-

Posts

4,286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

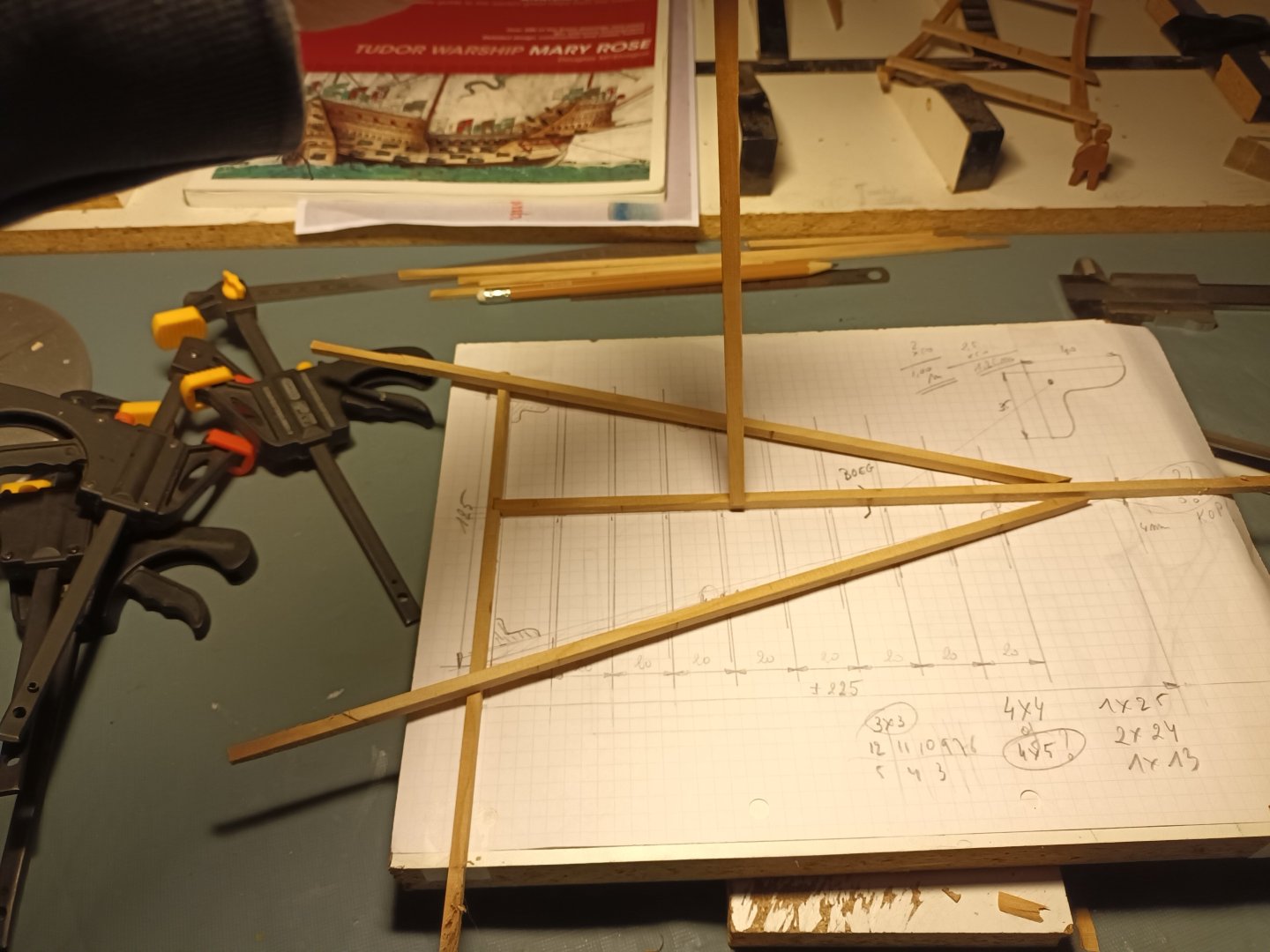

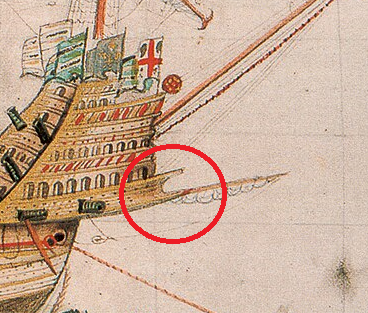

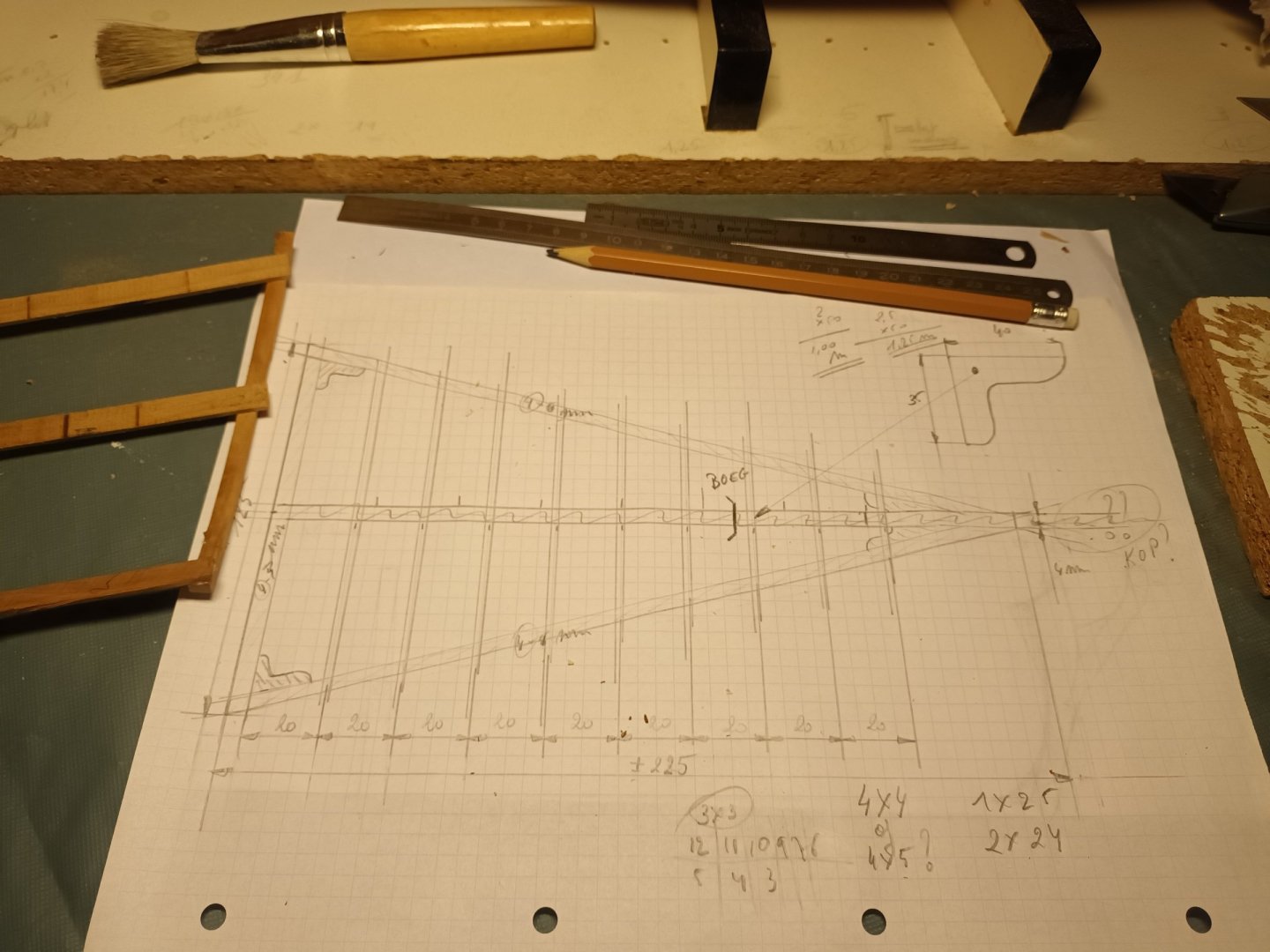

Small update The construction of the fore castle has only just begun and i already doing it wrong. There simply cannot be a beam in the middle because then there is no place for the fore mast... So new plan is needed without a beam in the middle. On all of Anthony's sketches of the large ships there is no "figurehead". Only on the contemporary drawings. So I am now starting with a regular triangle as a base.

-

Greetings from a clueless Patrick O'Brian fan

Baker replied to Galkar's topic in New member Introductions

-

Revell has chrome paint in a spray can (expensive) but also in a regular jar for the brush. https://revell.de/en/shop/product/chrome-spray-150ml?srsltid=AfmBOoogGk3qsx-Qh53CITe_fct7Ysy0_VkL5CZVw2KTfprmXiImrFtn

- 110 replies

-

- Paddlewheeler

- Ballarat

-

(and 3 more)

Tagged with:

-

Very nice work. I would go for the 1 gallon bottle. preferably red

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Off topic, but. As a former 3M employee (retired). Up until 25 years ago, the resin that "glues" the "sanding grains" to the paper was made from phenol and formaldehyde. Not environmentally and health friendly, but of great quality. Now a different, healthier resin is used. Less unhealthy, certainly. Better...? Search the 3M website. You might find the sandpaper you are looking for there.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

looks promising. facehugger... had to do a google search 👽🤔

- 30 replies

-

- Golden Hind

- Airfix

-

(and 1 more)

