-

Posts

1,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Overworked724

-

I plan to do individual tiles. Most builds approach the coppering this way.

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Ken! I know there are a lot of builds out there…some are rough, others are like works from pros. Don’t compare yourself. It’s your ship, and and deviating from the plans is fun! A couple options: 1) Go without rivets at all (who is really going to check?) 2) Paint the hull white below the waterline instead of coppering. For the foil not sticking, a lot of folks recommended sanding sealer or primer. It cleans up the wood surface and gives the foil something to stick to. When your build gets you stressed, do a side project to reset your head and allow your creative juices to give you ideas. It’s a marathon!! (A really long one!) Best Pat

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

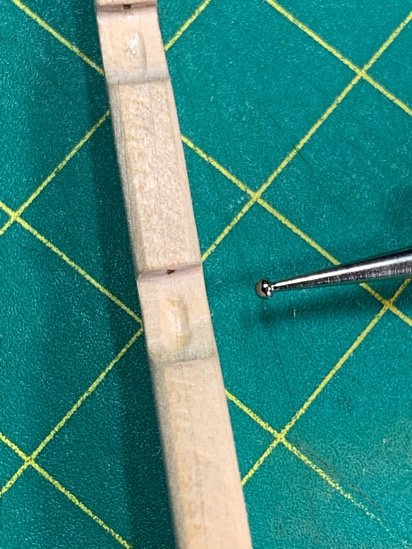

Hi @niwotwill Will, If you go to post #123 in my log, your questions are directly addressed! 👍🏽 Hope that helps! (0.4mm thickness) (1/8” cherry wood sections as sandwich bread 😁 ). Please note the correction. I'm sure this would work with sheets that are 1/16", but did a quick remeasure and find that sandwich sections (cherry wood) was closer to 1/8'. Either way...very easy to cut. One thing to keep in mind is to line up the grain of the wood with the direction of the cut for the strips...cuts much easier I think.

-

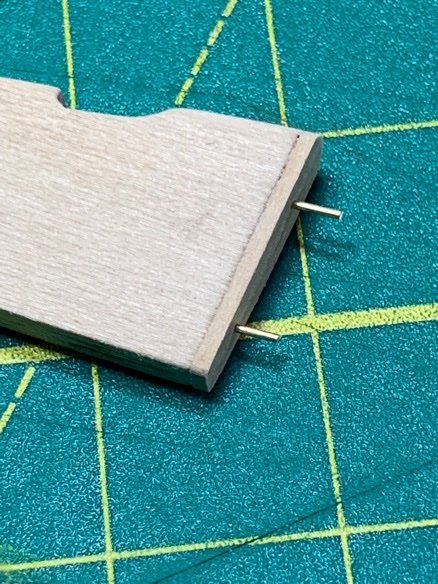

Still futzing with the rudder. Prepared all the pintles. Dry fit with nails. Used a manicure shaping tool to press in the wood in the rudder cavity to ensure a smooth fit with gudgeons. Looking fairly decent. Will use the rudder as it is to mark the gudgeons placement and get those prepared. Not sure how everyone else does it…but I really don’t trust myself in this part. But I am determined to ensure I can remove the rudder. I could have embedded the pins in the pintles. But I wanted some 'room' to play if things got finicky and the fit too tight/restrictive. I can always replace the thinner wire with a 20G copper section which would fit perfectly in the pintle. Moving on…

-

It occurred to me when trying the P&Gs on scrap basswood piece (same width as sternpost) that the width of the brass strap needs to be considered when the pintle and corresponding gudgeons are aligned (i.e. opposite direction of each other). So I decided to sand off a bit of the brass at the ‘peak’ where the hollow brass tubing sits. Also tried the small brass nails to lock it in place…and that sucker does not move!! Moving on…

