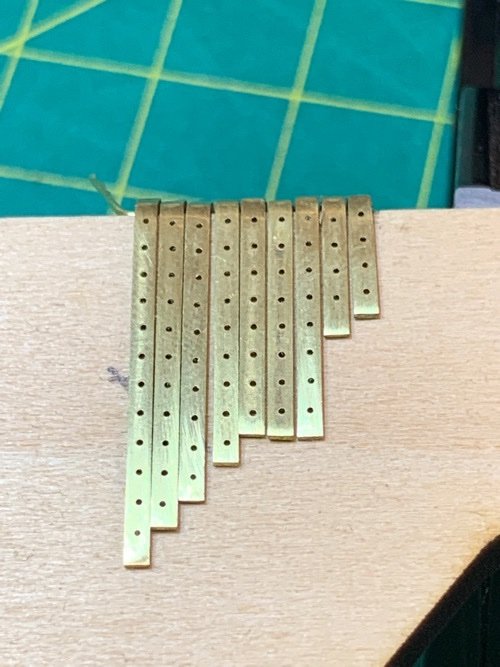

Ok. My technique for nail holes in my P&Gs is as follows. It might sound stupid…but it works! A mini drill press equipped with an x-y table are sort of mandatory for this to work.

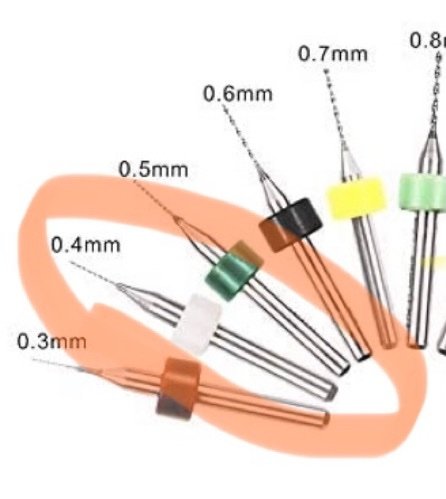

My initial trials with a #78 drill bit(s) met with disaster. I broke two before I went to the high precision PCB bits (0.4mm) and broke two of those little buggers. 🤬

