-

Posts

1,258 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Overworked724

-

Hi folks. Since work will take a bit of a front seat at this time...I will take a short 4 week sabbatical from the Sultana as I am caught in some excessive project activity which also requires some travel. Nice thing is that now I am in the position to work ‘off the ship’ a bit as I prepare the spars/masts/gaffs/booms/etc. So will reconnect with my log again soon. My goal is to finish by no later than end of April of this year — which I think is very achievable. Happy Modeling to all!!!

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Thanks so much, guys. Very kind support. But in truth, I am still just finishing the body of the ship....I have not started on the rigging....I hope I make a decent job of it!

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

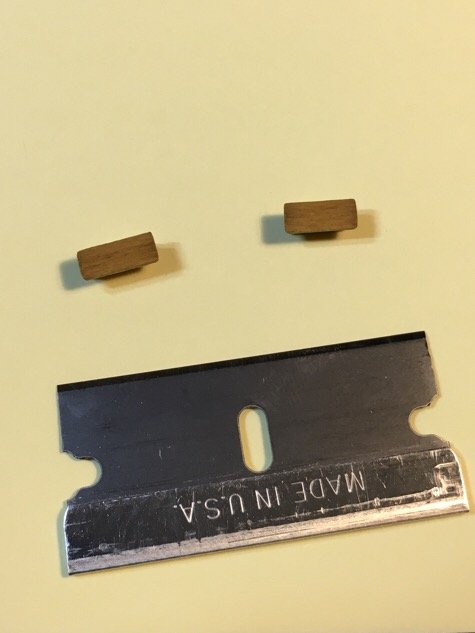

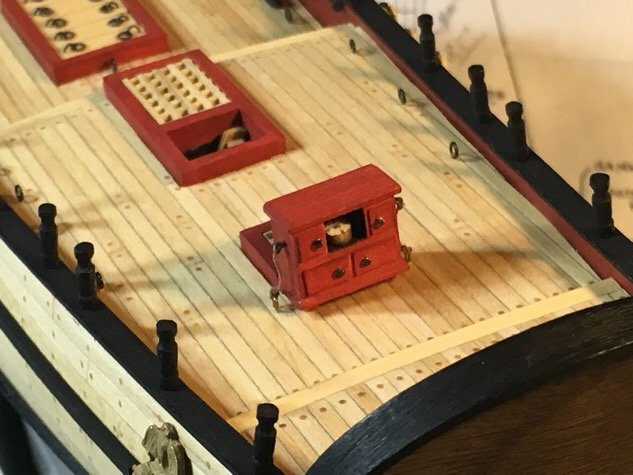

Some slight progress. Got poop rails on and the overall effect is certainly better than I’d hoped. The stanchions made from the toothpicks added a nice ‘splash’!! Attached tiller and pumps. (Running out of furniture...soon I’ll have to start working on the masts!) Luckily, I was able to justifiably procrastinate by building my last bit of furniture...the two steps on port and starboard which lead from the main deck to the quarter deck. I know Chuck’s awesome practicum shows an actual single step ladder, but after a few attempts I was certain the things were going to come out sub-par. So...opted for a less challenging option. I was thinking if I HAD to put a step there, I’d rather put a milk carton! So I thought, why not simply put a small step on a block. So I did....then stained them and glued in place. Not too shabby of a result for a cheapie sidestep. Moving on...

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Awesome progress! Watching this log with interest. Great job so far! (Love the eagle!)

- 74 replies

-

- Marine Model Company

- Joe Lane

-

(and 2 more)

Tagged with:

