-

Posts

4,894 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

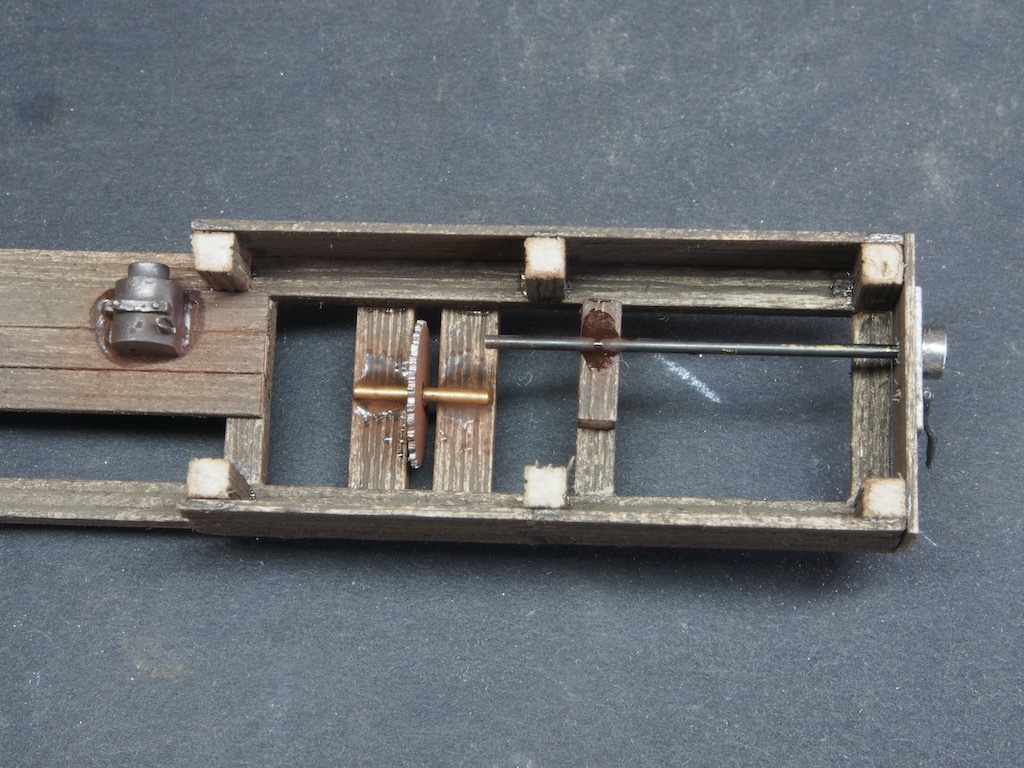

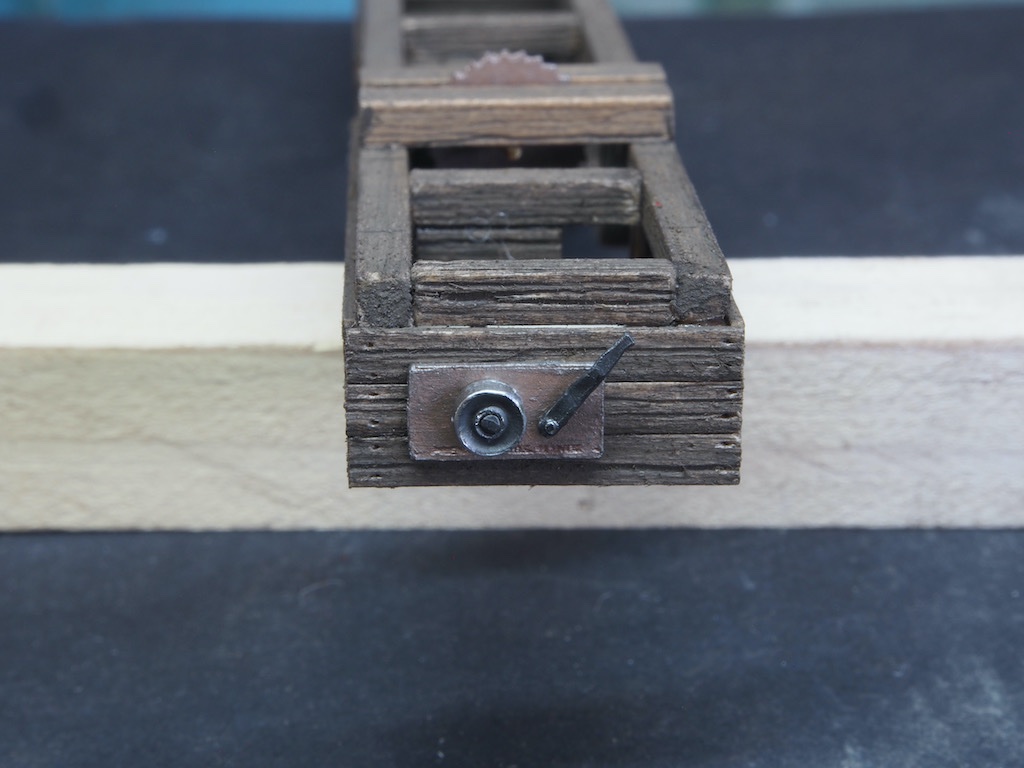

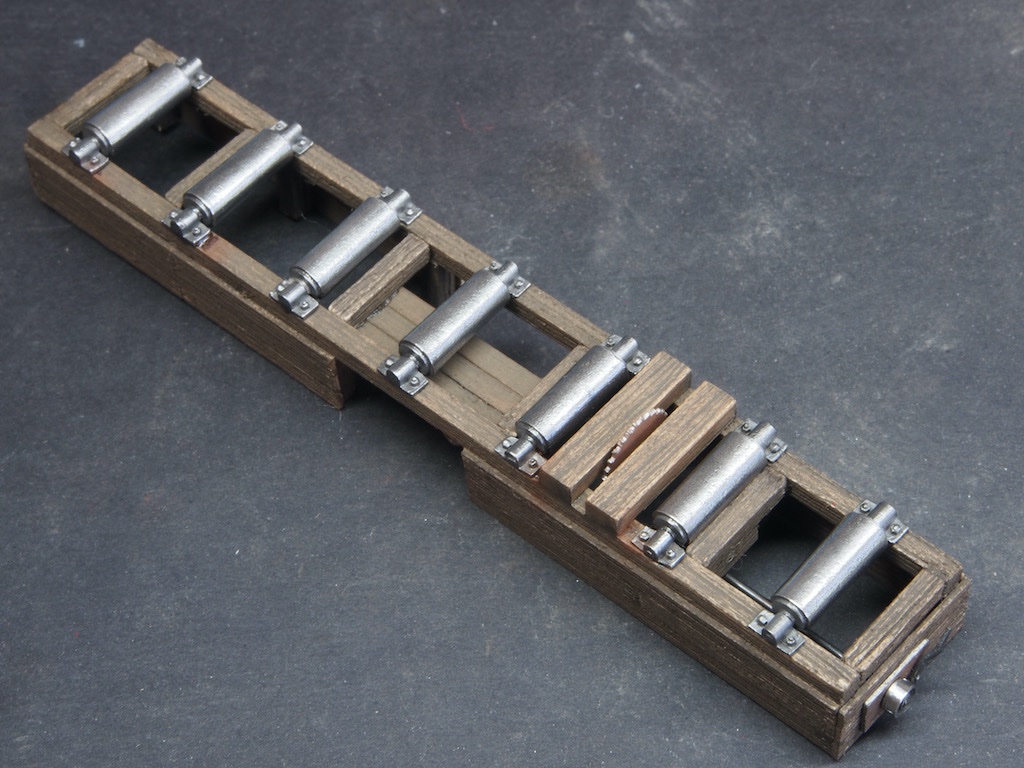

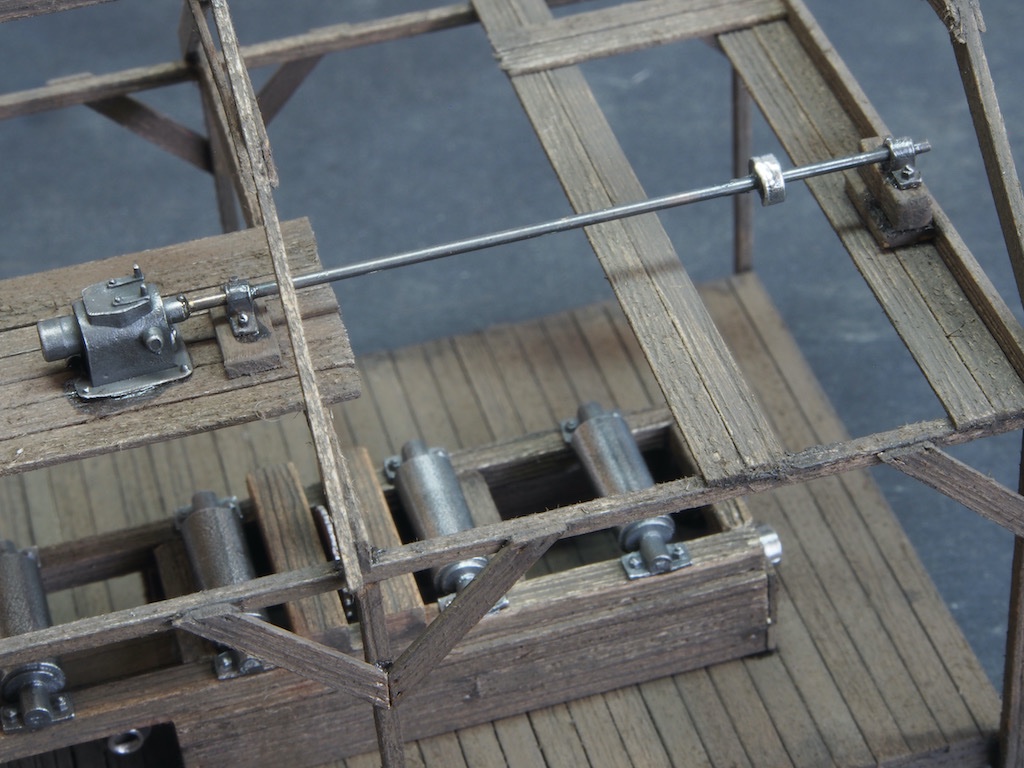

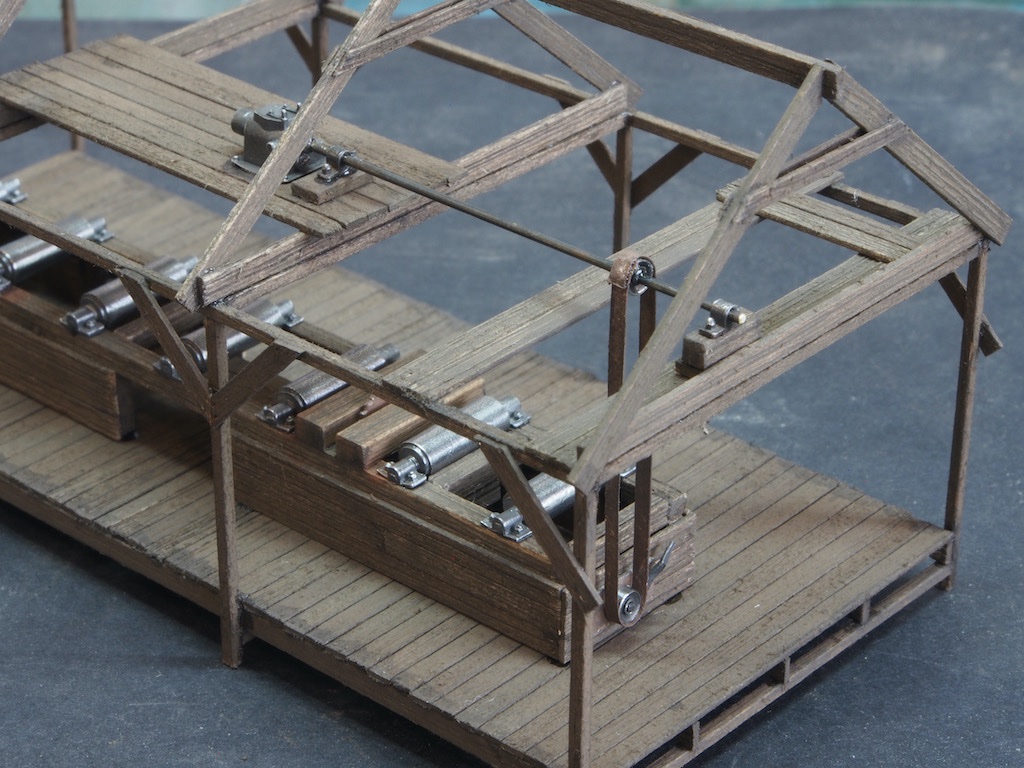

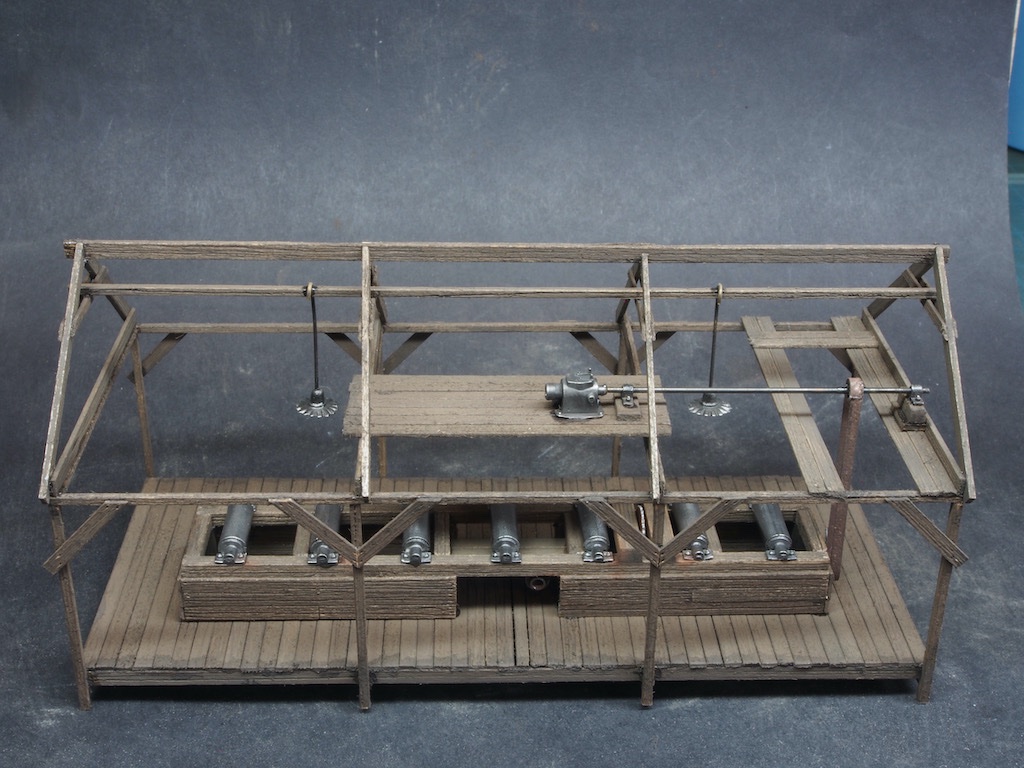

Continued from previous post... The saw blade receives a small brass rod “axle” and is then epoxied in place. At the same time, the end plate is glued in place and another shaft inserted through it. It is supported on a block on the underside of the table and as a drive wheel attached at the outer end. The end plate also receives a Feed Handle. This part is truly tiny. I dropped it on the carpet twice and was lucky to find it again both times! Returning to the top of the table, the rollers are now epoxied in place. With the Saw Table now complete, it is permanently attached to the floor of the shed – positioning is indicated on the template. Next, we add some decking to the attic space to support the electric motor and drive shaft. The electric motor is installed, along with the drive shaft, two pillow blocks mounted on scrap timber supports, and the driven wheel. Some special material is provided for the drive belt. All that is required is to cut a 1/16” wide strip, paint it and attach it to the two drive wheels. Two lamps are hung from a support beam to complete the internals of the Saw Shed. Next up we return to the roofing…