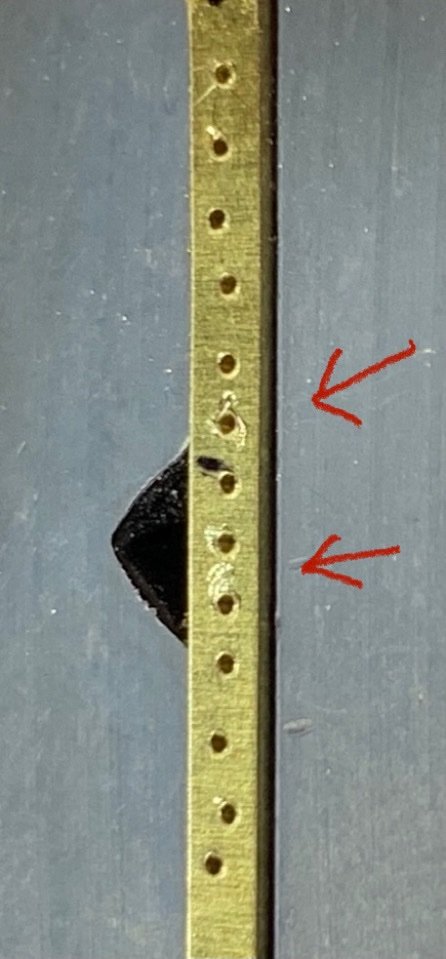

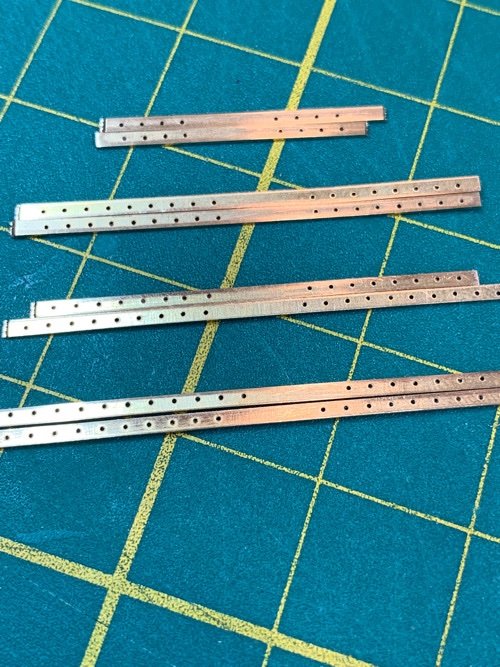

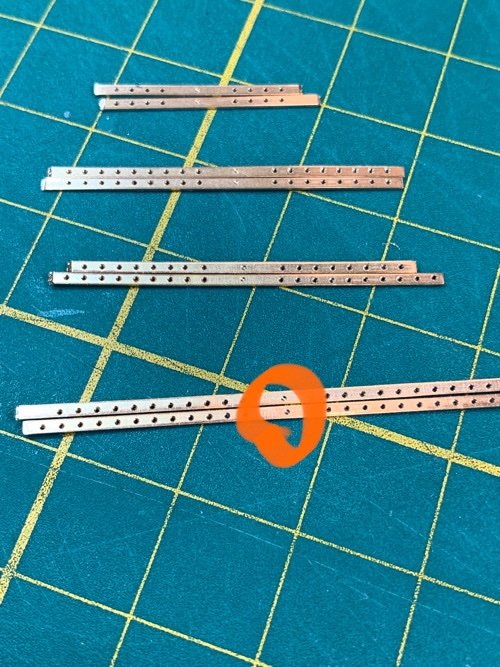

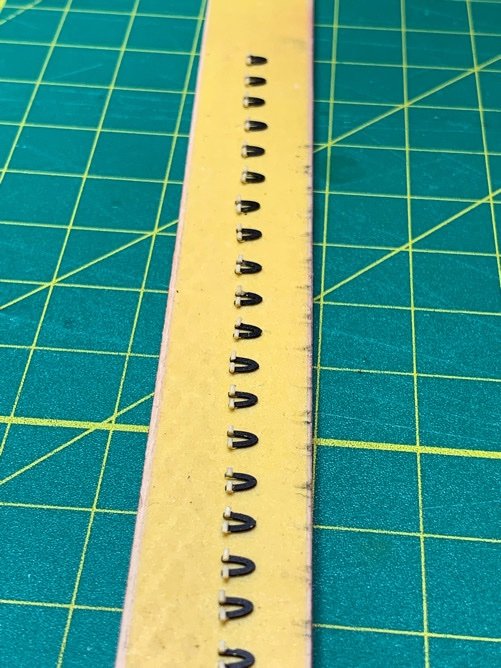

The pics below shows one of my strip attempts. You can see where the drill bit was drifting (red arrows) as it scored the brass. The bits invariably snapped. I was beginning to doubt my choice of 0.3mm brass nails! Those bloody things are tiny.

AND BEFORE ANYONE ASKS…YES, I HEATED UP THE BRASS!! I don’t believe it was annealed, as it was pretty soft. But the nail pattern looks like a drunk Irishman heading home on Saturday morning (said the drunk Irishman typing in a ship log).

Hard to believe that was done with an x-y table. That’s how much the tiny bits drift before they gain purchase. 😣

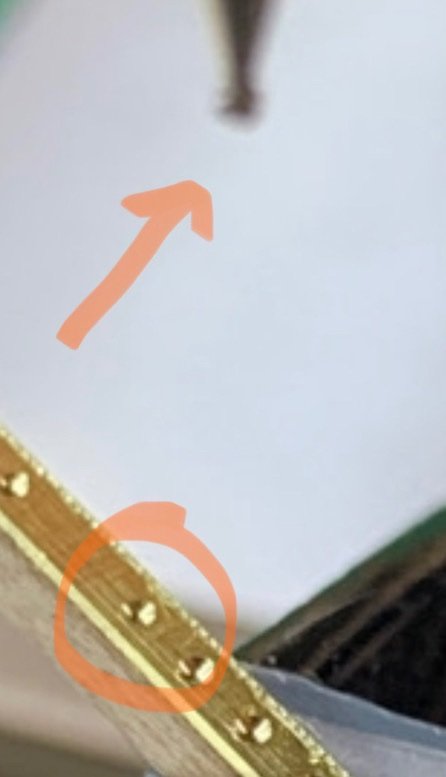

I figured giving the drill bit a cup or starter point would work. Using a hammer and awl just deformed the brass strip. So I opted for using an engraving cutter. It worked beautifully. I just pressed it lightly into the strip of brass and it made a prefect little divot.