-

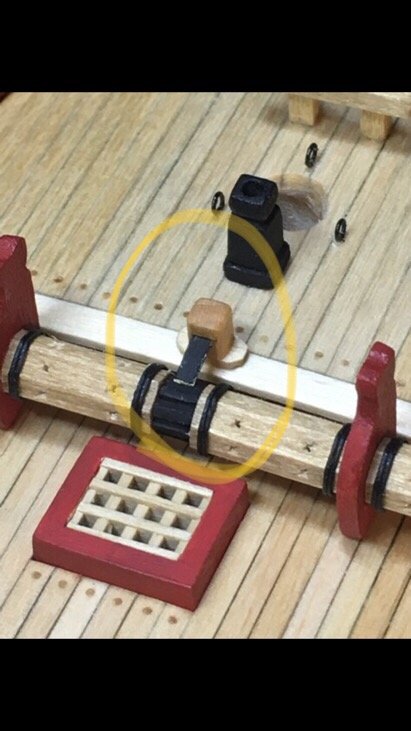

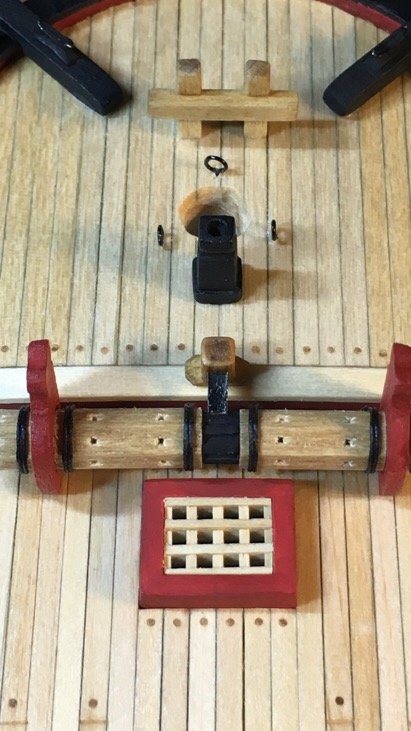

Installed binnacle. Started prepping the stanchions. As an afterthought, I also stained the upper part of the rudder above deck level to match the bitts/pawl/windlass. Once the rudder arm is installed (after poop rails are in), it should be a fairly nice match. I am getting a newfound respect for harder/tight grain woods. The toothpicks were a unique idea but the wood is crap...like basswood it gets very thready. Good to know for future!!! moving on...