-

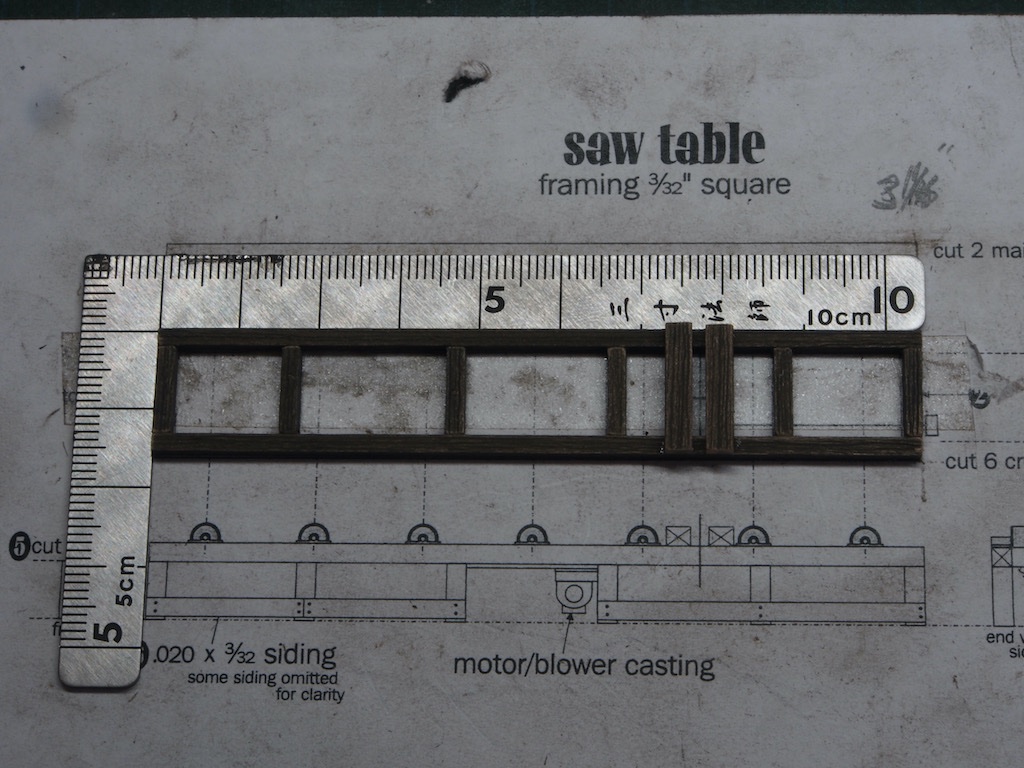

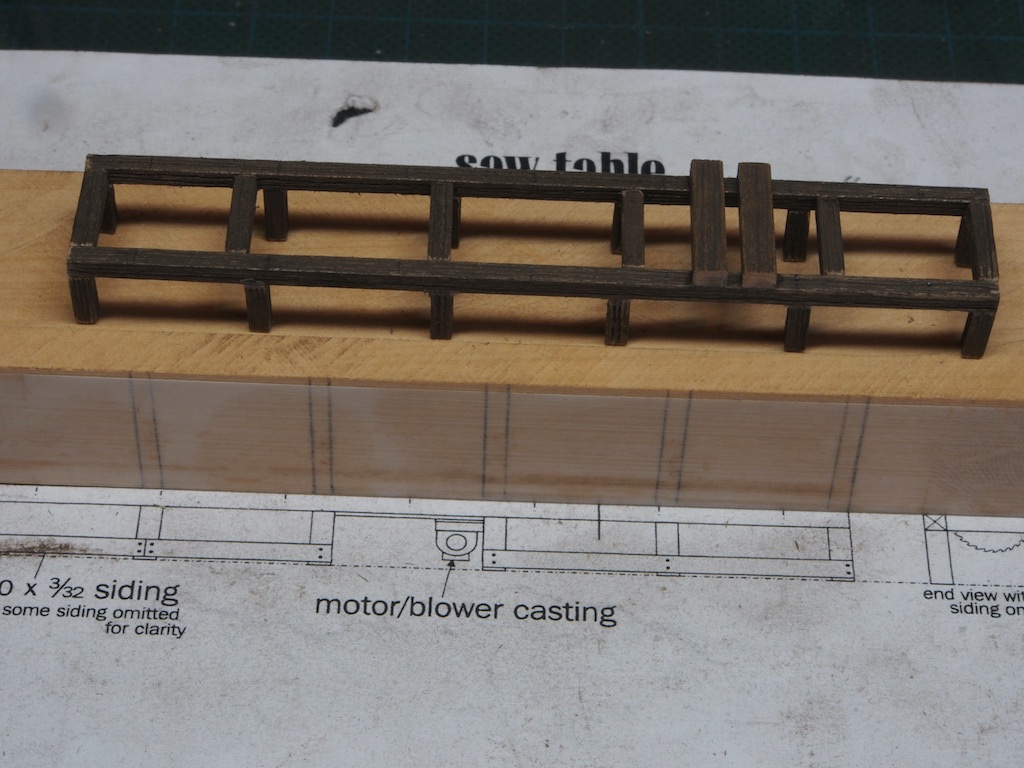

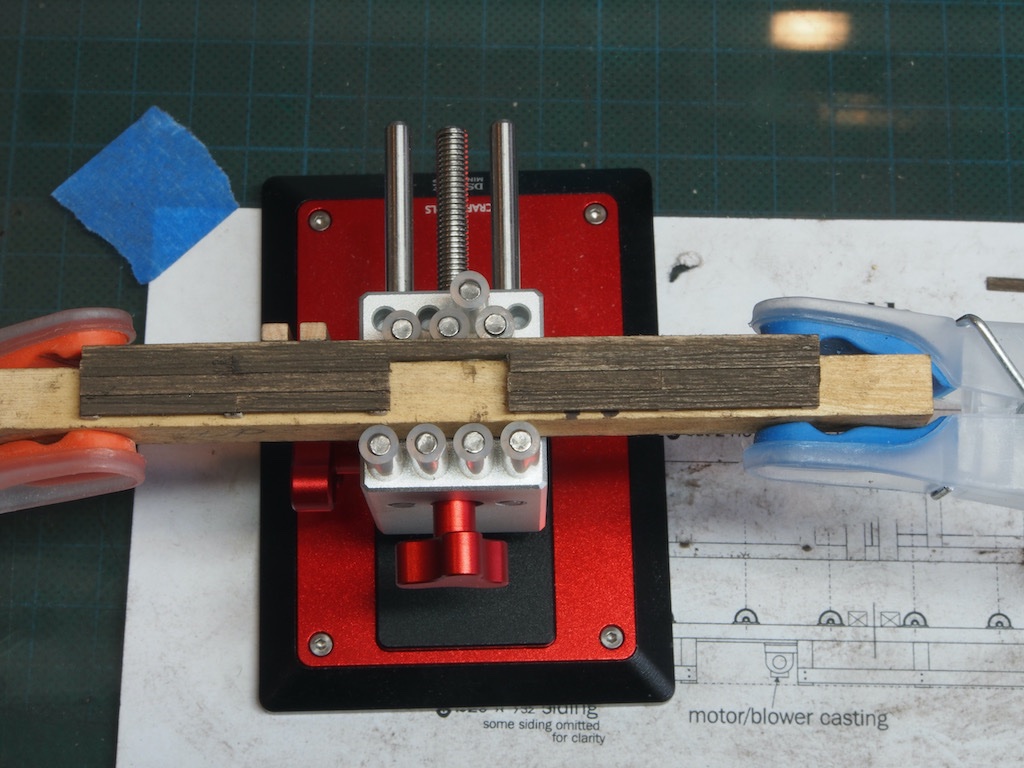

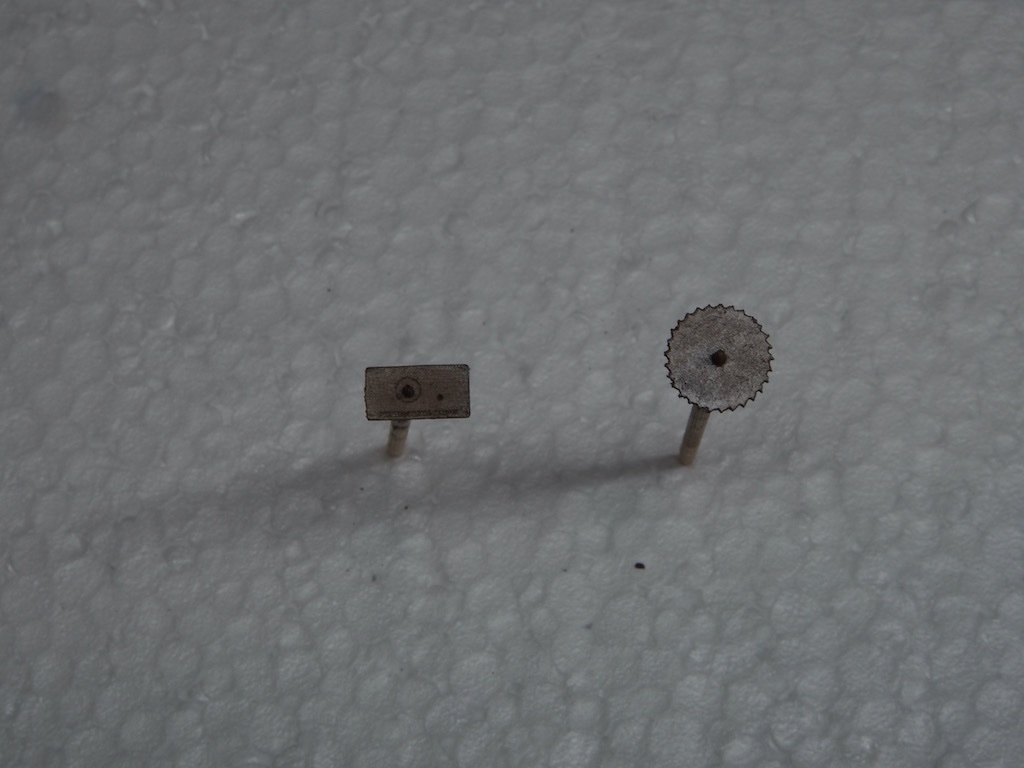

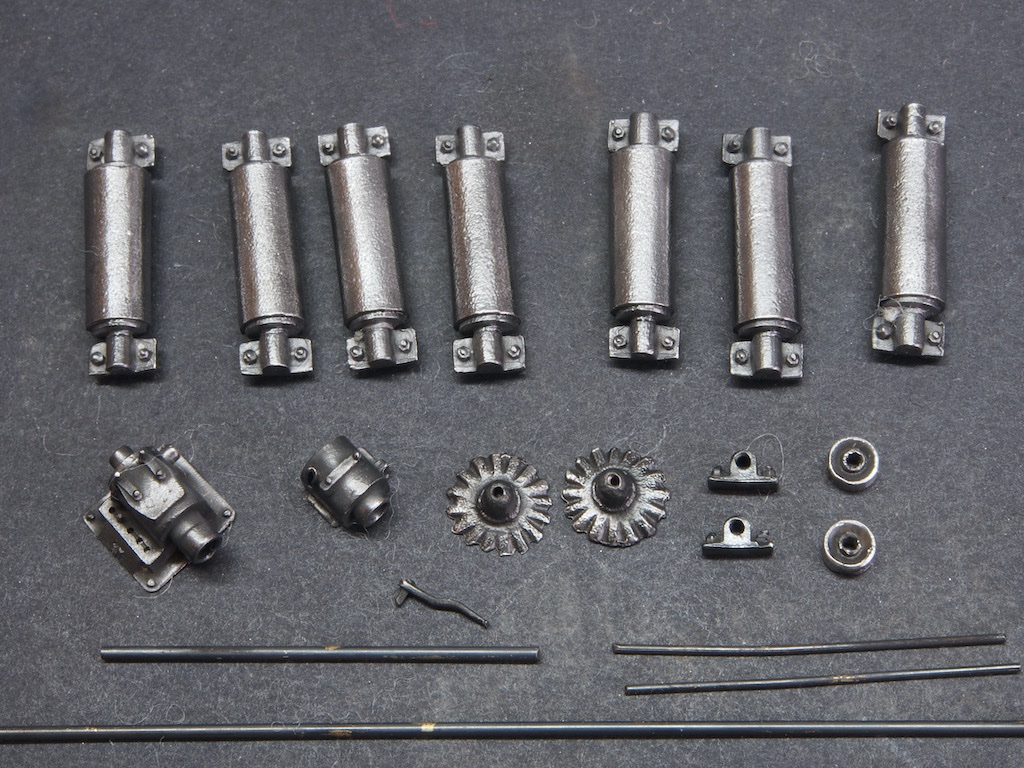

There are a lot of pictures for this update, so I'll spread this across two posts... The Saw Shed (Continued) We now turn our attention to the Saw Table. Once again, it is built directly onto the provided template. I have to admit, I was not happy with my first attempt at this and scrapped that before starting again. Here is the commencement of the process – the Table Top glued up. To help keep the legs aligned, I transferred their positions onto a large piece of scrap wood and using a second piece of scrap, clamped the tabletop between the two before attaching the legs on the first side. The table was flipped and the second set of legs attached. Here is the end result – much happier with this version. Sides were then added. To provide some support to the somewhat fragile assembly, I clamped it in a small vise with a piece of scrap of a convenient size for support. Here it is with all of the sides attached. The saw blade and an end plate are provided as laser cut pieces. These were painted with AK 11210 (Natural Steel) and then dirtied up with a bit of dark rust coloured chalk powder. In the picture below, they are each held on the end of a toothpick – just to give an indication of size! The next task was to clean, blacken and buff all of the metal castings and brass rod required for the rest of the saw table and shed. Some additional planking is added to the underside of the table and the blower unit epoxied in place. Continued next post...

-

EURYALUS 1803 by Peter6172 - 1:48

gjdale replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