Tagged with:

-

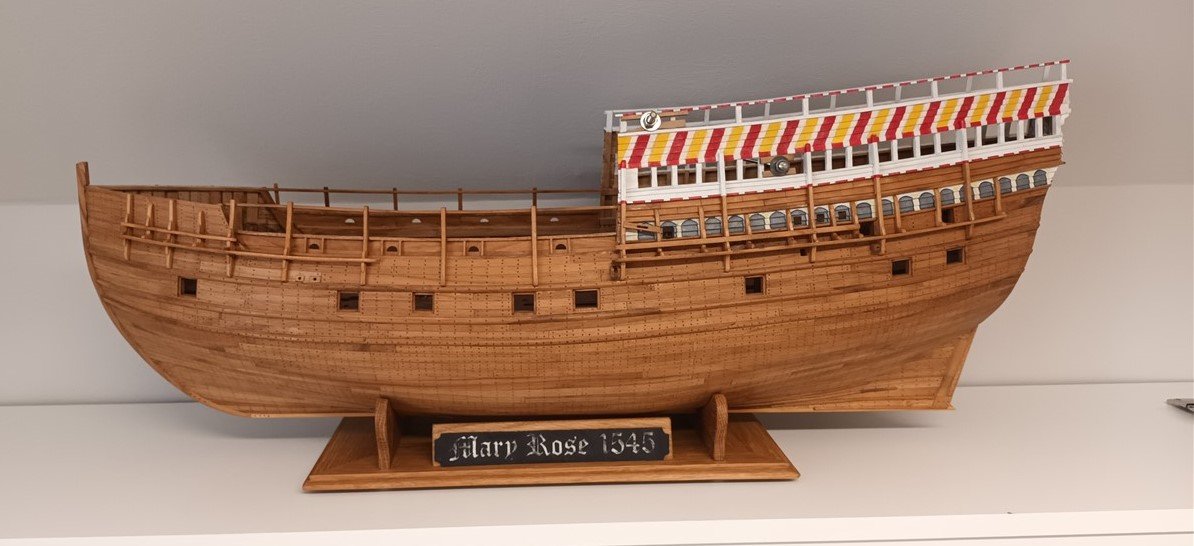

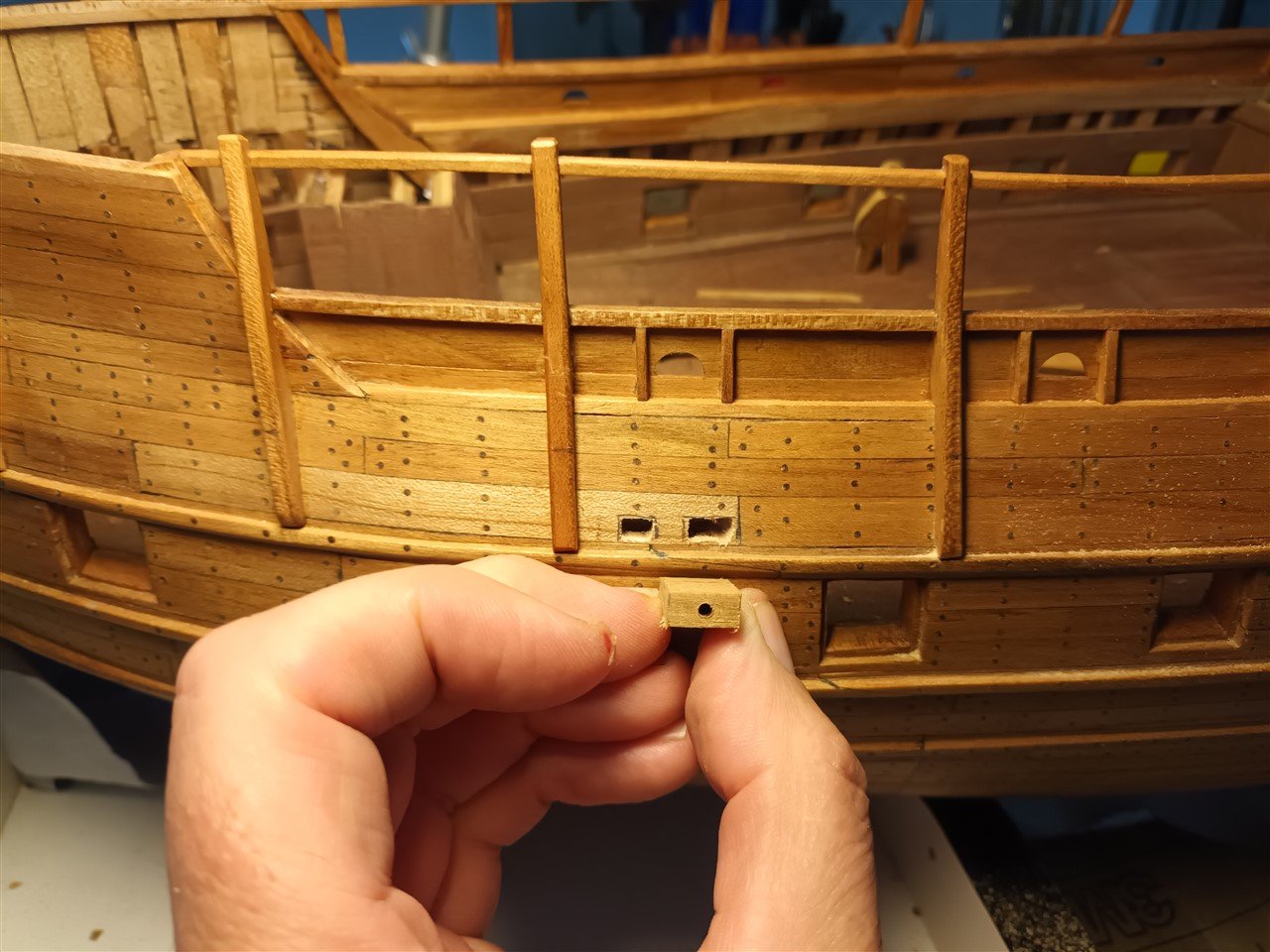

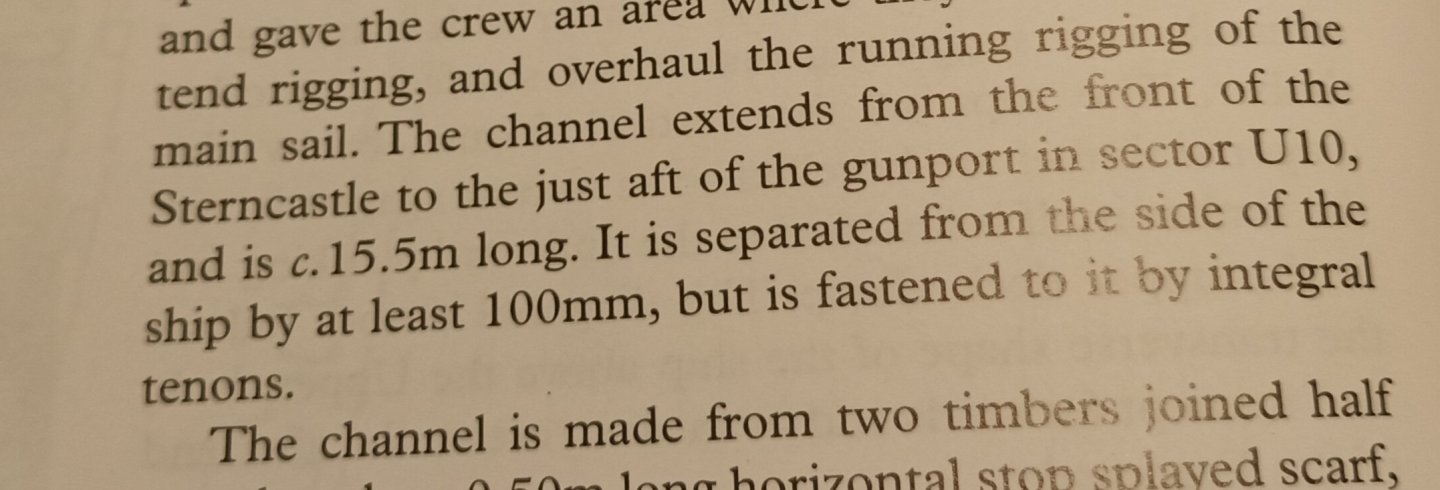

Before continuing with the forecastle, a few smaller items were added first. And yes, a hole was also drilled through the planking In this cabin on the starboard side, a hole was made through the hull here. so there is also one provided on the port side On each side, 3 standards were placed as a basis for the channel and rigging rail Next some extra parts (exact name?) And the basis for the port side channel, made from 3 parts Now first check whether the standing rigging of the fore mast has space in relation to the forecastle. No, so version 2 of the cardboard forecastle (right) My first impression of this channel. The right side should be narrower and would function as a rigging rail The schrouds (6) will be placed in the middle And the left side should also be narrower so that one of the two anchors can be attached there. Ideas, comments on this are always welcome

-

Indeed, wonderful. It was great to follow the build of this model. Whats next 😉 ??

- 508 replies

-

-

San Felipe by Roy812 - OcCre - 1/86

Baker replied to Roy812's topic in - Kit build logs for subjects built from 1501 - 1750

Good luck

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.