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

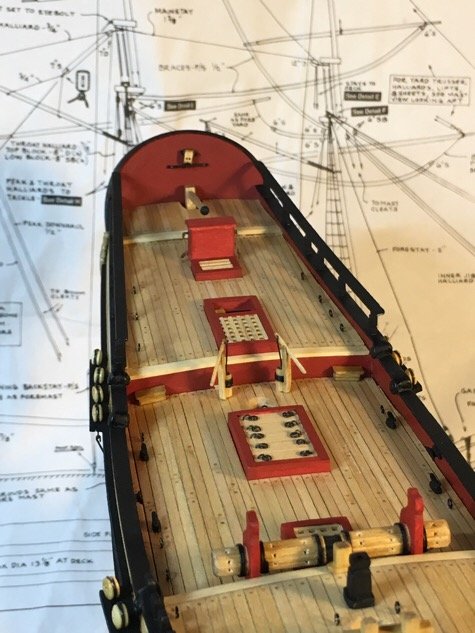

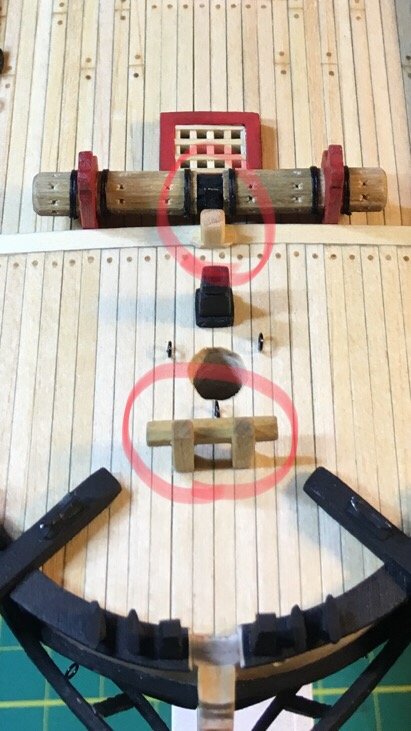

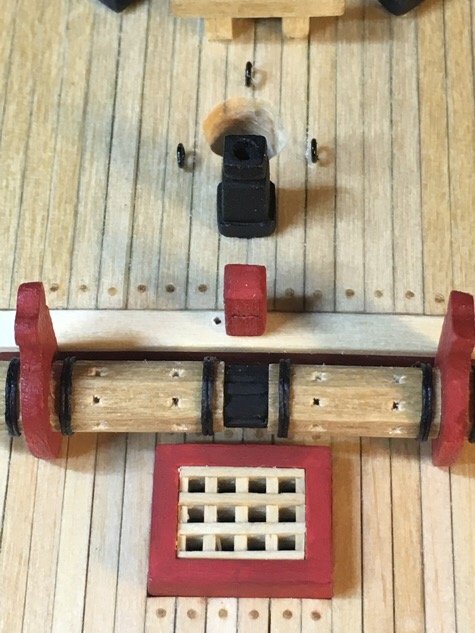

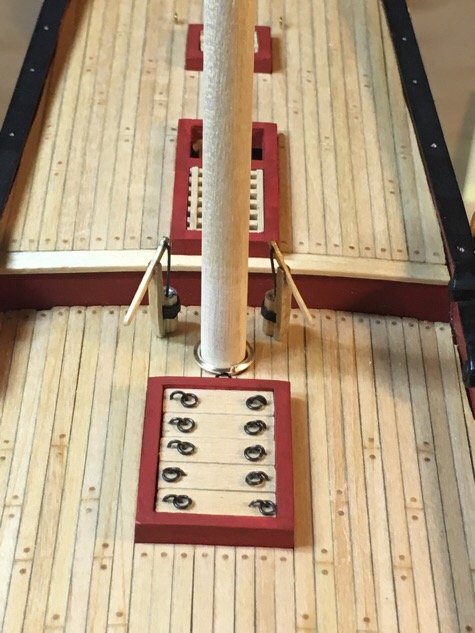

Needed to stop and back track a bit. The pawl looked like a stick of butter and the bits were askew ever so slightly. So removed and restained pawl with darker stain, and reset the bits. Much better...and yes, the foremast is off center by about 1mm. My eye sees it all the time, but I have learned to accept this little ship with all its (my) errors. She’s still looking mighty handsome!!! moving on...to binnacle and poop rails.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

I tried using CA on some unpainted cleats (metal) adhering them to basswood strips. The thin ‘waterlike’ CA doesn’t seem to give much purchase. Also, it bleeds all over the place. I got some ‘thick’ CA from Lowe’s (Scotch brand) which comes in a tube. Easy to apply and control amount on the part as the glue comes out as a light gel. Worked really well on the trial pieces. The cleats attached to the bulkhead on both sides of the main deck were a bit of a trial...touch up paint WILL be needed. 🙄 Finished up all cleats/eye bolts. Left the eye bolts in the front of both masts unglued since these both need a block stropped to them. Better to do that on the pins off the model and then set them in place...seems it would be much easier that way! (He said unconfidently...) moving on...

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Thanks, Kurt!! Will use CA. Many thanks.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Words cannot express my frustration at Britannia metal pieces. Trying to get the metal cleats to fasten to wood is difficult. I roughed the underside of the cleats and used carpenter’s glue. But they still do not seem to hold as fast as they should. I am hesitant to use CA glue...not sure if that would be any better. 😤 Touch up painting definitely in my future after I get the poop rail up. Moving on to remaining cleats, poop rail, rudder arm, binnacle, and swivel gun stocks...(then the masts/rigging if the bloody glue holds!!!)

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Friday was a mix of progress and setbacks. 1. Setting up deck furniture, eye bolts, cleats, etc. During drilling of guide hole for pin to set the pawl (the metal tongue holder to keep the windlass from spinning backwards when under load) I accidentally drilled the guide hole in the wrong place. After cursing, I realized the original pawl (following Chuck’s practicum) does not have the breadth to cover my mistake. So..decided to remake the pawl with a wide base and shortened it a bit. Effect was so nice, decided to forgo painting it and simply stained a natural finish before setting it on the step. Not a bad result. 2. Made mast coats using 22g wire per Chuck’s practicum. Will paint later but checks out nicely and allows room for pumps for the main mast. Easy to make but may do wood for next ship. Moving on.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