Peter - just a thought on the use of the sticky label paper. If you cover your timber with painter's masking tape first, it will be much easier to remove the labels after cutting out - and no sticky residue to clean up. -

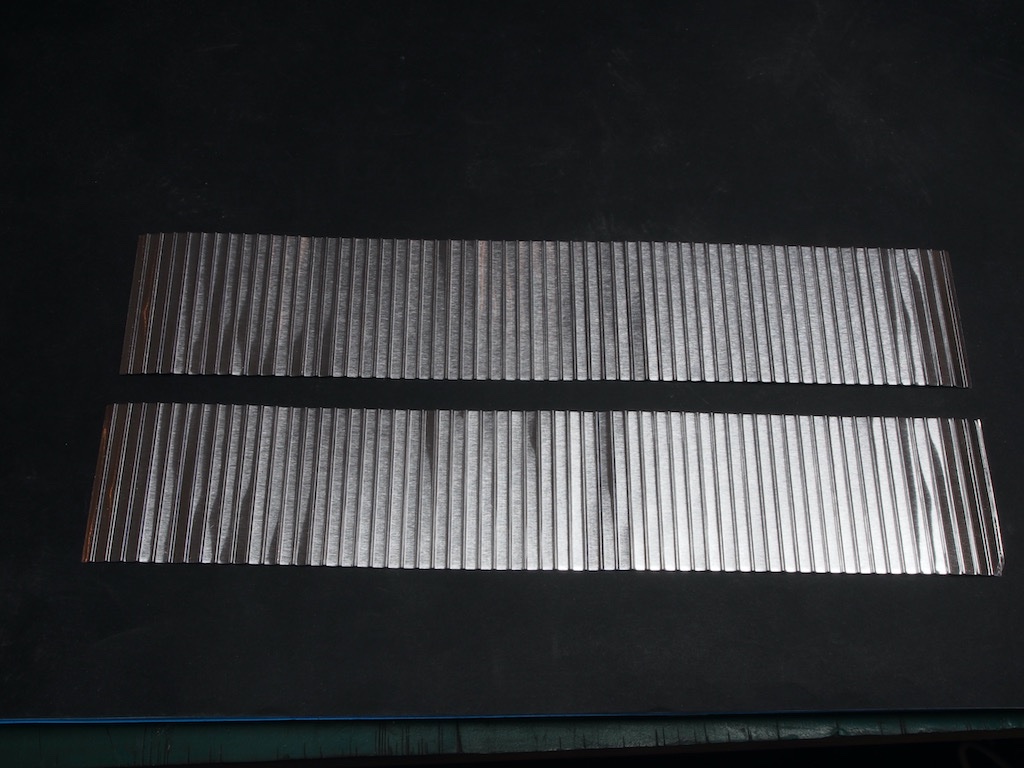

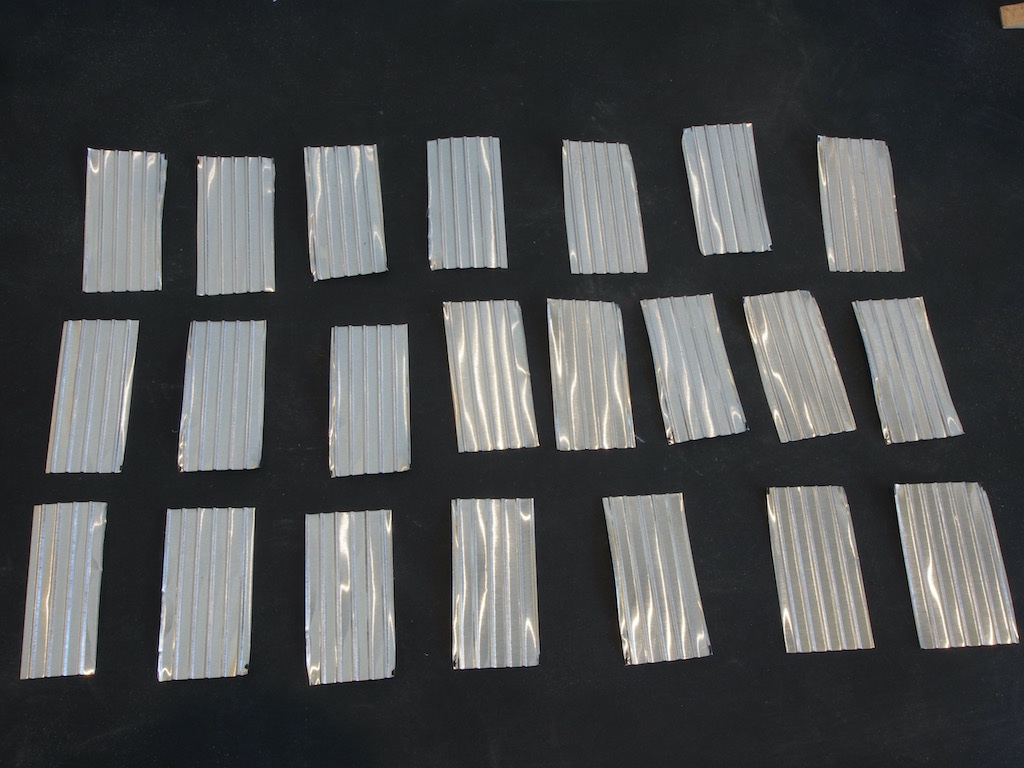

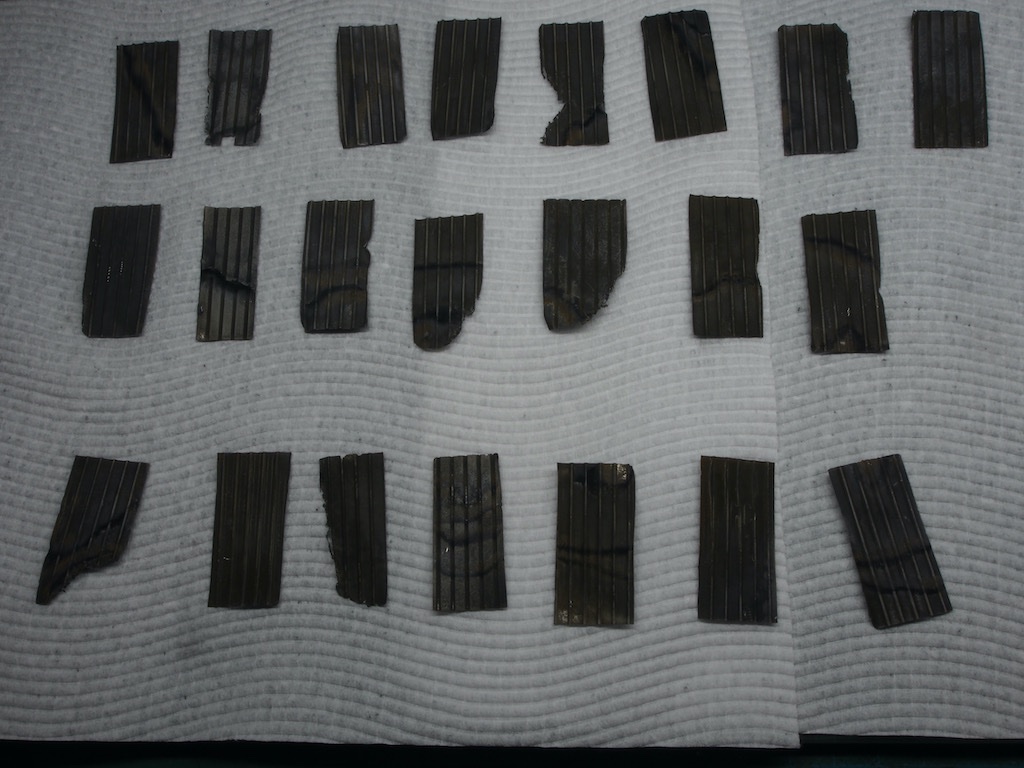

The Saw Shed (Continued) A minor update today. The Saw Shed Ridge Beam has now been installed. Our attention turns, temporarily, to the shed roofing. The Saw Shed is roofed with corrugated iron sheeting. The kit provides some corrugated aluminium siding and some instructions on how to prepare this. Here is the raw kit material – two strips about 8 inches long by 1 ½” tall. The first task is to cut this into strips about ¾” wide. Now the fun part…. To achieve an aged and rusted look, the aluminium is treated with Ferric Chloride PCB etchant solution. Yes, nasty stuff, but quite safe if proper precautions are taken – and the instruction manual is quite emphatic about this! The method is to dunk a piece of aluminium into the Ferric Chloride solution with a pair of long tweezers. The instructions say that after a few seconds the piece will start to bubble. I found that it took a good couple of minutes for any reaction to start, but once it started it was very quick! Once it does start to bubble, it is removed from the solution and dunked in clean water to stop the chemical reaction. The longer it is left to bubble, the more of the aluminium gets eaten away. I experimented a little bit to produce some with heavily frayed edges. I will use these judiciously to represent some more rusted/worn panels. Here are the pieces after the “mad chemist” treatment. These will eventually have rust coloured chalk applied before being installed, but for now they are put aside. The next task will be creating the Saw Table – a mini-project in itself….