-

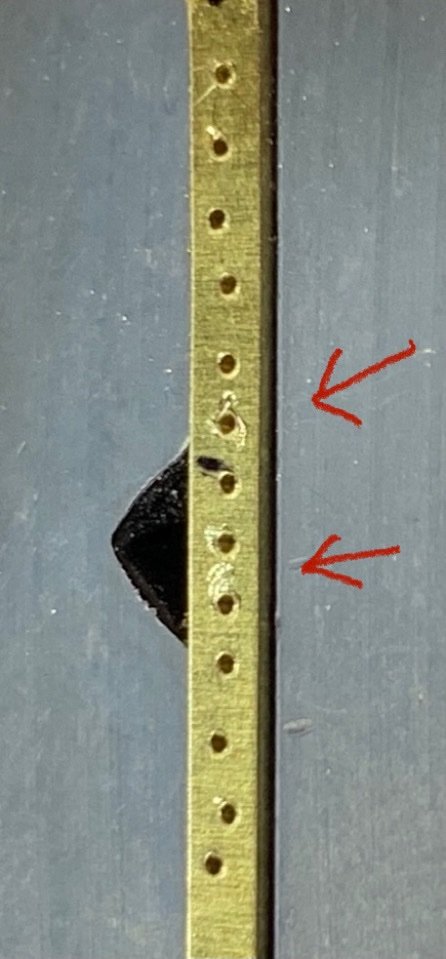

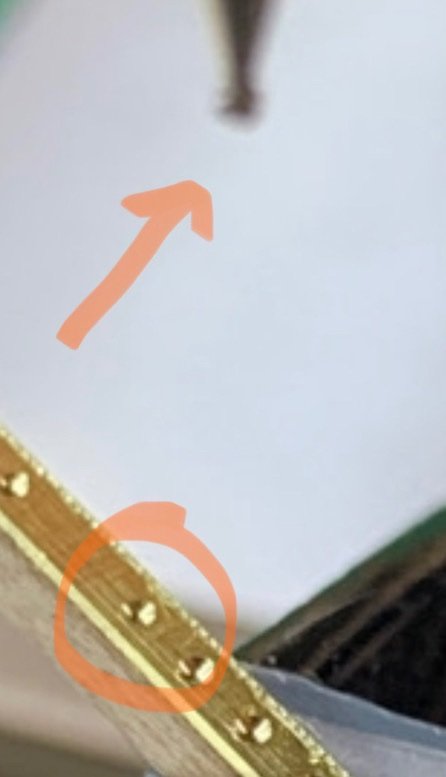

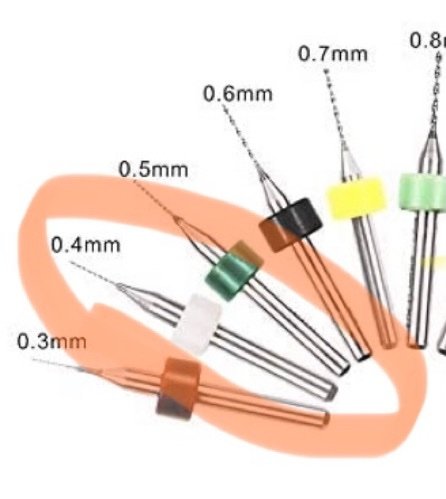

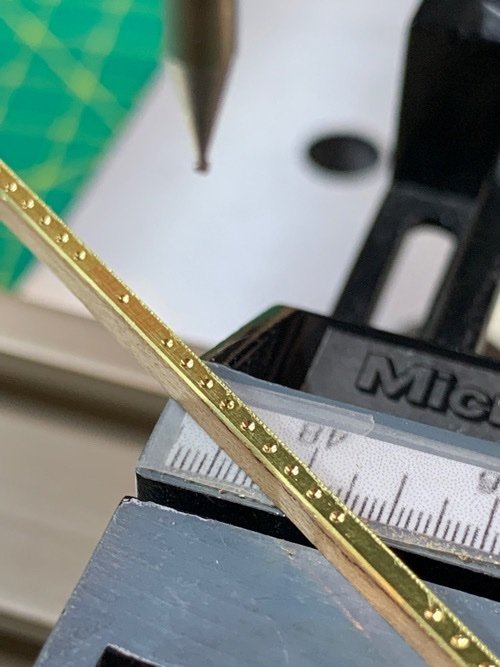

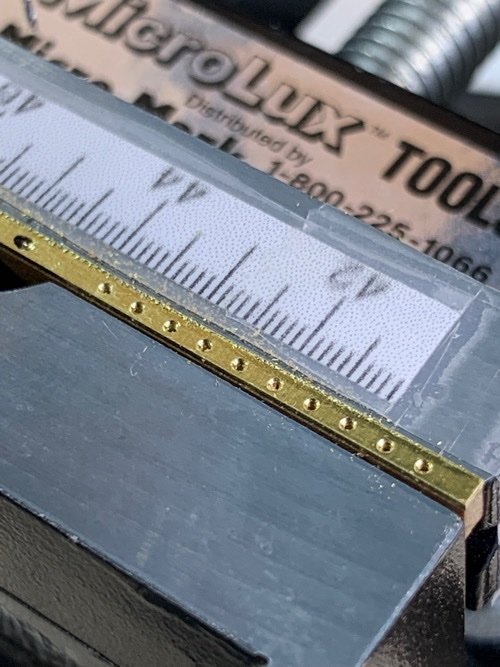

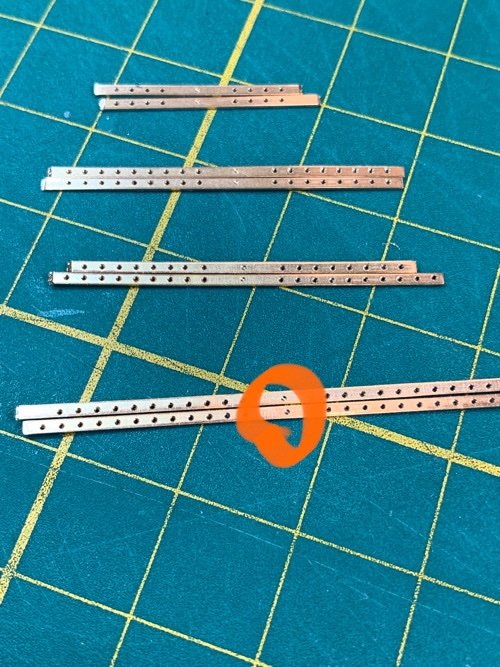

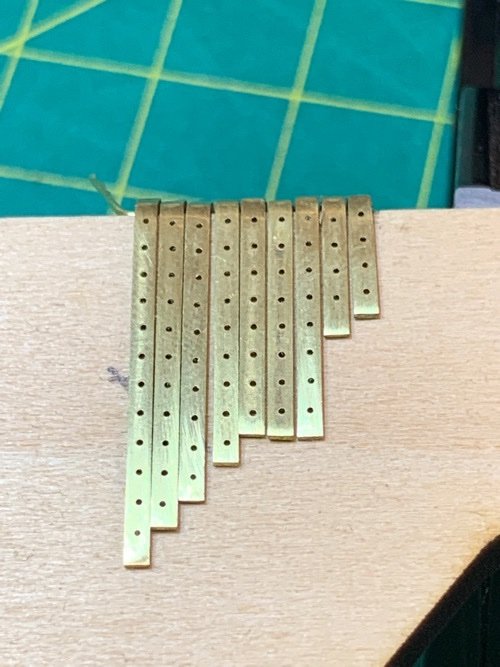

Dear @CPDDET Dave, Thanks again for the kind words. You and the other shipmates kudos always keeps wind in my sails! Ok. My technique for nail holes in my P&Gs is as follows. It might sound stupid…but it works! A mini drill press equipped with an x-y table are sort of mandatory for this to work. My initial trials with a #78 drill bit(s) met with disaster. I broke two before I went to the high precision PCB bits (0.4mm) and broke two of those little buggers. 🤬 The pics below shows one of my strip attempts. You can see where the drill bit was drifting (red arrows) as it scored the brass. The bits invariably snapped. I was beginning to doubt my choice of 0.3mm brass nails! Those bloody things are tiny. AND BEFORE ANYONE ASKS…YES, I HEATED UP THE BRASS!! I don’t believe it was annealed, as it was pretty soft. But the nail pattern looks like a drunk Irishman heading home on Saturday morning (said the drunk Irishman typing in a ship log). Hard to believe that was done with an x-y table. That’s how much the tiny bits drift before they gain purchase. 😣 I figured giving the drill bit a cup or starter point would work. Using a hammer and awl just deformed the brass strip. So I opted for using an engraving cutter. It worked beautifully. I just pressed it lightly into the strip of brass and it made a prefect little divot. Dremel 105 Engraving Cutter, 1/8" Shank , Gray https://www.amazon.com/dp/B00008Z9ZT/ref=cm_sw_r_cp_api_glt_fabc_AT62H13H1PW0ZN5DRMA5 After that, I just repeated the drill pattern using a tungsten high precision drill bit 0.4mm. Both the drill bits and Dremel engraving cutter are really cheap (yes…Amazon). The results speak for themselves. So…that’s my workaround. After I adopted this method, I cranked through the drilling portion in 45 min using one drill bit. No trouble.