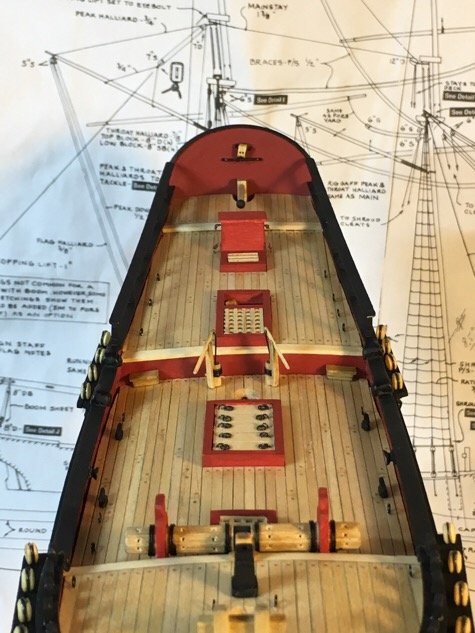

Side story: The first thing the Admiral said yesterday evening when she saw the brass eye bolts poking out of the bow wales was, "Your ship has some BLING!". I was miffed...I am too old to BLING anything, and would never consider BLINGING my beloved schooner. I honestly hate that word...BLING. So, after due consideration, decided to make my own eyebolts. Technique was pretty easy with a pair of wire benders. After some trials, found I could make many different sizes fairly reproducibly using 26g black wire. (Good investment!) In truth, the brass eye bolts simply seemed too flashy and a bit out of place. Replacing with the black eye bolts, other than being a bit more historically accurate, aren’t as distracting and seem to allow a more balanced impression. Moving on.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Thanks, Elijah. I have not included them...but I do have a couple of ideas on how to make them! If they turn out, I'll include them before I run the anchor.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Tragedy! I just discovered I accidentally included one extra timberhead on both side of the bow! Thank goodness I’m not a stickler for perfection. But since I have already deviated multiple times, this really isn’t too much of an issue for me!!! 🤣 I think she still looks good. Deciding to leave it rather than correct it. Moving on...

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

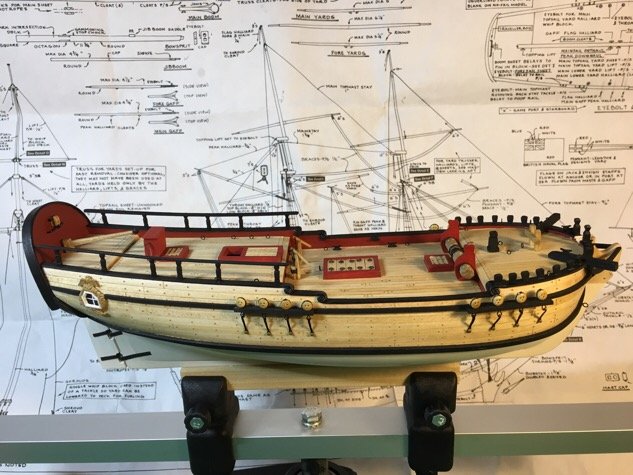

Finishing up the hull details and getting ready to move into masts/rigging. Lord help me...😣🙏🏼 Is nice seeing the ship take take on some more definitive look. Long way to go though. Will do do some touch up painting before I start messing around with masts! Also still need to make and fit the swivel gun mounts. Moving on....slowly.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Thanks, Russ! Well, I can honestly say that they will need to be ripped off since they certainly won’t be coming loose anytime soon. Will be putting in pins for the next build though.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

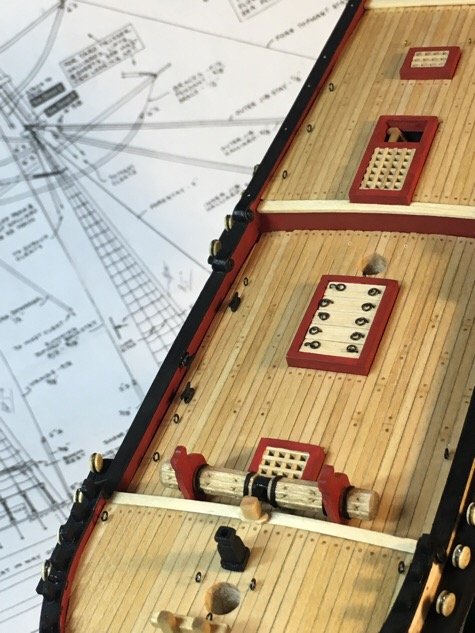

Ok. Going to stand back and admire my progress a bit. The chain plates I made turned out really nice and I am glad now I decided to make my own via wire/solder. The metal was very easy to bend and trim. Made for a fairly painless chain plate attachment and the effect was very clean. After it was done, I had to consider how much she is starting to look like an actual ship!!! Moving on...

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Nice progress! Looks sharp and the filler blocks are set just right. Also like the use of faux deck below cannon carriage to ensure no issues with porthole alignment. Good idea.

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks, Bob! I totally understand that! Very good tip which I will follow in future.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Got the port side channels/deadeyes installed. No pins for the channels...will simply say a prayer and hope the carpenter’s glue holds. 😁🙏🏼 Fairly lined up and not a bad result. Touch up paint is in my future. But if I only mount it with port side facing out, then I only have to do half the rigging!!!