-

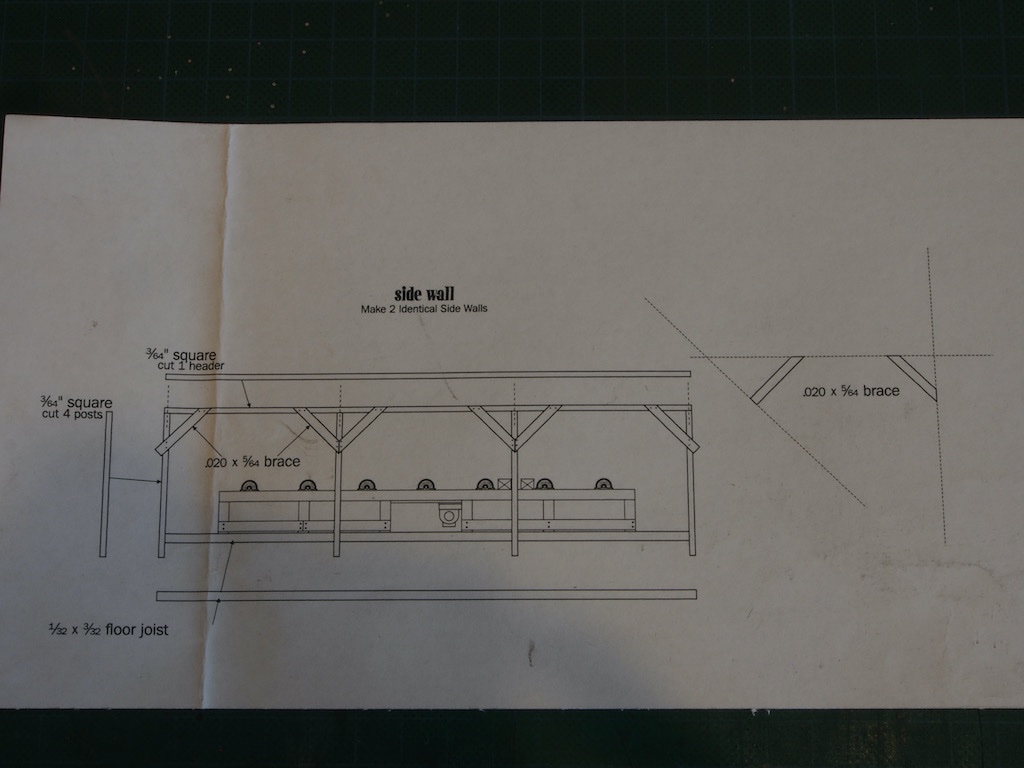

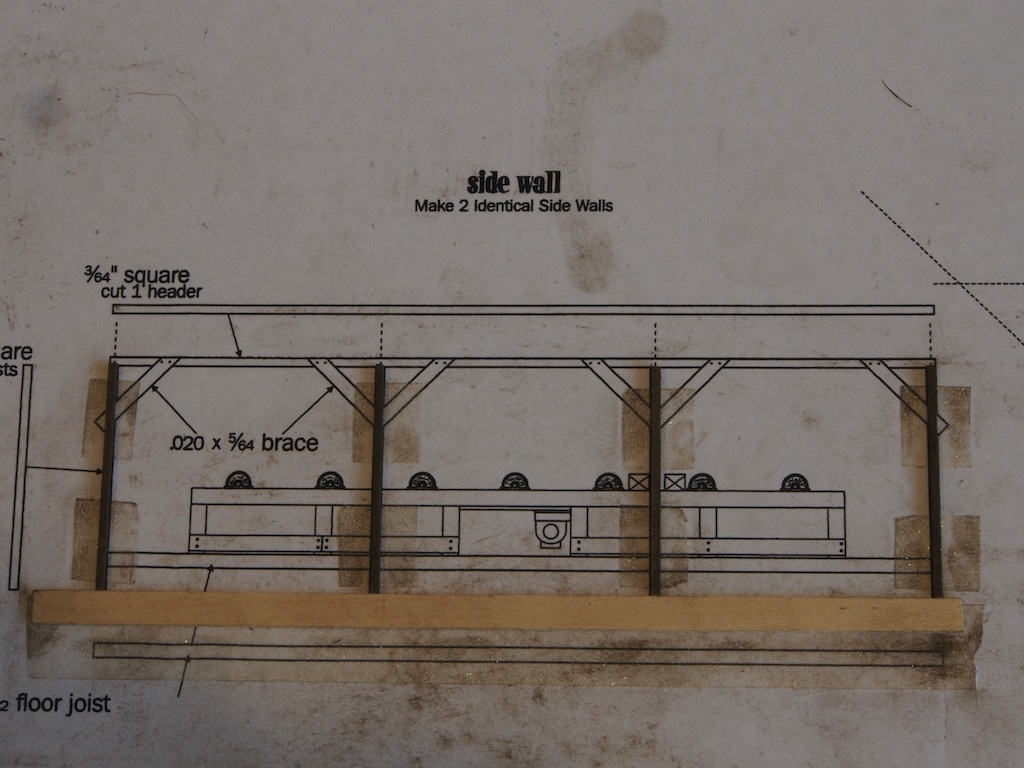

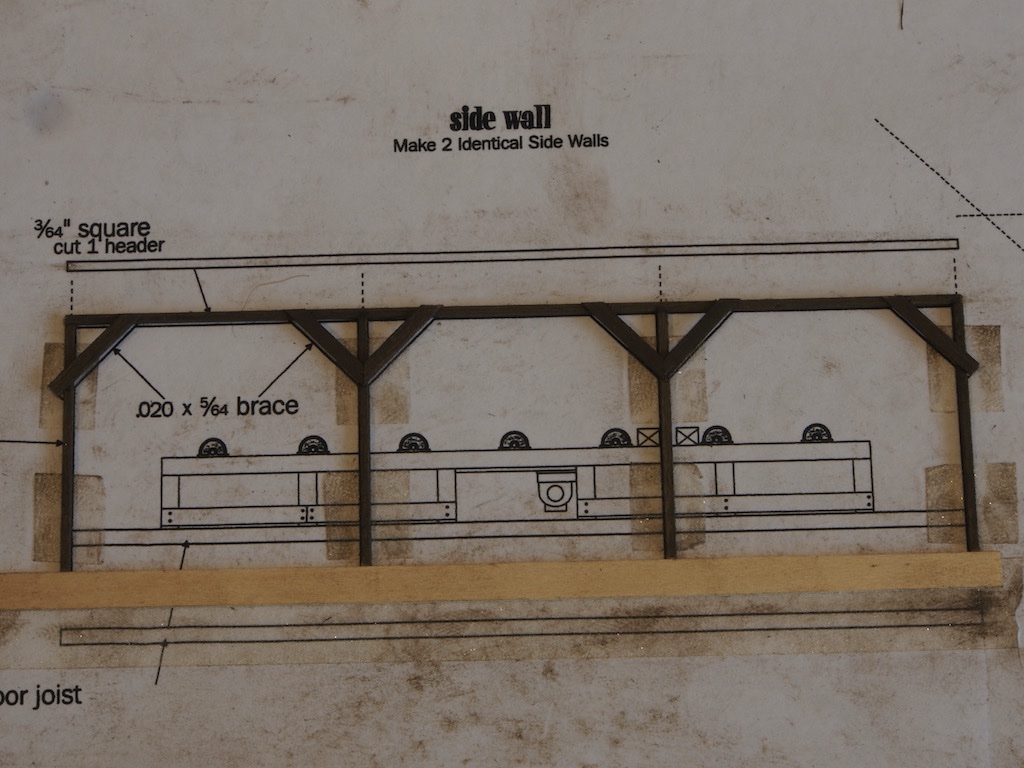

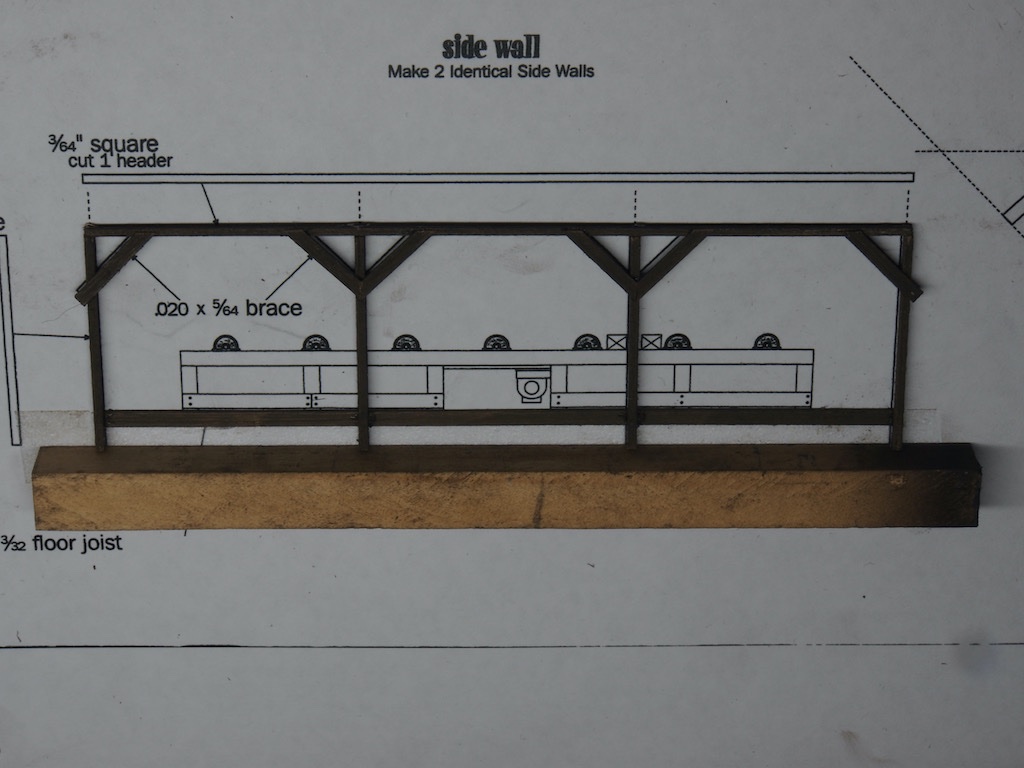

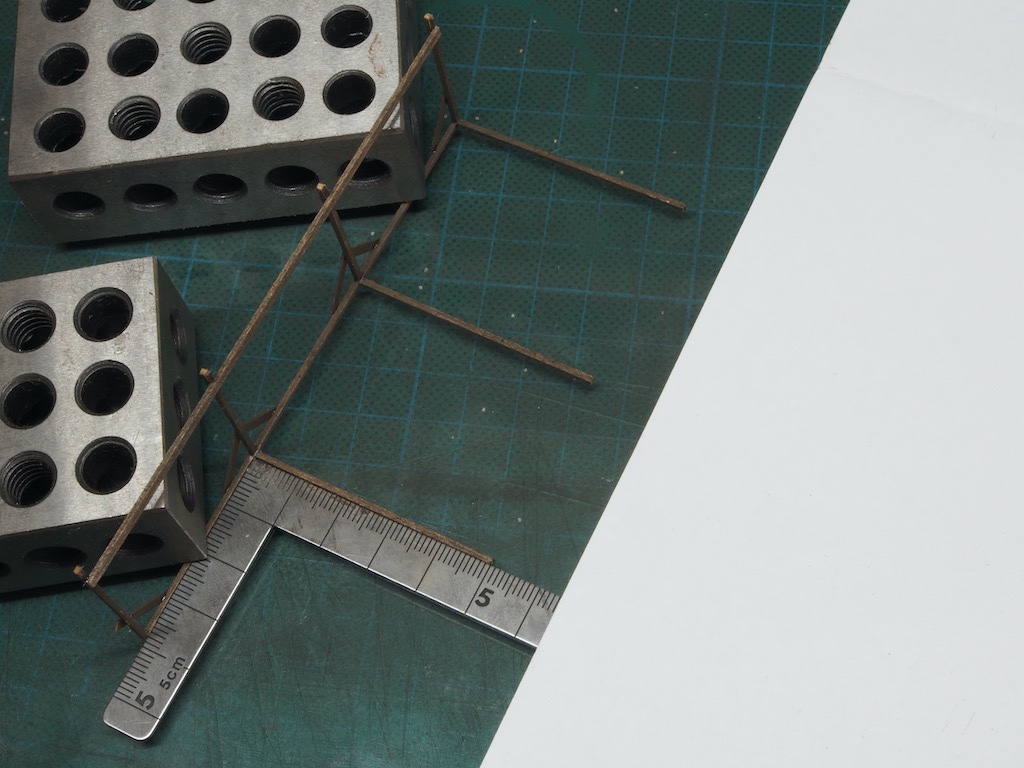

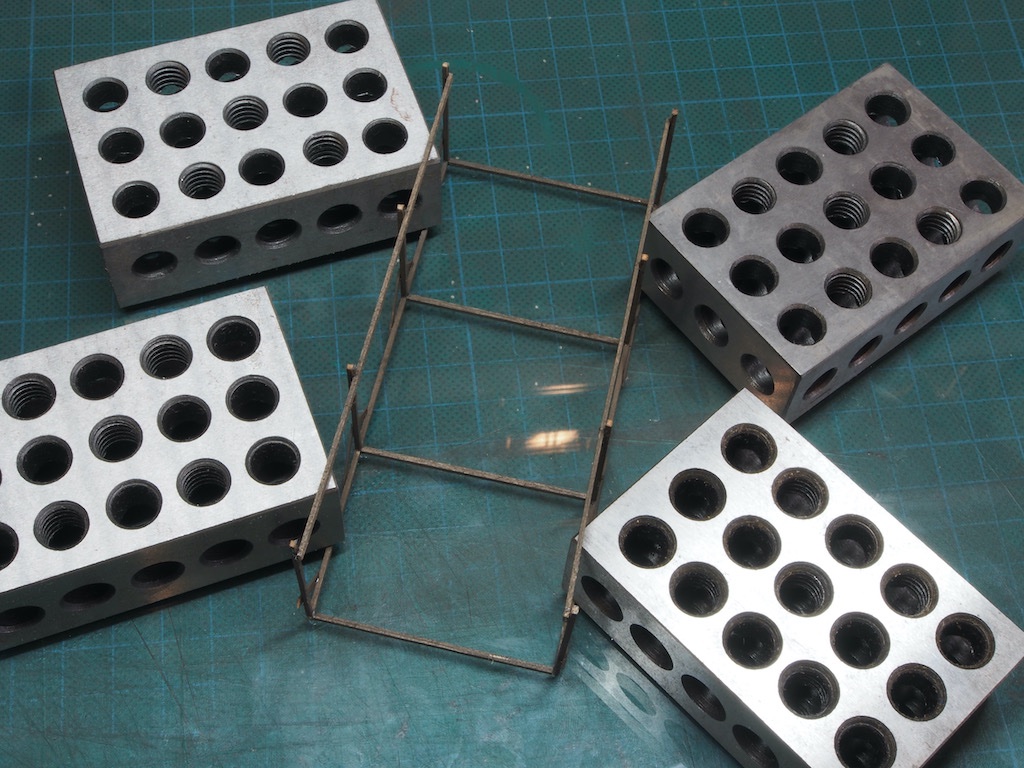

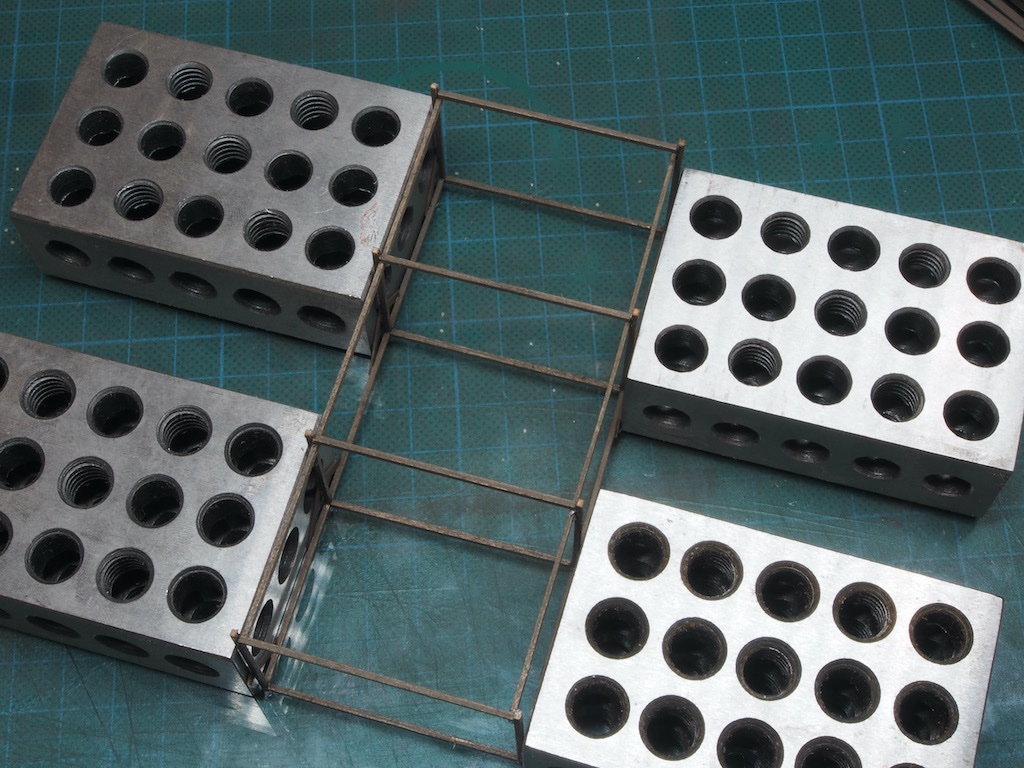

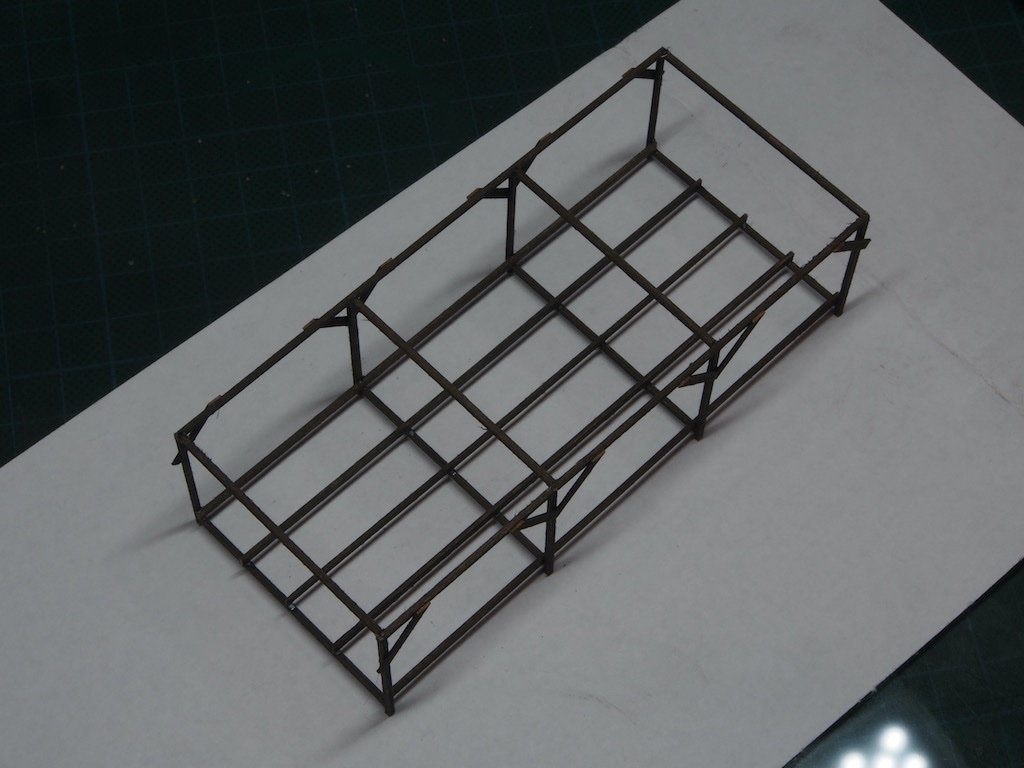

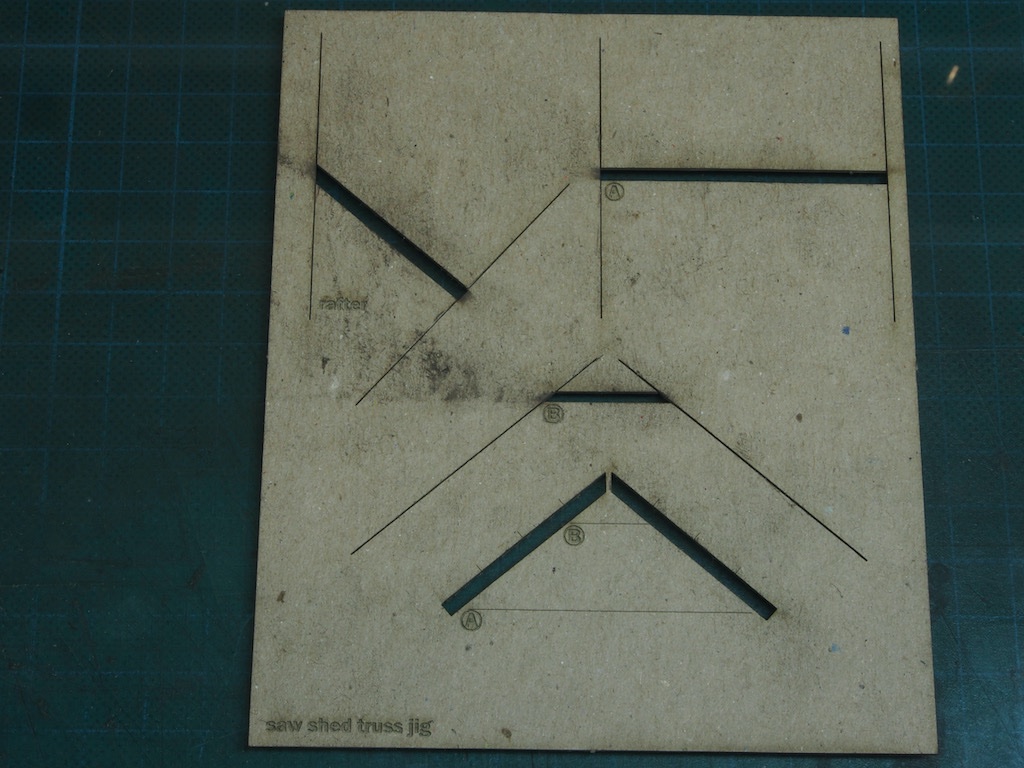

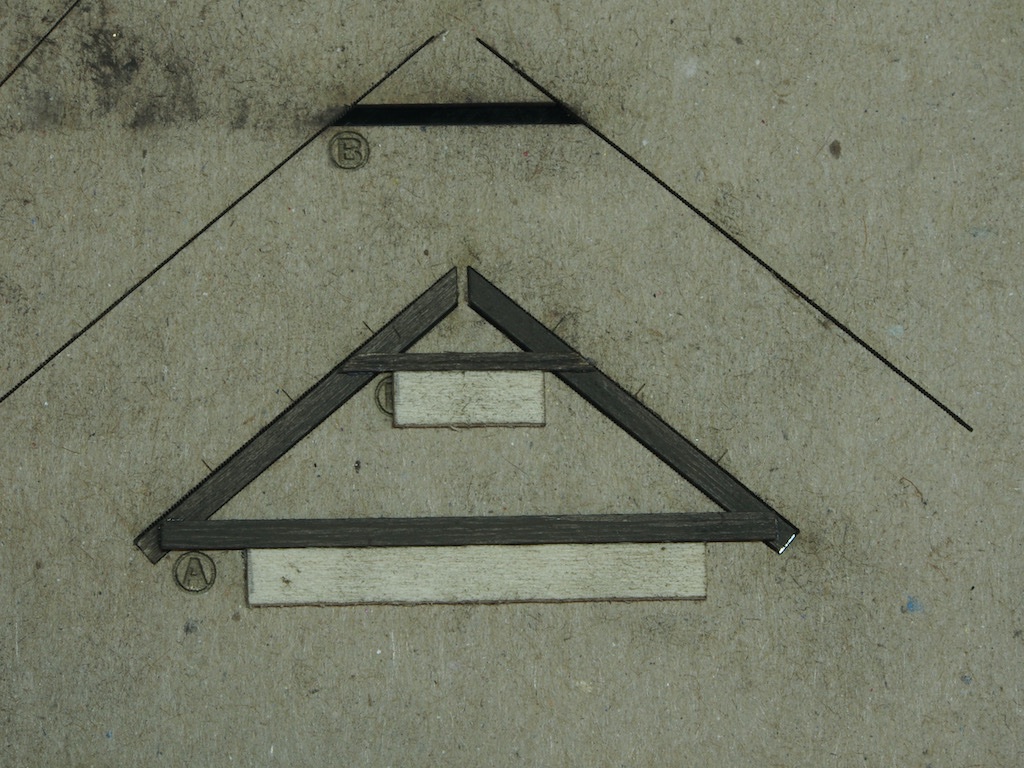

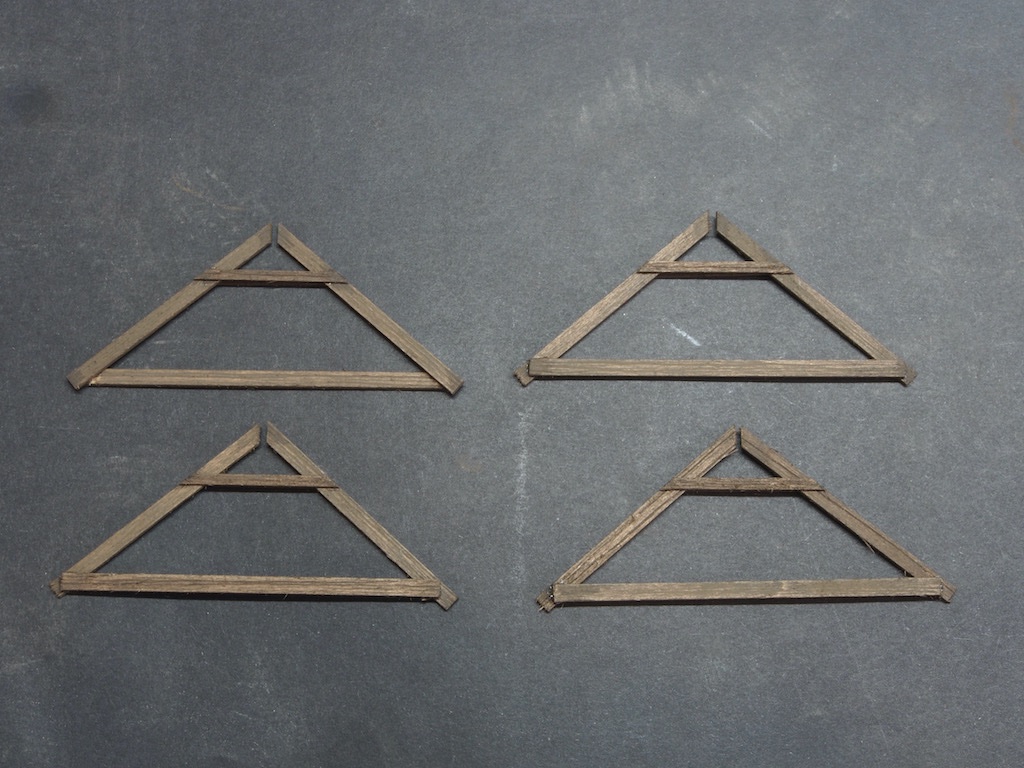

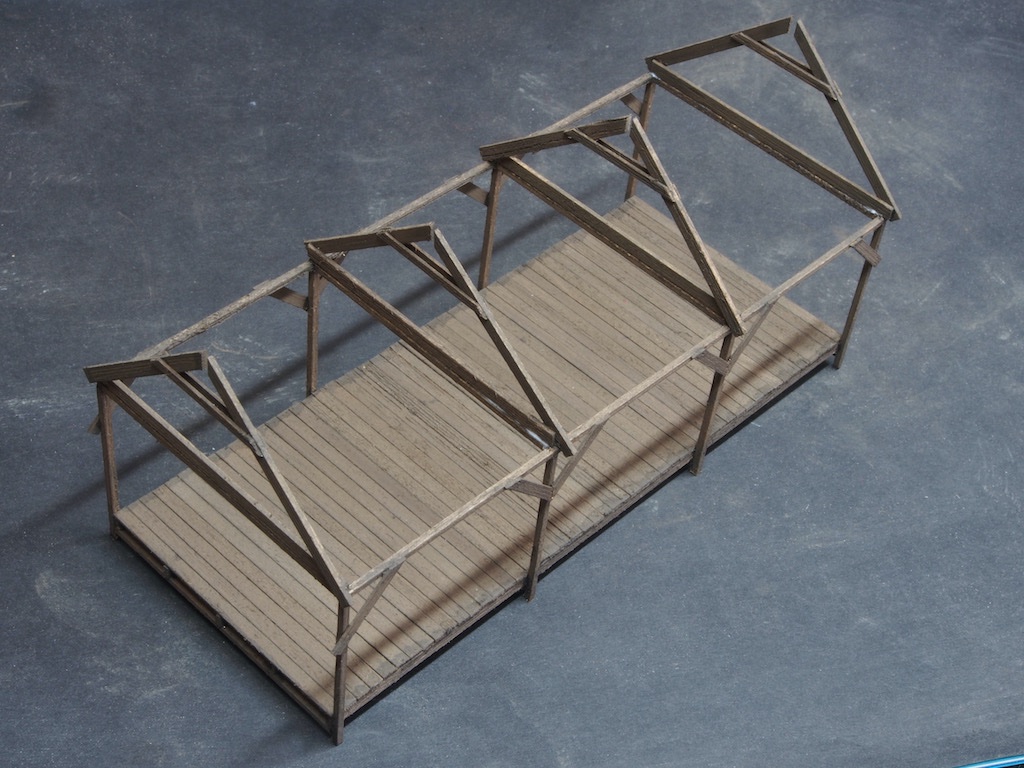

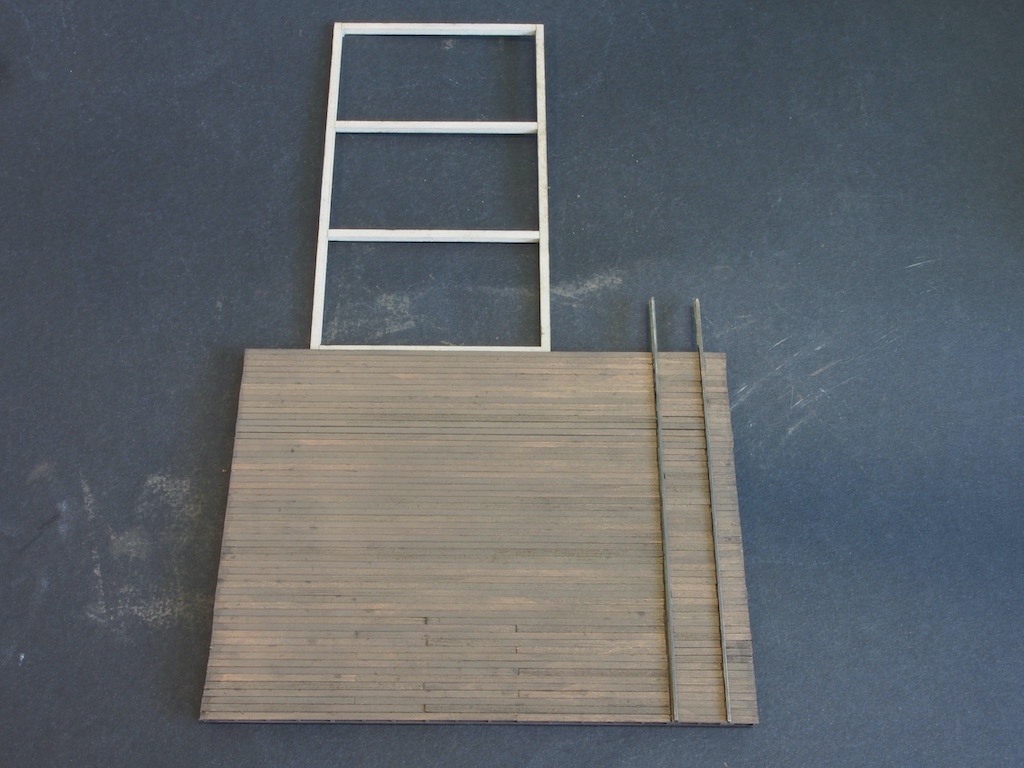

The Saw Shed The Saw Shed is quite a complex build and is very delicate. Ultimately, it will include a great deal of detail – but that’s a little way off just yet… We start with a template upon which we build two identical walls. As this is a destructive process for the template, I scanned and printed two copies so that I could build the two walls simultaneously. As can be seen from the dimensions on the template, the framework is built up from 3/64” (1.2mm) square stock. We start by using some double-sided tape to stick down a scrap-wood straight edge and the four upright posts. Then we add the header and the braces (the braces are 0.020” x 5/64”). A cutting guide for the braces can be seen at the top right the template drawing. The wall is then removed from the template, a floor joist positioned on a fresh version of the template and the wall is glued on top of the floor joist. Cross members are then added to one of the walls, inverted (ie we’re adding the top cross braces). A tricky business to be sure. The second wall is then attached – even trickier…. And the bottom cross braces installed