-

Posts

1,667 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Ian_Grant

-

-

18 hours ago, Kevin-the-lubber said:

The constitution is on my list, along with the cutty sark/Thermopylae, in fact I came close to buying the latter this week as something easier and quicker to do when I need a break from victory. The constitution seems very hard to get hold of here in the UK and ridiculously expensive for a plastic kit. However, what you’re suggesting sounds like a decent plan. Personally I’ll probably take liberties when I come to this stage, as I’m going for appearance over accuracy. It’s weird, isn’t it, that Heller took the trouble to make what is generally seen as the finest plastic large scale age of sail model, but did such a shocker of a job on the instructions. And no-one would bother writing a step by step guide for re-sale now, as they’d be pirated within days.

I built both Revell kits way back in the 70's; they're still sitting in the shipyard but very dusty and pirated for parts. I think the Constitution is regarded as the better model of the two; the Cutty Sark has weird issues like the deck caulking lines are proud of the planks not recessed, or the lower mast deadeyes (at least as supplied in my 70's model) are molded with lanyards that span about 8 scale feet !?, or the bow and stern decorations are simple decals with no 3D "presence" (again, at least in my 70's kit).

The Constitution is pretty good, except for the yards being just magically glued on to the masts with no parrals or lower yard truss pendants. And both models come with those molded "rubbery" shroud/ratline assemblies which I would not use again personally....

-

Bill, looking good! If the bitts behind the main mast aren't glued, you might want to drill some sheave holes at the base of the uprights in order to rig the three pairs of ropes passing thru the quarterdeck here sensibly.

Also, those little pillars are easy to knock off as you slide the quarterdeck into place. If they're not glued already, they're easy to add afterwards, and then you know you're lining them up with the skid beams properly.

-

On 9/4/2021 at 3:36 AM, Kevin-the-lubber said:

Does the kit have that 'main sheet block bracket' he mentions, Fig 55, that keeps the block clear of the hull? I don't see it in the instructions.

(Like I said, at this rate you'll be rigging by Christmas!)

No that bracket is not provided. You either believe it was there (see Dafi's recent posts here) and make one, or ignore it and put the block just on a long strop to the eyebolt.

-

22 hours ago, Kevin-the-lubber said:

Sorry Bill, I'm confusing the issue, I was looking at the wrong area of the hull and in any case was wrong. I'm pretty sure all of those rectangular slots are for the chain plates. I was thinking of the angled, oval shaped slots as I've seen ropes running through these in build logs but having just gone to the workshop see there is only one of those in each side whereas I thought there were more.

I think this is why everyone seems to say ignore the instructions for rigging and use e.g. longridge to figure it out. Myself, I think when I get to this stage I'll dry fit everything to the hull that has to go on, see what holes remain unused, and just try to logic out the rope lines.

True, you cannot do better than Longridge. He spells everything out clearly and succinctly, rigging line by rigging line.

-

BIll, you have it routed correctly, but to make it easier I would glue in an eyebolt for the standing end of the sheet (as in Longridge's diagram) instead of running this end of the thread through the hull. If you carry on as is, you will need to predict the exact length of thread you need to get the sheet block in the correct location be it with or without sail; if you add an eyebolt you can make the thread longer than needed, store it in a coil dangling from the hull, then when the time comes rig it and tie off the end.

EDIT: Sorry, I was away a few days, logged on and saw your original question about the main sheet and answered it without realizing there were all these interim posts.

Yes, many of the rectangular holes are for attaching the channels, which hold the lower deadeyes.

As for the main tack, after it emerges from the hull just below the big deck chock for the sheet anchor it passes through the sheave hole in the chess tree just aft of it (Longridge pg 252 "Tack"). See below, which shows the main tack and fore sheet crossing each other in this area. Again, I would add eyebolts as shown to make them easy to rig later.

On my model:

On the 1:1 model:

-

I don't recall butt-joining things like stag horns and bitts onto bulwarks or decks, but I think all the masts and spars lacked guide pins too rather like the cannon barrels.

My current Preussen kit has the same lack of "tenons" let's call them. Especially irritating was the tiny dolphin striker which was to be butt joined to the bowsprit; that would never have held. Same with the support stanchions for the boat skid beams. Must be a Heller tradition. On the other hand, though, all the kit parts fit well.