-

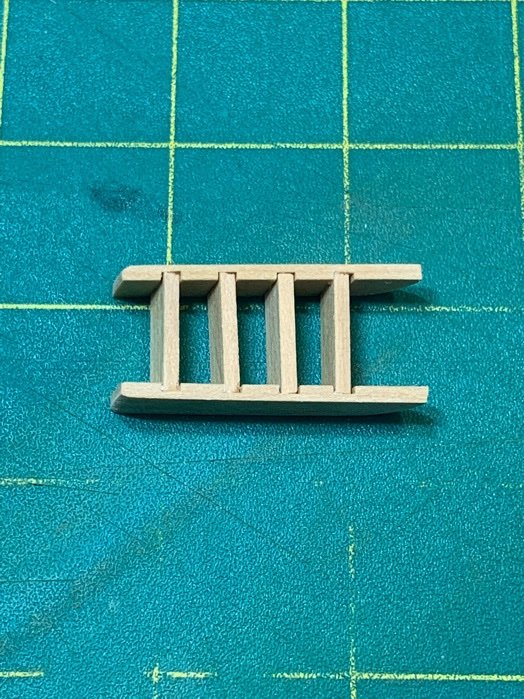

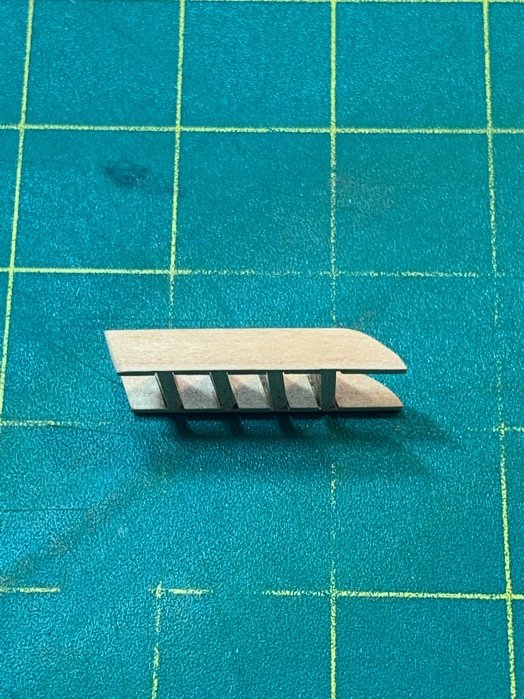

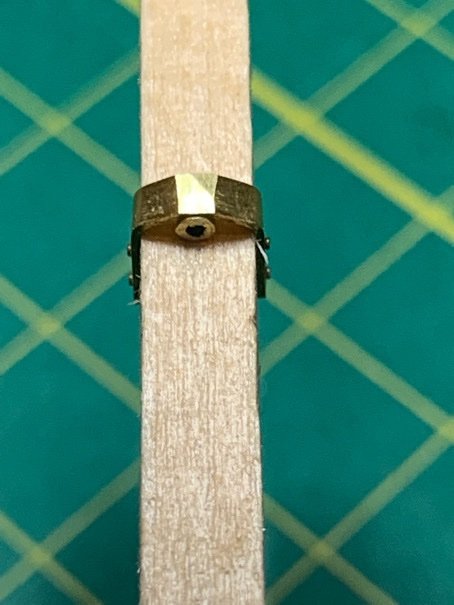

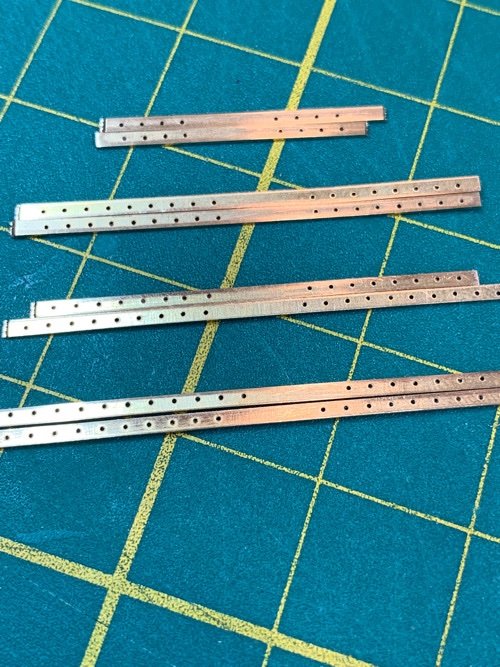

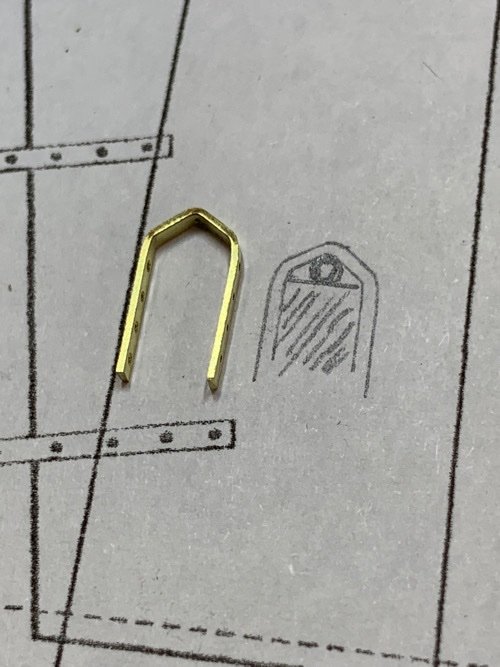

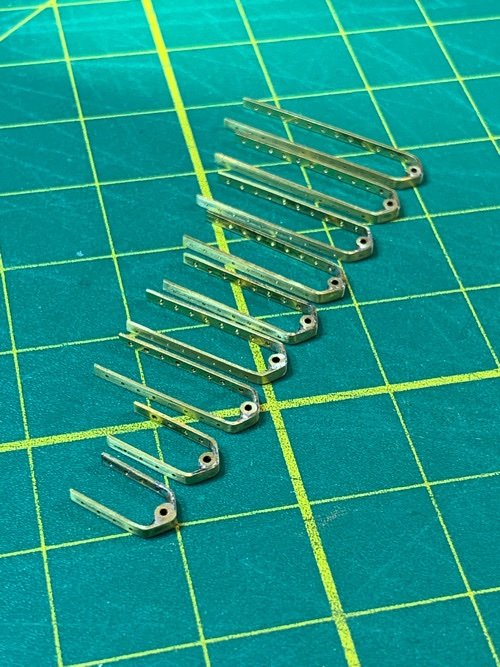

The one area which invariably ends up making or breaking the exterior view of a ship model is the Pintles and Gudgeons. These are really tricky for me, as few folks really break down the making, and installing of these things. So…been noodling and researching for a while…and experimenting quite a bit. For my Sultana, I ended up using paper because I couldn’t work with metal. This time I wanted to really give it the ol’ college try to get a good result using brass. So…here is where I’m at so far. Long post coming: 1. Recut my P&G’s thinner to more closely match the plans. I used my original brass sheet/cherry wood sandwich. 2. Separated one wooden side from all strips. 3. After cleaning off the spray glue from the exposed metal side with acetone (nail polish remover), I used a round head drill bit (wood carving Dremel bit) to score in a ‘divot’. This keeps the tiny drill bit from floating when I drilled the actual nail holes. Nothing worse than uneven nail holes! 4. Then I drilled the actual holes. 5. Then I separated the other half of the wood from the brass piece, cleaned it up, and cut it up into rough sections. The interior sides have the larger nail score mark and a center mark I put in to ensure my bending was consistent at the center. 