on top of the floor joists (since the walls are inverted, these will be below the floor joists once the walls are turned right way up). The assembly is then turned right way up and the remaining floor joists are added. Decking is then added on top of the floor joists – a relatively simple, though still delicate task. I worked from each end to meet in the middle and cut the last few boards to fill the gap. I have deliberately allowed a few gaps to appear in the decking. Next, we are provided with a cutting and assembly jig for making the roof trusses – a clever and convenient inclusion. A couple of scrap-wood guides are tack glued along the laser scribed lines to ensure that both the lower cross brace and the top brace are positioned exactly right. Once dry, they are removed from the jig and a second top brace is added to the opposite side. Here are the four roof trusses completed. The gap at the top is to receive a ridge beam. The roof trusses are then installed atop the cross members. The glue is still wet in this photo. Once cured, the ridge beam will be inserted. Then we start on the roof and the internal details…

-

Thanks Mark, Paul, Elmer, Alan and Ken. Ken - I’ve been thinking on this issue as I’ve got a few more stacks to put on the other buildings. I like your idea and had been thinking along similar lines myself. The parts don’t actually have locating pegs, so I would have to create some by drilling small holes into their bases and inserting some brass rod. Then I could do as you have suggested. It might be a little tricky to get a piece of wood into the underside of the roof, but I’m sure it can be done. I’ll have a good look at this before inserting any more stacks. Thanks for the input/suggestion. 😊