Dremel 105 Engraving Cutter, 1/8" Shank , Gray https://www.amazon.com/dp/B00008Z9ZT/ref=cm_sw_r_cp_api_glt_fabc_AT62H13H1PW0ZN5DRMA5

After that, I just repeated the drill pattern using a tungsten high precision drill bit 0.4mm. Both the drill bits and Dremel engraving cutter are really cheap (yes…Amazon).

The results speak for themselves.

So…that’s my workaround. After I adopted this method, I cranked through the drilling portion in 45 min using one drill bit. No trouble.

-

43 minutes ago, CPDDET said:

Beautiful work, Pat!

I would be very greatfull for a photo or link to the "round head drill bit" you refered to. Keeping wire size bits from straying has been an issue for me. Sounds like you have a good solution.

I snapped about 4 drill bits before I arrived at this solution and it worked like a charm. I’ll add a separate post with more info, Dave. -

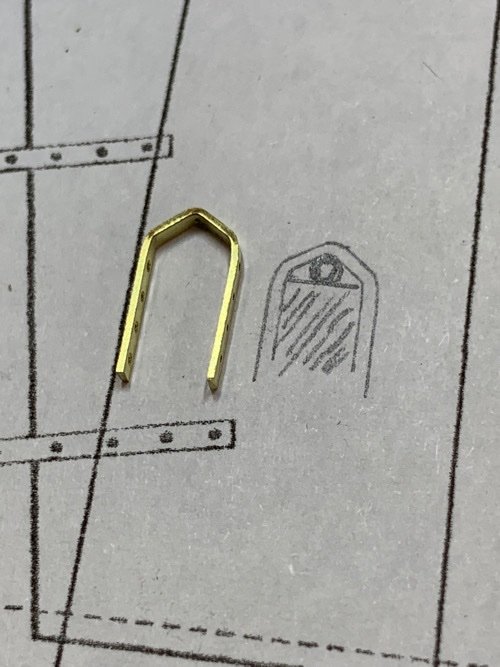

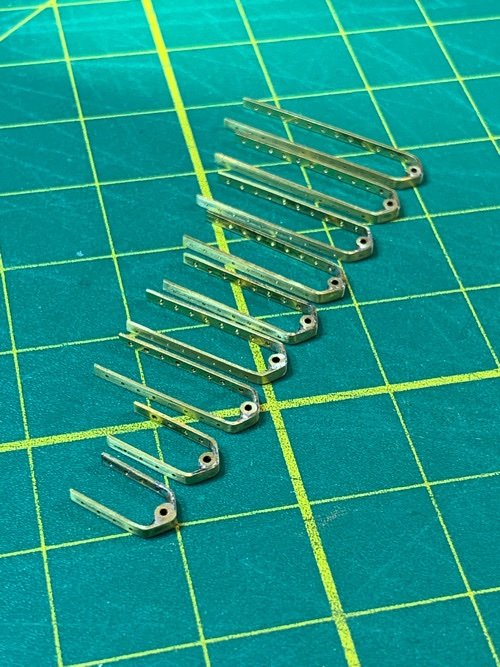

The one area which invariably ends up making or breaking the exterior view of a ship model is the Pintles and Gudgeons. These are really tricky for me, as few folks really break down the making, and installing of these things.

So…been noodling and researching for a while…and experimenting quite a bit. For my Sultana, I ended up using paper because I couldn’t work with metal. This time I wanted to really give it the ol’ college try to get a good result using brass.