6. I decided for a triangular bend rather than a rounded one. It ensured I had centered the brass rod in each P&G. I used a wire bender…no jig. I eyeballed it…because I simply could not figure out how to make a good bending jig!!!! 7. Soldered in the brass tubing, cut, and polished up the P&Gs. I made a bunch of various sizes. I can trim and adjust as needed during fitting. Placed them on a fake stern piece to ensure the general fit and alignment. I was pretty happy with the center alignment and width. Fit was nice and clean…no gaps. Still have a long way to go, but these are the first metal P&Gs I ever made…and I’m pretty happy with them so far. Moving on.

-

And with ship model building, there is always a persistent feeling of being rushed!!! 🤣 On a more serious note. Had to restart my pintles and gudgeons. Realized my original cuts were too thick. My goal is to ‘prefit’ my P&G’s so that my rudder is functional as well as removable. But I don’t want to mess with fitting 4 sets of these buggers after coppering the hull. I know I’d start scarring the copper and the illusion would be lost. My goal is to remove one area of anxiety and focus on coppering…then have my P&G’s sitting in the wings waiting for install. …he said no so confidently.

-

Wow. Didn’t think my Amazon ball bearing purchase would destroy Model-expo! 🤣 Well…two things…Model Expo doesn’t sell 2mm ball bearings I need. But if I need to go down in size…they do sell 1.5mm balls but at like twice the cost. But I do agree Amazon has done a fantastic job killing local manufacturing and business interests.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.