-

Congratulations Bob, I’m sure Hannah will love it - all the more by being made for her by you.

-

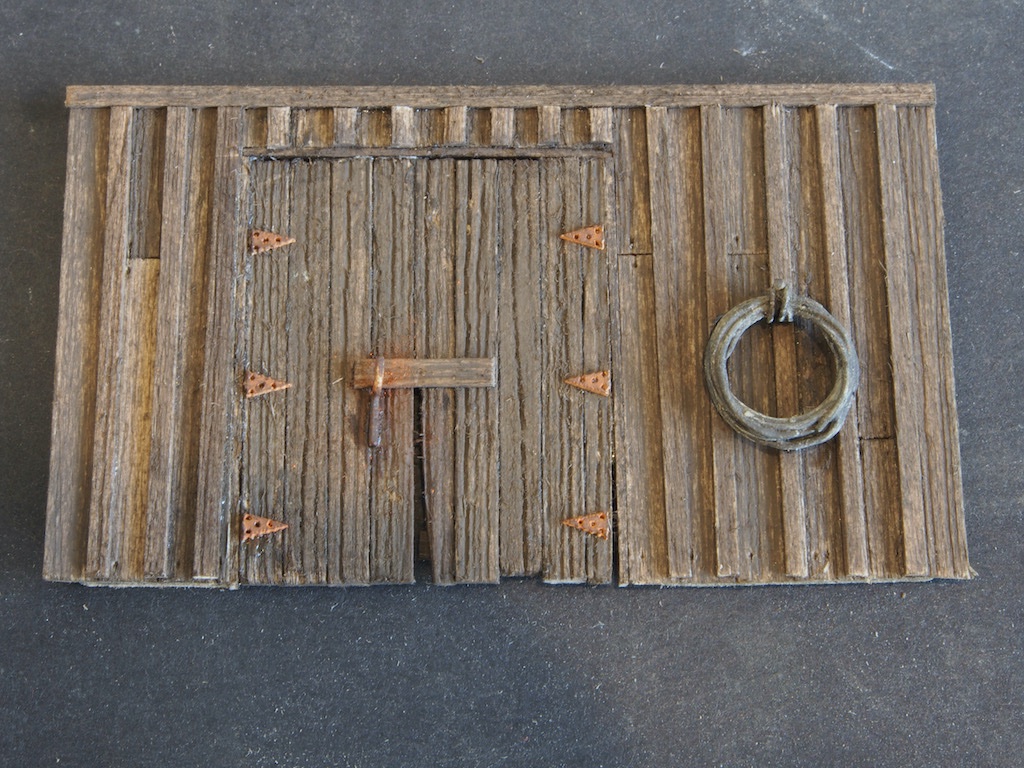

Thanks OC, Ron and Gary for your kind comments, and once again to all the "likes". Moving right along.... The Upper Yard Storage Shed This is another little gem of a building. Its construction starts in much the same way as the Derrick Storage shed just completed. Once the basic walls are completed, a new style of construction is introduced by the addition of thin vertical battens at the join between each plank. The effect is quite convincing. Each of the walls now gets its own level of detail. The Left Wall is left plain, with the exception of the addition of a window (not shown in this photo). The Rear Wall gets some double doors, complete with split boards, rusty hinges, and a locking bar/latch. It also gets a coil of rope that is actually a metal casting – cleaned, blackened, painted and chalked. The Front Wall gets an entry door, a mail box (a resin casting, painted and chalked), and a sign. And finally, the Right Wall gets a window and another sign. The walls are then glued together using the “trap” method as with the previous building, and a tar-paper roof. The roof also gets a stack – another casting that is cleaned, blackened, buffed, and epoxied in place. This was quite tricky to do due to the weight of the metal stack. I literally had to hold it in place until the epoxy started to set up. Here are a few shots of the completed building. That completes the Upper Yard Storage Shed. The Saw Shed is next…

