-

Posts

949 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by garyshipwright

-

Hi Ken. You may of already did this but what about breaking your hull up in to belt's. Am building Chuck's Winchelsea and he breaks up the hull below the wale in to 4 belt's of planking. Once you find the belts just take and using very fine tape, mark off the placement of that belt. Am using 1/64 that I got off of amazon and the belts are really making it so much easier planking the hull. Once you have your belt's located you can break each belt down to the number of plank's that will cover that belt, using a propotional divider or tick strip. Just look down the hull on that belt line and you will see where it needs to be adjusted. Take a tick strip and mark out the width of the belt, then using a planking fan you can find the number of planks in that belt. I like using a propotional divider because for me it's more accurate then using a tic strip because some times I make my tick mark's a little on the thick side. That really makes the plank a little on the wide side. Hope this is of some help to you good sir. Gary

-

Hi Kurt. I got my Preac in 2000 I believe at the Chicago NRG conference or was it the the Mariner's Museum can't remember which one. Charlie was still with us and we talked about his saw and getting one. Also meet David and Greg there with my daughter and misses. Believe she was 2. Do remember some one wasn't happy that we had brought our daughter to the conference, but every thing turned out ok. I also went to the 2010 which I believe was the Chicago one. What your seeing is just a piece of wood that is setting between the fence and blade which is for keeping the blade from cutting in to the fence. I did do one Mod to my Preac once I had all the pieces. My Byrnes saw came with the first mic that Jim installed on them which I got from him in 2002. When I sent my table in to Jim I had removed the old mic and rail along with its brackets from the table and mounted it to the Preac. You have to drill holes and thread them for the brackets, which keeps the rail in place, but it wasn't to bad at all. It worked good until I sold it to a good friend who brought it for his shop. I had them set up like you have your's for doing different cutting but I didn't use it much and figure selling it at a cost one could afford it, would be worth while. He also brought the hog and shipping which cost sometimes more then what you want for it just stop good folks from buying them if they lived to far away.

-

Hi Allan. You must be talking about the transom and the counter timber's David has a good article in vol 2 of his TFFM book, page 9/11. EdT also has a good article in his book of the Naiad Frigate vol two chapter 20. When I built Montague/Alfred I followed John Franklin articles in Model Shipwright Part 2 page 29. Just a ideal on how to get the curve aft and the curve up, first make the curve up on the right size piece of wood, thickness wise and then cut out the curve aft. I added some photo's that might help you. Gary

-

Hi Keith. As far as the blade guard I took mine off when I first got the saw and as you said, one has to be a lot more careful. To make up for the missing guard I use push stick's to keep my fingers a good distance from the blade. I also have a 10 inch table say but the guard stays on because it float's above the table and is also part of the dust collection. Works' great. I did just order the thin strip saw jig for my Byrnes saw. Should give me a nice cut plank using it. I don't think I have seen any one putting the top flush with the bench surface, and would like to see how they did it.

-

Hi Mike and outstanding good sir, she is a beauty. Now that you have her finished what's your next model going to be? Also I noticed that you have some paint on you work bench and was wondering what they are. May come in handy getting some for my Winchelsea. Look forward to your next build good sir. Gary

- 150 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Congratulations, Chuck, on a job well done and may you next one be just as good if not better. Look forward to seeing it and have enjoy watching your Winchelsea come to life. Gary

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Upgrading Mill

garyshipwright replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

Hi ChrisL. If I had to make a choice over what mill I would still get a Sherline . It really depends on how deep your pocket's are. They have a 14" Deluxe 8- direction Milling Machine which has a 15" extended Column upgrade, believe the cost was 1500, for the base package. They have a lot of accessories to fit all of your need's. They have a tilting angle table, Manual Rotary table Milling vise, and a rotating base to hold the Vise. Digital Readout to help you with the precision on your cutting. A sensitive Drilling attachment that you could also add. Works great when your using very small bit's so you don't break the bit's. It sort of lets you get a feeling of what the bit is doing. Of course it all comes at a price but I brought mine over the last few year's to help with the cost of it and have not regret it. You could go to their site, make a list of what you might need to get started and they will give you a package deal. Once you get the base package, what ever that may be then you can get the accessories you really need and not have to put out a chunk of money. You can do that over time because you are buying a tool for a life time. Also If you purchase their lathe get the 17 inch one, you can use the mill accessories on the lathe which would cut down on the cost of the accessories. -

