-

Posts

1,716 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Modeler12

-

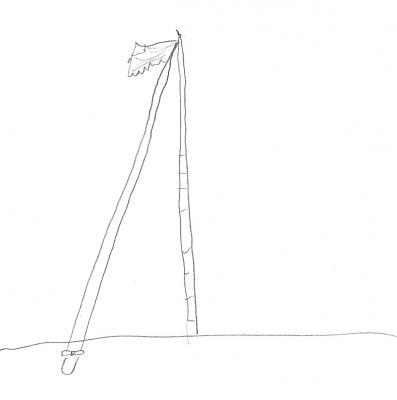

Coming from a young salt, thank you. Here is a view I don't hope to see again. It is 'pre-main-shrouds'. The lines from left to right are the two lines of the flag halliard, the royal backstay, the topmast backstay, and the four lines for the topgallant halliard (belayed as shown). I may still make a very small coil for the flag halliard. I'll do the same on the starboard side and then do the shrouds (I think).

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Graig, Actually making these coils was another interesting project. I made a video and if you fast forward towards the end you can see how I did them. I am sorry about my shaking hands, but I am not very good in front of a camera. Here is part of the collection. My first attempts were horrible, they are the ones towards the left top.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Since this is still my log, I would like to add another 'trial'. It is my first attempt to include some coiled rope on the belaying pins. This is along the bottom of the mizzen mast and along my 'bad side'; the port, where I make my first trial runs. I mentioned making coils before, but now I want to see what I can do with them. They are pre-made, not perfect, but so is life aboard. I am procrastinating with tackling the main mast shrouds, I know.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Great and thanks Henry. I hope one of the moderators is watching this and perhaps this part can be moved to a more appropriate place. To me the above comments are neat and this is probably interesting information for a lot of other folks. BTW there are several other threads talking about flags. Your search on top.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Great work!!! Where did you get the sailors, Peter? If you painted them, what kind of prep and paint? They really add a touch of scale and mean a lot more when you take pictures. Keep up the great modeling.

- 431 replies

-

- pegasus

- victory models

-

(and 1 more)

Tagged with:

-

Just for the heck of it, I happen to brake a drill (some day in the past) but continued drilling holes in wood with the stub that was still there. The holes were ok for what I wanted. But . . . I would not do this drilling any kind of metal. That is when a sharp drill (and a bit of lube) is necessary. PS. have you ever 'drilled' a hole in wood and have that turn into a black smoke? Especially with a high speed like tool? It is probably because of the same problems Anthony had. Buy cheap, work cheap.

-

Jud, if I am not mistaken, signal flags and what I was referring to are different. Signal flags do not go to the top of the mast. They would be coming down from the foremast jack, or some other place that is more adaptable to making changes. Help me here, someone.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Henry, that was more than I expected, and a great story. I was looking at the a previous post http://modelshipworld.com/index.php?/topic/1447-where-do-flag-halliards-go-deck-or-top/?hl=flags. It had a lot of good information, but don't see the 'admiral coming aboard' thing. It had to do with quickly raising the admirals flag as soon as he steps aboard. But your personal experience is always appreciated. I am still thinking of having 'the admiral' flag flying by the time I get this lady finished.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

So, what happens Henry? Does someone have to climb up there to untangle the ensign? I recall you were the one who suggested that the halliard should be aft of the backstay. You also had an interesting story about raising the admiral's flag when he came aboard. Mind sharing that again? Sorry the camera focused on other lines rather than the flag halliard. But you get the idea in this picture.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

I think we can all appreciate the problem you are having with the company that supplied those drills. Most retail stores here in the US have a standing policy that they will refund or replace items that are not satisfactory or defective. It may even be a law here. About two minutes after I read your post, Anthony, I had a telephone call from Floyd Warner in Utah. He apologized that he could not fill my order of wooden blocks right away because he ran out of the 4mm double blocks that are part of the order and needs to make some more. My point is that here is a guy that really appreciates his customers and tries his best to satisfy them. Do you think I will order more blocks from him in the future? Besides his blocks are much better than those square monsters that come in most kits, etc.

-

Here is a simple one that I almost fouled up. It involves the flag halliards. In order to raise and lower a flag from the mast or where ever it might fly, the halliard should be a continues loop. It should be fastened to a cleat, not a belaying pin, and the two lines (although one loop) should be parallel and not twisted. It was the latter that was a bit tricky because the lines kept twisting together when I took them to the cleat. It is hard to see with a photograph, so I made the crude sketch below. In order to keep them separated and look better, I kept the two apart when they went around the cleat rather than gathering them together. I know this is not important, but I thought it worth mentioning.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you guys. Indeed to stand back so once in while and look at what I have done the last couple years is ok. I feel like going on right now (which was not the case a couple months ago). But Alistaire, I know that I have a long way to go yet. After the shrouds are in place on the main and foremasts, I still have to rig those two topsails. Then there is the issue of the netting on top of the rail, the davits for to boats and the four boats themselves. Unlike Steve, who has been busy with those boats, all I have done is to cut a few pieces out of the laser cut sheets. Champagne should not be kept in the refrigerator too long, so I may have to buy another bottle towards the end of this year.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