-

Bill, she looks great! I like your weathered deck painting. I seem to recall being at step 9 for several months but you look likely to finish it in days. Remember BEFORE you glue in the quarterdeck that there are not only the lower sheets and tacks to attach to parts 41 & 100 we talked about already, but also lines to tie to part 89 (mainyard jeers, main topsail sheets, mainsail clew garnets; see note near top of pg 267 in Longridge). Regards, Ian

-

-

-

As Marc said, the centre head rail curls around this roundhouse corner and sweeps up to become the cathead support. What you are seeing is normal.

-

Ted, great questions! When I did my Victory, I saw a photo of someone's model with the fore jeer falls coiled in tight eliptical turns, and frapped, lying on deck fore-and-aft on each side of the mast between the bitts. I did the same, but I did not coil a realistic amount of thread for the function...

Neither did I coil realistic lengths for halyards and cat falls. Don't know how they handled it in reality. Raising anchors is not frequent - could they have long-spliced an extension to the catfall when needed? I don't know.

-

On 8/26/2021 at 4:03 PM, JKC27 said:

Roger, for those hatches I'd be sorely tempted to get some 3D printed parts especially as there are so many of them and the eye would be drawn to any differences between them. You could draw them with all the flanges and gussets in TinkerCAD, which is free and can be learned in a day for such simple shapes. With your .stl file on a memory stick, you could get them printed at any 3D CAD shop assuming you don't have a printer.

- thibaultron and mtaylor

-

2

2

-

On 8/22/2021 at 8:33 PM, Bill97 said:

Dogged determination or needing to be on medication! 😀

By the way where did you go camping 12 hours from Ottawa? Sure it was beautiful.

Bill your copper looks great!

Drove over to Lake Superior, a little past Sault Ste Marie. Pitched the tent at Pancake Bay Provincial Park and explored around there and in Lake Superior Provincial Park. Beautiful area; hadn't been up that way since 1992. Lovely lookout views by hiking, and even canoed in Lake Superior off Agawa Rock (waited for a VERY calm day 😉).

Later Edit: Forgot to mention that we were amazed at all the trees around Sudbury now - in 1992 hwy 17 bypassing Sudbury was completely barren, bare rock due to 70's acid rain. Great to see nature taking over again, and isn't life tenacious? Sorry to go off topic, but Bill asked! 😁

-

8 minutes ago, Bill97 said:

Spending a lovely Sunday relaxing and applying copper tape to my hull. I wanted to add the appearance of nails to the copper but I do not have one of those handy dandy roller tools Daniel had when he did it so I am doing it the old fashioned way. Push pin one poke at a time (12 pokes per plate)! 🤪

12 pokes per plate............God, you have dogged determination. 😲

- Jeff T and Old Collingwood

-

2

2

-

A72 is the main sheet. Pass a thread through the sheave hole in the hull and rig the inboard end to the staghorn on the maindeck bulwark. Then coil the excess outside until needed. You'll need enough thread to go from the sheave, through the block mounted on the hull, up to the main yard if rigging without sails, or to the clew of the mainsail if included, then back down to an eyebolt on the hull. When you do come to rig it, just pass it through the necessary blocks and tie the standing end off at its eyebolt.

Again, the Heller instructions are best employed as a spur to make you look up the real answer in Longridge. The best illustration of this particular area is Fig 56 on pg 95. Longridge has the mainsheet block rigged with a little bracket; there are existing photos of the block just attached to an eyebolt. Take your pick; I made a little bracket just because it seemed better than the block banging against the hull.

-

No, just drill and glue in the eyebolts and rig the shrouds later.