So…here is where I’m at so far. Long post coming:

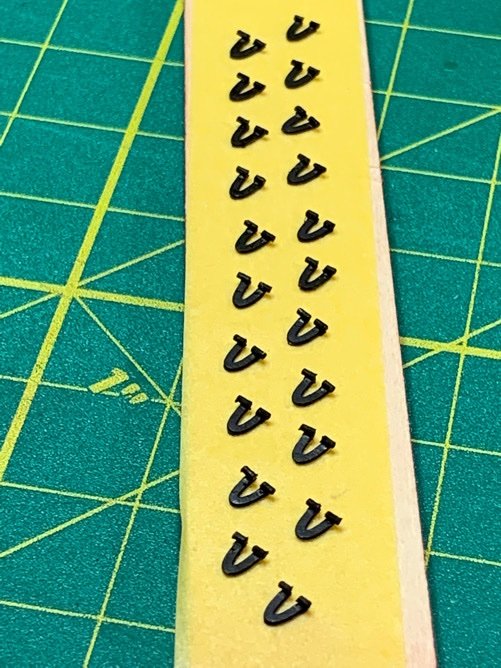

1. Recut my P&G’s thinner to more closely match the plans. I used my original brass sheet/cherry wood sandwich.

2. Separated one wooden side from all strips.

3. After cleaning off the spray glue from the exposed metal side with acetone (nail polish remover), I used a round head drill bit (wood carving Dremel bit) to score in a ‘divot’. This keeps the tiny drill bit from floating when I drilled the actual nail holes. Nothing worse than uneven nail holes!

4. Then I drilled the actual holes.

5. Then I separated the other half of the wood from the brass piece, cleaned it up, and cut it up into rough sections.

The interior sides have the larger nail score mark and a center mark I put in to ensure my bending was consistent at the center.

6. I decided for a triangular bend rather than a rounded one. It ensured I had centered the brass rod in each P&G. I used a wire bender…no jig. I eyeballed it…because I simply could not figure out how to make a good bending jig!!!!

7. Soldered in the brass tubing, cut, and polished up the P&Gs. I made a bunch of various sizes. I can trim and adjust as needed during fitting.

Placed them on a fake stern piece to ensure the general fit and alignment. I was pretty happy with the center alignment and width. Fit was nice and clean…no gaps.

Still have a long way to go, but these are the first metal P&Gs I ever made…and I’m pretty happy with them so far.

Moving on.

-

1 hour ago, abelson said:

Excellent, detailed roof! You have a lot of patience - a ship builders virtue.

Thanks, Abe! Your build continues to inspire me as well. 👍🏽 -

9 hours ago, niwotwill said:

How's the shoulder doing?

Doing better! It’s a journey, but I’ve been religious with my exercises and physical therapy. 👍🏽 -

1 hour ago, CPDDET said:

My "I need this yesterday" attitude hasn't helped either. But who can argue with almost instant gratification.

And with ship model building, there is always a persistent feeling of being rushed!!! 🤣On a more serious note. Had to restart my pintles and gudgeons. Realized my original cuts were too thick.

My goal is to ‘prefit’ my P&G’s so that my rudder is functional as well as removable. But I don’t want to mess with fitting 4 sets of these buggers after coppering the hull. I know I’d start scarring the copper and the illusion would be lost. My goal is to remove one area of anxiety and focus on coppering…then have my P&G’s sitting in the wings waiting for install.

…he said no so confidently.

-

Wow. Didn’t think my Amazon ball bearing purchase would destroy Model-expo! 🤣

Well…two things…Model Expo doesn’t sell 2mm ball bearings I need. But if I need to go down in size…they do sell 1.5mm balls but at like twice the cost.

But I do agree Amazon has done a fantastic job killing local manufacturing and business interests.

-

9 hours ago, niwotwill said:

You might check with Model Shipways that multiple size cannon balls.

Good suggestion, Will. But I found some cheap 2mm diameter bearings on Amazon cheap. 👍🏽 Arrive tomorrow. -

Meandering thought led me to a quick realization…the cannon balls for my replacement carronades are way too small…by amount 1mm. I did a bore measurement of the carronades and it’s just shy over 2mm. So, I need to replace the kit beads (~1mm) with correctly sized bearings.

Amazon to the rescue.