With the braces and other lines belayed and 'snugged-up', the rigging is starting to look a bit better. I still like the addition of the furled sails on the top spars; so a bit of time was lost for the good. Next step will take a while. I have to finally start fixing the main shrouds in place, plus all those nice rat-lines that go with them.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

I mentioned the little problem I had with the bowlines for the topsail. I tried to fix that and now it looks better; albeit not perfect. At least the idea is there and, you can see that those lines help to set the shape of the sail. More needs to be done with the sheets and braces for the mizzen jack, but all in due time.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Although large, the Shopsmith can still be a very handy tool. I have had mine for more than forty years and have adapted it to many situations. I have made my USS Constitution masts on it and made a crude table saw with a four inch blade. It has done pretty well for me. The one thing I don't like about it is the constant changing of set-ups. Hence, I also have separate other tools.

-

Things are looking up. The 'poop deck', or what ever it is called now, is a lot cleaner without all those lines on deck. Most of the lines coming from above are belayed, except for the sheets of the mizzen topsail. I still need to replace the bowlines and I think that will help to adjust the lay of the topsail. I certainly learned a lot with making these changes (including adding the furled sails) Hopefully I will be smarter with the main and foremasts and their rigging.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Good, but my wife is better. Actually I really like my drill press. I can drill, sand contours, sand planks to width and thickness, and even use it as 'plank saw'. I can also mount my old Dremmel like tool to the quill. That allows me to drill large and tiny holes with all the other operations. My wife does not like my drill press, because I spend too much time with it.

-

Here is another heads-up for those who are starting to make the masts and do the rigging. The mast caps require a lot more eye bolts than I had counted on. Especially if you are adding sails. Last count there are eight bolts on the main mast cap plus a bullseye (to guide the mizzen topgallant stay). I kept adding, and adding eyebolts, but a hard look at the plans and all the detailed sketches helps. Here is the list, they are on both the port and starboard sides: Trusses, lifts, mizzen topsail braces, and bowlines. The bowline eyebolts are not obvious until you look at sheet 8. A quick count of most (or all) the eyebolts required comes to more than 150. And that does not include another 150 or so for the jackstays on top of the spars. My point is, if you are going to make your own eyebolts, make a lot.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

You know the old saying, Steve, 'No pain, no gain'. Right now I feel a gain. I am back on track, I think.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Here is another 'hick-up', for those who are thinking of adding sails. Earlier I stressed that I wanted to add as many lines to the sails before they are rigged in place. I still believe in that except for the bowlines. The picture below may look cute, but the lines are going the wrong direction. I did not find out about that until I installed the mizzen topsail. The bowlines (one on each side) go forward and up to the main mast cap where they go through blocks and down to the deck. That means that the lower part of the three sections you see below should be a lot longer while the top section is shorter. What I am going to do is to remove the bowlines I have now and replace them with new lines that will be installed and adjusted later on. They are on the outside edge (leech) and should be easy to get to. I will keep the line and bullseye that already goes to the cap. To give you an idea what this line looks like installed, here is one more picture. When I pull on the line in the upper right hand corner, the whole thing becomes a mess. The clew you see is the mizzen topsail. The course jack is the black one below that. The topsail sheet has not yet been set.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Here are a couple pictures of what the lines look like lying on deck. The white tags identify some of them. I have finished re-rigging the braces and checked that all is ok. So I am ready to belay the lines you see below. Many of them had to be loosened and redone, but now I can also see that my approach of not rigging the shrouds paid off before. As you can see the shrouds for the main are still hanging loose. That gives me room to get to the fife rails a bit easier. Whereas the shrouds for the mizzen will be in the way for this re-work. The pins behind the mast are now hard to get to. I know I am a bit of a maverick with this crazy method, but I am still convinced that working from the top down has some merit. The thing I did learn, however, from what I did for the mizzen, is to do as much as possible to the course jack and even install it before the topsail goes in place. There are too many 'black' lines such as the sling, trusses and jeers (shown below) that are hard to install with the sail hovering above them.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Just one more picture after I epoxied the main royal and topgallant spars in place. Still a lot of alignment to do.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Correct hitch and advice on rigging a flag needed

Modeler12 replied to Gabek's topic in Masting, rigging and sails

You might be interested in an old thread about flags: http://modelshipworld.com/index.php?/topic/1447-where-do-flag-halliards-go-deck-or-top/?hl=flags It includes comments by Stockholm Tar, and an old tar he is. And I should not forget Popeye with his marvelous experience and insight.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.