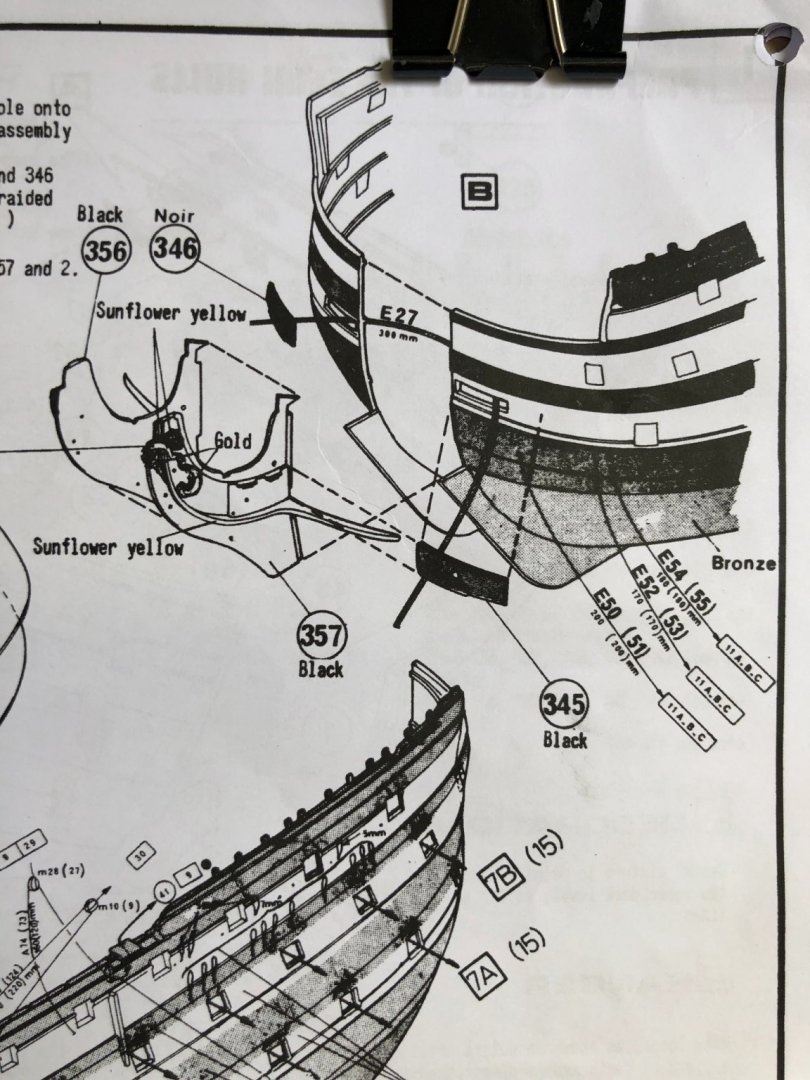

The lines you do need to add before you glue in the quarterdeck are the main sheet and tack, and the fore sheet (A72, A74, and A125 respectively on Heller pg 6). These all attach to staghorns on the maindeck bulwarks, part no. 41 and 100 (see heller pg 7). These lines should be passed through the holes in the hull, coiled on the staghorns, and the excess left coiled outside the hull until needed (years in my case, probably months in yours 😁). But you have a ways to go before you need to worry about them.

-

11 hours ago, Ian_Grant said:

Bill; yes, plate 71 is not too helpful. But plate 74 shows the two starboard shrouds emanating from the hull eyebolt(s) just behind the lower edge of the cheek, below/ahead of the first lower deck gunport. You can just see the lines heading up to the right, towards the bowsprit. Note that text on pg 226 says two eyebolts for the two shrouds but this picture seems to show both hooked to a single eyebolt. That's what I did.

It's too dark in this image to see what happens at their other ends. Fig 118 pg 187 shows the two hearts on the side of the bowsprit to which the shrouds attach. As the text pg 226 states, each shroud has a heart on its end, these hearts being lashed to the bowsprit hearts with several turns.

Bill, I made a mistake in my earlier message; had just completed a 12 hour drive back from a camping trip. Where I mentioned bobstays I meant shrouds, corrected in red above. Sorry for the confusion!

I believe E50 is a Hellerism. They probably thought there should be the same number of shrouds as bobstays, however Figure 118 shows there is no shroud pair at the outer bobstay. Model on!

-

On 8/17/2021 at 11:43 AM, Bill97 said:

Ian back in my blog, comment #202 you explained the rigging of the Bowsprit Shrouds. You suggested I ignore the Heller instructions and refer to Longridge’s book. I did that and found the paragraph on page 226 as you said. However I am still a bit stumped. I am hoping to find an illustration in the book that shows what I am to do. Do you know if there is one? It says Plates 71and 74. But I am not finding anything there.

Bill; yes, plate 71 is not too helpful. But plate 74 shows the two starboard shrouds emanating from the hull eyebolt(s) just behind the lower edge of the cheek, below/ahead of the first lower deck gunport. You can just see the lines heading up to the right, towards the bowsprit. Note that text on pg 226 says two eyebolts for the two shrouds but this picture seems to show both hooked to a single eyebolt. That's what I did.