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Happy New Year, Lou! Your kind support is always welcome! Sometimes it helps to vent my frustration...and I truly hope I give more opportunities for you to enjoy the build...slow as it is! Cheers Pat

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

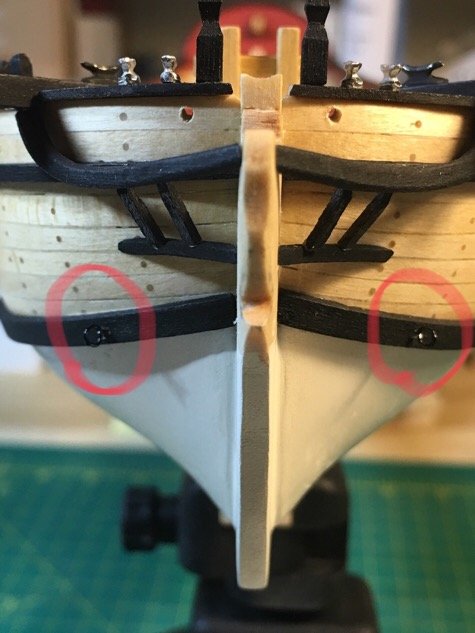

A bit more perspective in the bow/stem section. Yes, I omitted a LOT! But this was not without a considerable amount of forum searching and assessment of other builds. In short...the Sultana is a small kit, and trying to create the same level of detail as described in the plans is simply beyond me capabilty at this time without some consideration for a beginning level modeler. Seriously...hey Model Shipways! Ever hear of laser cut parts? No? Well you should...21st century modeling....how about you people get with the program and get some laser cut parts for your old kits? Who knows you may actually attract some NEW MODELERS to the craft. 😤🙄 Ok. Chuck’s practicum gives the perfect tips to do this, but it is simply time to move on....so I did. Made appropriate adjustments to make it look nice (but probably not very nautically accurate) and it is what it is... Moving on...and for those going to attempt this kit, I would say that this kit comes with a lot of potential for doing your own thing...and if so...then just do it. Don’t be afraid of doing something different. The plans are good for accuracy vs the Sultana, but Who says you can’t just do your own thing.... We we will see where this goes....but I know the Bob Stay hole is too far behind the figurehead base....so there will be some interference there....all about accommodations at this point...adapting to previous errors....ugh. But that’s thwhat fun of this hobby....always something! Moving on.....to the chain plates and swivel gun mounts.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Well. Where to start. Server went down when I was gaining some Holiday traction. Progress report: Great cabin windows, stem post (and massive deviation from plans), mounting screw arrival. Great cabin windows: (Metal fittings suck) Like a more earthy tone so scrapped the historic yellow. Looks too gaudy and garish. Does not match the natural wood warmth I want to portray. Painted a desert yellow with white window frames. The window frames needed some thought. No...no more trim tape as referred in Chuck’s practicum. Opted for a 3x5 note card, a black Sharpie pen, some stick glue, and scissors. Turned out beautiful! Wish I had done the same on the transom windows. Stem post: Ok. Let’s be honest. Chuck is a professional modeler and I’m NOT. So...tossed the practicum and deviated from the plans. Handshaping/sculpting wooden sections the size of a mouse turd is neither fun nor easy for me. Decided to enjoy my model rather than fret over historical inconsistency. Decided to scrap the ‘knees’ altogether...and put in upper and lower ‘cheeks’ (sorry if I’m screwing up the nautical terms) with cross braces connecting them. These tiny bits actually ARE the size of mouse turds! Cannot truly describe how difficult it was to place these things without spreading glue all over. In short...focus on maintaining symmetry as much as possible...I mean I simply eyeballed it since there was simply not opportunity to be precise at this scale. Mounting screws came. Yay! Got at least 1.5” of screw to set the ship. The Admiral simply asked, “Aren’t the screws too long?” Too funny...wish I had longer screws. But what the hell...I won’t be playing football with the model after it’s under glass. 🙄 Pics below....moving on! Happy New Year!!! Cheers, Patrick

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Ok. A bit of progress mixed with procrastination. Painted the knight heads with decent result. Decided to put together my channels before putting them on the ship. (May sound odd but I have my reasons. We shall see) Also tried a couple of different size square dowels (basswood) to see a sense of scale for the swivel cannon stocks. Will go with the smaller stock. But the metal fixtures are crap. Model Shipways should be ashamed. However, I think that putting on the stocks/cannon will be best done as one of the last finishing touches for the ship. I will prepare them, and ensure good fit...but putting them on before the rigging doesn’t make sense to me. They will simply get in the way and Also put on a couple coats of natural finish to the wooden balls and mounting board. Muuuuuch better. Now jumping on the cheeks...sigh. Will need to adjust considerably from the plans. anyhow....moving on.

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

Yes...the knight heads seem high. I may need to trim them a bit more but will wait until I have a better sense once the bow sprit is seated. Sigh...always something. 🙄

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.