-

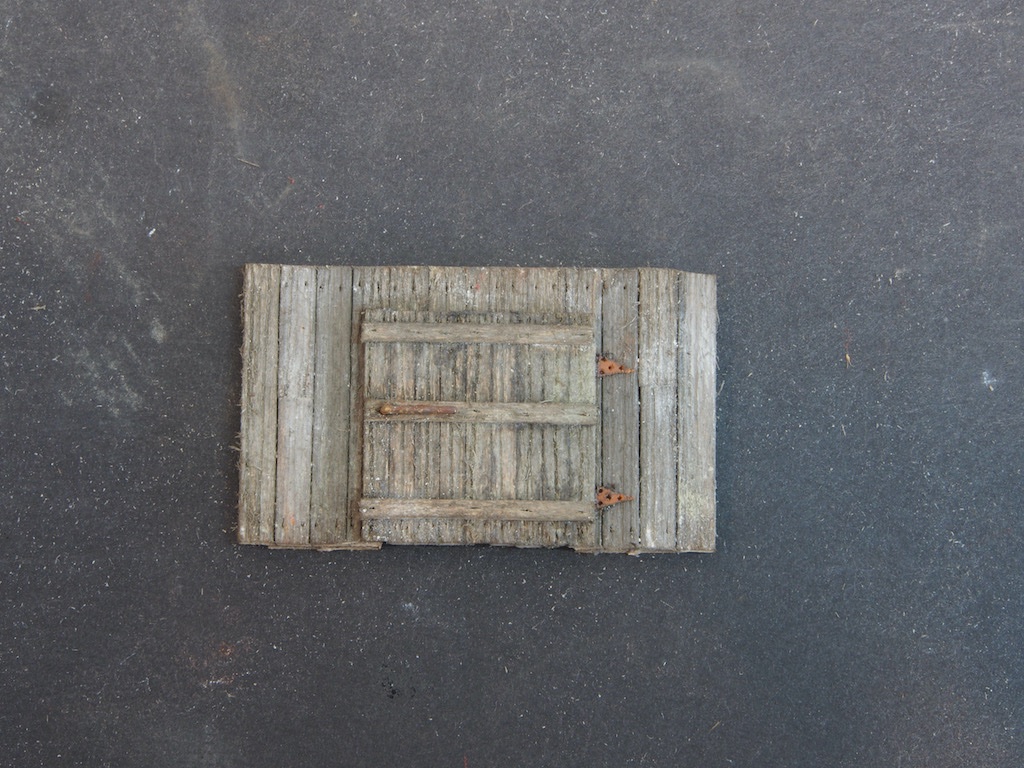

The Derrick Dock Storage Shed This little building is a gem. It is made up by gluing strip-wood boards (prepared as per previous boards, but with a little extra greying to show a more weather-beaten look) over a carboard substrate. However, some clever design here creates a “trap” to assist in gluing up the walls. In the following photo you can see some scrap-wood guides tack glued in place along some scribed lines. These will help to form the “trap” on the front and rear walls. In the lower part of the picture, strip-wood boards are being glued over the side walls. Here are the completed walls. The front and rear walls are upside down to show the “trap”. A door has also been constructed for the front wall, complete with rusty handle made from a tiny piece of brass wire. Here is a shot of the completed front wall, with door in place and rusty hinges added. The hinges are laser cut board that have been painted and then dusted with rust-coloured chalks. The building is then assembled and the roof added. The roof is made up with some “tar paper”, this time grey in colour, and with some light streaking added once in place. Some additional interest is added by placing some detritus on the roof. Here I’ve used some scraps of wood, a coil of rope, and a couple of chain links made by bending, soldering and blackening some brass wire. And here is the shed placed temporarily on the Barge Derrick Dock to give a better idea of scale (it really is tiny!). The Upper Yard Storage Shed will be next…

-

Thanks Ron. No, I have never done a FSM kit. I'm not actually a railroad guy - I'm just doing this kit 'cause it looked really cool! I can certainly recommend the Sierra West kits. They are top notch quality and the instructions are first class. They are also well supported with their own forum and the kit designer/producer provides first class after-sales support and will look in on any build logs on that site to offer encouragement/advice along the way. He has also recently introduced 3-D printing to replace some of the castings in his kits. And yes, every single one of his kits would make an excellent stand-alone diorama as well as being part of a railroad layout.

-

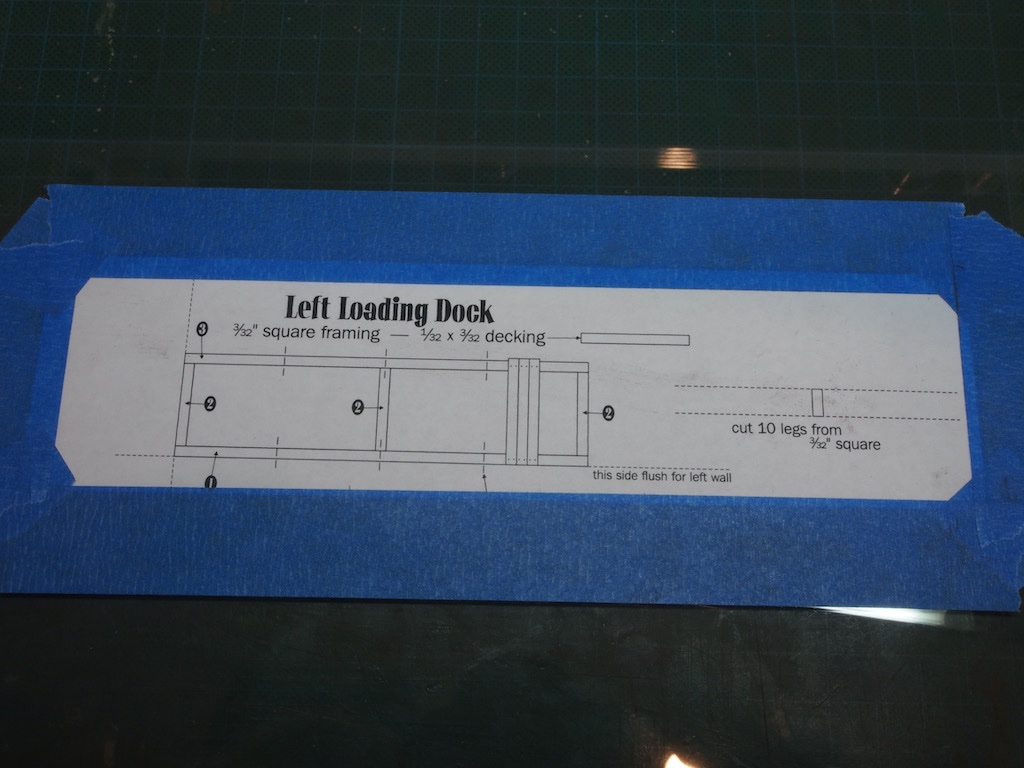

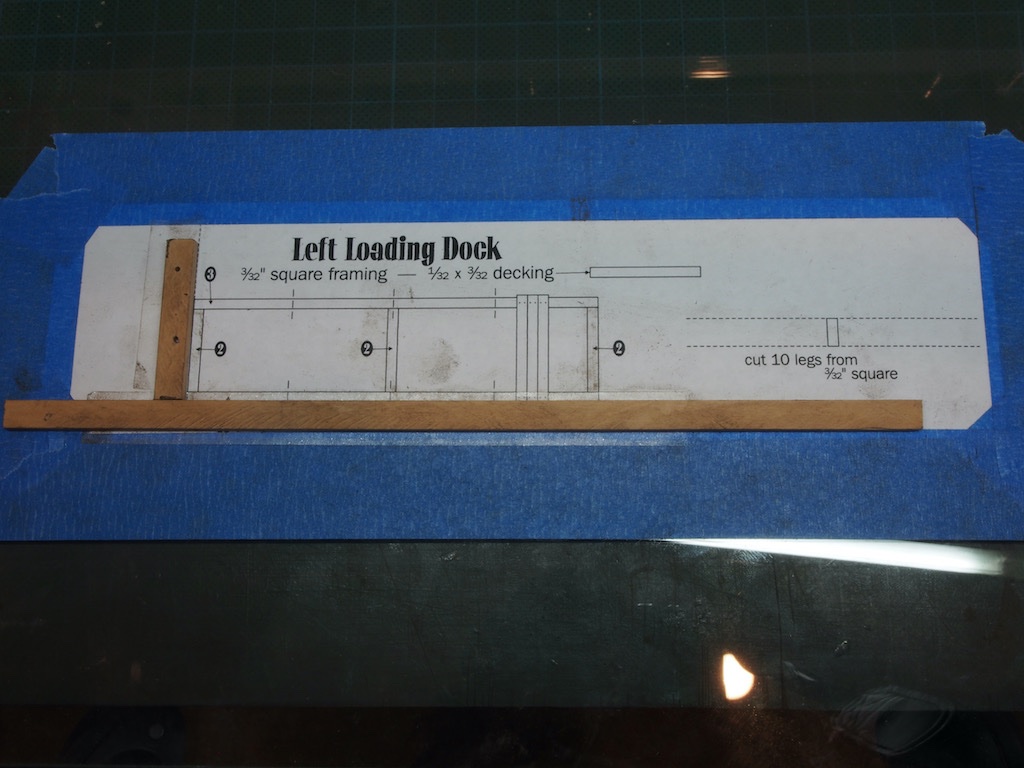

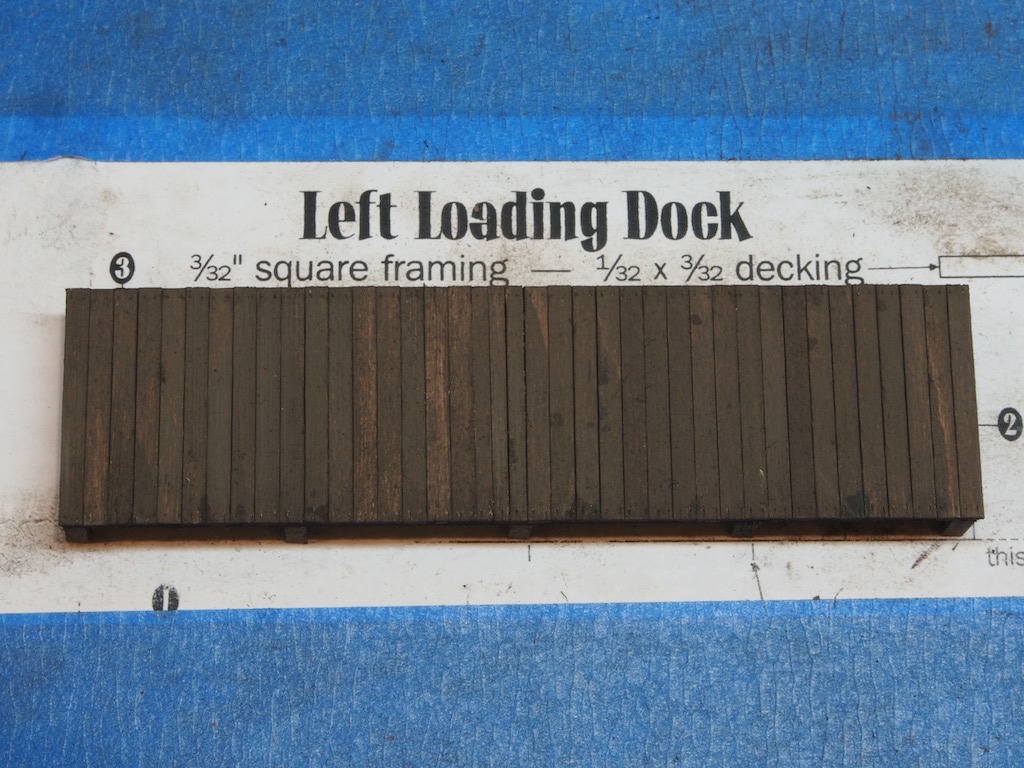

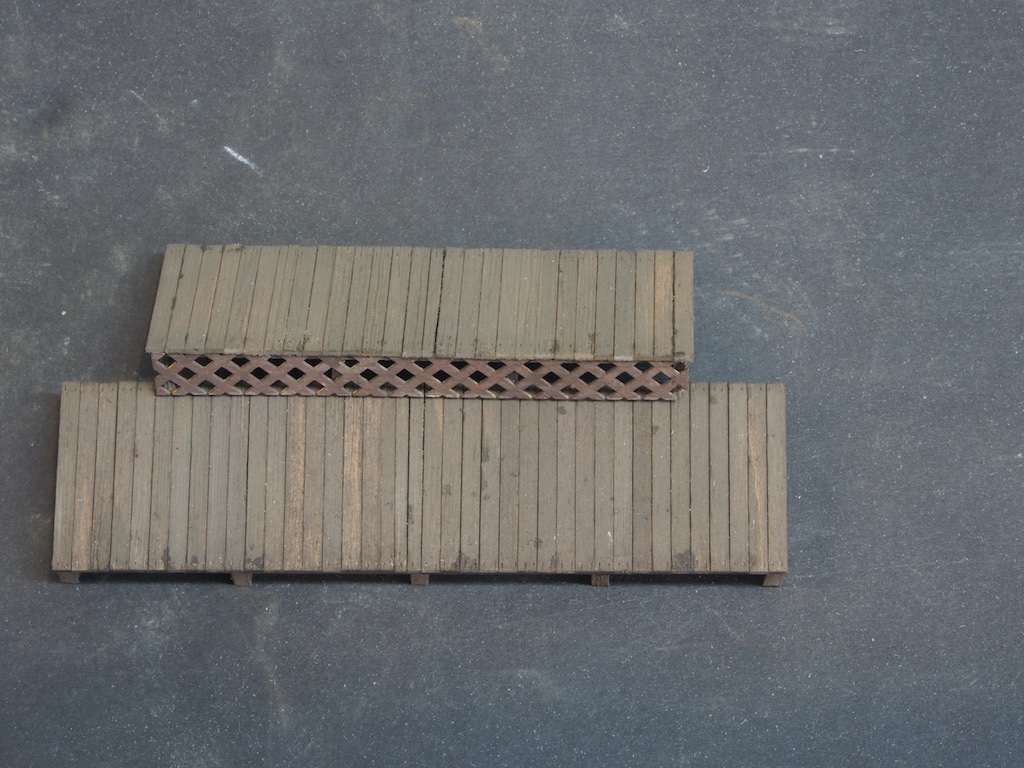

Thanks very much Elmer and Ken, and also everyone for the likes. I'll add a little more "soot" to the Chimney prior to installing. In the meantime … The Loading Docks While waiting for the additional shingles to arrive, I have made progress by constructing the Loading Docks. These are all made in basically the same way, with a couple of variations. All the docks have a paper template that the dock is built directly upon. Here is the Left Loading Dock template taped down to my glass plate and ready for action. Some guides made from scrap wood are then attached with double sided tape and the frame is built up. The decking is then added and nail holes applied before giving the deck a final light wash with the black ink/alcohol mix. Finally, dock legs are cut to length and attached to the underside of the frame. The Right Loading Dock is made the same way, only this time some bracing is added to the legs. The Barge Derrick Dock is similar again. A hole is left un-planked to receive the derrick later on. The legs under the larger left-hand end of the dock also receive some barnacles around their lower sections. These were represented by a mix of three different shades of ballast. The Sales Office Porch is once again constructed in the same way, this time with the addition of some lattice work. (Propped up on one of the other docks in this photo to show the lattice work.) The Main Dock, together with the Foundations for the main buildings are constructed at the same time in the same manner. In this photo, the framing is complete along with a series of joists for the Main Dock. A staggered "shift of the butts" was used on the Main Dock decking, except where the Dock will be covered by the main buildings. The Main Dock also receives a set of railway tracks as part of the construction. I couldn’t source separate track easily, so I bought some FlexTrack and “deconstructed” it to remove the tracks from the plastic ties. I also blackened the tracks to remove the bright brass look they came with. That completes the Loading Docks. We now move on to some more of the out buildings….