It's too dark in this image to see what happens at their other ends. Fig 118 pg 187 shows the two hearts on the side of the bowsprit to which the bobstays attach. As the text pg 226 states, each bobstay has a heart on its end, these hearts being lashed to the bowsprit hearts with several turns.

-

That's true - with high thrust I could shorten the loom of the oars and achieve a full sweep in less distance hence less time. Might need carbon fiber oars though, to handle the stress point at the thole....😁

The US$100 linear 3050 moves 1.2" in 1 second with 6.8 lbs thrust. That's about what I'd like to achieve as a highest "ramming speed" sweep time. I could set the loom length such that 1.2" gives the full sweep. As a bonus, shorter looms reduces internal width of machinery which increases space for the battery and ballast along the keel.

On the other hand a CDN$60 Futaba FUTS3305 dual ball-bearing high torque servo provides 7.7 lb-in and moves in half the time. Not that I need any faster, but assuming I get 120 degrees out of the servo a 0.7" arm would give me 1.2" of sweep at 11 lbs thrust.

Some study required to find the best solution........🤔

-

Some slight progress to report: Components received from Digikey and soldered onto Arduino daughter board. It took me a while to find a layout which best takes advantage of the copper connections on the board. I included four fuses to protect the oar servos; optional jumpers to bypass each fuse (for the demo jig if not the actual ship); a quad DIP switch for future contingencies; a little decoupling for each servo supply. The large DIP header is for battery supply for servos, which is independent of the Arduino +5V rail. A 9V battery will supply the pittance of current required by the Arduino (which regulates down to +5V) as well as the RC Receiver, via its servo connection wires to the Arduino.

I have not yet soldered hook-up wire to make the connections; that will have to be after we return from camping up by Lake Superior next week.

-

Hi Bedford, thanks for the idea! Yes I saw linear servos on ServoCity's web site before. What put me off were the prices on their only Linear Servo line at the time: US$300 apiece!!!!! 😒. Plus they need 12V. That said, you are right even this small demo jig is very noisy! If I can convince myself that this thing is feasible I will take another look at these new Hitec linears, at least for the sweep motion. I think I am limited to rotary for the up/down motion just because of space limitations in the proposed hull. One thing I do notice in the video, though, is that they're quite slow.

I have just screwed the servos down on the jig, without the little rubber mounting pads, so perhaps the entire assembly is acting like a piano sound board? I must add the rubber in and see if the noise reduces. Perhaps an actual hull would muffle it somewhat? Perhaps I could enclose them in a padded waterproof box using those rubbery pushrod doo-dads you pointed out earlier?

-

-

Hi Bill; thanks for reminding me of this model ship collection. I did go there once a few years ago when we were passing through (used to take the kids to the nearby "Prehistoric World"), but it was closed. I since forgot about it. I see it is closed for the entirety of 2021 too 😞. I have also been meaning to visit the Thompson model ship gallery at the Art Gallery of Ontario in Toronto, but haven't been yet. Toronto is not a place I go to for pleasure, having grown up there 40 years ago and seen traffic explode since.

http://www.ago.net/thomson-collection-ship-models

In other news, I see I missed the visits of the "Theodore Too" tugboat along the St Lawrence and lake Ontario on his way to a new berth in Hamilton. Many years ago we took our son on a road trip to ride in "Thomas the Train's" passenger cars in the railway museum in Strasbourg Penn, and then we saw "Theodore Too" in Philadelphia. Fun times 😀. Plus dad got to see "Moshulu".

-

Well, ahem, no, only the port side is seen at present. Suppose I could turn it when occasionally removing the case for cleaning.

I kept the extra cannons in my parts box, for who knows what future use?

Those wires are for making the gunport lanyards; see pg 15 near the right margin. They expect you to cut them to perfect length and glue the ends🤪.

I didn't use them.

Frigate Commander; non fiction, Napoleonic War period

in Book, Monograph and Magazine reviews and Downloads. Questions and Discussions for Books and Pubs

Posted

While searching for this, also came across "Commander" by Stephen Taylor. This is about the real-life Edward Pellew and his exploits in "Indefatigable". Obviously I have not read it, yet, but it seems highly rated.