-

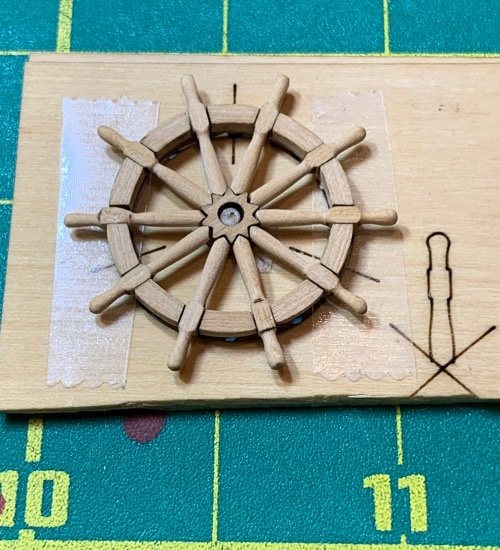

Small detour to bash the other metal pieces. Ship’s wheel was certainly not something I planned on using from the kit.

I opted for one of the boxwood ship wheel kits made by Chuck’s company (Syren). I got the 15/16” boxwood ship wheel pack which was actually a lot of fun to put together. It also had a lot of extra parts in case I screwed up!

Here are a few pics…

Template worked great to manage the little bits.

My rotary tool made the creation of the wheel spokes a fairly quick job.

And a quick coat of Golden Oak on the final product made it obvious why I went with a wood wheel. 😁 Wouldn't even know how to make the metal piece look realistic!!

Moving on…

-

-

The sweep doors are done. Not certain if the hinges look ok or not…seem to be passable. I painted the interior side red and stained after the pics below were taken.

I’ll glue them in once the coppering is done. That’s next on the agenda..,once I finally figure out my pintles and gudgeons.

Here are a couple pics. Interested in feedback if anyone has any.

Moving on…

-

-

Ok. Not sure how everyone else did their sweep port doors, but I’m approaching this like the galleries. I’ll get them set for gluing on then put them off to the side until later.

I sanded them flush so they aren’t proud of the side of the ship. I’ve decided I’ll put a single coat of ship’s bulkhead red on the interior sides. Then I’ll pencil the edges, glue on the hinges, test fit…then set them off to the side until I’m ready to glue them in…which will take only a few minutes.

Im a bit afraid of snapping off the little hinges or worse…and once those things are in they aren’t coming out.

🤔

- CPDDET and Ryland Craze

-

2

2

-

Got the sweep port doors made for both sides. Took a while as some of the openings were more trapezoidal than rectangular! 😖

Unstained, they do pop out.

I checked the fit/look of the hinges on one of the doors. I’m satisfied that I can align the hinges cleanly.

I also tried using a simple red sharpie to ‘color’ the shipboard side. Since the sweep ports are so small, you can’t really see any details for the sweep port doors. So I figured a quick slap with a red sharpie would be fine.

Moving on…

- GrandpaPhil, Ryland Craze and ccoyle

-

3

3

-

Ken, every model has warts. Kind of like houses. My Syren does not follow the typical symmetrical butt shift pattern, because I butted the sections at the points where a frame was located. Actual ship framing would make this job fairly simple. So, my Syren is not ‘historically accurate’.

Just saying…no model is perfect. 😁 But I love doing stuff in my shiproom…the hobby is filled with great people/historians/shipwrights which make this a great forum.

Enjoy the day!!! I think your perseverance is inspiring. 👍🏽 I continue to watch your build with great interest and I am learning from your challenges as well. 🦃🍁🍽

-

The little wooden hinges for the sweep port doors actually turned out looking ok. They weren’t that hard to put them on, just finicky work.

We’ll see if I can do justice to making the doors. 🙏🏻

Moving on….

- CPDDET, GrandpaPhil and Ryland Craze

-

2

2

-

1

1

-

Ken, we all run into these types of setbacks. Pics help (and embarrassing as it might seem…my screw ups brought a lot of brilliant feedback from experienced modelers). Don’t be afraid to post them. This forum’s value really comes from the helpful feedback.

Gun port doors closed is one way to fix the cosmetics. Remember, it’s your model, and as long as your learning and having fun (marathon…not sprint) then that’s all that counts.

👍🏽

-

Great way to plan those plates, Dave!

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

in - Kit build logs for subjects built from 1801 - 1850

Posted · Edited by Overworked724

In truth…I’m posting my little successes on the easy stuff as I build up my courage to attack the copper plating.

I’m chicken. 😖