-

I somehow missed the start of this build Glen, but I’m caught up now. Fantastic project and a great start. Re separating the nail heads, just wondering if you could reverse the application - ie, hold the nail spinning in the rotary tool and bring the cut-off tool to the nail (much like using a lathe). The cut off part would then tend to drop off rather than being flung around the room.

-

Looking good Bob. What are you going to do about sails? Are you going to use the kit provided material or make your own? I would recommend having a go at making your own using silk span - it’s really not that difficult to do.

-

Great work so far Bob. And yes, it’s a very tight fit to get it into the bottle, so grinding a little off the keel is a good idea.

-

Making brass parts chrome

gjdale replied to John Ruy's topic in Painting, finishing and weathering products and techniques

I’ve used both the plating method using the Calwell system mentioned above, and the Molotow liquid chrome. Both work but the Molotow would be less expensive. If using the Molotow, I would recommend buying a “refill” and then spraying the contents through an airbrush - it sprays beautifully with no thinning required. Be aware though, that the Molotow will not stand up to handling - it needs to be left alone for several days to a week, and then handled the minimum amount possible. I do not know of any top coat that can be used without dulling the shine. I used the Molotow on plastic parts of my Pocher car model. I used the Calwell plating system on the scratch built brass parts of my Dumas Chris Craft model. Being RC, this model gets handled a lot more. I was happy with both results. -

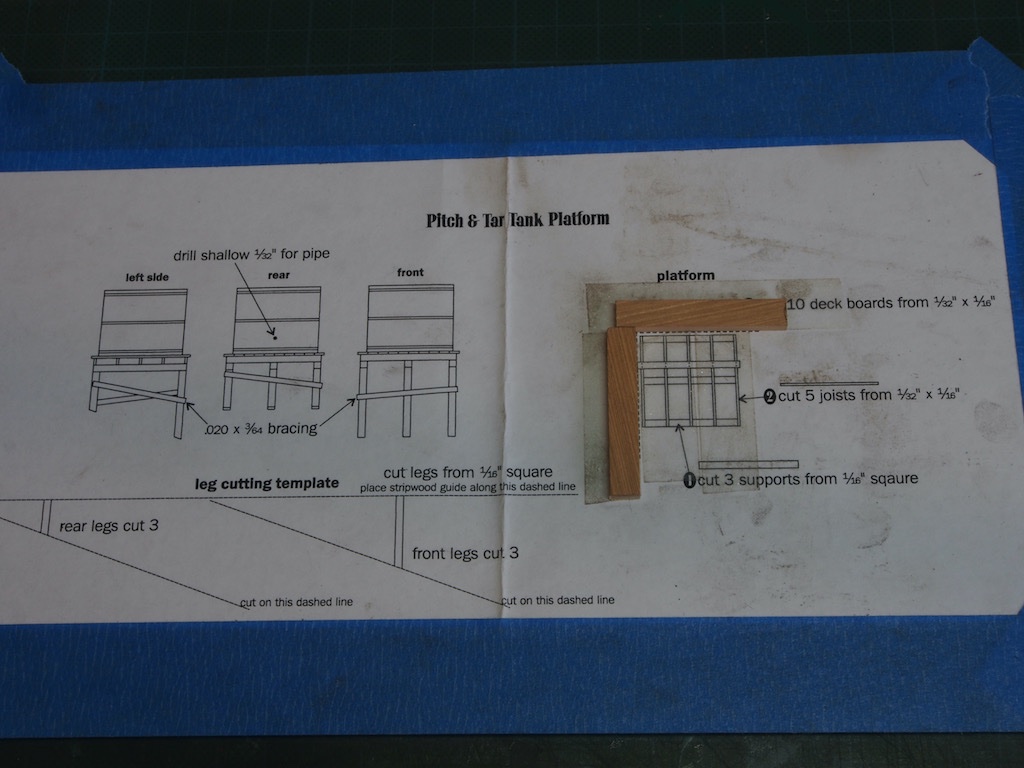

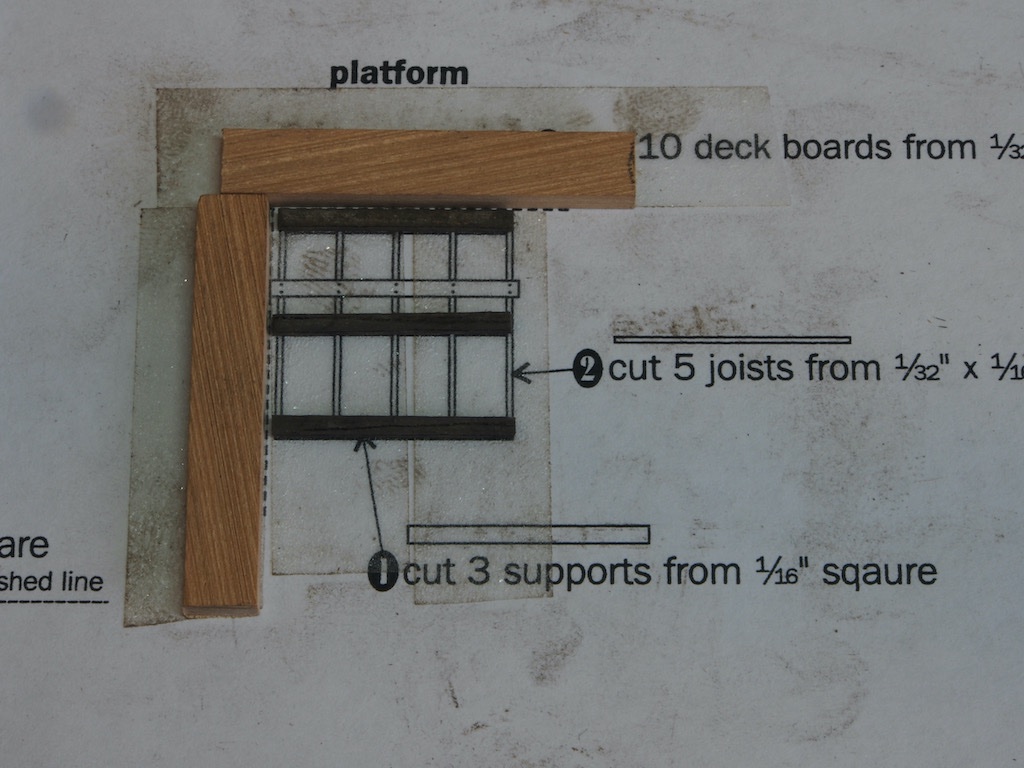

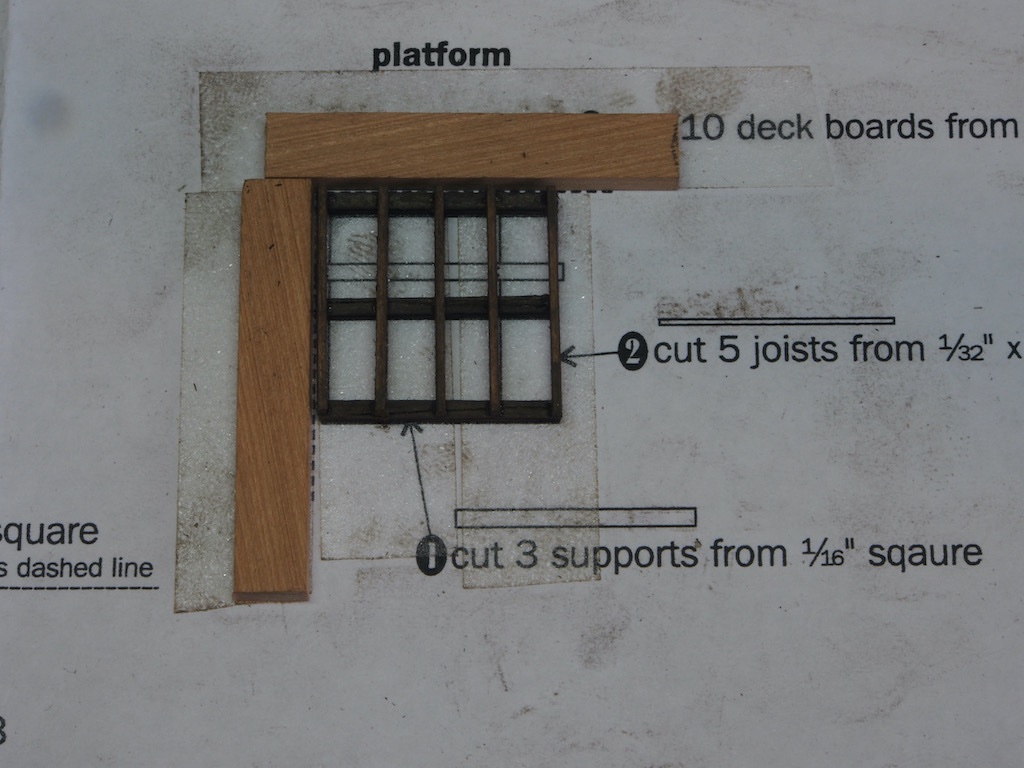

Thanks Gary. Details, details, details… While waiting for the additional shingles to arrive, I have begun work on some further details. First up is adding the Pitch and Tar Tank and it’s platform. A 1:1 scale drawing is provided as a template upon which the platform is built. A couple of scrap wood guides are first attached to the template with double-sided tape. Three support beams are then cut to the size specified on the drawing and these are also attached to the template using double-sided tape. The five joists are cut to size and glued atop the support beams. We are then instructed to cut 10 deck boards from the 1/32” x 1/16” material. As can be seen from the first picture above, the drawing shows these 10 deck boards in place. The only problem with this is that the completed platform measures 7/8” x 7/8”. 10 deck boards that are each 1/16” wide are only ever going to cover 5/8” (or very slightly more allowing for a little size variation and potential small gaps). In the end I needed 13 boards to fill the space, with the last one trimmed back a little. I checked the size of my completed platform against the drawings, and it matches these. It is also a good fit for the size of the tank. No big deal, but there is definitely a discrepancy in the drawings/instructions/materials here. Anyway, once the platform is completed, some bracing is added to all sides. Here is a picture of the completed platform. The Pitch and Tar Tank is a resin casting. This is our first foray into the plethora of resin and metal castings included in the kit. It is prepared by painting a light undercoat and then dry-brushing a darker brown over the top. It is then given a dusting of dry chalk powder to finish. Subsequent to this photo being taken, I decided to give the entire tank a dunk in my Alcohol/Ink mixture and was quite pleased with the result. Here are a couple of pictures of the completed structure in place atop the Warehouse roof. Note also the addition of support blocks around the platform legs. Prior to final placement, the metal pipe was prepared, blackened and attached to both the tank and the roof. As with previous metal fixtures, black paint was added to the epoxy glue to represent tar and pitch where the pipe enters the roof. It has yet to be finally finished off with some chalk to dull it down a little further. The Chimney and Stacks for the other roofs were then prepared. These are all white metal castings. With the exception of the Chimney, they are simply cleaned, blackened, polished, and dusted with some grey chalk powder. The Chimney itself has a multi-phase preparation. An undercoat of AK11007 (Rock Grey) is used in place of the Pollyscale Concrete called for in the instructions. This represents the mortar between the bricks. AK 11087 (Scarlet Red) is then used in place of Floquil Scarlet Red and dry-brushed over the top. The aim is to colour only the bricks, leaving the mortar seams untouched. This project has been my first real attempt at the dry-brushing technique, so I’m learning as I go. From normal viewing distance I think it looks okay – the macro lens of the camera is a little brutal though. The top of the Chimney is painted with AK11021 (Basalt Grey) in place of Floquil Grimy Black and finished off with a dusting of black and grey chalk powders to give a “sooty” appearance. All of these parts, except the Pitch and Tar Tank pipe, have now been set aside and will be fitted in place once the Yard Master’s Office roof has been completed and that building attached to the Warehouse front. Next up, I’ll be starting work on the loading docks…

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.