Hi Kris and thank you. I did find a place, the office depot does this accept they use plastic rings instead of metal. She also put a clear plastic sheet on the front cover and a blue one on the back cover. Came out real nice and now resides in my library. Was very happy how it came out that's for sure. Once again thank you very much for putting this on the site. Gary

-

Looking real good. Maybe I get there one day.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

There is a 2 part to David's Drawing Techniques for the modeler but doesn't really have any thing really on the stern other then correcting the stern tilt so you can make the parts for the ship the right length. If you want it let me know and will add it. Also if you want I can delete some of the Franklin stuff so it doesn't clutter up your log once you have down loaded them unless other's want this to. Gary

-

Hi No Ideal. When I come to hard spot's like what your up against you might take some painter's tape, take it and push it in place, then taking a pencil, mark around the planks and see what comes out. It usually a rough copy imprint of the area but it does give you a starting point. I do this a lot when I get to a place like your self. Hope this help's good sir. Gary

-

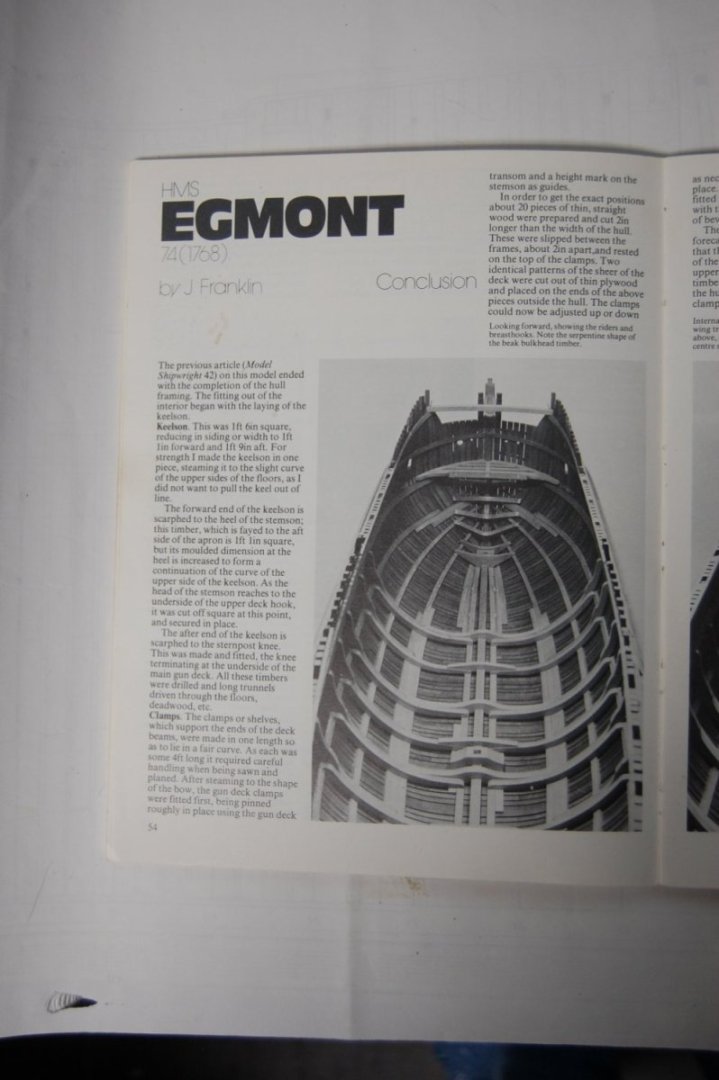

Alan there is a good article by John Franklin in Model ship Wright, HMS Egmont(74) 1768 41/4 and 42/29 that will give you some help on building your stern. I used his article's and David Anscherl such as Drawing Techniques for the Modeller and his 64 gun ship Polyphemus. If you don't have them let me know and I will copy them and send them to you. They always had such wonderful article's it a shame they stop producing them. Gary

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.